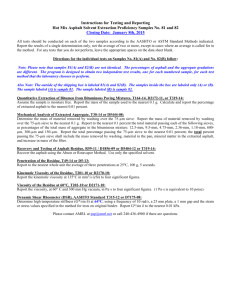

Bituminous Mixtures

advertisement