FM 4-20.105-2 TO 13C7-1-51 VOL II Airdrop of Supplies and Equipment:

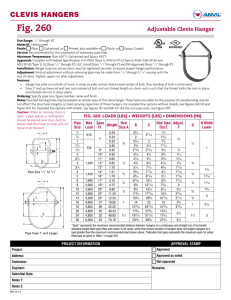

advertisement