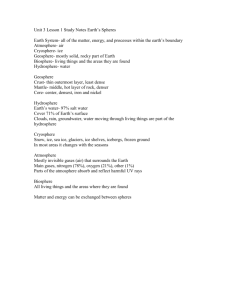

by 1977

advertisement