Mechanical and electronic approaches to improve the sensitivity of microcantilever sensors

advertisement

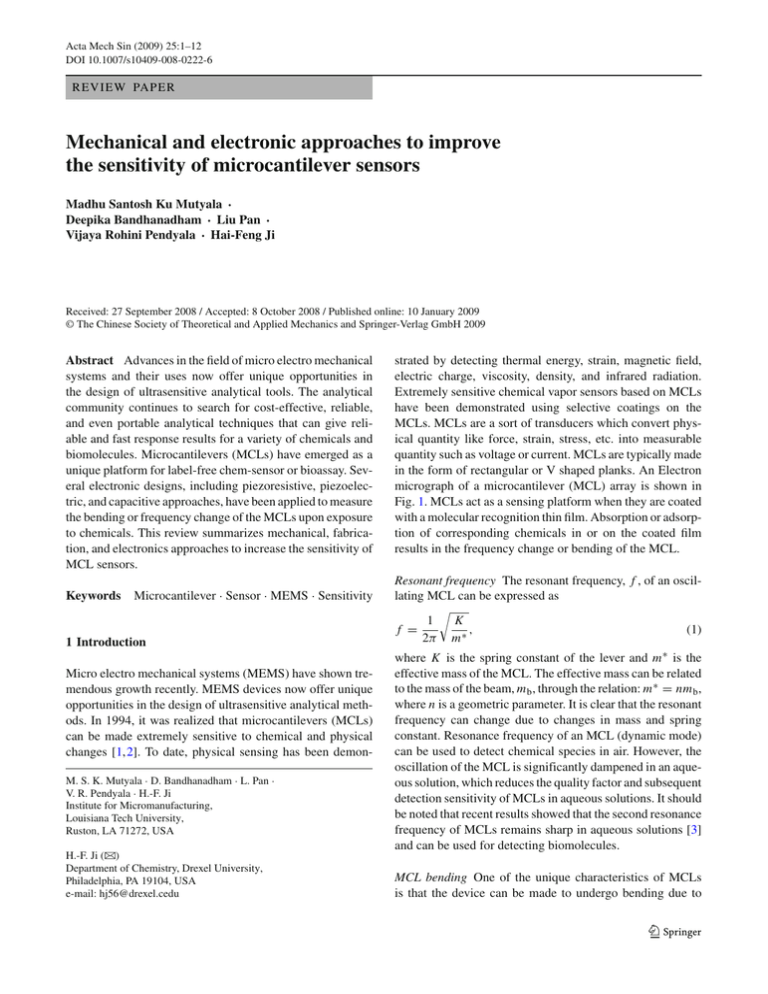

Acta Mech Sin (2009) 25:1–12 DOI 10.1007/s10409-008-0222-6 REVIEW PAPER Mechanical and electronic approaches to improve the sensitivity of microcantilever sensors Madhu Santosh Ku Mutyala · Deepika Bandhanadham · Liu Pan · Vijaya Rohini Pendyala · Hai-Feng Ji Received: 27 September 2008 / Accepted: 8 October 2008 / Published online: 10 January 2009 © The Chinese Society of Theoretical and Applied Mechanics and Springer-Verlag GmbH 2009 Abstract Advances in the field of micro electro mechanical systems and their uses now offer unique opportunities in the design of ultrasensitive analytical tools. The analytical community continues to search for cost-effective, reliable, and even portable analytical techniques that can give reliable and fast response results for a variety of chemicals and biomolecules. Microcantilevers (MCLs) have emerged as a unique platform for label-free chem-sensor or bioassay. Several electronic designs, including piezoresistive, piezoelectric, and capacitive approaches, have been applied to measure the bending or frequency change of the MCLs upon exposure to chemicals. This review summarizes mechanical, fabrication, and electronics approaches to increase the sensitivity of MCL sensors. Keywords Microcantilever · Sensor · MEMS · Sensitivity 1 Introduction Micro electro mechanical systems (MEMS) have shown tremendous growth recently. MEMS devices now offer unique opportunities in the design of ultrasensitive analytical methods. In 1994, it was realized that microcantilevers (MCLs) can be made extremely sensitive to chemical and physical changes [1,2]. To date, physical sensing has been demonM. S. K. Mutyala · D. Bandhanadham · L. Pan · V. R. Pendyala · H.-F. Ji Institute for Micromanufacturing, Louisiana Tech University, Ruston, LA 71272, USA H.-F. Ji (B) Department of Chemistry, Drexel University, Philadelphia, PA 19104, USA e-mail: hj56@drexel.cedu strated by detecting thermal energy, strain, magnetic field, electric charge, viscosity, density, and infrared radiation. Extremely sensitive chemical vapor sensors based on MCLs have been demonstrated using selective coatings on the MCLs. MCLs are a sort of transducers which convert physical quantity like force, strain, stress, etc. into measurable quantity such as voltage or current. MCLs are typically made in the form of rectangular or V shaped planks. An Electron micrograph of a microcantilever (MCL) array is shown in Fig. 1. MCLs act as a sensing platform when they are coated with a molecular recognition thin film. Absorption or adsorption of corresponding chemicals in or on the coated film results in the frequency change or bending of the MCL. Resonant frequency The resonant frequency, f , of an oscillating MCL can be expressed as K 1 , (1) f = 2π m ∗ where K is the spring constant of the lever and m ∗ is the effective mass of the MCL. The effective mass can be related to the mass of the beam, m b , through the relation: m ∗ = nm b , where n is a geometric parameter. It is clear that the resonant frequency can change due to changes in mass and spring constant. Resonance frequency of an MCL (dynamic mode) can be used to detect chemical species in air. However, the oscillation of the MCL is significantly dampened in an aqueous solution, which reduces the quality factor and subsequent detection sensitivity of MCLs in aqueous solutions. It should be noted that recent results showed that the second resonance frequency of MCLs remains sharp in aqueous solutions [3] and can be used for detecting biomolecules. MCL bending One of the unique characteristics of MCLs is that the device can be made to undergo bending due to 123 2 Fig. 1 Electron micrographs of an MCL array molecular adsorption by confining the adsorption to one side of the MCL. This bending is due to the adsorption-induced differential stress or film volume change on the MCL (static mode). For the surface stress induced MCL bending, from molecular point of view, the binding results in electrostatic repulsion or attraction, intermolecular interactions, or a combination of these that alter the surface stresses on the MCL. Using Stoney’s formula [4], the bending deflection of the MCL due to adsorption can be written as: 3(1 − ν)L 2 δs, (2) Z = ET 2 where Z is the observed deflection at the end of the MCL, ν and E are Poisson’s ratio (0.2152) and Young’s modulus (70 GPa for SiO2 , 156 GPa for silicon, 300 GPa for Si3 N4 ) for the substrate, respectively, T is the MCL thickness, L is the length of the MCL, and δs is the differential stress on the MCL. Both frequency and bending approaches have been demonstrated to detect chemicals with sensitivity as high as partsper-trillion, and each approach has its own advantages and disadvantages which can be used for specific applications. MCL sensors hold a position as a cost-effective, sensitive sensor platform for environmental, biomedical, homeland security, and industrial applications. Compared to existing technologies for chemical and biomolecular detection in general, the MCL sensor technology has three key advantages: Low cost—Electronics for operation and control are relatively simple and inexpensive. Low-power consumption—For static mode, since the MCL’s bending signal is driven by molecular recognition, the only power needed is for detection and display, allowing use of light-weight battery power or photovoltaic cells. Small size—The entire sensor could fit in an area with its sides less than a few millimeters. The device can be readily 123 M. S. K. Mutyala et al. integrated into a robot system without much increase of weight in order to protect the operator and to guarantee uniform detection strategies. Other than those, MCL arrays could be used to simultaneously detect and identify various chemicals on a single chip; the analysis time is relatively shorter because the assay does not require extensive sample preparation or signal amplification; it could be used for in-situ detection. By monitoring changes in bending response or frequency change of an MCL, mass change and surface stress changes induced by adsorption or molecular recognition can be recorded precisely and accurately. Optical, piezoresistive, piezoelectric, and capacitive methods have been used for the detection of MCL’s deflection (Fig. 2). Each sensing mechanism has its own advantages and drawbacks. Optical method is sensitive and can measure deflection as small as 1 nm. However, the optical system is complicated and not user friendly compared to the other methods. The sensing systems based on piezoresistive, piezoelectric, and capacitive methods are much simpler and hold the potential for implantable biosensing applications. These methods do not require complex adjustment and alignment systems as needed in optical readout scheme, and they could readily be integrated with electrical circuit. However, the sensitivity of these methods is generally lower than that of the optical method. Research is underway to either improve these approaches or develop new approaches for MCL based sensing. This review summarizes recent developments in improving the sensitivity of MCL sensors based on the piezoresistive, piezoelectric, and capacitive approaches. 2 Piezoresistive readout scheme The piezoresistive phenomenon is the change in resistivity of a material when subjected to stress. The piezoresistivity of a material depends on its type; the change in its geometry upon application of stress over it. Piezoresistive approach is one of the most widely applied techniques for measuring stress applied on an MCL. The advantage of this technique is that the electrical output can be readily measured and the MCL can be integrated on integrated circuit (IC) [5]. In a piezoresistive MCL the relationship between the stress and the change in resistance is shown as the following equation: R = πl σl + πt σt , (3) R where R is initial resistance, R is change in resistance; πl , πt are longitudinal and transverse piezoresistive coefficients, respectively; σl , σt are lateral and transverse stress, respectively. The change in the resistivity is typically measured by using a Wheatstone bridge as shown in Fig. 3. A Wheatstone bridge Approaches to improve the sensitivity of microcantilever sensors 3 Fig. 2 Illustration of four methods for detecting MCL motion with sub-nanometer precision—(left) Laser-beam deflection method; (middle) Piezoresistive and piezoelectric method; and (right) Capacitive method displacement and the R/R change increase with the decrease in the thickness of piezoresistors; the highest sensitivity can be obtained when the piezoresistor’s length is approximately 2/5 of the SiO2 MCL’s length (Fig. 4); an increase of both Si and the leg width result in a decrease in MCL’s deflection and its sensitivity; the sensitivity of the MCLs with lower doping concentrations is more significant than those with higher doping concentrations. Temperature control is critical for thin piezoresistor in lowering the S/N ratio and increasing the sensitivity. Fig. 3 A Wheatstone bridge scheme[5] 2.2 Material selection is made up of four piezoresistors: R1 , R2 , R3 , and R4 . One of these resistors is replaced by an MCL. The differential voltage (Vg ) from the Wheatstone bridge is proportional to the change in the resistivity of the MCL [5]. The output voltage, V0 , from the Wheatstone bridge is given as in Eq. (4). Vin R , (4) V0 = R 4 Most of the MCLs are made of silicon or silicon nitride (Si3 N4 ) materials. Li et al. showed that piezoresistive MCLs made of silicon dioxide were more sensitive than the siliconbased MCLs due to lower Young’s modulus of SiO2 (57–70 GPa) when compared to that of Si (170 GPa) and Si3 N4 (290–380 GPa). The embedded piezoresistor is made of single crystal silicon and is fully insulated by SiO2 (Fig. 5). This reduces the electronic noise of the MCL since it is isolated from the surrounding environment [8]. where Vin is applied input voltage. The output voltage is directly related to the change in the resistance R with respect to the initial resistance R. The first piezoresistive MCL showed the resistivity change (R/R) of 1.2×10−7 when subjected to 1Å deflection [6]. It should be noted that this MCL was not originally designed for sensors, but for atomic force microscopy. Since then, a variety of strategies have been applied to increase the sensitivity. 2.1 Geometry optimization The dimensions of the MCL and the piezoresistor play a critical role in the sensitivity of MCL sensors. By using Finite Element Method (FEM) analysis, Chivukula et al. have shown that optimizing the device dimensions is useful to a greater extent in increasing the sensitivity of the device [7]. FEM analysis was done to investigate the optimized device dimensions by varying the MCL and piezoresistor geometries and the doping concentration of the piezoresistive device. The simulation results showed that both MCL deflection 2.3 Stress concentration method Concentrating the stress to a designated area is another approach to enhance the sensitivity. Yu et al. reported a method to concentrate the stress by introducing holes in the MCLs. These holes caused the stress to be concentrated in its vicinity. The size of the holes is 10µm × 5µm [5]. The results showed the MCLs with holes were 1.3 times more sensitive than those without holes in response to the same MCL deflection (Figs. 6 and 7). This increase in the surface stress is attributed to the discontinuity of the MCL structure due to the holes. Decreasing the thickness of the MCLs is a common strategy to increase the sensitivity. However, thin MCLs are more fragile and harder to handle than the thicker ones. Naeli et al. [9] reported with another stress-concentrating design that made it possible to achieve both high sensitivity and toughness. In this design, they separated the stress in the piezoresistors from the stress on the beam structure. In fabrication, the piezoresistive strings were laid on the wafer surface with 123 4 M. S. K. Mutyala et al. Fig. 4 Change is the resistance of the piezoresistor vs. the thickness and length of the piezoresistor when a 2 N/m surface stress is applied on the surface of a SiO2 MCL [7] Fig. 5 Schematic of a piezoresistive SiO2 MCL [8] Fig. 7 Stress distribution vs. vertical displacements of MCLs with and without holes [5] 2.4 Integration with piezoactuators Fig. 6 The layout of a Wheatstone bridge design of piezoresistive MCLs with stress concentrating holes [5] a cavity underneath. Two thin piezoresistive clamped silicon beams were released on the MCL surface. The new piezoresistive design showed an increase in the relative resistance change by a factor of 5.2, as shown in Fig. 8, compared to an MCL with the same thickness and conventional piezoresistor design. 123 Piezoresistive MCL can also detect mass change by integration with piezoactuators. Sone et al. [10] introduced an MCL device that consists of a piezoresistive design, a Wheatstone bridge circuit, a positive feedback controller, an exciting piezoactuator, and a phase-locked loop (PLL) demodulator (Fig. 9). In the design, R1 represents the piezoresistive MCLs in the Wheatstone bridge. The oscillator includes a positive feedback system, a preamplifier, and a piezoactuator driver. The phase locked loop circuit is used for demodulating the frequency signals from the circuit. Results showed that a mass sensitivity of 190 fg/Hz and a mass resolution of about 500 fg were obtained in water. The mass sensitivity is 100 times greater than that of a quartz crystal oscillation system. 2.5 Minimizing the thermal effect One concern in the field of piezoresistive MCL sensors is that the sensor performance is readily influenced by the thermal Approaches to improve the sensitivity of microcantilever sensors 5 Fig. 8 Left Comparison between conventional and stress-concentrating MCLs. Right SEM images of stress-concentrating beams isolated from MCL base [9] higher than that of the mechanical bandwidth of the MCL is applied. The output current measured with respect to the applied voltage gives the capacitance value which is a measure of the displacement of the MCL. The capacitive current, IC (t), at the output [12] due to the MCL displacement is given as: ∂ VAC ∂c(t) ∂ (C · V ) ∼ + VDC , (5) = Cp ∂t ∂t ∂t where, C is the capacitance between the MCL beam and the driver. This capacitance consists of static component, Cp , and the capacitance because of the MCL displacement, c(t). The first term in the above equation, Cp ∂ V∂tAC , indicates the parasitic current, and the second term, VDC ∂c(t) ∂t , indicates the current due to the MCL oscillation. The main advantages of capacitive microsensors are low-power, simple structures, low temperature sensitivity and low cost integration of the read out to the portable systems. It outdraws peizoresistive systems because of its low power consumption. The drawback is that the bending amplitude is limited by the space between the MCL and the bottom electrode. IC (t) = Fig. 9 A harmonic vibration mass biosensor system based on MCLs [10] stress during operation. Yang et al. developed a double-MCL design to overcome the thermal stress effect which improves the sensitivity as shown in Fig. 10 [11]. The double MCL is composed of a top immobilized MCL and a bottom sensing MCL. These two MCLs are connected in a way that the biaxial surface stress in the former can be converted to uniaxial strain in the latter. The sensitivity of the double MCL could be increased by increasing the length ratio or by decreasing the thickness ratio of the two MCLs (Fig. 11). More than two orders of sensitivity enhancement have been achieved and the induced thermal effects are minimized. 3 Capacitive readout scheme A capacitive readout scheme consists of an MCL over an electrode which is ground biased as shown in Fig. 12. In a capacitive sensing scheme, an AC voltage of frequency 3.1 Size, shape, and materials of the MCL Li et al. [13] developed an MCL that is actuated to resonance by in-plane electrodes as shown in Fig. 13. The resonant frequency is detected by the capacitive approach with on-chip circuitry. For resonance frequency measurement, the sensitivity improvement can be realized by reducing the MCL dimensions in order to increase stiffness and subsequent resonant frequency. 123 6 M. S. K. Mutyala et al. Fig. 10 a A conventional MCL system with only one MCL; b Double MCL design with one MCL on the top and another at the bottom [11] Fig. 13 Circuit diagram of an electrostatically driven MCL to the resonant frequency shift [13] Fig. 11 Surface stress sensitivity of double and single MCL systems with respect to the length ratio [11] results suggest that the micro-bridge type of humidity sensor provides a lower sensitivity, it is a more robust device than the single beam MCL type. 3.2 Elimination of the parasitic effect It is shown from Eq. 6 that the sensitivity of the capacitive MCL sensors improves as the parasitic capacitance is decreased [12]. Cp Cp Vdc Ic ∼ Vac + 0.39 A = ωCpa Cp + Cpa Cp + Cpa δ0 = Vp + Vd , Vg = Fig. 12 Basic schematic of a capacitive MCL [12] However, for bending mode, higher sensitivity will be achieved with lower stiffness MCL and larger electrode area [14]. In this work, Lee et al. compared the sensitivity of three MCL shapes: single beam, double beam, and microbridge as shown in Fig. 14. The three sensors were tested in a closed chamber with humidity level ranging from 45% Relative humidity (RH) to 95% RH. Figure 15 shows the single beam MCL sensor provides a high degree of humidity sensitivity. Although the 123 (6) where, Vp is the parasitic voltage, which is due to the applied AC voltage, Vd is corresponding to the MCL displacement and is proportional to both the DC voltage and the oscillation amplitude, Vg is the resulting voltage. Furthermore, reducing the dimensions typically results in an increase of the mass responsibility and subsequent sensitivity. However, reducing the dimensions will also raise problems due to low-level current and the parasitic capacitance. Electrostatic transduction in the nanometer-size regime requires the minimization of the parasitic capacitance to increase the sensitivity. Several CMOS circuitry [12,15,16] were designed and placed very close to the transducer structure for such purpose to increase the sensitivity. Approaches to improve the sensitivity of microcantilever sensors 7 Fig. 14 SEM images of the fabricated: a Single beam MCL; b Double beam MCL; c Microbridge [14] 4 Piezoelectric readout technique Fig. 15 Temperature effect on sensitivity of the three sensors [14] One CMOS circuitry to eliminate the parasitic capacitance induced by the external bonding pads and wires [12] is shown in Fig. 16. This CMOS circuitry is integrated with an MCL by using a monolithic technology that combines a standards CMOS processes and a nanofabrication method. The integrated system demonstrated a high sensitivity (10−18 g) and a high spatial resolution (300 nm) and also had less noise compared to resistive and transimpedance methods. Ghatnekar-Nilson et al. [16] used electron beam lithography to define the resonator system comprising of an MCL, an actuator, and a capacitive readout circuit on a CMOS circuit (Fig. 17). This has improved the MCL sensitivity by reducing the effects caused by parasitic capacitance. An MCL of 420 nm in width, 20µm in length, and 600 nm thickness is fabricated on the pre-processed CMOS chip. The mass sensitivity is 17 ag per Hz. Davis et al. [17] shows, by reducing the size of MCL to nanometer scale, the Q-factor has dramatically increased from 50 to 100 in air and from 20 to 30,000 in vacuum. This system has shown a reduction in parasitic capacitance to approximately 3fF, which is sufficiently low for the capacitive readout system to function. Another recently booming technique to measure the MCL deflection or its resonant frequency change is the piezoelectric design. Piezoelectricity is the property of a material in which a potential is developed across a material when it is subjected to strain [18]. A piezoelectric MCL can be used for actuation as well as sensing. The piezoelectric materials, such as ZnO, are usually deposited at the fixed ends of an MCL as shown in Fig. 18. The deposition of the piezoelectric films onto the MCL is carried out by several methods which include metal organic chemical vapor deposition (MOCVD) [19], hydrothermal method [20], sputtering [21], pulsed laser deposition [22], and Sol-gel method [23]. Among these methods, sol-gel deposition method is considered to be most cost-effective and convenient. The formation of a highly homogenous piezoelectric layer and its composition can be readily controlled. The factors that determine the sensitivity of the piezoelectric MCLs are discussed below. 4.1 Piezoelectric materials Materials with higher piezoelectric constant normally result in higher sensitivity. A wide variety of piezoelectric materials can be chosen for fabricating piezoelectric MCLs. The most commonly used materials are ZnO and Lead Zirconium Titanate (LZT, also known as PZT) [18–24]. PZT has a higher piezoelectric constant than ZnO, thus the sensitivity of the MCL is improved when PZT is used as the piezoelectric material for the force sensor, instead of ZnO [25]. It is also believed that this PZT sensor is easy to use in severe environments such as low temperature and ultrahigh vacuum. The orientation of these layers also plays a pivotal role in determining its sensitivity [26]. A PZT piezoelectric layer with an orientation of <100> is used because its piezoelectric constant is 1.7 times of that of <111> orientation. The 123 8 Fig. 16 Left Schematic drawing of the NEMS system based on a laterally vibrating MCL (s direction) electrostatically excited and with capacitive readout. The structural layer for the MCL is one of the polysilicon layers used in CMOS technology. Right Optical images of the nanomechanical resonator integrated monolithically with the CMOS M. S. K. Mutyala et al. voltage amplifier. The large image shows the CMOS circuit and the area where the nanomechanical device is fabricated. The inset ia a zoom image of it, where it can be better appreciated the MCL, the driver and the integrated capacitor for proper circuit polarization [12] Fig. 17 Optical images of combined EBL and DWL [16] thickness of the film and roughness of the surface also plays a role in determining the piezoelectric constant [27] and the subsequent sensitivity. 4.2 MCL geometry Piezoelectric MCL dimensions play a role in determining the piezoelectric constant and resonance frequency which in turn determines the sensitivity of the MCL. Yi et al. investigated the effect of piezoelectric MCL’s length, width and resonance mode on its sensitivity by determining the resonant frequency shift per mass change ( f /m) [18]. The tip of the piezoelectric unimorph MCL (made up of PZT and stainless steel layer) was loaded with point mass. The resulting resonance frequency change was determined and 123 compared experimentally and theoretically. Figure 19 shows the f /m is larger when the MCL dimensions are smaller. The influence of the MCL’s dimensions and the material’s property on the resonance frequency shift, f , with respect to the loaded mass, m is given by Eq. 7: f n /m = (vn2 /4π )(1/L 3 w)(1/0.236 12ρ) E/ρ, (7) where, the f /m is directly proportional to eigen value υn2 and inversely proportional to length, L, and width, w; E is the effective Young’s modulus and ρ is the effective density of the unimorph MCL. By keeping the MCL thickness, Young’s modulus and density constant and decreasing the MCL length and width by a factor of α, f /m can be increased by a factor of α 4 . Approaches to improve the sensitivity of microcantilever sensors Fig. 18 Schematic of a typical piezoelectric MCL [18] 9 Fig. 21 Experimental and theoretical f with respect to m of the MCL with 1.03 cm in length, 0.4 cm in width at mode 1 (squares) and mode 2 (circles) [18] the MCL is narrower. The influence of the resonance mode of the MCL on its sensitivity (Fig. 21) shows that the frequency shift is larger for the mode 2 operating MCL than the mode 1 with respect to the same mass loading. 4.3 Substrate effect on sensitivity Fig. 19 f /m versus length for all the modes and widths [18] Figure 20 shows that for the same MCL width the resonance frequency increases as the MCL length increases. This was proved both theoretically (solid lines) and experimentally (symbols). The effect of the width on the frequency shift (Fig. 20 right) shows the frequency shift is larger when The electrical properties of one piezoelectric material depend mainly on the crystallographic orientation of the material. One factor affecting the sensitivity of the piezoelectric MCLs is the substrate on which the piezoelectric layer is deposited. Wang et al. [24] investigated the sensitivity of PZT thin films on Pt/Ti and Ir/IrO2 substrates and the X-ray diffractometer (XRD) results showed that the PZT film fabricated on Pt/Ti substrates has a highly preferred orientation in the direction of <100> and no preferred orientation on the Ir/IrO2 substrate. This is because Ir undergoes oxidation during annealing and the PZT deposition on the randomly oriented IrO2 does not produce the <100> orientation. The PZT film was crystallized with columnar grains on the Pt/Ti substrate and without columnar grains on Ir/IrO2 and the PZT layer on the Pt/Ti surface was smoother and more uniform than that on the Ir/IrO2 (Fig. 22). The PZT deposited on the Pt/Ti substrate Fig. 20 Left Experimental and theoretical f with respect to m of the MCL with, Left varying lengths at a fixed 0.4 cm width, Right length 1.05 cm, width 0.4 cm (squares) and length 0.99 cm, width 0.2 cm (circles) [18] 123 10 M. S. K. Mutyala et al. Fig. 22 SEM images of PZT films deposited on (left) Pt/Ti and (right) Ir/IrO2 [24] Fig. 24 Schematic of an MCL sensor unit with two PZT layers [20] Fig. 23 Charge change versus displacement before and after poling [18] has a higher piezoelectric constant than that on the Ir/IrO2 substrate. Further studies showed that Pb diffused through the Pt/Ti layer. On the other hand IrO2 has a very good barrier effect. So, Pt/IrO2 is a suitable substrate to achieve higher piezoelectric constant and less defective microstructures. 4.4 Improving sensitivity by poling Dong et al. developed [28] a new fabrication technique wherein the PZT layer is subjected to poling. The PZT layer is polarized at 100◦ C with an electric field of 125 kV/cm for one hour. The MCL sensibility was 1.61 pC/mm before poling and rose to 3.25pC/mm after poling (Fig. 23). This sensitivity increase was attributed to the increase in the piezoelectric constant of the PZT layer upon poling. 4.5 Optimized positioning of the piezoelectric layer Du et al. [20] fabricated a piezoelectric MCL sensor that contains two PZT layers (Fig. 24). The PZT layers were synthesized by hydrothermal method and placed on a titanium 123 Fig. 25 Optimized positioning of the PZT layer for maximum sensitivity. L is the MCL length, L p is the length of the sensing and actuation layer, and a is the length between the fixed end of the MCL and the left edge of the actuation/sensing layer [20] substrate. The top layer acted as an actuation layer and the bottom one acted as a sensing layer. This work showed that the location of the actuation and sensing layer played a role in improving the MCL sensitivity. The MCL is most sensitive when the two ends of the actuation and sensing layers were placed at the points where the strain is zero (Fig. 25). 4.6 Anti-cracking The piezoelectric constant of the PZT film increases with the thickness of the PZT layer but may result in cracks after reaching certain limit due to the residual stress developed. The cracks will result in lower sensitivity. In a conventional sol-gel process, the PZT films are patterned after the Approaches to improve the sensitivity of microcantilever sensors 11 Fig. 26 Piezoelectric MCL fabricated with (left) conventional and (right) modified method [29] Fig. 27 SEM image of the surface undergoing (left) three annealing cycles; (right) four annealing cycles [23] completion of the annealing process. In a modified process developed by Xie et al. [29], patterning is done before each post-annealing process to remove unwanted PZT film. Figure 26 compared the PZT surfaces fabricated by the conventional method and the modified process. Liu et al. also developed [23] a similar method to avoid cracks of the PZT layer by modifying the layer coating process (Fig. 27). 5 Conclusion MCLs provide an ideal platform for chemical and biomolecular detection. We can foresee the upcoming of more MCL sensors. However, there is still a long way to go to convert the proof-of-concept results to robust, commerciallyavailable products. This review focuses on enhancing the sensitivity of MCL sensors operating based on piezoresistive, capacitive, and piezoelectric principles by optimizing its dimensions, choosing proper material, and adopting novel fabrication techniques. It is seen that these factors play a significant role in the MCL sensitivity. References 1. Chen, G.Y., Warmack, R.J., Thundat, T., Allison, D.P., Huang, A.: Resonance response of scanning force microscopy cantilevers. Rev. Sci. Instrum. 65, 2532 (1994) 2. Gimzewski, J.K., Gerber, C., Meyer, E., Schlittler, R.R.: Observation of a chemical reaction using a micromechanical sensor. Chem. Phys. Lett. 217, 589 (1994) 3. Campbell, G.A., Mutharasan, R.: Escherichia coli O157:H7 detection limit of millimeter-sized PZT cantilever sensors is 700 Cells/mL. Anal. Sci. 21, 355 (2005) 4. Stoney, G.G.: The tension of metallic films deposited by electrolysis. Proc. R. Soc. (Lond.) 82, 172 (1909) 5. Yu, X., Tang, Q., Zhang, H., Li, T., Wang, W.: Design of highsensitivity cantilever and its monolithic integration with CMOS crcuits. IEEE Sens. J. 7, 489–495 (2007) 6. Tortonese, M., Yamada, H., Barrett, R.C., Quate, C.F.: Atomic force microscopy using piezoresistive cantilever. Solid State Sens. Actuators 448–451 (1991) 7. Chivukula, V., Wang, M., Ji, H.F., Khaliq, A., Fang, J., Varahramyan, K.: Simulation of SiO2 -based piezoresistive MCLs. Sens. Actuators A 125, 526–533 (2006) 8. Li, P., Li, X.: A single-sided micromachined piezoresistive SiO2 cantilever sensor for ultra-sensitive detection of gaseous chemicals. J. Micromech. Microeng. 16, 2539–2546 (2006) 9. Naeli, K., Brand, O.: Cantilever sensor with stress-concentrating piezoresistor design, sensors, 2005 IEEE, pp. 592–595 (2005) 10. Sone, H., Ikeuchi, A., Izumi, T., Okano, H., Hosaka, S.: Femtogram mass biosensor using self-sensing cantilever for allergy check. Jpn. J. Appl. Phys. 45, 2301–2304 (2006) 11. Yang, S.M., Yin, T.L., Chang, C.: Development of a double-MCL for surface stress measurement in microsensors. Sens. Actuators B 121, 545–551 (2007) 12. Verd, J., Abadal, G., Teva, J., Gaudo, M.V., Uranga, A., Borrise, X., Campabadal, F., Esteve, J., Costa, E.F., Perez-Murano, F., Davis, Z.J., Forsen, E., Boisen, A., Barniol, N.: Design, fabrication, and characterization of a submicroelectromechanical resonator with monolithically integrated CMOS readout circuit. J. Microelectromech. Syst. 14, 508–519 (2005) 123 12 13. Li, Y.C., Ho, M.H., Hung, S.J., Chen, M.H., Lu, M.S.C.: CMOS micromachined capacitive cantilevers for mass sensing. J. Micromech. Microeng. 16, 2659–2665 (2006) 14. Lee, C.Y., Lee, G.-B.: Micromachine based humidity sensors with integrated temperature sensors for signal drift compensation. J. Micromech. Microeng. 13, 620–627 (2003) 15. Teva, J., Abadal, G., Torres, F., Verd, J., Pérez-Murano, F., Barniol, N.: A femtogram resolution mass sensor platform, based on SOI electrostatically driven resonant cantilever. Part I: Electromechanical model and parameter extraction. Ultramicroscopy 106, 800–807 (2006) 16. Ghatnekar-Nilsson1, S., Fors’en, E., Abadal, G., Verd, J., Campabadal, F., Pérez-Murano, F., Esteve, J., Barniol, N., Boisen, A., Montelius, L.: Resonators with integrated CMOS circuitry for mass sensing applications, fabricated by electron beam lithography. Nanotechnology 16, 98–102 (2005) 17. Davis, Z.J., Abadal, G., Helbo, B., Hansen, O., Campabadal, F., Pérez-Murano, F., Esteve, J., Figueras, E., Verdb, J., Barniol, N., Boisen, A.: Monolithic integration of mass sensing nano-cantilevers with CMOS circuitry. J. Sens. Actuators A 105, 311–319 (2003) 18. Yi, J.W., Shih, W.Y., Shih, W.-H.: Effect of length, width, and mode on the mass detection sensitivity of piezoelectric unimorph cantilevers. J. Appl. Phys. 91, 1680–1686 (2002) 19. Shimizu, M., Okaniwa, M., Fujisawa, H., Niu, H.: Ferroelectric properties of Pb(Zr, Ti)O3 thin films prepared by low-temperature MOCVD using PbTiO3 seeds. J. Eur. Ceram. Soc. 24, 1625–1628 (2004) 20. Du, L., Kwon, G., Arai, F., Fukuda, T., Itoigawa, K., Tukahara, Y.: Structure design of micro touch sensor array. Sens. Actuators A 107, 7–13 (2003) 123 M. S. K. Mutyala et al. 21. Thomas, R., Mochizuki, S., Mihara, T., Ishida, T.: Effect of substrate temperature on the crystallization of Pb(Zr, Ti)O3 films on Pt/Ti/Si substrates prepared by radio frequency magnetron sputtering with a stoichiometric oxide target. Mater. Sci. Eng. B 95, 36–42 (2002) 22. Husmann, A., Wesner, D.A., Schmidt, J., Klotzbucher, T., Mergens, M., Kreutz, E.W.: Pulsed laser deposition of crystalline PZT thin films. Surf. Coat. Technol. 97, 420–425 (1997) 23. Liu, M., Wang, J., Wang, L., Cui, T.: Deposition and characterization of Pb(Zr, Ti)O3 sol-gel thin films for piezoelectric cantilever beams. Smart Mater. Struct. 16, 93–99 (2007) 24. Wang, Z.J., Chu, J.R., Maeda, R., Kokawa, H.: Effect of bottom electrodes on microstructures and electrical properties of sol-gel derived Pb(Zr0.53 Ti0.47)O3 thin films. Thin Solid Films 416, 66–71 (2002) 25. Lee, C., Itoh, T., Sasaki, G., Suga, T.: Sol-gel derived PZT force sensor for scanning force microscopy. Mater. Chem. Phys. 44, 25–29 (1996) 26. Gong, W., Li, J., Zhu, X., Gui, Z., Li, L.: Preparation and characterization of sol-gel derived (100)-textured Pb (Zr, Ti) O3 thin films: PbO seeding role in the formation of preferential orientation. Acta Mater. 52, 2787–2793 (2004) 27. Udayakumar, K.R., Schuele, P.J., Chen, J., Krupanidhi, S.B., Cross, L.E.: Thickness-dependent electrical characteristics of lead zirconate titanate thin films. J. Appl. Phys. 77, 3981–3986 (1995) 28. Dong, W., Lu, X., Liu, M., Cui, Y., Wang, J.: Measurement on the actuating and sensing capability of a PZT MCL. Meas. Sci. Technol. 18, 601–608 (2007) 29. Xie, J., Hub, M., Ling, S.-Fu, Dua, H.: Fabrication and characterization of piezoelectric cantilever for micro transducers. Sens. Actuators A 126, 182–186 (2006)