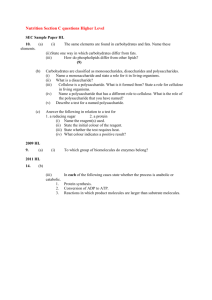

Real-Time Detection of the Morphological Change C E

C

OMMUNICATION TO THE

E

DITOR

Real-Time Detection of the Morphological Change in Cellulose by a Nanomechanical Sensor

Liming Zhao,

1

Ahmed Bulhassan,

2

Guoliang Yang,

1

Hai-Feng Ji,

2

Jun Xi

2

1

Department of Physics, Drexel University, Philadelphia, Pennsylvania

2

Department of Chemistry, Drexel University, Philadelphia, Pennsylvania 19104; telephone: 215-895-2648; fax: 215-895-1265; e-mail: jun.xi@drexel.edu

Received 19 February 2010; revision received 23 March 2010; accepted 30 March 2010

Published online ? ? ? ? in Wiley InterScience (www.interscience.wiley.com). DOI 10.1002/bit.22754

ABSTRACT: Up to now, experimental limitations have prevented researchers from achieving the molecular-level understanding for the initial steps of the enzymatic hydrolysis of cellulose, where cellulase breaks down the crystal structure on the surface region of cellulose and exposes cellulose chains for the subsequent hydrolysis by cellulase.

Because one of these non-hydrolytic enzymatic steps could be the rate-limiting step for the entire enzymatic hydrolysis of crystalline cellulose by cellulase, being able to analyze and understand these steps is instrumental in uncovering novel leads for improving the efficiency of cellulase. In this communication, we report an innovative application of the microcantilever technique for a real-time assessment of the morphological change of cellulose induced by a treatment of sodium chloride. This sensitive nanomechanical approach to define changes in surface structure of cellulose has the potential to permit a real-time assessment of the effect of the non-hydrolytic activities of cellulase on cellulose and thereby to provide a comprehensive understanding of the initial steps of the enzymatic hydrolysis of cellulose.

Biotechnol. Bioeng. 2010;9999: 1–5.

ß 2010 Wiley Periodicals, Inc.

KEYWORDS: cellulose; structural change; microcantilever; cellulase; nanomechanical; surface detection

One of the most critical aspects of biofuel production is conversion of cellulosic biomass to fermentable sugars via enzymatic hydrolysis of cellulose (Wilson, 2009). The enzymatic hydrolysis of cellulose requires the enzyme cellulase first to break down the crystal structure on the surface region of cellulose, then to bind to the partially liberated single glucan chains of cellulose, and finally to hydrolytically cleave these liberated glucan chains. The non-hydrolytic breakdown of the crystal structure on the surface region of cellulose has been speculated to be the rate-limiting step for

Correspondence to: Jun Xi

Contract grant sponsor: National Science Foundation (NSF)

Contract grant number: CBET-0843921

Contract grant sponsor: National Institutes of Health

Contract grant number: R01-GM071793 the entire enzymatic hydrolysis of crystalline cellulose

(Wilson, 2009).

Such disruption of the cellulose surface is expected to be localized in the outer layer, and to occur intermittently on very small areas of cellulose. Most surface detection methods, such as Fourier transform infrared spectroscopy

(Fengel et al., 1995), Raman spectroscopy (Eronen et al.,

2009; Schenzel et al., 2005), and X-ray photoelectron spectroscopy (Fardim et al., 2005) are unable to monitor such changes because they are focused on global changes of cellulose that occur over relatively large surface areas.

Although atomic force microscopic (AFM) imaging has the capability and sensitivity to assess the surface structure of cellulose (Eronen et al., 2009), it is limited to analysis at discrete time points. Both scanning electron microscope and transmission electron microscopy have the same limitations.

In recent years, both quartz crystal microbalance with dissipation (QCM-D) and ellipsometry have been also used to examine the property of cellulose in response to salts

(Ahola et al., 2008; Freudenberg et al., 2007; Tammelin et al.,

2006) and enzymes (Josefsson et al., 2008; Turon et al.,

2008). Measurements by these two techniques are mainly based on changes in total mass and/or thickness of the thin film of cellulose and the results are not very informative about changes in the structural property of the surface region of cellulose. Technical limitations such as these have contributed at various extents to our limited knowledge of a detailed molecular mechanism of non-hydrolytic breakdown of the crystal structure on the surface region of cellulose. Such knowledge is essential to the success of improving catalytic efficiency of cellulase in biomass conversion.

Many of the aforementioned limitations in detecting minute changes in surface structure of cellulose in real time can be overcome with the use of the microcantilever technique. This technique uses microcantilevers (Datskos et al., 2005) that are widely used as force transducers in

AFMs. Microcantilevers are usually made of silicon or silicon nitride and are available in a variety of shapes and

ß 2010 Wiley Periodicals, Inc.

Biotechnology and Bioengineering, Vol. 9999, No. 9999, 2010

1

BIT10-150.R1(22754)

stiffnesses. Their typical dimensions are 200 m m long, 1 m m thick, and 20 m m wide. Such small size makes for high sensitivity, fast response, and the ability to investigate small areas (microenvironments). In the static mode of microcantilever detection, microcantilevers can be bent by stresses that occur on or within its surface (Fig. 1a) (Datskos et al.,

2005), such as those caused by dimensional changes in the surface coatings. Stoney’s equation relates the amount of microcantilever bending to the differential change in surface stress (Fig. 1b). The deformation of a coated microcantilever is in the range of 10

6 to 10

12 m and can be measured by a laser beam reflecting from the tip of the microcantilever

(Fig. 1a) in the AFM.

The application of such technique allows the detection of the surface stress induced by conformational (structural) change of surface-bound molecules, including proteins,

DNA, and polymers (Godin et al., 2004; Karnati et al., 2007;

Moulin et al., 1999; Shu et al., 2005). For example, Zhou et al. (2006) used the microcantilever technique to probe the structural change of polyelectrolyte brushes (20 nm thickness) immobilized on a microcantilever in response to a variety of environmental changes, such as pH and salt concentrations. These reports have established that the microcantilever technique has the specificity and sensitivity to detect real-time structural changes in a thin layer of surface-bound macromolecules.

In the present study, we apply the microcantilever technique to monitor changes in the structure of the surface region of a cellulose coating on a microcantilever in response to a concentration gradient of sodium chloride. The results of our study demonstrate the capability of such nanomechanical approach in real-time detection of the minute a Photo Detector

W

Laser

Deflection

L b

∆ z =

1 l

2

=

2 R

3 l

2

( 1 -

υ

)

∆σ

E t

2

Figure 1.

The deflection of a microcantilever in an AFM.

a : Deformation in the

6 range of 10 to 10

12 m of a coated microcantilever can be precisely measured by the reflection of a laser beam from the tip of the microcantilever.

b : The deformation of the microcantilever D Z follows the Stoney equation (Datskos et al., 2005).

R is the radius of the curvature of the microcantilever, y is the Poisson ratio for the substrate, E is the

Young modulus for the substrate, l is the length of the microcantilever, t is the thickness of the microcantilever, and D s is the differential surface stress. The AFM instrument is modified so that it can be used to detect and record the deflection in the microcantilever in real time.

change in surface structure of cellulose. This nanomechanical approach has the potential to reveal the non-hydrolytic breakdown of the crystal structure on the surface region of cellulose by cellulase and to eventually achieve a comprehensive understanding of cellulase actions on cellulose.

It is generally agreed that the natural substrate is often too complicated to be useful for detailed characterizations of cellulases (Kontturi et al., 2006). Various cellulose model surfaces have therefore been developed in the past decade

(Kontturi et al., 2006) and utilized extensively in a variety of studies including investigation of interaction between cellulose and cellulase. We have developed a protocol to coat the surface of microcantilever with a model film of cellulose II having a thickness between 10 and 20 nm. The reason we decided to use cellulose II was that this model film has been used most often and there is much technical information available about it. We also took advantage of the fact that the surface of cellulose II is relatively easier to prepare and characterize. All these made the cellulose II film as an ideal model surface for the current study. We are also in the process of exploring a film of native cellulose, which can be prepared from a nanocrystal suspension

(Edgar and Gray, 2003; Habibi et al., 2007) or from a nanofibril dispersion (Ahola et al., 2008). For the future study, we intend to use the nanofibril film, which is expected to preserve most of the structural properties of wood fibrils and to offer the best option for the surface of cellulose.

Attachment of a thin layer of cellulose to the surface of a microcantilever requires a thin anchoring layer, such as polyvinyl amine (PVAM), to improve the adhesion between the substrate and the cellulose (Fig. 2a). The anchoring layer was prepared by the introduction of PVAM directly onto the silicon surface of a microcantilever beam. In our case, both the front side and the back side of the microcantilever were coated with PVAM. The cellulose was then deposited on the top of the anchoring layer on the front side of the microcantilever (Fig. 2a) in the form of microcrystalline cellulose dissolved in a mixture of N -methylmorpholine-

N -oxide (NMMO) and dimethyl sulfoxide (DMSO) with a desired viscosity (Falt et al., 2003). The characterization of each layer by means of AFM imaging shows the modification in the surface topography after each coating step (Fig. 2b–d).

AFM imaging was performed on at least three different areas of the same specimen.

The microcantilever coated with cellulose II was treated with a successive exposure of different water/salt environments, and the bending of the microcantilever was monitored by the deflection of the microcantilever at its apex. To compensate for bulk effects of the buffer and the salt, we measured the differential bending, termed simply ‘‘bending’’ hereafter. The bending is the difference in deflection of the microcantilever with the cellulose coating and without the cellulose coating.

The result of bending of the microcantilever is presented in Figure 3a. In the experiment, the coated microcantilever was allowed to equilibrate in water for 2 h prior to the first injection to achieve a stable baseline. Such a short time to

2

Biotechnology and Bioengineering, Vol. 9999, No. 9999, 2010

Figure 2.

Surface coating on the microcantilever.

a : The coating scheme.

Attachment of a thin layer of cellulose to the surface of the microcantilever required a thin anchoring layer, such as polyvinyl amine (PVAM), to improve its adhesion to the microcantilever. The anchoring layer was prepared by introducing PVAM directly onto the silicon surface of a microcantilever beam. Microcrystalline cellulose was dissolved in a mixture of N -methylmorpholineN -oxide (NMMO) and dimethyl sulfoxide

(DMSO) and was deposited on the top of the anchoring layer on the front side of the microcantilever.

b – d : AFM images of surface coatings (5 m m 5 m m). b: The surface without any coating. c: The surface coated with PVAM. d: The surface coated with cellulose. The characterization of each layer by means of AFM imaging shows the modification in the surface topography after each coating step (b–d).

e : The picture of the microcantilever used in the experiment.

Figure 3.

The morphological and structural changes of cellulose monitored by means of the microcantilever technique.

a : The bending of the microcantilever increased with the increasing NaCl concentration. The bulk effects of the buffer were compensated by measurement of differential bending, which is the difference in deflection between the microcantilever with the cellulose coating and without the cellulose coating.

b : AFM image of the surface of the cellulose coating on the microcantilever. Mean roughness: 1.80 nm with a Z range of 25 nm.

c : AFM image of the cellulose surface (as shown in b) after being treated with 0.1 M NaCl. Mean roughness: 1.84 nm with a Z range of 25 nm.

d : The cellulose surface (as shown in c) after being treated with 1.0 M NaCl. Mean roughness: 2.59 nm with a Z range of 25 nm.

achieve the equilibrium can be attributed to the unique size of microcantilever and the thin layer of cellulose coating, which allow a fast response to change of the solution environment.

has also benefit all the following studies involving changes of the salt concentrations. The measurement was initiated with the injection of water and a constant bending was observed during the first 45 min. After injection of a solution of 0.1 M NaCl, the level of bending remained virtually constant. During the next two stages, higher concentrations of NaCl (0.5 and 1 M) were applied.

All salt solutions were prepared in water. A continuous rise in bending was detected at a pace of roughly 1 nm/min and a cumulative bending of more than 100 nm was seen at the end of the experiment.

We attribute the observed bending of the microcantilever to the change in the surface structure of the cellulose coating resulting from change in repulsive interactions among cellulose molecules. When a cellulose model film is exposed to an electrolyte solution, the cellulose undergoes a change in internal charge density, the magnitude of which depends on the concentration of the electrolyte (Ahola et al., 2008;

Freudenberg et al., 2007; Tammelin et al., 2006). The change in charge density in the cellulose film will change the intermolecular repulsion among cellulose molecules and will cause the surface structure of the cellulose to alter. When the cellulose is coated on one surface of the microcantilever

(Fig. 2a), such changes in the surface structure of the cellulose coating can exert a differential mechanical stress between the opposite surfaces of the microcantilever, leading to bending of the microcantilever.

Unlike QCM-D and ellipsometry, the bending of the microcantilever does not respond to minor changes in mass or thickness of the surface coating (Datskos et al., 2005). The microcantilever technique specifically measures the mechanical stress induced by the structural changes in cellulose

(Datskos et al., 2005). Thus, such measurement is expected to be more informative about the non-hydrolytic disruption of the surface structure of cellulose by cellulase than those of

QCM-D and ellipsometry.

The level of change in the microcantilever bending is indicative of the extent of change in the surface structure of the cellulose coating. As the increasing salt concentration results in a continuous change in the repulsive interactions among cellulose molecules in the cellulose coating, a more significant alteration of the surface structure of the cellulose coating as well as a larger rise in the microcantilever bending would be expected. This was verified when we characterized the surface of the microcantilever by means of AFM imaging to evaluate changes in surface morphology of cellulose after each salt treatment. We found no visible change in surface

Zhao et al.:

Sensor

Biotechnology and Bioengineering

3

morphology (2.2% increase in mean roughness) after 0.1 M

NaCl treatment, which is consistent with very little change in bending (Fig. 3c). When the surface was further treated with 1 M NaCl, a significant change in morphology (43% increase in mean roughness) was observed (Fig. 3d), which is correlated well with the large rise in bending. This AFM imaging study further confirms the link between the bending of microcantilever and the change in surface structure of cellulose.

Overall, microcantilever bending correlates well with the change in molecular structure of the surface region of the cellulose film. This validates that the microcantilever technique is highly sensitive and specific in detecting real-time changes in surface structure of cellulose. In our further work, we will apply the microcantilever technique to study the effect of cellulase on the surface structure of cellulose.

All the solutions were introduced through injection in a batch mode, where each solution was injected all at once.

The cellulose was usually allowed to equilibrate with water for at least 2 h prior to any addition. Each assay was run against a reference assay where the microcantilever was coated with only PVAM to allow the subtraction of the background signal and the bulk solvent effect.

A desktop PC, running programs written in LabView

(National Instruments, Austin, TX), was used to record the cantilever deflection signal from the AFM via a data acquisition board with a maximum data acquisition rate of

300 kHz. During a measurement, 100,000 data points were taken every 30 s at a rate of 100 kHz. The bending of the cantilever was obtained by simply averaging the data points.

Materials and Methods

Materials

Microcrystalline cellulose, DMSO, and NMMO were purchased from Sigma–Aldrich (St. Louis, MO). Polyvinylamine (PVAM) was purchased from BASF (Florham Park, NJ). The microcantilevers (200 m m 25 m m 2 m m, 0.1 N/m) were home-made.

Preparation of Cellulose II Model Surface

The cellulose II surface was prepared on the front side of a microcantilever that was made of SiO

2

. The surface of the microcantilever (200 m m 25 m m 2 m m, 0.1 N/m) was first treated with UV ozone for 20 min. It was then immersed in 0.22% PVAM for 60 min followed by rinsing with water. Both the front side and the back side of the microcantilever were coated with PVAM. A suspension of

0.5 mg of microcrystalline cellulose powder in 25 mL of 50%

NMMO was heated while stirring until a transparent brown solution was obtained. While still warm, DMSO was added to afford the cellulose solution with a final concentration of

1%. Such solution was evenly applied onto the surface on the front side of the PVAM-coated microcantilever. The microcantilever was allowed to sit for about 1 h, and then a drop of water was added to precipitate the cellulose. The cellulose film was soaked in water for 4 h and the water was replaced every 30 min. The resulting cellulose film was then incubated in the oven at 80 8 C for 1 h.

Microcantilever Experiment

All the experiments were performed using a modified commercial scanning probe microscope (Nanoscope III from Digital Instruments, Inc./Veeco, Santa Barbara, CA).

The cellulose-coated microcantilever was mounted with the coating facing down in a liquid cell with a volume of 50 m L.

AFM Imaging

To characterize the coverage, morphology, roughness, and thickness of model films, AFM imaging was performed using a Nanoscope IIIa multimode scanning probe microscope from Digital Instruments, Inc. The samples were scanned in contact mode in air using silicon nitride cantilevers (MLCT) manufactured by Veeco (Camarillo, CA), with a nominal spring constant of 0.05 N/m. The size of the images was

5 m m 5 m m, and images were scanned on at least three different areas of the sample. The images of both height and deflection modes were captured. The surface morphology was analyzed using image-processing software.

This work was supported by a grant from the National Science

Foundation (NSF) CBET-0843921 and in part by a grant from

National Institutes of Health R01-GM071793. The authors thank

Dr. Lynn S. Penn for helpful discussions. We also acknowledge the fact that many important publications on the subject were not cited due to the limit set by the publisher.

References

Ahola S, Salmi J, Johansson LS, Laine J, Osterberg M. 2008. Model films from native cellulose nanofibrils. Preparation, swelling, and surface interactions. Biomacromolecules 9(4):1273–1282.

Datskos PG, Lavrik NV, Sepaniak MJ. 2005.

and biological sensors based on microcantilevers. In: Yurish F SY, Gomes MTSR, editors. Smart sensors and MEMS. p 331–379.

Edgar CD, Gray DG. 2003. Smooth model cellulose I surfaces from nanocrystal suspensions. Cellulose (Dordrecht, Netherlands) 10(4):299–306.

on cellulose supramolecular structure studied with combined confocal

Raman spectroscopy and atomic force microscopy. Cellulose (Dordrecht, Netherlands) 16(2):167–178.

Falt S, Waagberg L, Vesterlind E-L. 2003. Swelling of model films of cellulose having different charge densities and comparison to the swelling behavior of corresponding fibers. Langmuir 19(19):7895–7903.

Fardim P, Gustafsson J, von Schoultz S, Peltonen J, Holmbom B. 2005.

Extractives on fiber surfaces investigated by XPS, ToF-SIMS and AFM.

Colloids Surf A 255(1–3):91–103.

Fengel D, Jakob H, Strobel C. 1995. Influence of the alkali concentration on the formation of cellulose II. Study by X-ray diffraction and FTIR spectroscopy. Holzforschung 49(6):505–511.

4

Biotechnology and Bioengineering, Vol. 9999, No. 9999, 2010

Freudenberg U, Zimmermann R, Schmidt K, Behrens SH, Werner C. 2007.

Charging and swelling of cellulose films. J Colloid Interface Sci

309(2):360–365.

Godin M, Williams PJ, Tabard-Cossa V, Laroche O, Beaulieu LY, Lennox

RB, Grutter P. 2004. Surface stress, kinetics, and structure of alkanethiol self-assembled monolayers. Langmuir 20(17):7090–7096.

Habibi Y, Foulon L, Aguie-Beghin V, Molinari M, Douillard R. 2007.

Langmuir-Blodgett films of cellulose nanocrystals: Preparation and characterization. J Colloid Interface Sci 316(2):388–397.

Josefsson P, Henriksson G, Wagberg L. 2008. The physical action of cellulases revealed by a quartz crystal microbalance study using ultrathin cellulose films and pure cellulases. Biomacromolecules 9(1):249–

254.

Karnati C, Du H, Ji H-F, Xu X, Lvov Y, Mulchandani A, Mulchandani P,

Chen W. 2007. Organophosphorus hydrolase multilayer modified microcantilevers for organophosphorus detection. Biosens Bioelectron

22(11):2636–2642.

Kontturi E, Tammelin T, Osterberg M. 2006. Cellulose-model films and the fundamental approach. Chem Soc Rev 35(12):1287–1304.

Moulin AM, O’Shea SJ, Badley RA, Doyle P, Welland ME. 1999. Measuring surface-induced conformational changes in proteins. Langmuir

15(26):8776–8779.

Schenzel K, Fischer S, Brendler E. 2005. New method for determining the degree of cellulose I crystallinity by means of FT Raman spectroscopy.

Cellulose (Dordrecht, Netherlands) 12(3):223–231.

Shu W, Liu D, Watari M, Riener CK, Strunz T, Welland ME, Balasubramanian S, McKendry RA. 2005. DNA molecular motor driven micromechanical cantilever arrays. J Am Chem Soc 127(48):17054–17060.

Blodgett-cellulose surfaces by using horizontal Dipping procedure.

Application for polyelectrolyte adsorption studies performed with

QCM-D. Cellulose (Dordrecht, Netherlands) 13:519–535.

Turon X, Rojas OJ, Deinhammer RS. 2008. Enzymatic kinetics of cellulose hydrolysis: A QCM-D study. Langmuir 24(8):3880–3887.

Wilson DB. 2009. Cellulases and biofuels. Curr Opin Biotechnol 20(3):295–299.

Zhou F, Shu W, Welland ME, Huck WTS. 2006. Highly reversible and multi-stage cantilever actuation driven by polyelectrolyte brushes. J Am

Chem Soc 128(16):5326–5327.

Q2: Author: Please verify/modify the sentence ‘‘This has also...’’ for clarity.

Q3: Author: Please provide the publisher name and location and also check the editors names.

Zhao et al.:

Sensor

Biotechnology and Bioengineering

5

1 1 1 R I V E R S T R E E T , H O B O K E N , N J 0 7 0 3 0

***IMMEDIATE RESPONSE REQUIRED***

Your article will be published online via Wiley's EarlyView® service ( www.interscience.wiley.com

) shortly after receipt of corrections. EarlyView® is Wiley's online publication of individual articles in full text HTML and/or pdf format before release of the compiled print issue of the journal. Articles posted online in EarlyView® are peer-reviewed, copyedited, author corrected, and fully citable via the article DOI (for further information, visit www.doi.org). EarlyView® means you benefit from the best of two worlds--fast online availability as well as traditional, issue-based archiving.

Please follow these instructions to avoid delay of publication.

READ PROOFS CAREFULLY

• This will be your only chance to review these proofs . Please note that once your corrected article is posted online, it is considered legally published, and cannot be removed from the Web site for further corrections.

• Please note that the volume and page numbers shown on the proofs are for position only.

ANSWER ALL QUERIES ON PROOFS (Queries for you to answer are attached as the last page of your proof.)

• Mark all corrections directly on the proofs. Note that excessive author alterations may ultimately result in delay of publication and extra costs may be charged to you.

CHECK FIGURES AND TABLES CAREFULLY

• Check size, numbering, and orientation of figures.

• All images in the PDF are downsampled (reduced to lower resolution and file size) to facilitate Internet delivery.

These images will appear at higher resolution and sharpness in the printed article.

• Review figure legends to ensure that they are complete.

• Check all tables. Review layout, title, and footnotes.

COMPLETE REPRINT ORDER FORM

• Fill out the attached reprint order form. It is important to return the form even if you are not ordering reprints. You may, if you wish, pay for the reprints with a credit card. Reprints will be mailed only after your article appears in print. This is the most opportune time to order reprints. If you wait until after your article comes off press, the reprints will be considerably more expensive.

RETURN PROOFS

REPRINT ORDER FORM

CTA (If you have not already signed one)

RETURN IMMEDIATELY AS YOUR ARTICLE WILL BE POSTED ONLINE SHORTLY AFTER RECEIPT;

FAX PROOFS TO 201-748-7670

QUESTIONS? Production Editor

E-mail: bitprod@wiley.com

Refer to journal acronym and article production number

(i.e., BIT 00-001 for Biotechnology and Bioengineering ms 00-001).

Color figures were included with the final manuscript files that we received for your article. Because of the high cost of color printing, we can only print figures in color if authors cover the expense.

Please indicate if you would like your figures to be printed in color or black and white. Color images will be reproduced online in Wiley InterScience at no charge, whether or not you opt for color printing.

You will be invoiced for color charges once the article has been published in print.

Failure to return this form with your article proofs will delay the publication of your article.

JOURNAL

BIOTECHNOLOGY AND BIOENGINEERING

MS. NO.

NO. OF

COLOR

PAGES

TITLE OF

MANUSCRIPT

AUTHOR(S)

No. Color Pages Color Charges No. Color Pages Color Charges No. Color Pages Color Charges

1 500 5 2500 9 4500

2 1000 6 3000 10 5000

3 1500 7 3500 11 5500

4 2000 8 4000 12 6000

***Please contact the Production Editor for a quote if you have more than 12 pages of color***

Please print my figures in black and white

Please print my figures in color

Please print the following figures in color:

BILLING

ADDRESS:

C O P Y R I G H T T R A N S F E R A G R E E M E N T

Date: Contributor name:

Contributor address:

Manuscript number (Editorial office only):

Re: Manuscript entitled for publication in published by

(the “Contribution”)

(the “Journal”)

(“Wiley-Blackwell”).

Dear Contributor(s):

Thank you for submitting your Contribution for publication. In order to expedite the editing and publishing process and enable Wiley-Blackwell to disseminate your Contribution to the fullest extent, we need to have this Copyright Transfer Agreement signed and returned as directed in the Journal’s instructions for authors as soon as possible. If the Contribution is not accepted for publication, or if the Contribution is subsequently rejected, this

Agreement shall be null and void. Publication cannot proceed without a signed copy of this Agreement.

A . C O P Y R I G H T

1.

The Contributor assigns to Wiley-Blackwell, during the full term of copyright and any extensions or renewals, all copyright in and to the Contribution, and all rights therein, including but not limited to the right to publish, republish, transmit, sell, distribute and otherwise use the Contribution in whole or in part in electronic and print editions of the Journal and in derivative works throughout the world, in all languages and in all media of expression now known or later developed, and to license or permit others to do so.

2.

Reproduction, posting, transmission or other distribution or use of the final

Contribution in whole or in part in any medium by the Contributor as permitted by this Agreement requires a citation to the Journal and an appropriate credit to Wiley-Blackwell as Publisher, and/or the Society if applicable, suitable in form and content as follows: (Title of Article, Author, Journal Title and

Volume/Issue, Copyright © [year], copyright owner as specified in the Journal).

Links to the final article on Wiley-Blackwell’s website are encouraged where appropriate.

B . R E TA I N E D R I G H T S

Notwithstanding the above, the Contributor or, if applicable, the Contributor’s

Employer, retains all proprietary rights other than copyright, such as patent rights, in any process, procedure or article of manufacture described in the

Contribution.

C . P E R M I T T E D U S E S B Y C O N T R I B U T O R

1. Submitted Version. Wiley-Blackwell licenses back the following rights to the Contributor in the version of the Contribution as originally submitted for publication: a. After publication of the final article, the right to self-archive on the Contributor’s personal website or in the Contributor’s institution’s/employer’s institutional repository or archive. This right extends to both intranets and the Internet. The Contributor may not update the submission version or replace it with the published Contribution. The version posted must contain a legend as follows: This is the pre-peer reviewed version of the following article: FULL CITE, which has been published in final form at [Link to final article]. b.

The right to transmit, print and share copies with colleagues.

2. Accepted Version.

Re-use of the accepted and peer-reviewed (but not final) version of the Contribution shall be by separate agreement with Wiley-

Blackwell. Wiley-Blackwell has agreements with certain funding agencies governing reuse of this version. The details of those relationships, and other offerings allowing open web use, are set forth at the following website: http://www.wiley.com/go/funderstatement. NIH grantees should check the box at the bottom of this document.

3. Final Published Version.

Wiley-Blackwell hereby licenses back to the

Contributor the following rights with respect to the final published version of the Contribution: a.

Copies for colleagues. The personal right of the Contributor only to send or transmit individual copies of the final published version in any format to colleagues upon their specific request provided no fee is charged, and further-provided that there is no systematic distribution of the Contribution, e.g. posting on a listserve, website or automated delivery.

b.

Re-use in other publications. The right to re-use the final Contribution or parts thereof for any publication authored or edited by the Contributor

(excluding journal articles) where such re-used material constitutes less than half of the total material in such publication. In such case, any modifications should be accurately noted.

c.

Teaching duties. The right to include the Contribution in teaching or training duties at the Contributor’s institution/place of employment including in course packs, e-reserves, presentation at professional conferences, in-house training, or distance learning. The Contribution may not be used in seminars outside of normal teaching obligations (e.g. commercial seminars). Electronic posting of the final published version in connection with teaching/training at the Contributor’s institution/place of employment is permitted subject to the implementation of reasonable access control mechanisms, such as user name and password. Posting the final published version on the open Internet is not permitted.

d.

Oral presentations. The right to make oral presentations based on the

Contribution.

4. Article Abstracts, Figures, Tables, Data Sets, Artwork and Selected

Text (up to 250 words).

a.

Contributors may re-use unmodified abstracts for any non-commercial purpose. For on-line uses of the abstracts, Wiley-Blackwell encourages but does not require linking back to the final published versions.

b.

Contributors may re-use figures, tables, data sets, artwork, and selected text up to 250 words from their Contributions, provided the following conditions are met:

(i) Full and accurate credit must be given to the Contribution.

(ii) Modifications to the figures, tables and data must be noted.

Otherwise, no changes may be made.

(iii) The reuse may not be made for direct commercial purposes, or for financial consideration to the Contributor.

(iv) Nothing herein shall permit dual publication in violation of journal ethical practices.

CTA-A

D . C O N T R I B U T I O N S O W N E D B Y E M P L O Y E R

1.

If the Contribution was written by the Contributor in the course of the

Contributor’s employment (as a “work-made-for-hire” in the course of employment), the Contribution is owned by the company/employer which must sign this Agreement (in addition to the Contributor’s signature) in the space provided below. In such case, the company/employer hereby assigns to

Wiley-Blackwell, during the full term of copyright, all copyright in and to the

Contribution for the full term of copyright throughout the world as specified in paragraph A above.

2.

In addition to the rights specified as retained in paragraph B above and the rights granted back to the Contributor pursuant to paragraph C above, Wiley-

Blackwell hereby grants back, without charge, to such company/employer, its subsidiaries and divisions, the right to make copies of and distribute the final published Contribution internally in print format or electronically on the Company’s internal network. Copies so used may not be resold or distributed externally.

However the company/employer may include information and text from the

Contribution as part of an information package included with software or other products offered for sale or license or included in patent applications.

Posting of the final published Contribution by the institution on a public access website may only be done with Wiley-Blackwell’s written permission, and payment of any applicable fee(s). Also, upon payment of Wiley-Blackwell’s reprint fee, the institution may distribute print copies of the published Contribution externally.

E . G O V E R N M E N T C O N T R A C T S

In the case of a Contribution prepared under U.S. Government contract or grant, the U.S. Government may reproduce, without charge, all or portions of the Contribution and may authorize others to do so, for official U.S. Government purposes only, if the U.S. Government contract or grant so requires. (U.S.

Government, U.K. Government, and other government employees: see notes at end)

F. C O P Y R I G H T N O T I C E

The Contributor and the company/employer agree that any and all copies of the final published version of the Contribution or any part thereof distributed or posted by them in print or electronic format as permitted herein will include the notice of copyright as stipulated in the Journal and a full citation to the

Journal as published by Wiley-Blackwell.

G . C O N T R I B U T O R ’ S R E P R E S E N TAT I O N S

The Contributor represents that the Contribution is the Contributor’s original work, all individuals identified as Contributors actually contributed to the Contribution, and all individuals who contributed are included. If the Contribution was prepared jointly, the Contributor agrees to inform the co-Contributors of the terms of this Agreement and to obtain their signature to this Agreement or their written permission to sign on their behalf. The Contribution is submitted only to this Journal and has not been published before. (If excerpts from copyrighted works owned by third parties are included, the Contributor will obtain written permission from the copyright owners for all uses as set forth in Wiley-

Blackwell’s permissions form or in the Journal’s Instructions for Contributors, and show credit to the sources in the Contribution.) The Contributor also warrants that the Contribution contains no libelous or unlawful statements, does not infringe upon the rights (including without limitation the copyright, patent or trademark rights) or the privacy of others, or contain material or instructions that might cause harm or injury.

C H E C K O N E B O X :

Contributor-owned work

AT TA C H A D D I T I O N A L S I G N AT U R E

PA G E S A S N E C E S S A RY

Contributor’s signature Date

Type or print name and title

Co-contributor’s signature

Type or print name and title

Date

Company/Institution-owned work

(made-for-hire in the course of employment) Company or Institution (Employer-for-Hire)

Authorized signature of Employer

U.S. Government work

U.K. Government work

(Crown Copyright)

Other Government work

NIH Grantees

Note to U.S. Government Employees

A contribution prepared by a U.S. federal government employee as part of the employee’s official duties, or which is an official U.S. Government publication, is called a “U.S. Government work,” and is in the public domain in the United States. In such case, the employee may cross out Paragraph A.1 but must sign (in the

Contributor’s signature line) and return this Agreement. If the Contribution was not prepared as part of the employee’s duties or is not an official U.S. Government publication, it is not a U.S. Government work.

Note to U.K. Government Employees

The rights in a Contribution prepared by an employee of a U.K. government department, agency or other

Crown body as part of his/her official duties, or which is an official government publication, belong to the

Crown. U.K. government authors should submit a signed declaration form together with this Agreement.

The form can be obtained via http://www.opsi.gov.uk/advice/crown-copyright/copyright-guidance/ publication-of-articles-written-by-ministers-and-civil-servants.htm

Note to Non-U.S., Non-U.K. Government Employees

If your status as a government employee legally prevents you from signing this Agreement, please contact the editorial office.

Note to NIH Grantees

Pursuant to NIH mandate, Wiley-Blackwell will post the accepted version of Contributions authored by NIH grant-holders to PubMed Central upon acceptance. This accepted version will be made publicly available

12 months after publication. For further information, see www.wiley.com/go/nihmandate.

Date

Date

CTA-A

BIOTECHNOLOGY AND BIOENGINEERING

Telephone Number: • Facsimile Number:

To: BIT Production Editor At FAX #: 201-748-7670

From: Dr.

Date:

Re: Biotechnology and Bioengineering, ms #

Dear Production Editior

Attached please find corrections to ms# __________. Please contact me should you have any difficulty reading this fax at the numbers listed below.

Office phone:

Email:

Fax:

Lab phone:

I will return color figure proofs (if applicable) once I have checked them for accuracy.

Thank you,

Dr.

E-proofing feedback comments:

C1

REPRINT BILLING DEPARTMENT

••

111 RIVER STREET, HOBOKEN, NJ 07030

PHONE: (201) 748-8789; FAX: (201) 748-6326

E-MAIL: reprints@wiley.com

PREPUBLICATION REPRINT ORDER FORM

Please complete this form even if you are not ordering reprints.

This form MUST be returned with your corrected proofs and original manuscript. Your reprints will be shipped approximately 4 weeks after publication. Reprints ordered after printing will be substantially more expensive.

JOURNAL

Biotechnology and Bioengineering

VOLUME ISSUE

TITLE OF MANUSCRIPT

MS. NO.

NO. OF PAGES AUTHOR(S)

No. of Pages

1-4

5-8

9-12

13-16

17-20

21-24

25-28

29-32

33-36

37-40

100 Reprints

$

336

469

594

714

794

911

1004

1108

1219

1329

200 Reprints

$

501

703

923

1156

1340

1529

1707

1894

2092

2290

300 Reprints

$

694

987

1234

1527

1775

2031

2267

2515

2773

3033

400 Reprints

$

890

1251

1565

1901

2212

2536

2828

3135

3456

3776

500 Reprints

$

1052

1477

1850

2273

2648

3037

3388

3755

4143

4528

**REPRINTS ARE ONLY AVAILABLE IN LOTS OF 100. IF YOU WISH TO ORDER MORE THAN 500 REPRINTS, PLEASE CONTACT OUR REPRINTS

DEPARTMENT AT (201) 748-8789 FOR A PRICE QUOTE.

Please send me _____________________ reprints of the above article at

Please add appropriate State and Local Tax for United States orders only.

$

(Tax Exempt No.____________________) $

Please add 5% Postage and Handling $

TOTAL AMOUNT OF ORDER**

**International orders must be paid in currency and drawn on a U.S. bank

Please check one:

If credit card order, charge to:

Check enclosed

American Express

Bill me

Visa

Signature Credit Card No

BILL TO:

Name

SHIP TO:

Name

$

Credit Card

MasterCard

(Please, no P.O. Box numbers)

Exp. Date

Institution

Address

Institution

Address

Purchase Order No.

Phone

Fax

Softproofing for advanced Adobe Acrobat Users - NOTES tool

NOTE: ACROBAT READER FROM THE INTERNET DOES NOT CONTAIN THE NOTES TOOL USED IN THIS PROCEDURE.

Acrobat annotation tools can be very useful for indicating changes to the PDF proof of your article.

By using Acrobat annotation tools, a full digital pathway can be maintained for your page proofs.

The NOTES annotation tool can be used with either Adobe Acrobat 4.0, 5.0 or 6.0. Other annotation tools are also available in Acrobat 4.0, but this instruction sheet will concentrate on how to use the NOTES tool. Acrobat Reader, the free Internet download software from Adobe,

DOES NOT contain the NOTES tool. In order to softproof using the NOTES tool you must have the full software suite Adobe Acrobat 4.0, 5.0 or 6.0 installed on your computer.

Steps for Softproofing using Adobe Acrobat NOTES tool:

1. Open the PDF page proof of your article using either Adobe Acrobat 4.0, 5.0 or 6.0. Proof your article on-screen or print a copy for markup of changes.

2. Go to File/Preferences/Annotations (in Acrobat 4.0) or Document/Add a Comment (in Acrobat

6.0 and enter your name into the “default user” or “author” field. Also, set the font size at 9 or 10 point.

3. When you have decided on the corrections to your article, select the NOTES tool from the

Acrobat toolbox and click in the margin next to the text to be changed.

4. Enter your corrections into the NOTES text box window. Be sure to clearly indicate where the correction is to be placed and what text it will effect. If necessary to avoid confusion, you can use your TEXT SELECTION tool to copy the text to be corrected and paste it into the NOTES text box window. At this point, you can type the corrections directly into the NOTES text box window.

DO NOT correct the text by typing directly on the PDF page.

5. Go through your entire article using the NOTES tool as described in Step 4.

6. When you have completed the corrections to your article, go to File/Export/Annotations (in

Acrobat 4.0) or Document/Add a Comment (in Acrobat 6.0).

7.

When closing your article PDF be sure NOT to save changes to original file.

8. To make changes to a NOTES file you have exported, simply re-open the original PDF proof file, go to File/Import/Notes and import the NOTES file you saved. Make changes and reexport NOTES file keeping the same file name.

9. When complete, attach your NOTES file to a reply e-mail message. Be sure to include your name, the date, and the title of the journal your article will be printed in.