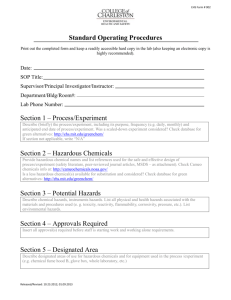

UW-Stout Chemical Hygiene Plan

advertisement