Milwaukee Area Technical College Office of Workforce and Economic Development Duane Schultz

advertisement

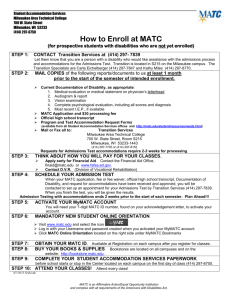

Milwaukee Area Technical College Office of Workforce and Economic Development 2010-2011 Annual Report Duane Schultz Director August, 2011 Dear Interested Parties: Welcome to the Annual Report for the MATC Office of Workforce and Economic Development (OWED). This description provides a brief overview of the year’s activities working toward the twin goals of workforce development and economic development. The workforce development goal is to develop a skilled workforce, while, at the same time providing leadership as a proactive member of the area’s economic development team. This is consistent with the strategic plan of the college, with close alignment with several goals; promotion of student pathways and enhancing stakeholder partnerships. As the latest reorganization of this office was made in the summer of 2010, this has been a time of change and of adaptation to meet the needs of companies, organizations and students. To accomplish this during severe budget limitations and difficult times in the local labor market has been challenging. The Office of Workforce and Economic Development (OWED) develops training contracts, administers a variety of grants and has been assigned responsibility for the majority of the continuing education program offerings at the college. The successes of our office can be directly attributed to the professionalism and dedication of our staff. The team extends to include many faculty and staff from across the college who assist in achieving successful projects. The academic divisions have provided high levels of direction and support for the offerings that come through this office. Academic leadership and strong faculty make for our successes. The important work contributed by staff in the grants department, business office, and student services helps achieve successful delivery of classes. This report provides an overview and highlights of the many OWED roles and functions that work to enhance funding of projects and pilot efforts to more effectively meet the complex training and education needs of those we serve. I hope that you will find the report interesting and informational. The office actively looks to build partnerships and work collaboratively to provide career options for individuals, develop credentialed pathways to the college and demonstrate our commitment toward forging a highly skilled labor force in our region. Sincerely, Duane E Schultz Duane E Schultz Director MATC Office of Workforce and Economic Development 2010 – 2011 Annual Report Table of Contents OWED Overview ……………………………………………………..…..…..3 Contract Training……………………………………………………….………4 Workforce Advancement Training Grants ……..…..….…...….5 MSSC program……………………………………………………………….….7 National Retail Federation Certification …………….…….…….…8 WISTEC Grant…………………………………………………………….………9 FSET grant……………………………………………………………….……..…10 Grant development……………………………………………….………...11 Continuing Education………………………………………………….…….12 Summary and Future Directions………………………………….…….13 College Cost Savings…………………………………………………….……14 Organizational Structure and Staff ……………………………..….15 Workforce Partners and Participating Companies …….…..…16 Instructional Offerings …………………………………………….……….17 2 Introduction and Overview Milwaukee Area Technical College (MATC) has been providing outreach training and technical services since the early 1980s. With many changes in structures, functions and staffing for the outreach unit; the role of the staff --to develop and deliver quality training, has been consistent since the office was first organized as Business and Industry Services. OWED helps to provide a broad range of training, education and economic development activities that are part of the outreach mission of the college. To achieve the goal of a skilled workforce, three key strategies are being used; upgrade and certify current worker skills, develop and certify skills of those actively engaged in preparing for a new career, and prepare foundation skill sets with career pathways to technical skills acquisition and certification for the future workforce. Many of our efforts are targeted to employees of the current workforce. To address companies’ changing skill requirements, classes in new skill areas, certifying current skills or ensuring the skills to implement new processes are being provided across the district. Our most important workforce partner is the Milwaukee Area Workforce Investment Board. Through its network of agencies and funding, MATC is collaborating on training implementation, grant development and innovative projects. In conjunction with the HIRE Center consortium, we have worked to meet the transition and reemployment needs of the area’s unemployed and dislocated workers. As traditional job clusters are reduced in scope and size, more people are looking to MATC as the means to redefine their careers and enhance their job opportunities. For many adults in the labor market, current work experience and job skills are inadequate to access a good paying position. Strong basic and foundation skills are a requisite in gaining access to technical education opportunities. Many residents do not possess critical reading, writing, comprehension, math and computer literacy. This office has worked diligently to advocate for approaches that will build these skills sets in a timely and efficient way, with alternative models to integrate education training and work. This active role in developing a skilled workforce is, at the same time, our key contribution to the area’s growth and development. Toward this end, OWED has used its budget authority, its grants development approach and its coordinating, partnering strategies to solicit resources and develop new ways of building skills sets. The priority is to utilize a coordinated workforce development approach as a key and effective economic development strategy for our region. 3 Business Industry MATC DWD BIT HS MAWIB T&AS Pre-College CBO’s and workforce agencies Contract Training Number of Contracts 77 LAS Tech Colleges AFL-CIO Contract Revenues $2,045,087 Number of Students 5240 Number of Classes 142 A central function of this office is to work with area business to meet their workforce training needs. Contracts for training may also be negotiated with governmental bodies, community based agencies and a broad array of related organizations. The contracts may be let for training, curriculum development or other technical assistance work with organizations. Utilizing the contracting systems, the office has also delivered courses, workshops and seminars to meet statewide professional licensing requirements and assist students in their quest for advanced certifications in their occupational area. The largest activities in 38.14 contracts were with dislocated workers in the MATC District that included several funding sources such as the Trade Adjustment/Re-Adjustment Act (TAA), Special Response, National Emergency Grant (NEG), and WIA Dislocated worker (that included limited English speakers, Spanish and Hmong). Many of these resource flow through the MAWIB. Bilingual training for current workers with limited English was also a key aspect of the training projects. Contracts to provide training for dislocated and incumbent workers included career areas such as manufacturing, electricity, electronics, construction trades, green technology, business and information technology, health services and culinary arts. These efforts were carried out in coordination and collaboration with MATC’s divisions and departments in the School of Technology and Applied Sciences, School of Business and Information Technology, School of Health Services, School of Liberal Arts and Sciences, and School of the Pre-College. A sampling of testimonials from students and company representatives: “As always, the depth of knowledge of the instructors and their ability to relate to the real world make the course enjoyable and the material easy to learn and remember”… “Very informative and easy to follow along and understand. The CPR instructor was fantastic!”…e “I had the chance to briefly look at the class comments on the training. Yes, the instructor does do an excellent job even at 6:00am. Thanks for all your help. I am so pleased that we switched to MATC for our first responder training. “ 4 Workforce Advancement Training Grants (WAT) Number of Grants 8 Training Resources $384,873 Number of Students 181 Number of Classes 10 Section 38.41, Wis. Stat, authorizes the WTCS Office to make grant awards to technical colleges for worker skills training. Grants in this category are awarded to promote increased investments in the development of incumbent workers, while improving Wisconsin businesses’ productivity and competitiveness, augmenting the state’s economic base, and expanding technical college training services to businesses and industry. Grants are provided to upgrade the skills and productivity of employees of established businesses operating in Wisconsin, with the broader objective of supporting regional workforce and economic development efforts. Training under these grants must focus on occupational skills but can include a combination of occupational, academic, and employability topics or courses. Milwaukee Area Technical College has actively participated in this grant program. The following provides highlights of training we have completed for the companies that were awarded WAT grant resources during the last fiscal year: Milwaukee Cylinder – Technical skills training was provided in CNC Turning, Machine Tool Technology, Machine Trade Math and Blueprint Reading for 37 employees. The company viewed this training resource as a means to increase their long term viability and save jobs. At the same time, they are interested in gaining certification for their workforce while providing promotion opportunities. MEC Midwest— Technical, management and preparatory training was provided for 50 employees in electronics, management and related areas. The company valued the training project as a way to increase workforce skills and credentials, save 10 jobs and increase their overall profitability. GE Healthcare— Machining, Statistical Process Control and Train the trainer classes were provided for 300 employees. The company has achieved a scrap reduction rate of 17%, a 3% reduction in inventory costs and a decrease of 3% in perishable tool costs. The project also assisted the company to increase their internal training capacity by 25%. Harley Davidson Motor Company – Technical training was provided in Millwright and Pipefitting skills for 28 employees. These resources were a means to increasing the knowledge and skills of the participating incumbent workers. It will also prevent the company from having to relocate work and save jobs here in Milwaukee. The training will stabilize the firm’s maintenance program and improve productivity which will help improve the overall viability and competitiveness of the firm. 5 Johnson Controls— This company has operations in 59 countries and manages more than one billion square feet worldwide (customer relationships often spanning entire building lifecycles), it is critical that employees apply consistent standards of customer service excellence globally. A four hour “Customer Satisfaction for Tomorrow” course was designed and delivered for two employee groups: The Milwaukee service/ system technicians and sales representatives as well as JCI’s global trainers. This will provide Johnson Controls the capacity to deploy this standard, customized training on a global scale. At the Milwaukee facility, 44 Milwaukee employees were trained in methods of exceptional customer service, making their jobs easier and giving them additional skills for promotability and higher pay. At the same time, 33 internal trainers were trained to deliver the seminar across the United States, giving many employees additional skills sets needed by the company’s business plan. The company viewed this training as a way to increase profitability and to raise the skills of the workforce. Master Lock Company— This firm has worked closely with MATC, utilizing MSSC certification for their workforce. The WAT grant provided resources to provide assessment and certification services to 35 employees at the Milwaukee facility. Through active leadership from the local union working in partnership with management through their collective bargaining agreement, a strong encouragement is being given to all hourly workers to improve their skills base. The company used the grant resource to increase company viability and profitability as well as to provide more stable employment in Milwaukee. For the employees, this provides key skill sets that can increase qualifications, upgrade job positions and increase wage levels. Columbia Grinding— Through the WAT grant resources, the objective with this company was to provide machining skill training for fourteen employees. The company viewed the training as a way to improve the viability and profitability of the firm, while improving skill sets and long term wages. The Laser Shop— Using the WAT grant program, this company worked with MATC to garner welding training for 12 employees and achieve certification for their workforce. This project was a priority for the company as the key goals of productivity and quality were incorporated as outcomes of the grant. 6 Manufacturing Skills Standards Council Certification (MSSC) Number of Companies 5 Number of Assessments 120 Number of Classes 12 Number Certified to date 700 In 1997 the National coalition for Advanced Manufacturing (NACAM), through its Manufacturing Skill Standards Council (MSSC), assembled major stakeholders for strong U.S. manufacturing including company leaders, workers, educators, and other workforce development experts. Their goal was to create the basic set of skill standards needed by today’s production worker to succeed and for industry to survive. The secondary goal was portable credentials, reflecting that individuals meet the minimum skills standards, to satisfy rapidly shifting manufacturing and employment needs. About 4000 workers from 750 companies, 300 subject matter experts and 30 support organizations worked diligently to develop MSSC production worker skill standards. The team developed a multiple-choice test, combined with a computer simulation exercise, comprised of four modules that in aggregate formed the minimum requirement for a worker to gain certification. The system measures and certifies the foundational skills and knowledge of students, educators, and production workers from entry level to first line supervision in all sectors of manufacturing. The four areas of concentration (modules) are Safety, Quality, Manufacturing Processes and Maintenance Awareness. In 2001, MSSC standards were federally recognized by the National Skill Standards Board. In 2008, logistics industry subject matter experts identified skills standards for two new levels of certification. Both CLA (Certified Logistics Associate) and CLT (Certified Logistics Technician), that address work activities and related skills involved with moving material throughout the supply chain: to warehouses, distribution centers and to material handlers within the various transportation networks. These six certifications are offered through OWED at MATC. The college is giving Advanced Standing credits for each certificate to students who successfully pass the modules. As a certified testing site for MSSC, qualified faculty from the related departments provide all instruction. MSSC has announced that in October, 2011, the Green Production Module will be launched. This nationally portable credential will focus entirely on enhancing the green production skills of frontline production workers in all sectors of manufacturing. This will go beyond the manufacture of green products to enhance the greening of the entire manufacturing sector. Feedback received from the National MSSC: “We at MSSC have had an excellent relationship with MATC over several years. Not only have we been impressed with the professionalism, knowledge, and outcomes of your instructors and administrative staff, but also with the diversity of MSSC training and assessment programs you have offered. We greatly appreciate your support, but also MATC leadership in driving the MSSC Certification Systems into the employer, secondary and post-secondary communities. We look forward to continuing what has been a very beneficial relationship in 2012”. 7 National Certifications – National Retail Federation (NRF) Number enrolled 376 Number of classes 12 Number of certifications 282 The NRF Foundation offers a number of certifications to professionalize the retail workforce and promote uniform standards of excellence. The NRF Foundation professional credentials include individual certification in four areas: Customer Service, Sales, Retail Management, and a Professional Retail Business Credential. This standards-based approach to building a common set of skills and knowledge establishes clear performance expectations and provides hiring managers assurance that candidates are prepared to succeed. Retailers can use certification as preferred qualifications for hire or on-boarding programs. Educators and workforce development agencies can use certification as capstones to class work and connections to related training programs. Career applicants in this area benefit from the credential as it is portable, recognizable and supported by the retail sector. The skills development approach that has been implemented here in the Milwaukee area has been based on a partnership approach; MATC has been working with the Milwaukee Area Workforce Board, the Multicultural community organization (NRF certified testing site) and retail sector employers and associations to recruit, assess and train participants for careers in the retail sector. With an onsite facility located in the Bay Shore Town Center mall, known as Career Works, the consortium has carried out a series of training and assessment sessions. The emphasis has been to meet the staffing and employee needs of the retail industry. Career Works has also worked with area employers on training in customer service for call center staff, promoted career / job fairs and facilitated application and hiring processes. For individuals who are planning for a career in retail occupations, the NRF certification process provides a straightforward approach to documenting skill sets for this sector. The steps include the following: 1. 2. 3. 4. Review knowledge and skill areas in the certification exams to determine if training is needed, Schedule exam at the local testing center, Complete the online exam and receive instant notification of pass/fail status, and Passing candidates receive a formal certificate and letter of recognition. 8 Community Based Job Training Grant – WISTEC Grant Timeframe Number enrolled Number capacity building Number of classes held Curriculum for classes Number of certifications Fiscal Yr 2011 162 1209 11 1 1 Overall Grant Results 854 4836 80 15 12 Community based job training grants are employer-focused and build on the High Growth Job Training Initiative, a national model for demand-driven workforce development implemented by strategic partnerships between the workforce investment system, employers, and community colleges and other training providers. The primary purpose of the WISTEC grant was to build the capacity of Milwaukee Area Technical College to train workers with skill sets required to succeed in high growth/high demand industries. The US Department of Labor funded MATC’s grant application in Advanced Manufacturing and Energy for a three year period. The grant was successfully completed and closed out as of December, 2010. The project had five key goals: 1. 2. 3. 4. 5. Curriculum development and alignment between secondary and post-secondary institutions. The WISTEC grant provided focus on key courses in the Science, Technology, Engineering, and Math (STEM) areas to ensure articulation and expand the offerings at area high schools. Teacher training and certification was a critical aspect of the grant as area high school teachers and MATC instructors were provided career development opportunities, while expanding the number of certified faculty for emerging courses and certifications in advanced manufacturing and energy related career areas. Career planning, effective training and implementation systems and strategies were utilized in the training that was carried out, in partnership with the area workforce board, the dislocated worker programs and area community based organizations. More than 850 enrolled in training over the course of the grant and 162 enrolled in training during the last phase of the project. The grant targeted participants with skill deficits through reorganizing and reconfiguring curriculum and student preparation. Finally, the grant worked diligently to Increase the number of advanced and technical core certifications so that students can more effectively build their credentials for careers in these fields. Certifications were developed in consultation with key departments with the Technology and Applied Sciences Division. 9 Food Share Employment and Training Program (FSET) FSET Grants Core Match Number of projects PACE Program Three Projects Number of Students 833 45 Number of Classes College enrolled 3 Estimated Revenue $500,000 $500,000 The Food Stamp Employment and Training (FSET) is the employment and training program for the Supplemental Food and Nutrition Program (SNAP) and administered by the state. Locally, the Milwaukee Area Workforce Investment Board (MAWIB) subcontracts with MATC and three other agencies that manage the Job Centers (Maximus, YWCA and UMOS). The core State FSET program is a combination of federal and GPR funds. Wisconsin operates a voluntary program and participants may enroll in the following areas: Education, Job Search, Work Experience or Self Employment. Post secondary education must be for at least two months but not more than two years, including short term certificates or diplomas through a local technical college. MATC’s FSET planning team is co-chaired by the Director of OWED and the Director of Grants and Development. MATC FSET services consist of closed sections for prevocational training and career readiness services for selected community based learning center students. The types of short term training delivered since 2009 includes Office Skills Practicum, IBEST Office Technology Microcomputer Skills, IBEST Energy Efficiency for Building Construction, General Banking and Finance, Culinary Arts, Fundamentals of Manufacturing Skills and General Health Care Skills. FSET students who enroll in the college are also enrolled in PACE, which provides case management and support services to facilitate successful completion of college technical diploma and associated degree programs. As part of the MATC plan, 50-50 matched resources increase the number of students served. This model is designed to enhance career pathways for FSET students enrolled in basic skills. 1. Students enrolled in an adult basic skills program (NRS level 3 or below) will receive tutorial support services via supplemental computer based instruction to increase students reading academic skills and to demonstrate grade level gain improvement to the next NRS level, based on a pre and post TABE-test assessment. 2. Students enrolled in an adult basic skills program and placed in NRS level 4 or higher will utilize WisCareer’s occupational interest assessment to determine an occupational goal. Students will access ACT Work Keys National Career Readiness Certificate (NCRC) occupation data bank to determine foundational skill levels necessary for the selected occupation. Instruction will be provided via Key Train as well as a “soft skill” assessment using AccuVision and Personal Qualities Skills Development (PQSD) to enhance student success along their career pathway. 10 Grants and Grant Development Over the past year, OWED staff joined with various units of the college and external partners to increase grant resources for workforce development and related efforts. The office closely works in partnership with the MATC Office of Grants and Development to collaborate both in grant writing and implementation. A number of the grants administered from this office have been referenced elsewhere in this report. The following are a listing of the grants received by this office: • • • • • • • • An annual grant application to DOT for motorcycle training. The FSET program funding and transitioning with partners to a MAWIB based system. WISTEC, a DOL funded grant was for a three year period and FY2011 was the period for the final phase of the grant. A MSSC, MATC Foundation grant was funded for the entire fiscal year and worked to develop MSSC certification systems to prepare high school students for manufacturing careers. The MSSC Regional Grant was developed in conjunction with regional partners including the WRTP and the area workforce boards to increase the recruitment of manufacturing employees for certification in the MSSC area. A Power Control Industry Partnership grant was developed and funded over the past six months, with the training of power control entry level employees for hire at area companies. Jump Start was a MAWIB grant with MATC as a subcontractor to pilot a team teaching approach in the preparation of technical and soft skills for occupations in construction and weatherization. The Green Capacity grant for Photovoltaic Installation Helper training was a MAWIB sub grant to increase capacity to address skill needs for related energy jobs in the emerging green sector. Grant development continues to shift toward partnership based and more comprehensive applications. Over the past year OWED staff worked with the Grants office in a number of sectors: • • Several applications were developed for the health and related areas, including a close collaboration with the Health Information Technology (HIT) grant providing support on instructors and facilities. Several applications which required collaborating with departments as well as state wide or regional grant developments. The sectors included Information Technology, Machining, and Welding and Fabrication. 11 Continuing Education Departments Motorcycle Traffic Safety and Drive Ed Clothing, Crafts and Upholstery Other Continuing Ed Departments Continuing Education Totals Number of Students 298 4133 685 409 Number of Classes 31 218 91 52 Estimated Revenue $93,400 $661,516 $105,200 $57,842 5525 392 $917,952 MATC has traditionally provided continuing education classes to meet a variety of community needs and interests. The college has pulled together twelve departments of continuing education and assigned the management, implementation and oversight to this office. This provides an overview on these courses. The Motorcycle Program is funded through the Wisconsin Department of Transportation and provides Basic Rider motorcycle licensing training to individuals across the district. This program prepares individuals in motorcycle safety and an understanding of the State of Wisconsin rules and regulations. Through hands training using provided motorcycles, students gain the knowledge and experience to qualify them for a motorcycle operator’s license. The Traffic Safety and Driver Education program provides classes training and education on the hazards and costs of driving under the influence to youth and adults, first time and multiple offenders, and underage court mandated individuals due to alcohol and drug related violations. The Traffic Safety department also provides driver safety classes for other traffic violations such as speeding, reckless driving and/or other minor traffic offenses that threaten driving privileges. Responsible Beverage classes provide the training and certification required for individuals to serve alcohol. Clothing, Crafts, and Upholstery classes are provided to citizens in our community who wish to learn or develop their skills in these traditional areas for their business or home improvement activities. Many individuals attracted to these courses are of retirement age. Other Continuing Education Departments include commercial and related arts, horology (watch making) and foods. Classes are provided on campus or at outreach locations. The college also works with the UW School for Workers to coordinate classes for leadership development and training. 12 MATC— Office of Workforce and Economic Development Summary of Activities OWED Activity Contracts Grants -WAT Grants - MSSC Grants - WISTEC Grants - FSET Grants - Other Continuing Ed Totals Estimated Revenues $2,045,087 $ 305,671 $ 143,000 $ 200,000 $1,000,000 $ 175,000 $ 917,952 $4,786,710 Number of Students 5240 181 120 162 878 90 5525 12,196 Number of Classes 142 10 12 11 95% - program students 4 392 571 Number of Companies 35 8 5 8 0 4 0 60 As the above chart shows, the contracting function of the office makes up more than 40% of the revenues and about the same proportion of the students who enrolled in OWED based offerings. Within this area, we carried out considerable work in meeting continuing and advanced certification. Offerings were delivered in barber and cosmetology, medical coding and surgical technician training. Additionally, classes in fire safety certification as well as related areas were popular offerings. It should however be noted that we consider all of the programs and classes that we are connected with as key ways to connect past, present and future students with the college and provide beneficial education and credentials they need to be successful in their careers. For the WAT grants, this year marked a shift from a contract based approach to a grant delivery, making this an important economic development strategy to effectively work with companies. The grants in the MSSC area and through WISTEC provided resources for the college to extend our training and certification work, while enhancing the capability of the college to devise new courses and certifying methods to increase credentials of the local workforce. The FSET grant and related grant work has provided the potential for the college to focus on developing the pathways and more flexible curriculum to meet the training and educational needs of working men and women. The Continuing Education Departments include a wide variety of offerings and the intent of the OWED is to reconfigure these offerings into a cost effective approach to assist citizens in meeting their personal and occupational development goals. 13 Revenues and Cost Savings generated for the college The Office of Workforce and Economic Development is a slim staffed unit of the college. However, the critical budget issues confronting the college require that all units need to manage effectively and be creative in efforts that can generate revenues and, at the same time, create savings for the college as a whole. The current year has been challenging as several rounds of budget reductions were requested of all units. At the same time, the OWED staff has diligently worked to increase revenues while exacting cost savings for the college. Revenues Total contracts $2,045.087 Total direct costs $1,595,686 Indirect revenues $282,222 Margin revenues $179,456 Total revenues— indirect and margins $ 461,678 Cost Savings Staffing Allocation reductions One full time staff position Estimated Savings $100,000 One part time staff position Estimated Savings $ 47,600 Three full time faculty positions Estimated Savings $420,000 Contract and Grant Instructional Savings Full time faculty load charged to contracts Estimated Savings $125,000 Full time faculty load charged to WISTEC grant Estimated Savings $210,000 FSET Match Grant Estimated Savings $ 84,456 Total Cost Savings Grand Total Combined Revenues and Cost Savings $ 987,056 $1,448,734 14 OWED Structure and Staff Vice President, Dr. Pablo Cardona OWED Director, Duane Schultz Key Functions: • • • • • Business Outreach & Contract Services Workforce Development & Community Partnerships Continuing & Career Education Grants Development and Implementation Administrative and Program Support Staff: Al Luna & Rose Farrar Dick Buschmann & Candy Zielinski Mary Jo Travis & Sandra McClary Regina Moore, Kathy Petrovich & Shelly Helf The OWED office facility is located adjacent to the West Allis Campus at 1205 S 70th. The office reports to Dr. Pablo Cardona, VP at the West Allis Campus. Staff Duane Schultz Dick Buschmann Alfredo Luna Mary Jo Travis Sandi McClary schultzd@matc.edu buschmar@matc.edu lunaa@matc.edu travismj@matc.edu mcclarys@matc.edu Full Time Faculty Donald Wlodarski wlodarsd@matc.edu Hoja Stolen stoleng@matc.edu Rose Farrar Candice Zielinski Regina Moore Kathy Petrovich Shelly Helf farrarr@matc.edu zielinc@matc.edu moorer@matc.edu petrovik@matc.edu helfs@matc.edu Betsy Johnson Mitch Anderson johnsone@matc.edu andersmd@matc.edu It should be noted that more than 100 full and part time faculty provide instruction on an ongoing basis to execute the contracts, grants and the continuing education offerings. For many instructional assignments, full time departmental faculty as well provided outreach based instruction. Finally, specific kudos are included here for Ms. Mary Heiser, word processing associate who retired on June 30th, 2011 and Mr. Greg Hansen who retired in December, 2010 as a full time faculty member and a key contributor to the MATC Traffic Safety Program. 15 Partners and Participating Companies Workforce and Economic Development Partners Milwaukee Area Workforce Investment Board and related regional workforce boards Mayor’s office and the Milwaukee Economic Development Corporation Milwaukee Metropolitan Association of Commerce and Area Chambers Milwaukee Public Schools and all public schools across the district UWM, Marquette and Milwaukee School of Engineering Gateway Technical College, Waukesha County Technical College and the regional Tech Colleges Community Based Economic Development organizations such as Esperanza, Riverworks, Northwest Community Development Corporation, UMOS Small Business Development agencies such as the Women’s Business Initiative Corporation Neighborhood and Community Groups such as the Garden Homes neighborhood, 30th Street Corridor and Northcott Neighborhood Center M7 Participating Companies ABB Robotics Master Lock Corporation Advance Die casting Metalspun Products Company American Electric Power Miller Coors Astronautics Miller Compressing Briggs & Stratton Corporation Milwaukee Gear Company Calibre, Inc. National Technologies Charter Manufacturing Company P & H Mining Columbia Grinding PPG Industries EGS Electrical Pieper Electric, Inc. ER Wagner Company Reich Tool and Design Falk Corporation Rexnord Federal Tool Engineering Rockwell Automation Ford Motor Company Siemens GE Healthcare Snap-On Tools Harley-Davidson Stainless Foundry Helgesen Super Steel Helwig Carbon Products Tramont Corporation Johnson Controls Visa Lighting KMC Stampings WE Energies Milwaukee Electronics (MEC) Weyerhaeuser 16 Training Offerings Provided to Area Companies and Organizations Leadership Accelerated Management Programs Achieve Global Building High-Performance Teams Covey’s 7 Habits Effective Meeting Skills Organizational Leadership Supervisory Development Total Quality Management Customer & Market Focus Cross-Cultural Communications Foreign Languages High Impact Business Writing High Impact Customer Service Series Quality Function Deployment Service Plus Telephone Techniques Value Stream Mapping Human Resource Focus Communication Skills Diversity in the Workplace English as a Second Language Group Facilitation Skills Sexual Harassment Prevention Organizational Effectiveness Baldrige Assessment ISO/QS9000 Teambuilding Project Planning Skills Conflict Management Manufacturing Skill Standards Council Safety Assurance Quality and Continuous Improvement Manufacturing Process Maintenance Awareness Logistics – CLA/CLT Strategic Planning Cellular/Flow Manufacturing Change Management Facilitation Skills Failure Mode & Effects Analysis Management & Planning Tools Strategic Planning Training & Services Scenario Planning Superior Selling Strategies Computers and Information Technology Computer Skills Wireless Technologies Video-Conferencing via satellite Cisco Microsoft Active Directory Network Security Problem Solving Continuous Quality Improvement ISO 9000 Lean Transformation Quality Principles Quality Tools and Six Sigma Process Mapping Project Management Industrial and Technical Skills Electrical / Electronics Electrical Codes Emergency Response Forklift Safety Geometric Dimensional Tolerancing Hydraulics/Pneumatics Lean Manufacturing Machine Tool Metrology SPC/Blueprint Reading Technical Skills including CNC Welding Training, Testing / Certification 17