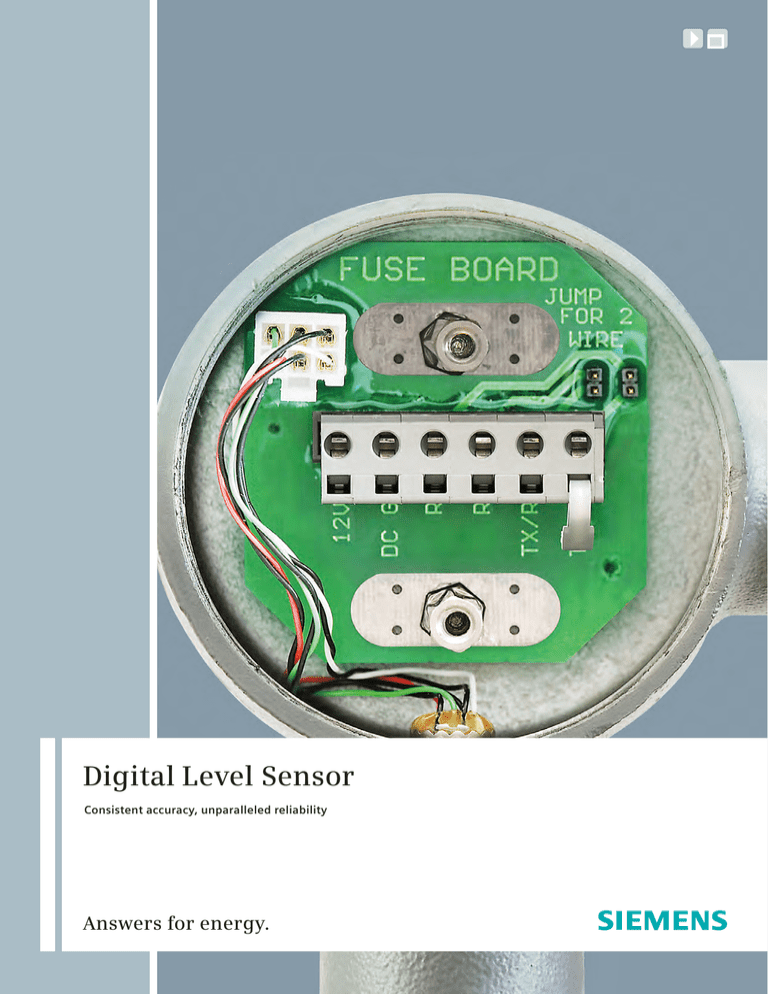

Digital Level Sensor

Consistent accuracy, unparalleled reliability

Answers for energy.

Consistent accuracy

Unparalleled reliability

2

The Siemens Digital Level Sensor

(DLS) is an engineered solution for

remotely monitoring liquid levels

in storage tanks. In addition to

offering true digital level

measurement in precise

increments, it accurately and

repeatedly measures two different

fluid densities and up to eight

temperatures on the same sensor.

Its accuracy is maintained over the

entire life of the sensor, thereby

helping to reduce long-term

maintenance costs.

3

Model 1000 Digital Level Sensor specifications

Standard features, applications,

benefits

Intrinsically safe apparatus

approved to meet UL913 standard

for safety

Low maintenance

Temperature changes do not affect

accuracy, unlike many other level

sensing devices

Applications include production

monitoring, inventory control, leak

detection, remote read-out of level in

H2S environment, high/low alarms and

many other applications

All electronics are sealed inside the

sensor tube

Sensor tube available in stainless

steel and fiberglass

Intrinsically safe apparatus when

connected to RLD model 1010 barrier

board

ETL-approved intrinsically safe barriers

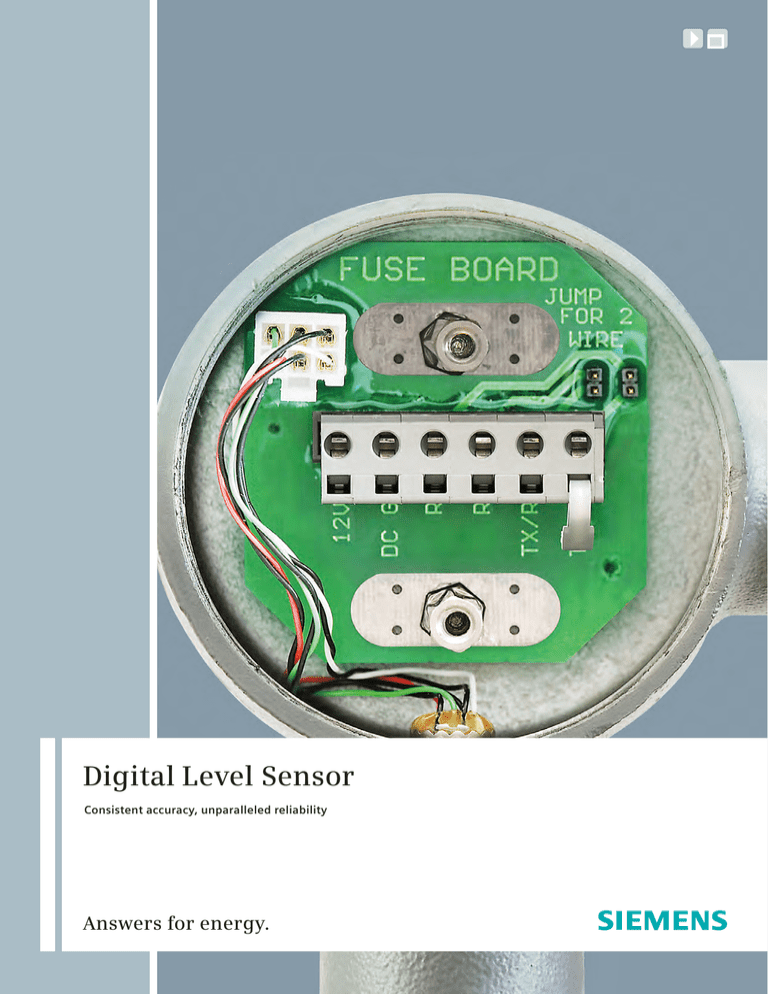

available to mount with the RTU

Field wiring that connects to a surgeprotected fuse board shielding the

sensor electronics from lightning

damage

Proven for use in many different fluids

and environments, including crude oil,

water, diesel, kerosene, condensate

and gasoline

Explosion-proof junction box suitable

for connecting to rigid conduits

Standard ASCII protocol for

communicating with several existing

remote terminal units via RS485/RS232

Digital-to-analog conversion available

for outputting either a 4-20mA or

1-5 VDC analog signal

4

Measurement length

Available from 2’ to 30’ in 1’ increments

Longer sizes available as custom orders

Tubing material

316L stainless steel: standard

18 gauge: standard

14 gauge: optional

Fiberglass: optional

Float

NYTROPHYL stainless steel: standard

Power requirements

12 VDC +/- 15% at sensor terminals

Power consumption

45mA nominal

70mA maximum

Pressure

15 psi: standard

Higher pressure ratings

available as custom orders

Communication

UHMW-NYTROPHYL: optional

RS485

One standard, two optional for water

interface

Two- or four-wire communications

Fits either 3” or 4” tank ports

Level measurement increments

and accuracy

Baud rate and parity programmable

(up to 38400 baud)

4-20mA signal available when

connected to digital-to-analog

converter board

Standard

1/4” resolution (+/- 1/8” accuracy)

1/2” resolution (+/- 1/4” accuracy)

Operating temperature range

-40° F to +185° F: standard

Wiring

Two-wire communication: two twisted

pair, (16-18 AWG) recommended

Four-wire communication: three

twisted pair, (16-18 AWG)

recommended

-40° F to +240° F: optional

Temperature measurement

Display of °F: standard

First sensor 12” from bottom: standard

1-8 temperature sensors available with

desired spacing: optional

+/- .5° F accuracy

5

Model 1000 terminal unit

The Model 1000 terminal unit is a solidstate stand-alone device designed to read

the digital signal from the Model 1000

Digital Level Sensor (DLS) and convert it

to an analog output. The intent is to

enable the superior accuracy of the

Model 1000 DLS to be used in a system

that has only analog inputs available for

receiving tank level data.

This unit can poll up to 16 individual

Model 1000 DLS units and output up to

eight analog signals based upon data

received from the Model 1000 DLS. The

analog outputs are user programmable

for either level or temperature from a

particular sensor. Each analog loop can

be set up to either source power or be

powered by the host unit. This unit is

programmable through a standard RS232

serial cable with RTS/CTS connected to a

computer running the Model 1000

terminal configuration software or any

terminal emulation software. Local

readout for the tank levels and

temperature are available with a four-line

by 20-character LCD display. It will display

up to two levels, temperature and tank

volume for each tank. Sockets are

provided for two optically isolated G4

digital output modules for alarming or

controlling based on user programmable

set points for any sensors.

The G4 modules can control either AC or

DC power to dry contact relays. An

expansion board has been developed to

allow for eight additional optically

isolated G4 digital output modules. With

this expansion board, a total of 10 digital

outputs are available.

Mechanical specifications

NEMA 4X enclosure

Optional eight D/O expansion board

can be mounted inside enclosure

Electrical specifications

Operating temperature range:

-40° C to +85° C

When equipped with LCD display,

operating temperature is 0° C to 70° C

Optional display heater for cold

operating conditions

Power requirements: 12 to 15 VDC

RS232 port

Provided for configuration and

diagnostics

9600 baud, no parity, eight data bits,

one-stop bit

Communication: HyperTerminal or

similar terminal emulation software

using ASCII commands

Configuration software available

RS485 port

Communication to the Model

1000 DLS

Four-wire communications

Power consumption

Standby without display: 75mA*

Standby with display: 85mA*

During scroll - LCD backlight: 210mA*

(scrolling period is programmable)

During poll: 100mA*

(polling time = 2 sec max)

Sleep mode: 9mA**

Analog outputs: 20mA max per

channel if unit sources loop power

*Power consumption does not include connected level

sensors. User must consider each sensor connected will

draw an average 45mA.

**Sleep mode is designed for stand-alone display

applications with no digital or analog outputs

programmed.

Cycles power to level Model

1000 DLS between polls

4-20mA conversion accuracy

(except as limited by sensor and protocol

resolution)

Resolution: 16 bit

Monotonicity: 16 bit min

Integral non-linearity: +/- 0.01% of FS

max offset (4mA) at 25°C +/- 0.1% of

FS max

Offset drift: +/- 25 ppm of FS/°C max

Total output error: (20mA) at

25°C +/- 0.2% of FS max

Total output drift:

+/- 50 ppm of FS/°C max

VCC supply sensitivity:

50 mA/mV typical

Optional digital outputs

Total of 10 output sockets available

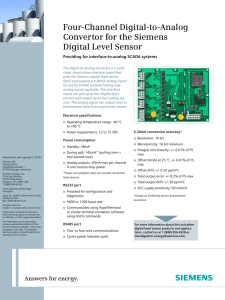

Model 1000 four-channel

output board

DAC4

The DAC4 is a solid-state stand-alone

interface board that polls the Model 1000

DLS and outputs a 4-20mA analog signal

for use by other field data collection

equipment. The intent is to enable the

superior accuracy of the Model 1000 DLS

to be used in a system that has only

analog inputs. The interface board can

poll up to four Model 1000 DLS and

output up to four analog signals based

upon data received from these sensors.

Not all analog channels need to be used.

The analog signal can output the level or

temperature data from a particular

sensor.

Electrical specifications

Operating temperature range:

-40° C to +85° C

Power requirements: 12 to 15 VDC

Power consumption

Standby: 38mA

During poll: 145mA*

(polling time = 2 sec max)

Analog outputs: 20mA max per channel

if unit sources loop power

*Power consumption does not include connected level

sensors. User must consider each sensor connected will

draw an average 45mA.

RS232 port

RS485 port

Communication to the Model

1000 DLS

Two- or four-wire communications

Cycles power to Model 1000 DLS

between polls

4-20mA conversion accuracy

(except as limited by sensor

and protocol resolution)

Resolution: 16 bit

Monotonicity: 16 bit min

Integral non-linerarity:

+/- 0.01% of FS max

Offset (4mA) at 25° C:

+/- 0.01% of FS max

Offset drift: +/- 0.25 ppm/°C

Total output error: +/- 0.2% of FS max

Total output drift: +/- 50 ppm/°C VCC

supply sensitivity: 50 mA/mV

For any specifications not listed above,

please see the specifications listed under

the Model 1000 terminal unit.

Model 3005 analog

board

The Model 3005 is designed to provide

a single analog output from the Model

1000 DLS. It provides a 4-20mA signal

output for the total fluid level of the tank.

This is an alternative to the Model 1000

terminal unit. It is intended for locations

requiring an analog signal for the tank

level where only one or two tanks are on

location. The Model 3005 replaces the

fuse board in the explosion-proof

housing on top of the Model 1000 DLS.

It provides the same protection to the

Model 1000 DLS as the fuse board

provides. The Model 3005 requires

24 VDC and controls power to the level

sensor. It powers the sensor on a preprogrammed schedule, polls for the level

analog value, powers the sensor down

and outputs the analog signal. The

configurations for the Model 3005 are

stored in the EEPROM of the Model

1000 DLS, allowing for replacement

when required.

Electrical specifications

Operating temperature range:

-40° C to +85° C

Power requirements: 24 VDC +/- 10%

Requires 125mA max

Requires two wires for power and two

wires for 4-20mA loop 4-20mA

conversion accuracy (except as limited

by sensor and protocol resolution)

Provided for configuration and

diagnostics

Resolution: 16 bit

9600 or 1200 baud communicates

using HyperTerminal or similar

terminal emulation software using

ASCII commands

Integral non-linearity: +/- 0.012% max

Monotonicity: 16 bit min

Offset: +/- 0.05% max

Total output error: +/- 0.15% max

Two sockets provide for optically

isolated G4 modules on board

(G4 modules sold separately)

6

Eight additional sockets with

expansion board

7

Published by and copyright © 2009:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

Oil and Gas Division

10730 Telge Road

Houston, TX 77095

1 (888) 856-4528 or +1 (281) 856-4530

Order No. E50001-D440-A123-V1-76US

Printed in USA

TD 20091118133638518T BR 1109.25

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.

www.siemens.com/energy