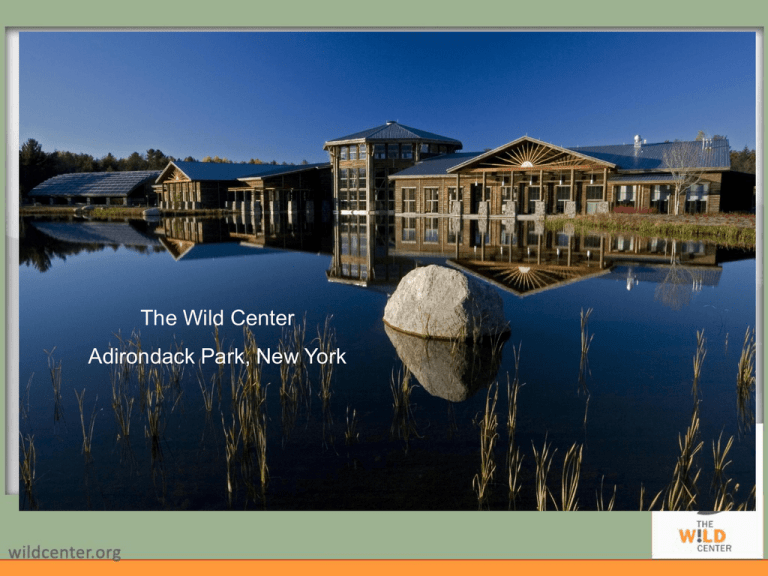

The Wild Center Adirondack Park, New York

advertisement

The Wild Center Adirondack Park, New York 31 Acre Site Opened to the public in July 2006 Climate Change and Green Initiatives New Path exhibits about green building elements First Commercial Scale Pellet Boiler in NY State Climate Change Conferences for Adirondacks Ongoing internal Green Team Youth Climate Summit for high schools Movie, A Matter of Degrees to NY schools Local Foods, programs & weekly farmers market Carbon Audit of Adirondacks ADKCAP, community climate action planning Green Weddings The New Path Green Tech Exhibit Convening the Community around Energy and Climate Issues The Youth Climate Summit workshop sessions in transportation, recycling, school and local gardening, energy efficiency, and green building design engaged school teams in meaningful learning and motivate action back at their schools. New Path – Pellet Boiler Pellet Boiler The Wild Center pioneered a renewable energy heating system coupling a highly efficient gasification wood boiler with a solar tube hot water collection system. Boiler: ACT BioEnergy, LLC 500kW (1.7MMBTU/hr) Output Combustion + 2 stage gasification, Efficiencies to 90% Fuel: Premium Wood Pellets (FSC Certified) Demonstration Project Objectives • Evaluate performance of a highly efficient gasification wood boiler integrated with a solar thermal hot water array. • Monitor and document emissions from an improved gasification type wood combustion system to allow comparison with conventional wood and fossil fuel boilers. • Monitor and document emissions from improved hydronic heating system energy efficiency, benefitting from solar heated hot water, with the pre-heated water stored and released to minimize part-load operation of boilers. • Reduce heating fuel cost and dependency on fossil fuels. • Public outreach and education Project Challenges • One of the first boiler of size and type manufactured in US and built to ASME standards (weights estimated and modular construction required to facilitate portability) Project Challenges • Installation in existing basement boiler room with limited access. • Large diameter chimney routing through existing occupied space. Project Challenges • Integration with existing (backup) LPG boilers control scheme Finished Boiler Installation Finished Pellet Storage Project Challenges • Aesthetically pleasing, low-profile pellet storage adjacent to main museum building. Easy fuel filling aspects. Artist’s Rendering Emissions Testing • Clarkson University • CK Environmental Services Ash Removal • All removed ash weighed • Ash used as soil amendment in high pH areas (pine tree beds) and binder for stone trail surfaces • 1st 12 tons of wood pellets burned generated only 100 pounds of ash (<0.5% by weight) Performance Monitoring Wood fuel feed rate (auger run-time meter), thermal energy output (boiler water flow rate and temperature delta) and backup LPG boiler fuel volume (gas meter) measured and recorded Performance Monitoring • Online monitoring of system performance Projected Economics • • • • • • • • WOOD LPG 2009 average LPG consumption (before wood) = 39,000 gallons Wood pellet boiler projected to satisfy 75% of heating demand 39,000 gal x 0.75 = 29,250 gal LPG offset by wood annually Heating energy of offset LPG = 29,250 gal x 90,500 BTU/gal = 2,467,125,000 BTUs = 24,670 therms Fuel cost per therm heating value LPG = $1.98 ($1.80 gal) Wood = $0.88 ($185.00 ton) Projected annual fuel $ savings = ($1.98-$0.88) x 24,670 therms = $27,140 Increased electricity purchase = 7500kWh x $0.45 = $340 Increased boiler maintenance (ash removal) = $1500 Projected Net savings = $27,140 – ($340 + $1500) = $25,300 New 2011 Additional Lighting Changes • Just installed state of the art Lutron Control system is expected to lower electrical use by 25% or more after 2011. • Kiosk for the public to show savings Upcoming Conference and Expo •Friday, April 29 Training •Saturday, April 30 Conference and Expo •Sunday, May 1 Public Programs and Expo Questions