Document 10678700

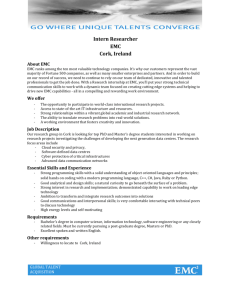

advertisement