The Development of Titanium-Catalyzed Enyne ... and Related Methodologies

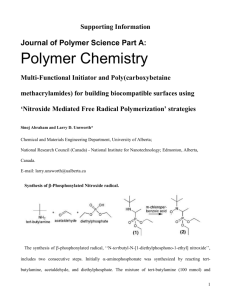

advertisement