Low Slope Product Data Guide 1/12 www.gaf.com

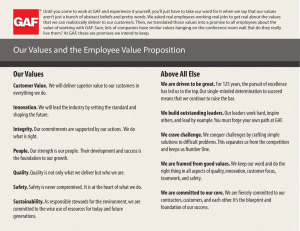

advertisement