Lipid and Protein Oxidation of Chicken Oxidation Levels and Packaging

advertisement

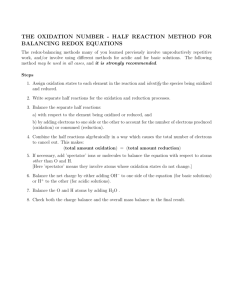

Lipid and Protein Oxidation of Chicken Breast Rolls as Affected by Dietary Oxidation Levels and Packaging C: Food Chemistry Shan Xiao, Wan Gang Zhang, Eun Joo Lee, Chang Wei Ma, and Dong U. Ahn Abstract: The objective of this study was to determine the effects of dietary treatment and packaging on the oxidative stability of breast rolls. A total of 120 4-wk-old broiler chickens were randomly assigned to control, oxidized diet (5% oxidized oil, PV = 100), or antioxidants-added diet (500 IU vitamin E + 200 ppm BHA) and fed for 2 wk. Breast muscles were separated from the carcasses and breast rolls were prepared. The rolls were cooked in a smoke house (85 ◦ C) to an internal temperature of 74 ◦ C, cooled, sliced to 2-cm thick pieces, individually packaged in oxygen permeable bags or vacuum-packaged in oxygen impermeable bags, and stored in a 4 ◦ C cold room for 7 d. Lipid, protein oxidation and volatiles were determined at 1, 4, and 7 d of storage. Dietary supplementation of antioxidants significantly reduced lipid oxidation (TBARS) and protein oxidation (carbonyls) in breast rolls, and the effect of dietary antioxidants on lipid oxidation was more pronounced than protein oxidation. Chicken breast rolls from antioxidants treatment group produced significantly lower amounts of hexanal and pentanal than those from control and oxidized oil treatments (P < 0.05). However, dietary oxidized oil did not increase lipid and protein oxidation in breast rolls. Vacuum-packaging significantly delayed the onset of lipid oxidation and protein oxidation in chicken rolls during 7-day refrigerated storage (P < 0.05). Therefore, it is suggested that appropriate use of dietary supplementation of antioxidants in combination with packaging could minimize lipid oxidation in chicken breast rolls. Keywords: antioxidants, breast roll, lipid oxidation, oxidized diet, protein oxidation Introduction Authors Xiao and Zhang are joint lead authors of this paper. meat during chilled storage (Mason and others 2006; Smet and others 2008). In addition, dietary supplementation of vitamin E improves the nutritional value of meat products. Another approach to control rapid oxidative deterioration of meat products during storage is the elimination of contact with oxygen. Vacuum-packaging is shown to reduce lipid oxidation during the storage of cooked meat (Ahn and others 1992; Nolan and others 1989). Oxidative stability of processed meat can be further improved through vacuum-packaging in combination with dietary addition of vitamin E (Ahn and others 1998). During the storage of meat and meat products, lipid oxidation results in quality loss through deterioration of flavor, odor, color, nutritional value, and safety of foods (Varnam and Sutberland 1995; Winne and Dirinck 1997; Bou and others 2001; Zouari and others 2010). In addition to lipid oxidation, oxidative reactions of proteins in raw meat can lead to functional changes in myofibrillar proteins, and negatively affect the tenderness, water-binding capacity, and juiciness of meat (Huff-Lonergan and Lonergan 2005). Oxidation of proteins resulted in reduced water-holding capacity and decreased texture-forming ability in processed meat (Xiong 2000). The oxidative status of fat in diet can have significant impact on the storage stability of raw chicken meats (Racanicci and others 2008; Zouari and others 2010). However, the effect of dietary supplementation of vitamin E on protein oxidation of meat during storage is still inconclusive, especially for processed meat. The aim of this study was to investigate the effects of dietary supplementation of vitamin E, oxidized oil, and vacuumpackaging alone or in combination on the quality of chicken breast rolls. Journal of Food Science r Vol. 76, Nr. 4, 2011 R C 2011 Institute of Food Technologists doi: 10.1111/j.1750-3841.2011.02137.x The consumer demands and popularity of ready-to-eat cooked meat products are increasing rapidly in recent years. However, processed meats are more vulnerable to oxidative changes than raw meat. Also, cooked chicken meat was more susceptible to oxidation than cooked beef and pork (Rhee and others 1996). It has been postulated that the amounts of polyunsaturated fatty acids (PUFA) and antioxidants (Morrissey and others 1994) are critical determinants of lipid oxidation occurring in processed meat. For many years, butylated hydroxytoluene (BHT), butylated hydroxyanisole (BHA), tertiary butyl hydroquinone (TBHQ), and other synthetic antioxidants have been extensively used to retard rancidity in meat products. However, consumers are concerned about using these additives in meat due to their possible carcinogenic effects to humans, and preferred meat products with reduced additives or use of natural antioxidants (Jan 1991). Vitamin E is a natural antioxidant that can be enriched to meat through dietary regimen. Growing number of researches suggested that dietary addition of vitamin E could maintain oxidative stability of processed MS 20101312 Submitted 11/18/2010, Accepted 1/14/2011. Authors Xiao, Zhang, Lee, and Ahn are with Dept. of Animal Science, Iowa State Univ., Ames, IA 50011, U.S.A. Authors Ahn, Zhang, and Lee are also with Dept. of Agricultural Biotechnology, Biomodulation Major, Seoul Natl. Univ., 599 Gwanak-ro, Gwanakgu, Seoul 151-921 Korea. Authors Ma and Xiao are with College of Food Science and Nutritional Engineering, China Agricultural Univ., Beijing 100083, China. Direct inquiries to authors Ahn and Ma (E-mails: duahn@iastate.edu, chwma@cau.edu.cn). C612 Further reproduction without permission is prohibited Materials and Methods Animals and diets One hundred and twenty, 1-day-old commercial broiler chicks were fed with a standard broiler corn-soybean diet (Table 1) for 28 d. On 29th day, 10 broilers were assigned to each of 12 floor pens. Four floor pens were randomly allotted to one of the 3 experimental diets including control, oxidized diet, and antioxidants-fortified diet. Control diet was prepared with fresh animal-vegetable fat (AV fat) blend (5%, Feed Energy, Co., Des Moines, Iowa, U.S.A.) with 25 IU vitamin E, oxidized diet was prepared after oxidizing the same AV fat by exposing to room temperature for a long time until attaining peroxide value (PV) value of 100 (AOAC 1965), and the antioxidants-fortified diet was prepared with the fresh AV fat supplemented with BHA (200 ppm) and vitamin E (500 IU) per kilogram of feed. Each of the diet was fed to the broilers for 2 wk with free access to water and diet. The animal work was performed in accordance with ethical guidelines of Iowa State Univ. and was approved by the Assurance Committee for the use of Animals in Research. Sample preparation At the end of the feeding trial, the birds were slaughtered following USDA guidelines (USDA 1982). Chickens were chilled in ice water for 2 h, drained and stored in a 4 ◦ C cold room, and deboned at 24 h after slaughter. The breast muscles from each pen were pooled and used as a replication. The pooled ground breast meat was ground through a 3-mm plate, mixed with 1.5% NaCl and Table 1–Percentage composition of diets fed to broiler.a Ingredients Corn Soybean meal AV fat Dicalcium phosphate Calcium carbonate Iowa Vit and Min Prx2 Sodium chloride Methionine, 99% Biolysine, 50.7% Threonine, 99% Choline chloride, 60% Calculated analysis Metabolizable energy, kcal/kg Protein Total sulfur amino acids Methionine Lysine Arginine Glycine + Serine Histidine Isoleucine Leucine Phenylalanine + Tyrosine Threonine Valine Calcium Available phosphate Total phosphate Sodium Starter (1 to 2 wk) Grower (3 to 4 wk) Finisher (5 to 6 wk)b 56.83 35.98 2.47 1.75 1.28 0.63 0.46 0.27 0.24 0.073 0.037 63.95 29.11 2.82 1.26 1.37 0.50 0.46 0.26 0.21 – 0.053 64.13 27.27 5.00 1.28 1.08 0.50 0.46 0.18 0.045 0.041 0.002 3005 22.48 0.98 0.61 1.34 1.45 2.02 0.59 0.92 1.90 1.35 0.91 1.01 1.00 0.45 0.73 0.20 3100 19.71 0.90 0.57 1.14 1.24 1.76 0.52 0.79 1.72 1.17 0.73 0.89 0.95 0.35 0.61 0.20 3226 18.70 0.80 0.48 1.00 1.18 1.68 0.49 0.76 1.65 1.12 0.74 0.85 0.85 0.35 0.60 0.20 a Control diet, 5% fresh AV fat and Iowa Vitamin and Mineral Premix; Oxidized diet: 5% oxidized AV fat (100 PV value); Antioxidants diet: 5% fresh Av fat and 500 IU + 200 ppm BHA per kg diet. b Iowa vitamin and mineral premix supplies per kg diet: retinyl acetate = 8065 IU; cholecalciferol = 1580 IU; 25-hydroxy-cholecalciterol = 31.5 μg; dL-α-tocopheryl acetate = 25 IU; vitamin B12 = 16 μg; menadcre = 4 mg; riboflavin = 7.8 mg; pantothenic acid = 12.8 mg; niacin = 75 mg; Choline chloride = 509 mg; folic acid = 1.62 mg; biotin = 0.27 mg; Mn = 80 mg; Zn = 90 mg; Fe = 60 mg; Cu = 12 mg; Se = 0.147 mg; sodium chloride = 2.247 g. 0.25% phosphate (Brifisol), 1.5% transglutaminase, 0.5% sodium caseinate, 0.5% dextrose, and 6.25% water for 5 min, stuffed into 150-mm collagen casings, and cooked in a 85 ◦ C smoke house with relative humility of 92% until the center temperature reached 74 ◦ C. After cooling to room temperature by a cold-water shower, the rolls were cut into 2-cm thick slices and individually packaged in vacuum bags (nylon/polyethylene, 9.3 mL O2 /m2 per 24 h at 0 ◦ C, Koch, Kansas City, Mo., U.S.A.) or oxygen-permeable bags (polyethylene, 2,300 mL/m2 per 24 h, 4 × 6, 2 MIL, Associated Bag Company, Milwaukee, Wis., U.S.A.). Samples were stored in a 4 ◦ C cold room for 7 d. Lipid, protein oxidation and volatiles were determined after 1, 4 and 7 d of storage. Lipid and protein oxidation Lipid oxidation was determined by a 2-thiobarbituric acid reactive substances (TBARS) method (Ahn and others 1998). Protein oxidation was determined by the method of Levine and others (1994) with minor modifications. One gram of muscle was homogenized using a Brinkman Polytron (Type PT 10/35; Brinkman Instrument, Inc., Westbury, N.Y., U.S.A.) in 10 mL of pyrophosphate buffer (2.0 mM Na4 P2 O7 , 10 mM Trizmamaleate, 100 mM KCl, 2.0 mM MgCl2 , and 2.0 mM EGTA, pH = 7.4). Two equal volume of meat homogenate (2 mL) were precipitated with 2 mL of 20% trichloroacetic acid (TCA) and centrifuged at 12000 × g for 5 min at room temperature. After centrifugation, the pellet from one sample was treated with 2 mL of 10 mM 2,4-Dinitrophenylhydrazine (DNPH) dissolved in 2 M HCl and the other was incubated with 2 M HCl as a blank. During 30-min incubation in dark, samples were vortex-mixed for 10 s every 3 min. The proteins were further precipitated with 2 mL 20% TCA and centrifuged 12000 × g for 5 min. DNPH was removed by washing 3 times with 4 mL of 10 mM HCl in 1:1 (V/V) ethanol-ethyl acetate followed by centrifuge at 12000 × g for 5 min after each washing. The pellets were finally solubilized in 2 mL of 6.0 M guanidine hydrochloride dissolved in 20 mM potassium dihydrogen phosphate (pH = 2.3). The samples were kept at 5 ◦ C overnight. The next day, the samples were centrifuged to remove insoluble material. The absorbance of supernatant was read at 370 nm. The absorbance values for blank samples were subtracted from their corresponding samples values. Protein concentration was determined using a Protein Assay kit from Bio-Rad laboratories. Briefly, protein determination was measured using a spectrophotometer at 595 nm. Protein concentration was expressed as milligram per milliliter. The carbonyl content was calculated as nmol/mg protein using an absorption coefficient of 22000 M−1 cm−1 as described by Levine and others (1994). Analysis of volatile compounds To determine the volatiles responsible for off-odor of the samples, a dynamic headspace analysis was performed using a Solatek 72 Multimatrix vial autosampler and a Purge & Trap Concentrator 3000 (Tekmar-Dohrmann, Cincinnati, Ohio, U.S.A.) connected to a gas chromatography-mass spectrometry (GC/MS, Agilent Technologies, Wilmington, Del., U.S.A.) according to the method of Nam and others (2007). Identification of volatiles was achieved by comparing mass spectral data of samples with those of the Wiley library (Agilent Technologies). Standards were used to confirm the identification by the mass selective detector. The area of each peak was integrated using ChemStationTM software (Agilent Technologies), and the total peak area was reported as an indicator of volatiles generated from the meat samples. Vol. 76, Nr. 4, 2011 r Journal of Food Science C613 C: Food Chemistry Dietary oxidation on meat oxidation . . . Dietary oxidation on meat oxidation . . . Statistical analysis The experiment was a factorial design with 3 diet, 2 packaging, and 4 replications. Data were analyzed by the procedure of generalized linear model using SAS 9.1 software (SAS Inst. 1995). Mean values and standard error of the means (SEM) were reported. C: Food Chemistry Results and Discussion Lipid oxidation No significant difference on TBARS was found between the rolls produced from the chickens fed oxidized and control diets during whole storage period (Table 2). Addition of oils (animal or vegetable) is a common practice in formulating broiler diet because it could not only give high energy but also provide unsaturated fatty acids, which are very important for the fast growth and the nutritional demands of broilers (Bou and others 2001; Baião and Lara 2005). Nevertheless, the supplemental oils could increase the possibility of dietary lipid oxidation. Therefore, many studies were conducted on the effects of dietary consumption of oxidized oil on performance, carcass characteristics, and oxidative stability of meats from various animal species. Many previous studies showed that dietary addition of oxidized oil adversely affected the oxidative stability of raw chicken meat (Engberg and others 1996; Bölükbaşi and others 2006; Zouari and others 2010). Some researchers reported that consumption of oxidized oil decreased deposition of endogenous α-tocopherol in muscle and lowered oxidative stability and shelf-life of fresh meat (Sheehy and others 1994; Ursini and Sevanian 2002). Our results, however, showed that adding 5% oxidized oil (PV = 100) to chicken diet before slaughter had no negative effect on lipid oxidation of chicken breast rolls during storage (Table 2), probably because the level of oxidized oil supplemented in diet was relatively low and the duration of feeding was relative short. Another reason could be due to the heat-induced changes of meat during cooking. Cooking process damages the structural integrity of muscle tissues and dramatically increases the oxidative stability of meat (Ahn and others 1992). All these reasons could, in some degree, have contributed to our observation in which no adverse effect was found in the chicken rolls from chickens fed oxidized diet. Feeding broilers with a diet containing 500 IU vitamin E/kg diet for 2 wk before slaughter significantly improved the storage stability of chicken breast rolls evidenced by lower TBARS level during the whole storage period (Table 2). TBARS values of chicken rolls from the antioxidants group were 0.30, 0.40, and 0.48 mg MDA/kg meat at day 1, 4, and 7, which were 78%, 85%, and 87%, respectively, lower than those of the control group. TBARS value of 0.5 to 1.0 mg malonaldehyde (MDA)/kg tissue is considered as a threshold for detection of oxidized flavor in meat (Boles and Parrish 1990). The TBARS value of chicken breast rolls produced from antioxidants diet increased from 0.30 to 0.48 mg MDA/kg meat while that from control diet increased from 1.36 to 3.56 mg MDA/kg after 7 d of storage indicating that dietary addition of vitamin E improved the oxidative stability of breast rolls. The results agreed with the reports of Wen and others (1996) who showed that cooked turkey burgers produced from turkeys fed a diet containing 300 or 600 mg a-tocopheryl acetate/kg feed were significantly more stable to lipid oxidation than those from control turkeys. Hams and bacons produced from pigs fed a-tocopherol supplemented diet had significantly lower TBARS levels than those produced from the control diet (Winne and Dirinck 1997; Walsh and others 1998; Cava and others 1999). Vitamin E, a natural and chain-breaking, lipid-soluble antioxidant, can react with peroxyl radical 200 times faster than synthetic antioxidant BHT (Burton and Traber 1990). Therefore, a small amount of vitamin E can protect large amount of PUFA from oxidation. In general, the higher the vitamin E and the longer the duration, the stronger antioxidant effect could be obtained (Morrissey and others 1994). A number of reports demonstrated that vitamin E significantly retarded lipid oxidation in raw chicken (Bölükbaşi and others 2006; Zouari and others 2010), pork (Nam and others 2007), turkey (Ahn and others 1998), and beef (Arnold and others 1993). Compared to raw meat, however, Table 2–Effects of diets and packaging on lipid oxidation during refrigerated storage of chicken rolls.1 Storage time (d) TBARS (mg MDA/kg meat) Treatment diet Control Oxidized Antioxidants SEM P 1.36a 2.60a 3.56a 1.48a 2.56a 3.84a 0.30b 0.40b 0.48b 0.038 0.19 0.16 <0.05 <0.001 <0.001s O2 -permeable 1.16a 2.48a 3.92a Vacuum 0.96b 1.20b 1.32b 0.022 0.16 0.13 <0.001 <0.001 <0.001 1 4 7 Package 1 4 7 1 On the same row, means with different letters differ significantly. Table 3–Effects of diets and packaging on protein oxidation during refrigerated storage of chicken breast rolls.1 Storage time (d) Carbonyl content (nmol/mg protein) Treatment diet Control a 1 4 7 Packaging Oxidized a 4.12 4.81a 5.63a,b O2 -permeable 4.50 5.26a 6.31a Vacuum 4.22 5.06a 6.42a 4.00 4.53b 4.92b 1 4 7 1 On 2 the same row, means with different letters differ significantly. NS = not significant. C614 Journal of Food Science r Vol. 76, Nr. 4, 2011 Antioxidants b 3.71 4.32b 5.06b SEM P 0.14 0.22 0.26 <0.05 <0.05 <0.05 0.11 0.10 0.023 NS2 <0.001 <0.001 processed meat is more susceptible to oxidative damage because meat products undergo physical manipulations during manufacturing process, which results in the disruption of muscle structure and exposure of muscle lipids to oxidative environment. Also, antioxidant enzymes in muscle are denatured and iron can be released from iron-protein during cooking process, which accelerates lipid oxidation. Furthermore, some ingredients added in processed meat can have positive or negative effects to the oxidative susceptibility of processed meat products: NaCl could promote lipid oxidation possibly through the displacement of iron from heme proteins (Kanner and others 1990; Ahn and others 1993) while phosphate has an antioxidant effect (Cheng and Ockerman 2003). Unlike the vitamin E added to meat during processing, dietary vitamin E can be directly deposited into subcellular structures. Deposited vitamin E becomes an integral part of muscle and fat tissues and is more effective against lipid oxidation (Winne and Dirinck 1997). Heating could result in around 25% of vitamin E loss based on the studies by analyzing the content of vitamin E after cooking and during storage of the cooked products (Wen and others 1996; Jensen and others 1998). Therefore, dietary supplementation of vitamin E can be of great significance to processed meat. Vacuum-packaging significantly delayed the onset of lipid oxidation in chicken breast rolls during the 7-d refrigerated storage (P < 0.001) (Table 2). The TBARS value of chicken rolls treated with vacuum-packaging (from 0.96 to 1.32 mg MDA/kg meat) were lower than those with oxygen-permeable packaging (1.16 to 3.92 mg MDA/kg meat). Packaging can reduce lipid oxidation in meat and meat products by controlling oxygen interactions at the meat surface. For meat, especially processed meat, elimination of oxygen from packing bags after cooking is very important to minimize lipid oxidation (Ahn and others 1992; Brewer and others Table 4– The interactive effects of diet and packaging on lipid 1992). Significant interactive effects between diet and packaging on lipid oxidation were found (P < 0.01) (Table 4). Lipid oxand protein oxidation of chicken rolls. idation in chicken breast rolls increased as the oxidation of oils Storage Probability Probability in diet increased. However, vacuum-packaging of cooked breast Source time (d) DF (TBARS) (Carbonyl) rolls reduced the oxidative changes during storage. Therefore, it Diet × Packaging 1 2 0.0032 0.34 is suggested that appropriate use of dietary supplementation of 4 2 0.0037 0.23 antioxidants in combination with packaging could minimize lipid 7 2 <0.001 0.14 oxidation in chicken rolls. Table 5–Volatile profile during refrigerated storage of chicken rolls.1 Diet Volatiles 2 Con Oxi Anti SEM O2 -per Packaging Vac SEM Total ion counts × 10 Hydrocarbons Octane Pentane Hexane Heptane 1 Storage period (d) 4 7 SEM 4 3006a 14257a 959a 1595a 3785a 14663a 1029a 1895a 2266b 7853b 420b 363b 207 2024 89 173 3577a 14804a 985a 1683a 2461b 9711b 620b 885b 170 1634 74 144 1135c 5028b 304c 354c 3477b 16677a 867b 1431b 4443a 15067a 1236a 2066a 205 2024 89 173 252a 3249a 54643 458a 454 225a 2790b 53464 434a 441 97b 3802a 50581 0b 0 10 252 2557 70 164 263a 5036a 55519 595a 560a 121b 1525b 50272 0b 0b 8 204 2064 58 134 76 1077c 37338b 0b 0b 200 2937b 59685a 0b 0b 298 5827a 61663a 892a 899a 10 252 2585 69 162 2466a 1559b 597 870 148937a 31563a 8403a 150a 730b 2214a 1356b 653 942 130359b 29169a 8259a 202a 1247a 222b 1905a 676 554 26413c 3477b 553b 27b 0c 199 172 33 116 4974 1903 624 25 148 3015a 2570a 764a 1070 173417a 38548a 10742 252a 1318a 253b 643b 520b 642 30390b 4257b 736 0b 0b 165 138 27 143 4090 1582 512 20 122 166c 339c 292c 330 19101c 2566c 198c 0b 0b 1383b 1493b 718b 862 113483b 20907b 5066b 153a 0b 3352a 2987a 915a 1340 173124a 40734a 11952a 224a 1796a 198 172 33 122 4919 1903 616 24 147 1597 455 1950 654 1602 635 189 79 1665 836a 1728 327b 120 66 1734 604a 1685 804a 1729 335b 188 78 1246a 268a 69 1415a 289a 53 151b 0b 61 190 20 6.43 1721a 372a 122a 154b 0b 0b 44 16 23 0b 0b 0b 0b 0b 87a 2812a 557a 96a 187 19 6.36 140 424b 104 616a 90 629a 21 71 119 848a 104 265b 17 58 0c 1156a 134b 0c 200a 513b 20 72 Ketones 2-Pentanone 2-Butanone 2-Propanone 2-Heptanone 2,3-Octanedione Aldehydes Butanal 2-Methylpropanal 3-Methylbutanal 2-Methylbutanal Hexanal Pentanal Heptanal Nonanal Octanal Sulfur components Dimethyldisulfide Carbondisulfide Alkenes 1,3-Octadiene 2,4-Octadiene Limonene Aromatics Tetrahydrofuran Thiobismethane the same row, means with different letters differ significantly (P < 0.05). Con = control; Oxi = oxidized; Anti = antioxidants; O2 -per = oxygen-permeable; Vac = vacuum. 1 On 2 Vol. 76, Nr. 4, 2011 r Journal of Food Science C615 C: Food Chemistry Dietary oxidation on meat oxidation . . . Dietary oxidation on meat oxidation . . . C: Food Chemistry Protein oxidation Similar to lipid oxidation, protein oxidation is considered as a chain reaction, which involves initiation, propagation, and termination steps. Protein damages in meat and meat products result in generation of carbonyls, formation of protein polymers, and scission of peptide bonds, which can lead to changes in protein structure and hydration (Xiong 2000). These changes in protein result in diverse functional consequences including lower waterholding capacity, and emulsification, and gelation properties (Hufflonergan and Lonergan 2005), which can partly contribute to the quality deterioration of meat and meat product. Recently, more attentions have been paid to the protein modification in meat and meat products. However, the influence of dietary addition of antioxidants on protein oxidation of meat is not studied extensively. No significant difference in carbonyls levels between rolls produced from the chickens fed oxidized diet and control diet during 7-d storage period was detected (Table 3). Protein oxidation of chicken rolls produced from the birds treated with different diets, monitored by carbonyls content, was ranged from 3.71 to 6.31 nmol/mg protein (Table 3), which much higher than those in raw meats (0.30 to 0.76 nmol/mg protein, unpublished data). This phenomenon could be explained by the fact that processed meat is more susceptible to protein oxidation than raw meat because of high concentration of oxidizable lipids, heme pigments, transition metal ions, and oxidative enzymes in processed meat products. In addition, as discussed above, many extrinsic factors such as temperature, restructuring, nonmeat ingredients, and heating have been changed during meat processing (Rhee 1999). ROS (reactive oxygen species) can also be generated during processing, which can strongly induce protein oxidation (Xiong 2000). The rolls manufactured from the chickens fed a diet containing 500 IU vitamin E/kg feed for 2 wk before slaughter had a significantly lower level of protein oxidation than those from the control diet at 1-, 4-, and 7-d storage point (P < 0.05) (Table 3). The initial level of protein oxidation in vitamin E supplemented group was approximately 3.71 nmol/mg of protein. The content of carbonyls increased to 5.06 nmol/mg protein level during the 7-d storage period. At 1-, 4-, and 7-d storage point, vitamin E supplemented group had 7.52%, 10.19%, and 10.12% lower carbonyl values than the control group at the respective storage day, which were much weaker than the inhibitory effect of vitamin E on lipid oxidation (78%, 85%, and 87% at each storage point). Salminen and others (2006) demonstrated that the inhibitory effect of dietary supplements on protein oxidation was marginal compared to that of lipid oxidation. They postulated that the inhibition of lipid oxidation was the primary target for antioxidants, but protein oxidation was the secondary target. Vitamin E is fat soluble, which may be why there was a more protective effect on lipid oxidation than protein oxidation. Thus, dietary addition of vitamin E showed a weaker effect in preventing protein oxidation than lipid oxidation in chicken breast rolls. Xiong (2000) demonstrated that oxidation of lipids and proteins occurred at the oil-water interface or at the fragmented lipid membrane. Due to the fact that a-tocopherol can compete for peroxyl radicals much faster than PUFA, a-tocopherol can protect a large amount of PUFA by breaking the chain of lipid oxidation (Morrissey and others 1994). Since lipid and protein oxidation are probably coupled with each other in meat and meat products (Reyftmann and others 1990), dietary addition of vitamin E may protect meat products from both lipid and protein modifications. C616 Journal of Food Science r Vol. 76, Nr. 4, 2011 Based on current study, it is suggested that dietary treatment of vitamin E is an excellent method to protect proteins from chemical and functional damages during processing and storage of meat products. The carbonyls contents of vacuum-packaged chicken rolls were 4.53 and 4.92 nmol/mg protein after 4 and 7 d storage, respectively (Table 3), which were 10.4% and 23.39% lower than those packaged in oxygen-permeable bags because oxygen catalyzes protein oxidation. It appeared that limiting oxygen contact to meat through vacuum-packaging was an effective method to minimize protein modifications. Volatiles Flavor precursors including lipid, carbohydrates, and other water-soluble nonprotein compounds such as amino acids, peptides, reducing sugars, vitamins, and nucleotides are originally present in raw meat. Hundreds of volatile compounds can be produced from the precursors upon heating, but only a few of those play significant roles in the development of characteristic flavor and aroma of meat. In current study, 25 volatile compounds were identified during the storage of chicken rolls (Table 5). They were classified into 6 groups, which include aldehydes, hydrocarbons, ketones, alkenes, aromatics, and sulfur components. Among them, aldehydes were the most abundant component, and were dominated with hexanal and pentanal. These results were in agreement with those of Winne and Dirinik (1997) who claimed that aldehydes were the most important contributor for the rancidity development in meat products. The work of Shahidi and Pegg (1993) as well as our results showed that aldehydes (hexanal and pentanal) were mainly responsible for rancidity development in chicken rolls. Varnam and Sutberland (1995) demonstrated that the unsaturated C18 fatty acid of meat, defined as Olenic acid (C18:1n-9), Linoleic acid (C18:2n-6), and Linolenic acid (18:3n-3), were responsible for producing low molecular weight (C3-C12) aldehydes, such as hexanal and pentanal. Thus, the methods that protect these fatty acids from modification could retard the onset production of aldehydes. Hexanal levels of the rolls prepared from chickens fed control and oxidized diet were 5.65-fold and 6.45-fold higher than that from antioxidants diet. A significant difference (P < 0.01) was also found between the rolls prepared from the chicken fed control diet and oxidized oil diet. These results indicated that adding vitamin E and oxidized oil to chicken diet significantly retarded or increased the production of hexanal during storage of chicken breast rolls. A significant difference in pentanal content was found between the rolls from chickens fed with oxidized oil and control diet (P < 0.01). These results coincided with the results of lipid oxidation measured by TBARS. Vacuum-packaged chicken breast rolls produced 82% and 89% lower amounts of hexanal and pentanal, respectively, than that of the oxygen-permeable packaged ones. This suggests that vacuum-packaging is very effective in preventing the production of hexanal and pentanal during the storage of chicken rolls. In order to detect the extent of lipid oxidation in meat and meat products, TBARS and rancidity development (especially production of hexanal) were widely used as indicators of lipid oxidation. Some studies reported strong correlations between 2 methods (TBARS and hexanal values) (Ahn and others 1998). It has been recognized that the contribution of a single volatile compound to the overall odor depended upon its odor quality and threshold (Varnam and Sutberland 1995). It should address that aldehydes played a critical role for the development of rancidity in meat products because they have low odor threshold values. However, single aldehyde may be not used as a sole index for lipid oxidation. From our study, hexanal and pentanal together could be used as an indicator of rancidity development during refrigerated storage of chicken breast rolls. Conclusions Dietary addition of vitamin E significantly decreased lipid and protein oxidation and the inhibitory effect of dietary antioxidants on lipid oxidation was more pronounced than that on protein oxidation. Vacuum-packaging significantly reduced lipid and protein oxidation, and dietary antioxidants in combination with vacuumpackaging could be an effective method to control lipid oxidation in chicken rolls. Hexanal and pentanal could be utilized as an indicator for the development of rancidity in chicken rolls during refrigerated storage. Acknowledgment This study was supported jointly by the Chinese Scholarship Council, Iowa State Univ., and WCU (World Class Univ.) program (R31-10056) through the Natl. Research Foundation of Korea funded by the Ministry of Education, Science and Technology. References Ahn DU, Wolfe FH, Sim JS, Kim DH. 1992. Packaging cooked turkey meat patties while hot reduces lipid oxidation. J Food Sci 57:1075–7, 1115. Ahn DU, Wolfe FH, Sim JS. 1993. The effect of free and bound iron on lipid peroxidation in turkey meat. Poult Sci 72:209–15. Ahn DU, Sell JL, Jo C, Chen X, Wu C, Lee JI. 1998. Effects of dietary vitamin E supplementation on lipid oxidation and volatiles content of irradiated, cooked turkey meat patties with different packaging. Poult Sci 77:912–20. AOAC Official Method 965.33. 1965. AOCS method Cd 8–53. Arnold RN, Arp SC, Scheller KK, Williams SN, Schaefer DM. 1993. Tissue equilibration and subcellular distribution of vitamin E relative to myoglobin and lipid oxidation in displayed beef. J Anim Sci 71:105–18. Baião NC, Lara LJC. 2005. Oil and fat in broiler nutrition. Braz J Poult Sci 7:129–41. Boles JA, Parrish FC Jr. 1990. Sensory and chemical characteristics of precooked mircrowavereheatable pork roasts. Food Sci 55:618–20. Bölükbaşi ŞC, Erhan MK, Özkan A. 2006. Effect of dietary thyme oil and vitamin E on growth, lipid oxidation, meat fatty acid composition and serum lipoproteins of broilers. S Afr J Anim Sci 36:189–95. Bou R, Guardiola F, Grau A, Grimpa S, Manich A, Barroeta A, Codony R . 2001. Influence of dietary fat source, α-tocopherol, and ascorbic acid supplementation on sensory quality of dark chicken meat. Poult Sci 80:800–7. Brewer MS, Ikins GW, Harbers AZ. 1992. TBA values, sensory characteristics, and volatiles in ground pork during long-term frozen storage: effects of packaging. J Food Sci 57:558–80. Burton GW, Traber MG. 1990. Vitamin E: antioxidant activity, biokinetics and bioavailability. Annu Rev Nutr 10:357–82. Cava R, Ruiz J, Ventanas J, Antequera T. 1999. Oxidative and lipolytic changes during ripening of Iberian hams as affected by feeding regime: extensive feeding and alpha-tocopheryl acetate supplementation. Meat Sci 52:165–72. Cheng JH, Ockerman HW. 2003. Effect of phosphate with tumbling on lipid oxidation of precooked roast beef. Meat Sci 4:1353–9. Engberg RM, Lauridsen C, Jensen SK, Jakobsen K. 1996. Inclusion of oxidized vegetable oil in broiler diets. Its influence on nutrient balance and on the antioxidative status of broilers. Poult Sci 75:1003–11. Huff-Lonergan E, Lonergan SM. 2005. Mechanisms of water-holding capacity of meat: the role of postmortem biochemical and structural changes. Meat Sci 71:194–204. Jan P. 1991. Natural antioxidants for food use. Trends Food Sci Tech 2:223–7. Jensen C, Lauridsen C, Bertelsen G. 1998. Dietary vitamin E: quality and storage stability of pork and poultry. Trends Food Sci Tech 9:62–72. Kanner J, Bartov I, Salan MO, Doll L. 1990. Effect of dietary iron level in situ turkey muscle lipid peroxidation. J Agric Food Chem 38:601–4. Levine RL, Williams JA, Stadtman ER, Shacter E. 1994. Carbonyl assays for determination of oxidatively modified proteins. Methods Enzymol 233;346–57. Mason L, Hogan S, Lynch AM, O’Sullivan K, Lawlor P, Kerry J. 2006. Quality characteristics of cured ham produced from Landrace and Duroc pigs fed restricted energy diets with and without α-tocopheryl acetate or green tea catechins. Anim Res 55:323–33. Morrissey PA, Buckley DJ, Sheehy PJA. 1994. Vitamin E and meat quality. Proc Nutr Soc 53:289–95. Nam KC, Ko KY, Min BR, Ismail H, Lee EJ, Cordray J, Ahn DU . 2007. Effects of oleoresin–tocopherol combinations on lipid oxidation, off-odor, and color of irradiated raw and cooked pork patties. Meat Sci 75:61–70. Nolan NL, Bowers JA, Kropf DH. 1989. Lipid oxidation and sensory analysis of cooked pork and turkey stored under modified atmosphere. J Food Sci 54:846–9. Racanicci AM, Menten JFM, Regitano-d Arce MAB, Torres EAFS, Pino LM, Pedroso AA. 2008. Dietary oxidized poultry offal fat: broiler performance and oxidative stability of thigh meat during chilled storage. Braz J Poult Sci 10:29–35. Reyftmann JP, Santus R, Mazière JC, Morlière P, Salmon S, Candide C, Mazière C, Haigle J. 1990. Sensitivity of tryptophan and related compounds to oxidation induced by lipid autoperoxidation. Application to human serum low- and high-density lipoproteins. Biochim Biophys Acta 1042:159–67. Rhee KS. 1999. Storage stability of meat products as affected by organic and inorganic additives and functional ingredients. In: Xiong YL, Ho CT, Shahidi F, editors. Quality attributes of muscle foods. New York: Plenum Publishing Corp. p 95–113. Rhee KS, Anderson LM, Sams AR. 1996. Lipid oxidation potential of beef, chicken and pork. J Food Sci 61:8–12. Salminen H, Estévez M, Kivikari R, Heinonen M. 2006. Inhibition of protein and lipid oxidation by rapeseed, camelina and soy meal in cooked pork meat patties. Eur Food Res Technol 223:461–8. SAS Institute. 1995. Version 9.1. Cary, N.C.: SAS. Shahidi F, Pegg RB. 1993. Hexanal as an indicator of meat flavor deterioration. J Food Lipids 1:177–86. Sheehy PJA, Morrisey PV, Flynn A. 1994. Consumption of thermally-oxidized sunflower oil by chicks reduces alfa tocopherol status and increases susceptibility of tissues to lipid oxidation. Br J Nutr 71:53–65. Smet K, Raes K, Huyghebaert G, Haak L, Arnouts S, Smet SD. 2008. Lipid and protein oxidation of broiler meat as influenced by dietary natural antioxidant supplementation. Poult Sci 87:1682–8. Ursini F, Sevanian A. 2002. Postprandial oxidative stress. Biol Chem 383:599–605. [USDA] U.S. Dept. of Agriculture. 1982. Guidelines for establishing and operating poultry processing plants. Agricultural handbook nr 581. Washington, D.C.: USDA-ARS. Varnam AH, Sutberland JP. 1995. The flavor of meat. In: Varnam AH, Sutberland JP, editors. Meat and meat products: technology, chemistry, and microbiology. London, U.K. p 30–1. Walsh MM, Kerry JF, Buckley DJ, Morrissey PA, Lynchc PB, Arendt E. 1998. The effect of dietary supplementation with a-tocopheryl acetate on the stability of low nitrite cured pork products. Food Res Intl 31:59–63. Wen J, Morrissey PA, Buckley DJ, Sheehy PJA. 1996. Oxidative stability and α-tocopherol retention in turkey burgers during refrigerated and frozen storage as influenced by dietary α-tocopheryl acetate. Br Poult Sci 37:787–95. Winne A, Dirinck P. 1997. Studies on vitamin E and meat quality. 3. Effect of feeding high vitamin E levels to pigs on the sensory and keeping quality of cooked ham. J Agric Food Chem 45:4309–17. Xiong YL. 2000. Protein oxidation and implication for muscle food quality. In: Decker EA, Faustman C, Lopez-Bote CJ, editors. Antioxidants in muscle foods: nutritional strategies to improve quality. New York: John Wiley and Sons. p 85–112. Zouari N, Elgharbi F, Fakhfakh N, Bacha AB, Gargouri Y, Miled N. 2010. Effect of dietary vitamin E supplementation on lipid and colour stability of chicken thigh meat. Afr J Biotechnol 9:2276–83. Vol. 76, Nr. 4, 2011 r Journal of Food Science C617 C: Food Chemistry Dietary oxidation on meat oxidation . . .