Developing & Applying a Miniaturized Active

Microchip Device

ARCHIVES

AS SACHUSETTS

By

Byron C. Masi

INSTRTUE

JULRAR2E

B.S. Chemical & Biomolecular Engineering

Johns Hopkins University, 2007

IES

Submitted to the Department of Chemical Engineering in

Partial Fulfillment of the Requirements for the Degree of

Doctor of Philosophy in Chemical Engineering

at the

Massachusetts Institute of Technology

June 2012

© Massachusetts Institute of Technology

All rights reserved

Signature of Author...............................

..................

Byron C. Masi

Department of Chemical Engineering

April 18 th 2012

Ce rtifie d by...........................................................................

Robert S. Langer

Institute Professor

'v A esis

e5

or

Ce rtified by........................................................................

4richael J. Cima

Professor of Material Science and Engineering

Thesis Supervisor

A ccepted by ...............................................

. . .................

. . .....

Patrick S. Doyle

Professor of Chemical Engineering

Chairman, Committee for Graduate Students

..................

Developing & Applying a Miniaturized Active Microchip Device

By

Byron C. Masi

Submitted to the Department of Chemical Engineering

On April 18 th, 2012 in partial fulfillment of the requirements for the degree of

Doctor of Philosophy in Chemical Engineering

ABSTRACT

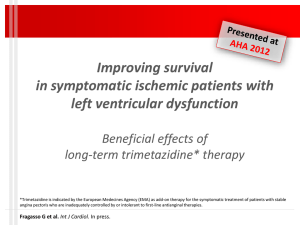

Glioblastoma multiforme (GBM) is the most common and aggressive malignant brain tumor.

Treatment of GBM is a daunting task with median survival just at 21 months. Methods of

localized delivery have achieved moderate success in treating GBM. Depot devices have been

limited due to the relatively narrow drug distribution profile they achieve. Convection enhanced

delivery has demonstrated that broad distribution is key, but is limited due to uncertain spatial

distribution and serious side effects. Miniaturized depot devices, implanted into the tissue

surrounding the tumor resection site, could achieve a broad aggregate distribution profile. The

capabilities of localized delivery can be enhanced by utilizing mircoelectromechanical systems

(MEMS) technology to deliver drugs with precise temporal control over release kinetics. An

intracranial MEMS based device was developed to deliver the clinically utilized

chemotherapeutic temozolomide (TMZ) in a 9L rodent glioma model. An activation mechanism

based on thermally induced membrane failure was developed and incorporated. The kinetics of

TMZ release were validated and quantified in vitro. The safety of implanting the device

intracranially was confirmed. The impact of TMZ release kinetics on survival was investigated by

comparing the effects of drug release rates and timing. TMZ delivered from the device

prolonged animal survival. The results from the in vivo efficacy studies indicate that early, rapid

delivery of TMZ from the device results in the most prolonged animal survival. This miniaturized

MEMS device holds tremendous potential for the treatment of GBM and related diseases.

Circuit diseases are neurological disorders that arise from the dynamic miscommunication

within a neural circuit. Anxiety, mood disorders, and the chronic effects of traumatic brain injury

(e.g. Parkinsonism) are prevalent, and are circuit diseases. Circuit diseases could be clinically

addressed by a technology capable of electrical, and chemical neuro-modulation. A catheter

based device capable of simultaneous infusion of multiple fluids and electrical stimulation was

designed and fabricated. Preliminary in vitro infusion studies indicate that the reliable and

reproducible infusion of multiple fluids is possible. Future work will focus on improving the

biocompatibility of the device and studying the performance of the device in non-human primate

models of neurological disorders.

Thesis Supervisors:

Thesis Committee:

Professor Michael J. Cima (MIT)

Institute Professor Robert S. Langer (MIT)

Professor Paula T. Hammond (MIT)

Dr. John T. Santini, Jr. (On Demand Therapeutics, Inc.)

2

Acknowledgements

Michael, you have taught me many lessons throughout the past 5 years, many of which will

remain with me for the rest of my life. Your influence has made me a better researcher and

thinker. Despite your busiest schedules you always make time for your students and never

cease to have insightful and instructive input. Thank you for mentoring me throughout my time

here.

Bob, I'd like to thank you for your never ending enthusiasm and support throughout my time

here. It has been an inspiration to work with you.

I would like to thank my thesis committee members John Santini and Paula Hammond for their

time, attention and guidance. Paula, you are consummately positive and motivating. Thank you

for being a part of my thesis. John, you have been tremendously generous with your time and

advice. Even when you moved to another state, you never ceased to be available for phone

calls and meetings. Thank you for your guidance and words of wisdom.

I would like to thank the members of the Cima lab, past and present, for their influence and

camaraderie. Karen, Grace, Heejin, Irene, Yibo, Yoda, Qunya, Maple, Vincent, Syed, Lenny,

Dan, Joan, Agata, Kevin, Negar, Jen, Anna R., Anna T., Yuan, Ollie, Matt, Laura and Jay, you

have all made for a rich, fun and welcoming group. Alex, thank you for working with me

throughout the early years. It was great to have a companion in putting together all those early

slide decks and figuring how on earth an 'HPLC' works. Hong Linh and Noel, I would like to

especially thank you two for being so helpful and giving with your expertise in MEMS and device

manufacturing. You both made my transition into an unfamiliar field very smooth, and relatively

painless. I wish you both the best with all your endeavors and growing families.

Very special thanks are reserved for Chris and Urvashi. Urvashi, your enthusiasm, humor,

support and astonishing intellect were crucial to my perseverance during the middle years of my

thesis. Thank you for guiding, and bolstering me throughout your time here. Chris, you are one

of the most remarkable people I have ever met. Your intellect, wit, patience and mentorship

have influenced me in countless ways. Thank you for the discussions and pep-talks when my

experiments weren't going well, and thank you for the constant good company and humor.

Steve, Justin, Josh and Adel: You were all a constant source of support, laughs and fond

memories. You're all the reason I survived our first year, and my time here at MIT was better for

having you four as close friends.

Mom, Dad, Dylan and Elizabeth: you have all helped make me the person I am today. Thank

you for your support during the hard times, enthusiasm during the successful times, and your

unerring advice throughout. You should all take pride in this document and the work it

describes. It would not have been possible without you.

3

Liz, you have been my most significant source of support and inspiration throughout my Ph.D.

You are one of the most thoughtful, enthusiastic, supportive, and sage people I have ever met.

Your strength, infectious work ethic, and dedication have bettered me in many ways. You have

made the last several years very special, and meeting you is the most significant event of my

time here at MIT.

4

Table of Contents

List o f Figu re s ................................................................................................................................................

8

List o f T a b le s ...............................................................................................................................................

13

1.

14

Introduction ........................................................................................................................................

1.1 M otivation.........................................................................................................................................14

1.2 Problem Statem ent...........................................................................................................................14

1.2.1 Methods of Local Delivery: Convection Enhanced Delivery & Depot Devices ......................

1.3 M iniaturized depot devices for im proved therapy ........................................................................

1.3.1 M icro-Electrical-M echanical-System s Based Depot Devices .................................................

14

17

18

1.4 Thesis Objectives...............................................................................................................................21

2.

1.5 Co n c lu sio n .........................................................................................................................................

22

Device Design ......................................................................................................................................

23

2 .1 . M ic ro c hip .........................................................................................................................................

23

2.1.1 Chip Release Kinetics .................................................................................................................

23

2.1.2 Device Activation M echanism : A New Approach ...................................................................

27

2.1.3 Energy Transm ission: Reducing Overall Device Invasiveness ...............................................

29

2 .2 Re se rvo ir ...........................................................................................................................................

3.

31

2.2.1 M aterial Selection ......................................................................................................................

31

2.2.2 Reservoir Architecture ...............................................................................................................

31

2.3 Activation Hardware .........................................................................................................................

33

M e th o d s..............................................................................................................................................

35

3.1. Clean room fabrication techniques.............................................................................................

35

3.1.1 Fuse Study Devices.....................................................................................................................

35

3.1.2 Three m em brane devices ..............................................................................................

36

3.2 TM Z analytics (HPLC).........................................................................................................................

37

3.2.1 High Pressure Liquid Chrom atography .................................................................................

37

3 .2 .2 Sta b ility ......................................................................................................................................

37

3.2.3 Solubility.....................................................................................................................................

38

3.3 Device Filling .....................................................................................................................................

5

38

3.3.1 Fuse Study Devices.....................................................................................................................

38

3.3.2 T M Z Devices ...............................................................................................................................

39

3.4 Device Assem bly ...............................................................................................................................

39

3.5 Release procedures...........................................................................................................................40

3.6 In vivo Studies ...................................................................................................................................

3.6.1 Biocom patibility study ...............................................................................................................

40

41

3.6.2 Efficacy Studies..........................................................................................................................41

3.7 Im m unohistological analyses............................................................................................................42

4.

Fuse Activation M echanism ................................................................................................................

43

4.1 Device M anufacture..........................................................................................................................

43

4.2 Activation Experim ents.....................................................................................................................45

4.2.180 pm mem branes.....................................................................................................................45

4.2.2 300 pm m em branes ...................................................................................................................

51

4.3 Release Experiments.........................................................................................................................52

5.

4.4 M echanism Discussion ......................................................................................................................

53

4 .5 C o n c lu sio n .........................................................................................................................................

56

In Vitro Characterization of Device Perfom ance............................................................................

5.1 T M Z Form ulation ..............................................................................................................................

57

57

5.1.1 Packaging in C02.........................................................................................................................57

5.1.2 Co-Form ulation of TMZ and

6.

...........................................................................................

59

5.2 In vitro Release Studies .....................................................................................................................

63

5 .3 Co n c lu sio n .........................................................................................................................................

67

In Vivo Studies.....................................................................................................................................69

6.1 Pilot in vivo studies ...........................................................................................................................

69

6.1.1 Potential toxicity and potential side effects ..........................................................................

69

6.1.2 Prelim inary survival studies ..................................................................................................

71

6.2 Large scal e in vivo .............................................................................................................................

73

6.2.1 Effect of TMZ delivery rate on efficacy.................................................................................

73

6.2.2 Effect of TMZ delivery time on efficacy .................................................................................

74

6.2.3 Com parison of the device to a polym er-based delivery system .............................................

75

6.2.4 Im m unohistological analyses..........................................................................................

6

76

6.3 Discussion of in vivo results ..............................................................................................................

6.3.1 Prelim inary in vivo studies .....................................................................................................

78

6.3.2 Efficacy Studies ..........................................................................................................................

78

6.3.3 Im m unohistological analyses.................................................................................................

80

6.4 Conclusions .......................................................................................................................................

7.

8.

78

Future W ork........................................................................................................................................

81

82

7.1 Co-delivery of synergistic m olecules for the treatm ent of GBM .................................................

82

7.1.2 Prelim inary tw o com partm ent device work ..........................................................................

84

7.1.3 Im pact of drug release kinetics on in vivo efficacy studies....................................................

86

7.2 Investigation of m ass transfer m echanism s in depot devices ......................................................

87

7.2.1 Varying Orifice Size and Num ber ..........................................................................................

88

7.2.2 Changing the Drug Payload ...................................................................................................

89

7.2.3 Including Excipient .....................................................................................................................

90

7.2.4 Plausible m echanism s and directions of further research....................................................

91

A new device: The 'Injectrode'...........................................................................................................

92

8.1 Circuit Diseases .................................................................................................................................

93

8.2 Clinical Rationale: Traum atic Brain Injury, Anxiety and M ood Disorders ....................................

94

8.2.1 Intractable Anxiety and M ood Disorders...............................................................................

94

8.2.2 Traum atic Brain Injury and Associated Chronic Neurological Disorders ...............................

95

8.3 Device Design and M anufacture...................................................................................................

96

8.3.1 The Prior Art for M icro-cannula Devices...............................................................................

96

8.3.2 The First Generation Injectrode ............................................................................................

98

8.4 In Vitro Infusion Results ..................................................................................................................

100

8.5 Future steps in the developm ent of this device .............................................................................

103

8.5.1 In vitro tissue phantom infusion studies.............................................................................

103

8.5.2 Device Coating for Structural Integrity and Biocom patibility ..................................................

104

8.5.3 In vivo experim entation to confirm neural circuit and behavior m odification ....................... 106

8.6 Conclusion.......................................................................................................................................107

9.

References ........................................................................................................................................

7

108

List of Figures

Figure 1.1 MRI images of a GBM patient. A coronal MRI image depicting a GBM lesion

(indicated by the white arrow) (A). Post resection surgery MRI depicting the void (white

arrow) left by the procedure (B). MRI image showing the same patient 6 months after

resection surgery, full chemotherapeutic, and radiation therapy regimen. Two recurrent

lesions are indicated by white arrows (C). Image post second resection surgery showing

two resection sites (D). Scan 3 months after second resection surgery depicting recurrent

15

lesions at the immediate periphery of the resection site (E). Image from Deorah et al.

Figure 1.2 Diagram of the envisioned device implementation. The primary tumor burden is

Infiltrative neoplastic cells

removed, to the extent possible, by surgical resection.

(cartooned here as the black shaded region surrounding the resection site) remain, and are

free to proliferate unless addressed by radiation and/or chemotherapy. Devices can be

packed within the resection site (not shown here for simplicity) and implanted into the tissue

immediately surrounding the resection site. Upon device activation the aggregate release

profile of many diffusion driven devices could be equivalent to the pressure driven release

18

profile of CED and hopefully address the majority of remaining glioma cells.

Figure 1.3 Schematic of the original MEMS based micro-chip drug delivery device

developed by John Santini, Ph.D.. In this manifestation the drug (active substance) is

loaded into micro-machined pyramidal reservoirs that are each capped by a gold

membrane. Activation induces the electrochemical dissolution (formation of gold chloride)

20

of the anode (membrane). Figure from Santini et al.

Figure 2.1 A CAD rendering of the active device in its current form. A liquid crystalline

polymer reservoir (gray) is capped by a silicon chip (purple and gold) that contains 3 nitride

membranes (green). Energy is delivered to the device via polyimide coated copper leads

23

(brown and gold).

Figure 2.2 Survival plots and in vitro release kinetics for the TMZ laden polymer study

conducted by Brem et al. Survival is depicted as the percentage of animals still alive

within a group as a function of time. Both polymer wafer groups displayed improved

median survival and number of long term survivors (animals surviving until the protocol

mandated stop date) when compared to oral treatment and control groups. Figure copied

from Brem et al. (A) The release kinetics of TMZ are first order and result in a final delivery

of approximately 70% of wafer payload in 75 hours. (B)

24

Figure 2.3 Sketch of the assumed spatial concentration profile as drug releases from the

device. The reservoir is assumed to be at saturation, Co. The exterior of the device is

assumed to be at infinite sink conditions, Ci = 0 mg/ml. Steady state, uni-directional

8

diffusion is assumed, allowing the gradient in Fick's first law to be one dimensionalized (Eq.

25

2) and linearized (Eq. 3).

Figure 2.4 Color photographs of the chip:lead assembly (A) and entire device and on a United

States penny (B). A close up photograph of the chip:lead assembly. Gold wire bonds are

visible between the gold coated copper pads of the flexible PCB and the patterned gold on

the chip (A). Photograph of the fully assembled device. The chip rests on the internal

shoulder of the reservoir, leaving a small space for the UV curable epoxy to wet into and be

cured within.

30

Figure 2.5 CAD rendering of the injection molded liquid crystalline polymer reservoir. The

reservoir dimensions are 3.7 by 3.2 x 2.2 mm. The total drug payload is 10 milligrams of

TMZ. The 200 pm shelf is visible on the interior face of the reservoir walls. This shelf

serves a seat for the chip and as an upper boundary for drug during the loading process. A

lead-way was designed in the top perimeter of the chip to allow the polyimide leads to

project out from the device.

32

Figure 2.6 Circuit diagram for the activation hardware. The switchbox (dashed box) contains a

matching resistor, shunt resistor and a single pole, triple throw switch. The head piece

contains each membrane on independent, parallel circuits. The matching resistor allows the

voltage source to be impedance matched to the load. The shunt resistor and membrane are

in parallel such that, when the membrane ruptures, current is directed through the shunt

resistor.

34

Figure 3.1 Fabrication process sequence for creating nitride membranes in the microchip. 36

Figure 4.1 Digital renderings of the suspended nitride membranes and overlying fuses. A.

Simple rectangular fuses (yellow) were deposited over the nitride (green) membrane in the

small membrane study. B. More intricate fuse geometries were studied in the large, 300

pm, membrane devices. Two 20 pm fuses, one 40 pm fuse, two 40 pm 'v' shaped fuses,

three 10 pm fuses, and one 40 pm diagonal fuse.

44

Figure 4.2 SEM microscope images showing the structure before and after activation for

each fuse width (250 nm Au layer). A. 20 pm wide. B. 40 pm wide fuse. C. 60 pm wide. 47

Figure 4.3 Confocal microscope images for 250 nm thick fuses. A. 20 pm wide. B. 40 pm

wide. C. 60 pm wide.

48

Figure 4.4 Oscilloscope capturing images showing activation pulse voltage values (blue)

and current (red) values for 250 nm thick fuses. A. 2 pm wide. B. 40 pm wide. C. 60 pm

wide.

49

9

Figure 4.5 Minimum energy to burst fuse as a function of fuse dimensions. Please refer to

Table 4.1 for values.

50

Figure 4.6 Light microscope images of ruptured 300 pm membranes.

ruptured via x fuses. B. Membranes ruptured via diagonal fuses.

A. Membranes

51

Figure 4.7 In vitro release profiles, n = 5, for activated devices, n = 5 for control devices.

Error bars represent standard deviation.

53

Figure 4.8 FEA Analysis of the suspended structure showing an

Misses stress on the surface area of the membrane,

displacement showing structural deformation. The mesh

approximately 10E5 elements. A. 20 pm wide fuse (B), 40 pm

fuse (D).

isometric view of the Von

and a lateral view for

of the analysis included

wide fuse (C), 60 pm wide

54

Figure 5.1 An example of inconsistent release profiles that result from packaging in C02.

The rate of release was consistent across the three devices and compares well to the

theoretical release. The onset of release and overall extent of release vary greatly across

the 3 devices. The theoretical line is based on zero order approximations of the release rate

utilizing Fick's first law. The controls demonstrate excellent sealing and drug retention

throughout the time scale for release.

58

Figure 5.2 Renders of the device in the three stages of assembly. A. An empty reservoir.

The shoulder that the chip must rest on is visible around the interior perimeter of the

reservoir. B. A filled reservoir. Drug and any excipients must be loaded into the device

without accumulating on the shoulder in order to ensure proper alignment during

subsequent assembly steps. C. An assembled device. The chip is placed in the reservoir,

resting on the shoulder. Biomedical grade epoxy is then used to secure the chip to the

reservoir and seal the reservoir.

60

Figure 5.3 A series of color photogrpahs depicting the steps in device filling. An empty

reservoir is placed in a fixture that allows a pre-weighed amount of drug to be added up the

the level of the shoulder (A). Drug is loaded into the reservoir and partially compacted to

create a small well within the drug powder. This well allows molten PEG to be added to the

reservoir (B). After typically three repititions, the majority of the air has been displaced from

the TMZ powder and replaced by PEG. The vacuum fixture ensures that TMZ and PEG do

not escape the reservoir or accumulate on the shoulder (C).

61

Figure 5.4 Schematic of the vacuum co-formulation process. The vacuum fixture clamps a

high air permeability Teflon AF membrane over the surface of the PEG:TMZ mixture. The

PEG:TMZ mixture is trapped within the reservoir, but any air is free to flux out when a

vacuum is pulled. Once the air is removed, PEG is free to wet within the interstices of the

TMZ powder.

62

10

Figure 5.5 Release curves for TMZ filled devices releasing into 37 0 C water. Devices (n=3)

with 3, 2, 1 or 0 membranes activated were placed in agitated baths and sampled for TMZ

content. The errors bars are the standard error. Release is a function of the number of

activated membranes and release does not occur unless the device is activated.

63

Figure 6.1 Graphical presentation of normalized animal weight as a function of time. All

animals displayed minimal weight loss during the acute phase and animal 5 displayed

robust weight gain over the chronic time scale.

70

Figure 6.2 Survival curves for the preliminary efficacy trial. Animals with activated devices

demonstrated the most prolonged survival. Un-activated devices had an identical impact

on animal survival as no treatment at all. Animals receiving aCSF had a slightly shorter

median survival than no treatment.

72

Figure 6.3 Impact of drug release rate on survival. Animals that received activated devices on

day 0 had median survivals of 40 (42.8 % LTS), 28 (28.5 % LTS), and 21 (12.5 % LTS)

days for 3, 2, and 1 membranes activated respectively.

73

Figure 6.4 Impact of drug release time on survival. Animals that had all 3 membranes activated

day 0, 3, or 5 had median survivals of 40 (42.8 % LTS), 24 (12.5 % LTS) and 23 days. 74

Figure 6.5 Comparison between microchip and polymer-based delivery methods. Those animals

that received two TMZ:polymer wafers on day 5 had a median survival of 34 days, while

those that had all 3 membranes opened on day 5 had median survival of 23 days.

75

Figure 6.6 Immunohistological results of Ki67 and caspace-3 staining. (A) Ki67 positive cells are

green and cell nuclei are blue. Each panel is a representative image from each efficacy

study group. The 3MOD (3 membranes activated on day 0) panel contains the fewest

number of Ki67 positive cells. (B) Quantitative results obtained by averaging 3

representative images from each group. The two longest surviving groups, wafer and

3MOD, have the lowest levels of Ki67 positive cells. (C) Caspase-3 positive cells are green

and cell nuclei are blue. Each panel is a representative image from each efficacy study

group. (D) Quantitative results obtained by averaging 3 representative images from each

group. The 3MOD (3 membranes activated on day 0) panel contains the second highest

number of caspace-3 positive cells.

77

Figure 7.1 CAD renderings of cross sectional views of the proposed two compartment

device. The reservoir architecture is essentially the same as the single compartment

device only mirrored around and internal plane. Each reservoir can be capped by the

normal chip without any alteration to the chip design or manufacturing.

84

11

Figure 7.2 Release of TMZ from a two compartment reservoir device. Each compartment was

loaded with 5 milligrams of TMZ and co-formulated with PEG. The first chip had 3

membranes activated at t = 0 hours and the second chip was activated at t = 162 hours. 85

Figure 8.1 Digital renders and SEM images of the core components of the injectrode. A CAD

rendering of the manifold. Four ports are visible. The port on the circular face is a through

hole through with the introducing needle and glass tube are threaded. The center port on

the cylinder surface is for filling the epoxy chamber (panel B). Pump tubing is inserted into

the remain two ports which service the infusion chambers (Panel B)( A). A cross sectional

view of the manifold depicting the epoxy chamber, two infusion chambers, and the silicone

septa (blue) (B). CAD rendering of the multi-lumen glass tube. The large lumen (90 pm)

houses the electrode. The two small (38pm) lumens conduct fluid from manifold down to

the distal tip of the device. Each 38 pm lumen has an access port cut into it to allow for

interfacing with the manifold (C). Scanning electron microscopy image of several glass

tubes viewed end on.

99

12

List of Tables

Table

Table

Table

Table

Table

2.1: Device dimensions for a 10 mg payload ............................................................

4.1: Activation energy values depicted in Figure 4.5. n = 5......................................

6.1: Survival data for the preliminary efficacy study .................................................

6.2: Survival data for the large scale efficacy study .................................................

8.1: Infusion results for the first two lumen device ......................................................

13

27

48

71

75

100

1. Introduction

1.1 Motivation

A glioma is a cancerous tumor arising from the glial cells of the brain.

The most

common and aggressive form of glioma that afflicts humans is glioblastoma multiforme (GBM)

[1]. GBM accounts for 12-15 percent of all primary brain tumors and afflicts 5000 Americans per

year [2, 3]. Glioblastoma multiforme is nearly invariably fatal and the average patient will survive

between a few months (minimal treatment) and 12 to 18 months (maximal treatment) [4, 5], and

those patients surviving 2-3 years are deemed 'long-term survivors'. Deorah et al, concluded

that GBM patients have not shown improved survival since the late 1980's based on a study

conducted in 2006 of brain cancer incidence and a review of survival rates in the United States

from 1973 to 2001 [1].

Glioblastoma multiforme and related gliomas present devastating

challenges to patient survival and demand improved treatment modalities.

1.2 Problem Statement

1.2.1 Methods of Local Delivery: Convection Enhanced Delivery & Depot Devices

Current treatment methods generally combine surgical resection (Figure 1.1) of the

primary tumor, radiation therapy and a chemotherapeutic regimen [5]. Chemotherapy is most

often administered systemically via intravenous injection or oral formulations. One of the major

limitations to the development of more effective brain tumor therapies is the presence of the

blood-brain barrier, which prohibits the transfer of molecules that are larger than 500 daltons or

are non lipid-soluble. The presence of the blood brain barrier causes only a fraction of

administered systemic dose to ever reach the brain. To achieve therapeutics levels within the

brain, excessive amounts of drug must be administered to account for the poor partitioning,

resulting in systemic toxicities. Dosing regimens are frequently designed to remain just under

14

toxicity thresholds, as opposed to achieving therapeutic tissue concentrations. Limitations in

drug exposure and systemic toxicity have spurred on the development of localized delivery

methods [6-12].

One method of circumventing the blood brain barrier is to pack the resection site with

drug depots which can then release drug into the afflicted tissue in a time-controlled manner.

These depot devices have shown promise in treatment, but achieve limited spatial distribution

[7, 8, 10, 13-15]. The concern is that the limited distribution of drug leaves wide spread, unresected, glioma cells unaddressed and free to proliferate (Figure 1.1 C,E) [7].

Efforts have

been made to find methods that improve spatial drug distribution.

One method for achieving increased drug distribution is convection-enhanced delivery

Figure 1.1 MRI images of a GBM patient. A coronal MRI image depicting a GBM lesion (indicated by

the white arrow) (A). Post resection surgery MRI depicting the void (white arrow) left by the procedure

(B). MRI image showing the same patient 6 months after resection surgery, full chemotherapeutic, and

radiation therapy regimen. Two recurrent lesions are indicated by white arrows (C). Image post

second resection surgery showing two resection sites (D). Scan 3 months after second resection

surgery depicting recurrent lesions at the immediate periphery of the resection site (E). Image from

Deorah et al.

15

(CED). A catheter is surgically placed in the target tissue under image guidance during CED.

An external pump is then used to infuse drug solution, and to drive subsequent fluid flow in the

tissue. CED has been shown to be efficacious both in achieving broad distribution of drug and

in retarding tumor progression [6, 7, 9, 12, 16-18]. The results of CED have demonstrated that

broad distribution is possible and is in fact critical to improved treatment, but as a treatment

modality CED suffers from several considerable drawbacks.

The medical procedure surrounding CED can be extremely inconvenient for the patient.

Catheter placement and infusion requires that the skull be immobilized in a stereotaxic device

and the catheter must be connected to an external pump and fluid reservoir during infusion.

Infusion times in the literature have ranged from hours to weeks and commonly last around 7

days [12, 15].

The greatest issue confronting CED is the uncertainty in fluid flow.

The physical

parameters and characteristics of the brain greatly dictate the direction of fluid flow. White

matter presents less resistance to fluid flow causing the infused fluid to preferentially flow

through white matter [7]. The natural structure of the brain can form conduits for fluid flow.

These effects are largely unpredictable and unavoidable.

Infusion itself changes the tissue

properties of the brain. The initial path of fluid flow alters the tissue, for example, by dilating the

ECM and causing it to present less resistance to fluid flow. Any subsequent administrations of

treatment, therefore, are more likely to follow the same path, possibly leaving portions of

diseased tissue completely unaddressed. CED's effect on surrounding tissue is so extensive

that it can cause edema that is in many cases indistinguishable from peri-tumoral edema [7].

Edema resulting from the disrupted vasculature of GBM tumors is already one of the leading

causes of morbidity in patients [19]. A treatment that exacerbates the level of edema, and

therefore morbidity, is severely limited.

16

The benefits and drawbacks of CED can best be understood in the context of the

disease. Glial tumors have been shown to have heterogeneous cellular populations within a

given tumor [4, 20, 21].

Two basic and easily defined cohorts are proliferative cells and

migratory cells. The presence of migratory cells is thought to be a leading cause of tumor

recurrence [20]. Migratory cells are able to infiltrate healthy tissue surrounding the primary

tumor. Their departure from the primary tumor allows them to avoid physical removal by

resection, and therapeutic insult because of the limited drug distribution profile discussed above

(Figure 1.1). A large distribution profile, therefore, is necessary for efficient treatment. Migratory

cells also tend to follow certain anatomical structures during infiltration [20]. These concepts

demonstrate that regional control of delivery of multiple agents is critical to disease treatment.

1.3 Miniaturized depot devices for improved therapy

Improved drug distribution is clearly necessary to improve treatment, but the migratory

nature of the disease exposes the fact that regional control of drug delivery is critical. The

uncertainty in fluid flow present in CED is unacceptable, but its increased distribution profile is

crucial. Depot devices could be employed in such a way as to both achieve an improved

distribution and capitalize on disease characteristics. Miniaturized depots could be packed into

the resection site as well as injected to a perimeter beyond the resection site (Figure 1.2). The

ability to place devices in specific locations facilitates delivery to specific anatomical features

while avoiding the uncertainty present in CED. Each device has its own reservoir allowing for

regional control of the delivery for each therapeutic. The majority of recurrent lesions occur

within 2-3 centimeters of the resection site [5]. Implanting devices within the tissue immediately

surrounding the resection site, therefore presents a promising approach to preventing tumor

recurrence. The use of miniaturized active devices allows for the heterogeneous nature of the

disease to be treated in a comparably heterogeneous fashion.

17

Figure 1.2 Diagram of the envisioned device implementation. The primary tumor burden is

removed, to the extent possible, by surgical resection. Infiltrative neoplastic cells (cartooned here as

the black shaded region surrounding the resection site) remain, and are free to proliferate unless

addressed by radiation and/or chemotherapy. Devices can be packed within the resection site (not

shown here for simplicity) and implanted into the tissue immediately surrounding the resection site.

Upon device activation the aggregate release profile of many diffusion driven devices could be

equivalent to the pressure driven release profile of CED and hopefully address the majority of

remaining glioma cells.

1.3.1 Micro-Electrical-Mechanical-Systems Based Depot Devices

Depot devices are excellent vehicles for drug delivery because they localize treatment,

avoiding systemic toxicity, and protect the drug from degradation and clearance until release.

Drug filled or impregnated depots have demonstrated success in both laboratory and clinical

settings (Gliadel @) [22-29]. Temozolomide loaded polymer microcapsules developed by Scott

et al achieved marked improvement in median survival over systemic administration in primary

18

brain tumor model [30]. These results motivate the development of miniaturized depot devices

for the local delivery of chemotherapeutic to the brain.

The versatility in function of depot devices can be enhanced by utilizing micro-electromechanical system (MEMS) technology. MEMS based, or 'active', devices offer the exquisite

advantage of being able to actively control the function of a device via minute electrical signals

[31-34].

Such communication offers the ability to control drug release rate and when drug

release begins, allowing for the creation of complex temporal profiles of one or multiple

therapeutics [32, 33, 35-41]. The physical manifestation of the devices is generally a macromachined drug reservoir that is capped by a micro-machined microchip such that drug release

is gated by the microchip. The microchip contains etched through-holes that are capped by a

ceramic or metallic membrane (Figure 1.3).

Patterned metallic layers serve as electrical

conduits for the purposes of device activation. The precise patterning of metal and membranes

dictates which, and how many membranes are activated (ruptured, dissolved or ablated) for a

given signal. The mechanism of activation depends on device design, but viable mechanisms

have included electrochemical dissolution', thermal ablation, thermally induced mechanical

failure and pressure gradient induced mechanical failure [40, 42-44]. The fundamental principle

of activation is that it removes the membrane(s) as a barrier to drug diffusion, thus allowing

release to begin.

1Application of this mechanism in vivo was limited by the adsorption of proteins to the electrochemically

active surfaces.

19

a

r-

Silicon

Cathode

Active

substance

Small reservoir opening

(usually covered by gold membrane)

b

-

Silicon side wall

Large reservoir

opening (for reservoir filling)

Figure 1.3 Schematic of the original MEMS based micro-chip drug delivery device

developed by John Santini, Ph.D.. The drug (active substance) is loaded into micro-machined

pyramidal reservoirs that are each capped by a gold membrane.

Activation induces the

electrochemical dissolution (formation of gold chloride) of the anode (membrane). Figure from Santini

et al.

The benefits of temporal control are more pronounced when viewed in the context of the

disease. Certain therapeutics have been delivered in tandem and demonstrated efficacy that is

greater than additive [21, 45, 46]. One of the agents, frequently is not itself efficacious, but

'potentiates' the primary agent, commonly by inhibiting natural biological methods of resistance

to the primary agent [46]. The efficacy of co-delivery can be temporally dependent such that a

pair of drugs will be much more effective when delivered at separate, specific times. There are

also two specific clinical scenarios where temporal control presents a pronounced advantage

over conventional depot devices. First, having precise control over when release begins allows

20

the clinician to implant multiple doses of drug during the initial procedure and to administer

those doses, at will, any time after implantation via activation. Polymer based devices either

begin releasing immediately or on a time scale dictated by polymer degradation (e.g. in the case

where drug reservoirs are capped by biodegradable polymers of varying molecular weight). The

clinician, therefore, can only implant a single dose or is bound to the dosing regimen dictated by

the degradation of the polymer itself. Second, the cellular composition of a tumor can vary with

time, either as a result of therapy or by natural means. The clinician, therefore, would benefit

from being able to implant devices containing an array of therapeutics, and to decide which

therapeutics are delivered during the course of therapy. This is the popular 'pharmacy on a chip'

idea. These concepts demonstrate that precise temporal control over delivery of multiple agents

would be a superb tool in treating glioblastoma multiforme.

Pulsatile release of drugs in vitro and in vivo has been achieved with a previous

generation of the active device [13, 47]. Controlled release devices utilizing MEMS technology

have been used for in vivo delivery of small molecules and polypeptides and have demonstrated

efficacy in reducing disease progression in a rodent flank glial tumor model [44, 47, 48]. The

first human trials, in fact, with a microchip drug delivery device were just completed with

stunning success[41]. These devices, however, have previously been restricted to the

subcutaneous space due to prohibitively large structural components. This work details the

design, manufacture and testing of a miniaturized MEMS based device aimed at treating GBM.

1.4 Thesis Objectives

The overarching objective of this work was to design and fabricate a miniature active

device that is capable of intracranial implantation and drug delivery in a rodent glioma model.

Sub-aims within this objective were to:

21

-

Conduct a redesign of the device structure and manufacturing techniques to reduce

overall size , while improving reliability

-

Introduce a new activation mechanism aimed at reducing the energy requirements of

activation and improving device reliability

-

Conduct in vitro release experiments to quantify and validate the reliable release of drug

from the device

-

Demonstrate device efficacy in an intracranial rodent model of glioma

1.5 Conclusion

Advances in fabrication techniques and a revamped structural design allowed for the

creation of an active device with characteristic dimensions similar to previously used polymer

based intracranial depot devices [28, 30]. This miniaturized device can now be implanted

intracranially and its efficacy studied in a rodent glioma model. A new activation mechanism

was adopted into the device design. The popular chemotherapeutic temozolomide (TMZ) was

chosen as our active agent and methods of loading and formulating were developed. In vitro

release studies quantified and validated the reliability and kinetics of TMZ release. The device

was designed and manufactured such that 3 different release rates are possible. Several in vivo

studies were conducted to determine the in vivo reliability in function of the device as well as the

efficacy of TMZ delivery against a rodent glioma model. In vivo survival studies in a 9L

gliosarcoma rodent study demonstrated that temozolomide delivery from the active device is

capable of prolonging animal survival. Subsets of these in vivo studies began to investigate the

impact of device release rate and release timing on animal survival.

22

2. Device Design

2.1. Microchip

Figure 2.1 A CAD rendering of the active device in its current form. A liquid crystalline

polymer reservoir (gray) is capped by a silicon chip (purple and gold) that contains 3 nitride

membranes (green). Energy is delivered to the device via polyimide coated copper leads (brown and

gold).

The active microchip device (Figure 2.1) has been an ongoing project in the Cima and

Langer Laboratories for many years. The device as a whole underwent a major revision

throughout this thesis work. This chapter is a summary of the major revisions that were made to

the device as well a brief discussion of the rationale utilized in each revision. The overarching

objective of each modification was to reduce the device size and to improve reliability and

efficacy.

2.1.1 Chip Release Kinetics

23

100

so

80

60

40

20

A

0

150

100

50

0

Time (Days)

4.0

o

3.5

f

__3.0Wi

0O

~2.5

20

M 1.5

1.0

B

0.5

0.0

0

10

20

.-

.-

.

.-

.

30

40

50

a.

.-

.

60

70

80

Time (hrs)

Figure 2.2 Survival plots and in vitro release kinetics for the TMZ laden polymer study

conducted by Brem et al. Survival is depicted as the percentage of animals still alive within a

group as a function of time. Both polymer wafer groups displayed improved median survival and

number of long term survivors (animals surviving until the protocol mandated stop date) when

compared to oral treatment and control groups. Figure copied from Brem et al. (A) The release

kinetics of TMZ are first order and result in a final delivery of approximately 70% of wafer payload in

75 hours. (B)

TMZ laden polymer wafers were chosen as a gold standard for the design of the active

device release kinetics. The wafers had proven efficacious in a 9L gliosarcoma rodent study,

prolonging survival over oral treatment (Figure 2.2 A) [28].

These wafers, when loaded with 5

mg of TMZ, release their payload with first order diffusion kinetics, achieving 70% release in

roughly 75 hours (Figure 2.2 B). This release rate was chosen as target rate to be achieved by

the active device. Zero order approximations of Fick's first law allowed for the total area for flux

required to be determined.

Where J is flux (mg/(s*cm 2)), D is the diffusivity, C is the

concentration, x is the vector normal to the surface of the chip, Ci is concentration outside the

device, C, is the concentration inside the device, A is the surface area for flux and m is the

mass transfer rate.

0

Orifice

Reservoir

Exterior

C

C

0

U

C1

x dimension

Figure 2.3 Sketch of the assumed spatial concentration profile as drug releases from the

device. The reservoir is assumed to be at saturation, Co. The exterior of the device is assumed to be

at infinite sink conditions, Ci = 0 mg/ml. Steady state, uni-directional diffusion is assumed, allowing the

gradient in Fick's first law to be one dimensionalized (Eq. 2) and linearized (Eq. 3).

1= -DVC

Eq. 1

I

Eq. 2

= -D

dC

2x

25

=

-D

Eq. 3

"o

(1-0)

Eq. 4

J= D

D

10 -=; Co =8.8 ';

C, = 0

=; 0.0003 cm

J -A = r

A =Eq.

Eq. 5-7

Eq. 8

9

The total area for flux is divided among several through-holes that are each capped by a

nitride membrane. Two constrictions were utilized to determine the size and number of nitride

membranes that would be incorporated into the device. First, a maximum membrane length

and width was set at 300 micrometers (pm). This dimension was set as a balance between

large membranes for rapid release and robust membranes that would be capable of enduring

the fabrication, assembly and implantation process 2. The suspended nitride membranes are

fabricated by a self-terminating 20% potassium hydroxide (KOH) wet etch. KOH etches silicon

100 anisotropically with an angle of 57.740 from the wafer plane, in this case resulting in a

truncated pyramidal shape with the suspended nitride membrane at the top. Each membrane,

therefore, requires a -720 by 720 pm square on the backside of the wafer to initiate the etch.

This larger feature determined the spacing between membranes, and the chip size per number

of membranes. The membranes we separated and staggered to increase the amount of bulk

silicon. The resulting membrane layout is depicted in Figure 2.4 A.

The second constriction is that the final device dimensions must allow for it to be

implanted within the cranium of a rat. Device dimensions for a payload of 10 milligrams (mg)

MIT Microsystems Technology Laboratory technicians served as knowledgeable sources for the upper bound of

robust nitride membranes. A test wafer was fabricated with 300 by 300 pm membranes and run through the more

vigorous processing steps (piranha, spin coating and dicing) to verify membrane survival before proceeding with

full mask design and purchase.

2

26

Table 2.1: Device dimensions for a 10 mg payload

Length

Width

Depth

Payload

(mm)

(mm)

(mm)

(mg)

5

4.2

4.2

1.6

10

3

3.7

3.2

2.2

10

2

3.7

2.6

2.6

10

# of Membranes

were calculated for devices containing 5 membranes, 3 membranes and 2 membranes (Table

2.1). Varying the number of membranes changes the dimensions of the chip and therefore the

dimensions of the reservoir. The wafers were again used as a standard. Two wafers implanted

simultaneously resulted in the best animal survival. The overall dimensions of two polymer

wafers are approximately 3 millimeters cubed. The final device design incorporates 3

membranes and has overall dimensions of, 3.7 by 3.2 by 2.2 mm3 . Approximations of Fick's law

predict a release rate of 3.5 milligrams in -120 hours.

Patterning of the metal layer was designed such that each membrane can be activated

independently.

The final device, therefore, is capable of 3 different release rates.

This

versatility is a valuable tool in ascertaining what release rate or range of release rates is

efficacious in vivo.

2.1.2 Device Activation Mechanism: A New Approach

A new device activation mechanism was proposed and reduced to practice in an effort to

improve device reliability, namely improved device sealing, as well as to reduce the energy

requirements of the device.

The opening mechanism is a thin metallic fuse that spans a

Betty Tyler of the Brem lab was a priceless resource for discussing the impact of implantation on device design.

Mock-up devices machined from polypropylene were sent to the Brem lab and implanted as a preliminary trial of

the device architecture.

3

27

suspended membrane structure that isolates the contents of the device reservoir from the

environment. The fuse is geometrically laid out on the structurally weakest point of the

membrane. Activation causes rapid resistive heating of the fuse material, creating large stresses

on the suspended structure leading to membrane rupture and reservoir exposure.

Previous device generations did not have a complete, uninterrupted nitride layer that

spanned the entire device. These devices, instead, had titanium and gold membranes that

spanned the orifices created by the KOH etching [13]. Sealing, therefore, depended strongly on

the degree of alignment between the patterned membranes and the etched orifices.

The

fabrication process for the fuse mechanism, however, leaves the original conformal nitride layer

intact. Sealing, therefore, is purely a function of the nitride remaining patent.

The previous activation mechanism relied on the thermal ablation of the gold and

titanium membrane. The fuse mechanism reduces the amount of gold and titanium for a given

orifice size. The energy required, therefore, to heat the metal is greatly reduced. The question

remained, however, whether a thin strip of metal was capable of rupturing a much larger nitride

membrane when heated. The role of fuse width, thickness and geometry was closely studied in

this work (Chapter 4). The primary metrics for activation were the extent to which the membrane

was ruptured and energy requirements for achieving rupture.

The fuse mechanism was ultimately adopted into the final device design. Two fuses, 40

pm wide by 250 nm thick, traverse each membrane. The fuses are patterned such that they

form two Vs with the vertex of each 'V near the center of the membrane. The details of how

these dimensions and geometries were finalized are discussed in detail in Chapter 4.

28

2.1.3 Energy Transmission: Reducing Overall Device Invasiveness

Previous generations of the active device utilized hand soldered connectors and bundled

copper wires to conduct energy to the device. The resulting structure was large, time consuming

to construct, and awkward to implement in vivo. A flexible printed circuit board (PCB) was

designed and outsourced to Flexible Circuit Technologies, Inc. (Minneapolis, MN). The PCB

contains 4 copper leads that are 0.012" by 0.0014" by 1.2 inches. One end the PCB (0.197" x

0.118) is designed to insert into a zero insertion force connector (Tyco electronics, Berwyn, PA)

built into the activation set up. The 4 copper leads splay out into gold coated copper pads

(0.027" x 0.118") spaced to mate with the copper heads of the connector and are reinforced with

a stiffening layer. The other end of the PCB (0.110" x 0.039") is designed to match up to the

gold patterning on the chip (Figure 2.4 A). The copper again splays out into gold coated copper

pads (0.016" x 0.039") that are spaced to allow for gold wire ball bonding between the PCB and

chip. The intervening lengths of copper are coated in an insulating, biocompatible layer of

polyimide. The leads are fixed to the chip with a small amount of biocompatible cyanoacrylate.

The leads are now biocompatible, miniaturized, and can be rapidly and reliably connected to the

chip and allow quick and repeatable device connection to a multi-meter or function generation.

29

Figure 2.4 Color photographs of the chip:lead assembly (A) and entire device and on a United

States penny (B). A close up photograph of the chip:lead assembly. Gold wire bonds are visible

between the gold coated copper pads of the flexible PCB and the patterned gold on the chip (A).

Photograph of the fully assembled device. The chip rests on the internal shoulder of the reservoir,

leaving a small space for the UV curable epoxy to wet into and be cured within.

2.2 Reservoir

The previous reservoir design utilized sand blasted Pyrex@ sheets. These sheets were

coated in epoxy, and stacked to form the reservoir. The result was a large, labor intensive,

structure that had 5 total sealing interfaces. A single component reservoir was designed and

injection molded. The new reservoir is a fraction of the size of the Pyrex @ reservoir and has

only one sealing interface when assembled with the chip.

2.2.1 Material Selection

The reservoir is injection molded (Matrix, Inc. Providence, RI) liquid crystalline polymer

(Vectra 1300 @). Vectra 1300 LCP is a biocompatible, chemically inert, thermoplastic with high

tensile strength and modulus and excellent structural stability. Its low melt viscosity makes it an

excellent candidate for injection molding thin walled parts.

Injection molding the reservoirs

allows for much thinner walls (down to 200 pm) and tighter tolerances to be achieved resulting

in smaller device volume while improving device reliability.

2.2.2 Reservoir Architecture

31

Figure 2.5 is computer aided design (CAD) rendering of the reservoir.

The inner

dimensions of the reservoir were sized such that it would contain a 10 mg payload of TMZ when

loaded in powder form and could be capped by a 3 membrane chip 4 . The overall reservoir

dimensions are 3.7 by 3.2 by 2.2 mm. The side and bottom walls are 400 pm thick. A 200 pm

wide shelf was designed into the inner wall of the reservoir. This shelf and the bordering walls

serve as a seat for the chip, ensuring reproducible alignment and sealing between the chip and

reservoir. The shelf is recessed 400 pm from the top of the reservoir such that when the 300

Shoulder

Lead way

3 mm

Figure 2.5 CAD rendering of the injection molded liquid crystalline polymer reservoir. The

reservoir dimensions are 3.7 by 3.2 x 2.2 mm. The total drug payload is 10 milligrams of TMZ. The

200 pm shelf is visible on the interior face of the reservoir walls. This shelf serves a seat for the chip

and as an upper boundary for drug during the loading process. A lead-way was designed in the top

perimeter of the chip to allow the polyimide leads to project out from the device.

4 A sister, polymer based, device in the lab developed by Alex Scott was used to approximate the packing density of

TMZ.

32

pm thick chip is placed in the reservoir and rests on the shoulder a thin bead of epoxy can be

run around the perimeter of the chip thus securing the chip and isolating the contents of the

reservoir from the environment. One of the short (2.2 mm) bordering walls is only 350 pm tall

(from the shelf) to allow for the previously described flexible PCB to protrude out from the chip

and reservoir assembly.

2.3 Activation Hardware

Peripheral hardware was designed and manufactured to facilitate the rapid and

reproducible activation of each device. The activation hardware consists of two primary units:

the switchbox, and the head piece, which together result in the circuit diagrammed in Figure 2.6.

The switch box contains a printed circuit board designed to accept electrical input from via BNC

connector. Electrical signal is first routed through a 10 ohm resistor. This resistor is in series

with each electrical fuse of the device and is present so that the power source can be

impedance matched to the load (i.e. the device and activation set up). A switch is in series with

the matching resistor. The purpose of this switch is to route current to each membrane

selectively. A 10 ohm shunt resistor is in parallel with the device. Each fuse on the device is

approximately 2 ohms. When the fuse is intact, therefore, the majority of current will flow

through the device and not through the shunt resistor. The resistance of the device increases

dramatically (i.e. >>10 ohms) once the membrane ruptures, causing the majority of the current

to flow through the shunt resistor.

This feature was designed in so that the instant the

membrane ruptures, current would stop flowing to the device, thus minimizing the exposure of

the tissue to heating and potential electrocution.

The head piece contains a printed circuit board that receives current and routes it toward

the zif connector. The head was made as small as possible and separated from the switch box

by a length of copper cabling. This was done so that the ZIF connector can be brought into

33

close proximity of the animal in a variety of orientations. In vivo activations can now occur,

rapidly, and reproducibly, with very little manipulation of the animal or device.

r-

~' -

|

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~~ ~ ~ ~ ~~~

~ ~ ~ ~ ~ ~ ~ ~l--

Rinat<.i

1A-

AIcin biratic

Figure 2.6 Circuit diagram for the activation hardware. The switchbox (dashed box) contains a

matching resistor, shunt resistor and a single pole, triple throw switch. The head piece contains each

membrane on independent, parallel circuits. The matching resistor allows the voltage source to be

impedance matched to the load. The shunt resistor and membrane are in parallel such that, when the

membrane ruptures, current is directed through the shunt resistor.

34

3. Methods

3.1. Clean room fabrication techniques

3.1.1 Fuse Study Devices

The fabrication process involves standard bulk micro-machining, shown in sequence in

Figure 3.1. The first step involves the deposition of low-stress, low pressure chemical vapor

deposition (LPCVD) Si3 N4 on 4 inch, 300 pm thick single-crystal-silicon (SCS) wafers

(orientation 100). One side of the wafer was patterned via standard photolithography and etched

via reactive ion etching (RIE) to define -200 pm by 200 pm regions of bare silicon. Exposure to

20% KOH solution resulted in a self-terminating etch that created 80 by 80 pm suspended Si3N4

membranes. Titanium and gold layers were sputtered after standard organic cleaning. The Au

thickness was varied at 100, 250 nm, 500 nm in order to vary the current density required to

experimentally burst the membranes.

The fuses were then defined using standard

photolithography, followed by sequential timed wet etching steps using gold and titanium

etchants. The lateral dimensions of the fuses were defined by the mask design as 80 pm long,

whereas the width was varied per design as 20, 40, 60 pm.

35

1. SCS Wafers coated

with 200 nm of LPCVD

Si3N4

2. Backside Photolith to

define membranes

3. KOH Etch defining

suspended membranes

4. Front-side Ti, Au

deposition

5. Front-side photolith to

define fuses and

electrodes

6. Au and Ti etching,

followed by organic

cleaning

Figure 3.1 Fabrication process sequence for creating nitride membranes in the microchip.

3.1.2 Three membrane devices

The same general fabrication process as outlined in 3.1.1.1 was used to generate the 3

membrane devices, except with minor edits to particular dimensions and geometries. One side

of the wafer was patterned via standard photolithography and etched via reactive ion etching

(RIE) to define -720 pm by 720 pm regions of bare silicon. Exposure to 20% KOH solution

resulted in a self-terminating etch that created 300 by 300 pm suspended Si 3N4 membranes.

Titanium and gold layers were sputtered after standard organic cleaning. The Ti thickness was

set at 30 nm and the AU thickness at 250nm. The fuses were then defined using standard

photolithography, followed by sequential timed wet etching steps using gold and titanium

etchants. The fuse dimensions were set at 250 nm thick by 40 pm. Fuse shape was varied to

36

determine which geometry resulted in the greatest area of membrane rupture. Eventually, the

fuse deposition step was reduced from a 2 step process to a single step deposition as lack of

conformal deposition on the second step led to variability in device activation reliability.

3.2 TMZ analytics (HPLC)

3.2.1 High Pressure Liquid Chromatography

Two methods were used to quantify TMZ using high pressure liquid chromatography

(HPLC). The first method was employed for samples of TMZ in water, ACSF, and pH buffers.

Briefly, 20uL of sample was quantified at 37C on Agilent 1200 SeriesHPLC using a Synchropak

SCD-100, 5 um, 150x4.6 mm column (Synchrom, Lafayette, IN, USA), a flow-rate of 1 ml/min,

0.01 M Ammonium Acetate (aq):Acetonitrile (92:8) mobile phase, and UV absorption at 316 nm.

A second method was used for quantification of TMZ in fetal bovine serum (FBS). The same

chromatographic conditions were used with the addition of minor sample preparation. 200 uL of

sample was added to 100 uL of 100ug/mL Hydrochlorothiazide. The resulting solution was

vortexed and then spun at 4500 G using a MiniSpin centrifuge (Eppendorf) at room temperature

for 1 minute. Samples of the supernatant were analyzed on the HPLC (These methods were

adapted from Kim et al 1997) [49].

3.2.2 Stability

Stability studies were conducted in HPLC-grade water (Sigma Aldrich), phosphate

buffered saline (PBS) (1x), artificial cerebrospinal fluid (aCSF) and pH7 buffer. Solutions of

approximately 0.5, 0.25 and 0.1 mg/ml were made for each solvent. The resulting solutions

were stored at 37 *C and sampled periodically. Samples were analyzed for TMZ content by the

HPLC methods described above.

37

3.2.3 Solubility

Saturated solutions of TMZ were prepared in pH 1,2,3,4, and 5 buffers and in pH 7

HPLC/MS grade water. Prior to mixing with TMZ, each buffer was analyzed using the HPLC

method described above to determine the presence of any interfering endogenous peaks. No

interfering peaks were found.

buffer solution at 37 OC.

Approximately 10 mg of TMZ were added to 500 pL of each

Each solution was left for 20 minutes at 37

0C

with intermittent

vortexing. Solutions were then spun at 10,000 RPM for 5 minutes. Precipitate was present in

all samples. Samples for HPLC analysis were prepared from the supernatant at the following

dilutions; pure supernatant, 1:5, 1:10, and 1:20. All dilutions were made with the appropriate

buffer pre-heated to 37

0C.

Samples that read in the linear range of the standard curve were

used to calculate solubility by adjusting the read concentration by the appropriate dilution factor.

3.3 Device Filling

3.3.1 Fuse Study Devices

Release study devices were assembled in the following fashion. The wafers were diced,

creating chips that each contained one membrane. The chips were affixed to Pyrex@ reservoir

pieces via UV cured epoxy. The Pyrex reservoir pieces are 2.2 mm thick, 6.5 mm long, 5 mm

wide, and drilled to define a cylindrical reservoir with a 3.5 mm diameter. The base layer was

affixed to the backside of the reservoir piece via UV cured epoxy. The devices were filled with a

motorized syringe unit (World Precision Instruments, USA) to provide a precise payload volume.

The input port was sealed with UV cured epoxy (Dymax, Inc) after filling the devices. The error

for volume loading was estimated as 1 pL. Copper wires were soldered directly on the electric

pads, and covered with UV-epoxy to prevent any contamination, and guarantee electrical

isolation.

38

3.3.2 TMZ Devices

Reservoirs were loaded with TMZ in solid form in order to maximize payload and drug

stability [37]. Polyethylene glycol (PEG) was added to displace air trapped within the packed

TMZ powder, therefore reducing air bubble formation within the reservoir. Molecular weight

1450 PEG was used because its melting temperature is between 43-46

0C.

The PEG,

therefore, is solid when implanted at body temperature, but the TMZ:PEG mixture can be

melted at moderate temperatures [37].

The process begins by packing the reservoir with TMZ powder. The reservoir is then

placed in a fixture that allows molten PEG to be pipetted onto the TMZ in each reservoir. The

second half of the fixture is then joined with the first half such that a high air permeability Teflon

AF membrane (Biogeneral Inc, San Diego, CA) is fixed over the PEG:TMZ surface. The

assembled fixture is placed in a vacuum oven and vacuum is pulled at 55

0C

for 20 minutes.

When the two halves of the fixture are joined the only path for air to travel is through the

membrane and out of the fixture. The TMZ and PEG are therefore trapped within the reservoir,

but air is free to flux out. Under vacuum and 55

0C

conditions, the air within the powder drug

fluxes out of the reservoir through the Teflon membrane. The molten PEG is then free to wet

the TMZ powder and fill in the interstices of the packed TMZ, therefore creating a homogeneous

mixture of TMZ and PEG throughout the reservoir. This process is repeated (typically 3 times)

until all of the air has been removed from the PEG:TMZ mixture.

3.4 Device Assembly

Polyimide coated copper leads were attached to each chip by biomedical grade

cyanoacrylate (Loctite Intl.).

A precision machined fixture was designed and fabricated to

ensure that the gold coated copper leads aligned precisely with the copper pads of the chip and

39

that a robust bond was made. Each copper lead was gold wire bonded to its corresponding

gold pad on the chip thus achieving electrical connectivity.

The chip:lead assembly was then placed on the shoulder structure of the reservoir such

that the upper most walls of the reservoir surround the chip. A bead of biomedical grade UV

curable epoxy (Dymax Corp., Torrington, CT) is then run around the perimeter of the chip such

that it fills the gap between chip and reservoir wall. The epoxy was then cured in place with a

compatible UV light source (Dymax Corp., Torrington, CT).

3.5 Release procedures

Fuse study devices were filled with known amounts of radioactive (C-14) mannitol

(Moravek Biochemicals Inc., Brea, CA) and activated to initiate release. Once activated, each

device was placed in a 4 milliliter (ml) stirred water bath at room temperature. Samples were

taken periodically to quantify the amount of radioactive material in the bath. Fresh water was

added to maintain the bath volume at 4 ml. Samples were mixed with scintillation fluid and

analyzed for radioactive content using a Packard Tri-Carb 2810 TR liquid scintillation counter

(Perkin Elmer, Waltham, MA).

TMZ devices were filled with known amounts of drug and then activated and placed in

agitated baths at 370C.

Release studies were conducted in both water and artificial

cerebrospinal fluid (Adapted from Alzet). The bath volume and frequency of sampling was

varied to ensure that samples contained quantifiable amounts of drug, but maintained

approximate sink conditions.

3.6 In vivo Studies

Female Fisher 344 rats weighing 125-175 grams were purchased from Charles River

Laboratories (Wilmington, DE). All animals were given free access to food and water at all

40

times. All animals were housed in accordance with the Johns Hopkins University Care and Use

Committee rules and regulations. Animals were intracranially implanted with 9L gliosarcoma

obtained from the UCSF Tumor Bank (San Francisco, CA) that has been passaged

continuously in carrier flanks of F344 rats.

The intracranial tumor and/or device implantation method used, as previously detailed by