Richard, this bullet is the first priority for me. ... find that as I shorten the nose on bullets I...

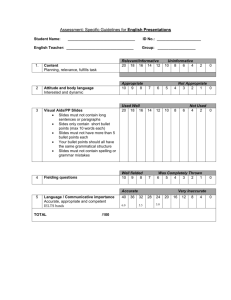

advertisement

Richard, this bullet is the first priority for me. It has a short nose to minimize slumping. I find that as I shorten the nose on bullets I have now, but going to a flat nosed punch or a blunter radius, or both, the better accuracy I get. This design is ultimately intended to optimize aerodynamics w/ minimal slump. This little ridge at the ogive is only 3 thousands of an inch high and has a 45 degree leading edge. Dick feels that this is very important although it costs a very slight amount in terms of ballistic coefficient. According to Dick, there will be a point near the ogive where turbulence must ultimately occur (sounds reasonable), but without the ridge the point that this happens could very slightly along the side of the bullet, causing an imbalance in friction I suppose. The little ridge or delaminator ring would make this initiation of turbulence occur at the same point over the entire circumference, and remove inconsistency. Sounds reasonable to me. Dick has a pretty good track record of designing slow moving bullets like this so I think his idea is likely to have some merit. At least, I’m willing to give it a go. Let me know what you think. This is the same bullet in cross-sectional diameters rather than radii. The tip can be sliced off flat to a 0.125”(or there abouts) meplat for the ejector pin to push against. Richard, this picture shows the same nose but a different base. I presume that this bullet could be made from the same point forming die, but with a different base punch. If it can’t, so be it. I don’t want to invest too much in this experiment, but if it’s only the price of a punch, it would be worth the trouble to me. I have asked that the rebate be about 0.02” so that it will be strong enough that the lip of the base punch will not deform. If it could be thinner, so much the better, if you feel it should be thicker, that’s okay too. With this rebated base, I think that the base punch might still be a bit fragile given the longish straight part. It would be fine with me if it was a straight taper from the rebate to the final base diameter. I think this would work much better when making the actual bullet, although it might compromise the flight somewhat. BTW, this bullet is predicted to have a ballistic coefficient of 0.59 in a 477 gr version. That’s more than 20% better (if true) than anything I’ve seen. G1 Bc v s S pe ed 0 .8 0.8 0 .7 0.7 0 .6 0.6 0 .5 0.5 G1 Bc Drag coeffic D ra g Co e ffic ie n t v s S p e e d 0 .4 0 .3 0.4 0.3 0 .2 0.2 0 .1 0.1 0 .0 0 .5 0 1 1 .5 2 2 .5 0.5 3 1 FN c D R N Bc G1 c D Gunn/Danielson Secant Paper Patch Flat Base Secant/shank junction angle 3.5 degrees. Boundary air delaminator .003" by 45 degrees. Ogive radius 1.75", nose tip radius 0.15625" 547 grains when swaged from 2.5% tin/lead alloy, Nose represents 27% of total weight Stability Factor 2.5 with 18" twist and 1350 fps MV 3 0 .8 0.8 0 .7 0.7 0 .6 0.6 0 .5 0.5 0 .4 0 .3 FN B c G1 B c G1 Bc v s S pe ed G1 Bc Drag coeffic 2.5 Dr. Richard F. Gunn Work #: (203) 378-3398 Fax #: (203) 377-8251 Email: rfgunn@aol.com D ra g Co e ffic ie n t v s S p e e d 0.4 0.3 0 .2 0.2 0 .1 0.1 0 .0 0 .5 2 S p e e d (M a c h # ) S p e e d (M a c h # ) RN cD 1.5 0 1 1 .5 2 2 .5 3 S p e e d (M a c h # ) RN cD FN c D G1 c D Gunn/Danielson Secant Paper Patch Boat Tail Secant/shank junction angle 3.5 degrees. Boundary air delaminator .003" by 45 degrees. Ogive radius 1.75", nose tip radius 0.15625" 477 grains when swaged from 2.5% tin/lead alloy, Nose represents 27% of total weight Stability Factor 2.5 with 18" twist and 1350 fps MV 0.5 1 1.5 2 2.5 3 S p e e d (M a c h # ) R N Bc FN B c Dr. Richard F. Gunn Work #: (203) 378-3398 Fax #: (203) 377-8251 Email: rfgunn@aol.com G1 B c