T Implementation of Single-Use Technology in Biopharmaceutical Manufacturing

advertisement

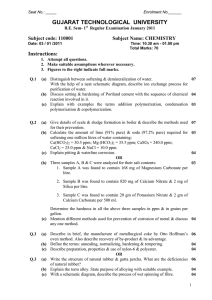

B i o P r o c e s s Technical Implementation of Single-Use Technology in Biopharmaceutical Manufacturing An Approach to Extractables and Leachables Studies, Part Three — Single-Use Systems Weibing Ding and Jerold Martin T he increasing application of single-use components and systems in bioprocessing represents one of the most significant changes in biopharmaceutical manufacturing in recent times. Driven by various factors such as improved efficiency, flexibility, and economics, this trend also presents specific challenges to end users. In one industry review by Langer, extractables and leachable compounds from disposable components were considered by end users to be a major area of potential concern regarding safety, efficacy, and stability of the pharmaceutical product (1). In a more recent survey by the BioProcess Systems Alliance (BPSA), however, extractables and leachable compounds were considered by only 13% of respondents to be a barrier in integrating single-use technologies into existing or new processes (2). The Product Focus: All biologics Process Focus: Upstream and downstream processing Who Should Read: Product/process development, QA/QC, and analytical Keywords: analytical methods, process validation, disposables Level: Intermediate 52 BioProcess International N ovember 2010 apparent change in thinking may be due, in part, to an increased amount of information available in published case studies, reviews, and industry guides such as those issued by BPSA (3, 4) covering regulatory issues, risk assessment, and test programs. Extractables are typically determined with laboratory tests using standard extraction fluids termed model solvents. Such tests are designed to exceed worstcase product and process conditions and reveal chemical entities that may migrate from process components into the final product as potential leachables. The quality and quantity of materials extracted from an organic polymer component depends not only on the materials of construction, but also on the contact fluid composition, temperature, contact area, and contact time. In a multicomponent single-use system, the importance of each parameter in the migration of potential leachable compounds will vary according to component type and process conditions. For example, a sterile connector may have only transient exposure to a fluid during transfer, whereas a flexible biocontainer may be in contact with product or process fluid for many hours, days, or even months. Similarly, a typical small capsule filter with an effective filtration area of 0.15 m2 may have an internal surface area of ~150 m2 compared with a 0.5-L flexible Pall life sciences (www.pall.com) biocontainer with a surface area of only 0.05 m2 ­— 3,000× smaller. For these reasons, extractables studies should be designed and performed under conditions appropriate for each specific component and process application. That can provide an accurate and suitable assessment of the potential for the component or system, to release leachables into the drug product. We applied this customized approach to two previous studies on extractables. In the first study, we reported extractables results from tests on sterile connectors and membrane filter capsules (5). The test articles were preconditioned by gamma irradiation at 50 kGy to represent worst-case sterilization conditions and extracted under exaggerated simulated conditions using a recirculating system with extraction times of four hours for ethanol and 24 h for deionized (DI)water. Qualitative and Table 1: Single-use components in a test system Component Sterilizinggrade capsule filter Figure 1: Fluid supply system and filter manifold Materials of Construction Membrane: PVDF surface-modified with hydrophilic acrylate copolymer; support and drainage = nonwoven polypropylene (PP) capsule shell/filter; hardware = PP Sterile connector Quick connector Flexible tubing Polycarbonate 1-L biocontainer Low-density polyethylene Fluid Supply PTFE Tubing PTFE Diaphragm Pump System Sampling Point for Negative Controls Sterile Connector Filter Manifold Sterilizing-Grade Capsule Filter Sterile Connector Acetal SEBS* thermoplastic elastomer; platinumcured silicone Line 1 Flush Sample Line 2 Time = 0 54 BioProcess International N ovember 2010 Line 3 Time = 7 days * styrene-ethylene-butylene-styrene/PP copolymer quantitative extractables results on sterile connectors using 13 analytical methods showed very low levels of extractables, mostly below the limit of detection (LOD) or no different from the controls. We concluded that the potential for these connectors to release leachable materials into compatible drug products was very low. For the capsule filters, higher levels of extractables were obtained, as expected from the high internal surface area of the microporous membrane within the filter. Qualitative analysis showed that all compounds detected were consistent with the filter’s materials of construction, which passed biological safety tests such as USP <88> “Biological Reactivity, in Vivo, for Class VI Plastics.” In the second study, we characterized extractables from thermoplastic tubing and flexible biocontainers (6). For the tubing, a worst case was represented by presterilizing with gamma irradiation at 50 kGy and agitating the test fluid of ethanol or DI water within clamped segments of tubing for 72 h. Very low levels of extractables were detected, many below the limit of quantification (LOQ ). For the biocontainers, a worst case was simulated by filling with test fluid and storing at 40 °C for 30 days. Results showed very few organic compounds above the LOD for water extracts and those identified were in the low parts per million (ppm) or parts per billion (ppb) range. Ethanol extracts gave some additional identifiable Extraction Fluid Glass Reservoir Total Length of Tubing from Point A to Final A Connector Identical for Flexible Tubing: A All Six Lines Platinum- Cured Silicone or SEBS Thermoplastic Elastomer Pinch Clamp 1 Pinch Clamp 2 Simultaneous Flow Through Lines 2– 6 to Biocontainers in Line 6 Collection Manifolds Time = Line 5 12 months Time = Line 4 6 months Time = 1 month Table 3: TOC, conductivity, pH and ions in water extracts1 Sample TOC (ppm) Conductivity System flush 2.81 ppm 7.08 µS/cm Storage time: 0 0.18 ppm 1.21 µS/cm Storage time: 1 month 0.34 ppm 1.82 µS/cm Storage time: 12 months 0.70 ppm 3.36 µS/cm Negative control or 0.003 ppm 0.82 µS/cm blank 1 pH 4.71 5.56 5.46 5.02 5.77 Acetate 0.025 ppm 0.006 ppm 0.006 ppm 0.310 ppm <0.001 ppm2 Formate 0.245 ppm 0.020 ppm 0.039 ppm 0.043 ppm <0.002 ppm2 Average values from two test systems; negative control values not subtracted; 2 limit of detection (LOD) compounds, which were mostly oligomers of the base polymers or degradation products of the antioxidants used in the polymer formulations. Here we report on extractables studies performed on a total system containing all four components previously tested: capsule filter, sterile connectors, plastic tubing, and flexible biocontainers. The test protocol was designed to simulate a typical operating procedure for this type of single-use system and under typical worst-case conditions. Objectives We set out to meet four objectives • To quantify and characterize extractables from a model multicomponent, single-use system. • To study the effect of system flushing • To assess the effect of storage and extraction times of up to one year in biocontainers • To develop a method of determining extractable and potential leachable compounds for process validation of single-use processes in biopharmaceutical manufacturing. Table 2: Analytical methods used for assessment of extractables Extract Analytical Method Total organic carbon (TOC) Water X Ethanol n/a pH X n/a Conductivity X n/a Ion chromatography (IC) Nonvolatile residue (NVR) X n/a X X Fourier transform infrared (FTIR) Ultraviolet spectroscopy (UV) Direct-injection gas chromatography/mass spectrometry (GC/MS) Headspace GC/MS X X X X X X X X Derivatization GC/MS X X High performance liquid chromatography with UV detection (HPLC/UV) Liquid chromatography /MS (LC/MS; LC/MS/MS) X X X X Inductively coupled plasma/MS (ICP/MS) X X Figure 2: Biocontainer manifold Figure 3: Procedure for extraction on single-use system Sterile Connector for Attachment to Filter Manifold Pinch Clamp Quick Connector Assemble fluid supply system. Recirculate ethanol to clean system. Validate cleanliness using GC/MS UV, and TOC. Rinse with DI water. SEBS Thermoplastic ElastomerBased Tubing Quick Connector Pump 2 L of DI water into Line 1 biocontainers. Quick Connector 1-L Biocontainer Bag 1-L Biocontainer Bag Label as “system flush” and analyze. Flush System Figure 4: FTIR spectra of NVRs Open pinch clamps on all Line 1 manifolds. Close Line 1 and open clamps to Lines 2–6. Connect assembled manifolds to fluid supply system. Pump 5 × 2 L of DI water simultaneously to Lines 2–6 and into biocontainers. Analyze Line 2 extract. Pump 6 × 2-L samples into PTFE bottles for negative controls. Connect gammairradiated filter and biocontainer manifolds by sterile connectors. Store remaining filled biocontainers for specified period and analyze extracts. System Flush Table 4: Nonvolatile residues in extracts1 Flush Sample 4,000 4000 3,500 3500 3,000 3000 2,500 2,000 1,500 1,000 500 System one Year Wave 2500 number 2000 1500 1000 500 System One Year 4000 4,000 12-Month Sample 2500 2000 1500 1000 500 2,500 1,000 500 3500 3000 Wavenumber (cm-1) 3,500 3,000 2,000 Wavenumber (cm- ) 1,500 1 2 Sample System flush Storage time: 0 Storage time: 12 months Water 1.9 mg 0.4 mg 1.1 mg Ethanol 119 mg 142 mg 216 mg Negative control <LOQ2 <LOQ2 Negative control values not subtracted. LOQ (Limit of quantification) was 0.1 mg Wave number Experiment Our test system included three separate segments: f luid supply system, filter manifold, and biocontainer manifold (Figure 1). The f luid supply system provided clean extraction f luid for the singleuse system manifolds and a sampling point for negative controls. To maintain the extraction f luides at highest purity, we used a polytetraf luoroethylene (PTFE) diaphragm pump and tubing with a glass reservoir. The filter manifold contained identical lengths of f lexible tubing between the filter and the final sterile connector to ensure the same contact area and extraction conditions. Each line was connected to a biocontainer manifold (Figure 2). Line 1 was used for the system f lush sample, and the other five lines were used for extractables time tests from zero to 12 months. The biocontainer manifold was designed to collect 2 L of extraction f luid using 2-L × 1-L biocontainer bags. The test manifolds were gamma irradiated at 50 kGy and all extractables tests (including biocontainer storage) were performed 56 BioProcess International N ovember 2010 at 21 °C. Test solvents were 18 MΩ-cm DI water and 100% ethanol HPLC grade. The complete study was performed in duplicate. The main components in this model single-use test system were the same as those used in our previous extractables studies on the individual components (5, 6). Table 1 shows further details. Test Procedure: Figure 3 summarizes the major stages of the test procedure. Analytical Methods: We performed qualitative and quantitative analyses on the extracts using 13 methods and reported details about these methods in previous studies (5, 6). Table 2 lists our analyses on water and ethanol extracts. Results and Discussion Because of space restrictions, we can’t report here our detailed results (information available from Pall Life Sciences on request). However, the main and the most significant results of the extractables analyses are presented here, which can be conveniently divided into three groups. Group 1 — TOC, Conductivity, pH, and Ion Chromatography: We performed these analyses on water extracts only (Table 3). TOC: TOC levels, after a system flush, were very low at <1 ppm, even after 12 months storage and extraction. The initial system-flush sample showed, as expected, a higher value (2.81 ppm) due to the removal of readily soluble compounds by the 2-L flush volume. In our previous extractables studies, we established that the bulk of the extractables were derived from the high-area filter membrane (5). Those results suggest that best practice for lowest leachable compounds is to perform an initial pref lush, whenever possible, of either the full system or the filter, and to discard the f lushed liquid. Conductivity: The conductivity values showed, after system flush, only a small increase over negative control and a slow rise in values over the 12 month storage and extraction period. pH: After the system flush, the pH values showed a shift of 0.21 units at zero time rising to 0.75 units after 12 months. These shifts are within one pH unit and in compliance with US Pharmacopoeia requirements. Ion Chromatography: We used ion chromatography to measure acetate and formate levels. Both compounds can be found in small quantities in most plastics and may come from the raw materials, but they are also the smallest breakdown products of larger molecules and can be a strong indicator of chemical instability of a component, especially under extreme conditions. All extracts, including the system f lush sample and the 12 Table 5: Identity of compounds in deionized water (DI) and ethanol extracts by GC/MS analysis Method Headspace GC/MS for volatiles Direct injection GC/MS for semivolatiles DI Water 12- Month Flush Sample Sample No peaks1 No peaks1 No peaks2 Derivatisation3 Oxalic acid GC/MS for organic (0.056 ppm) fatty acids Succinic acid (0.042 ppm) Ethanol Flush Sample 3-Methylpentane, hexane, methylcyclopentane, acetal, 3-methylheptane and octane; all <3 ppm Decamethylcyclo-penta-siloxane, dodecamethyl-cyclohexasiloxane, a series of siloxanes, 1,3-DTBB4, 2,4DTBP5, 1-dodecanol, lauryl acrylate and hydrocarbon isomer; all <1 ppm No peaks2 Benzoic acid (0.042 ppm) Oxalic, malonic, lauric, succinic, palmitic and stearic acid all <0.3 ppm 12-Month Sample 3-Methylpentane, hexane, methylcyclopentane, acetal, 3-methylheptane, octane, 2-methylpentane, cyclohexane, and 1-octene; all <5 ppm Decamethylcyclopentasiloxane, dodecamethylcyclohexa-siloxane, a series of siloxanes, 1,3-DTBB4, 2,4-DTBP5, 1-dodecanol, lauryl acrylate, hydrocarbon isomers, 1-tridecanol, 1-pentadecanol, 1-octadecanol, and a series of aliphatic hydrocarbons (C12 to C26); all <3 ppm Succinic, palmitic and stearic acid; all <0.3 ppm 1 Limit of detection: 0.001 ppm using 2-methyl-2-propanol; 2 Limit of detection (LOD): 0.010 ppm using 2,4-ditertbutylphenol; 3 BF3/1-butanol used as derivatization agent; 4 1,3-ditertbutylbenzene; 5 2,4-ditertbutylphenol months storage sample, showed levels <1 ppm. Group 2 — Nonvolatile Residues (NVR) and Fourier Transform Infrared (FTIR) Spectroscopy: NVR analyses provide a quantitative measure of low volatility extractables. Dried residues (obtained after evaporation of test solvent) from the extract can then be analysed qualitatively by FTIR to identify specific functional groups and differences between test extracts. Using the results of NVR in water and ethanol extracts (Table 4) we can make several conclusions. First, the NVR level in the flush sample for DI water of 1.9 mg is relatively low compared with the ethanol extract of 119 mg. That is typical of extractables data on singleuse components because ethyl alcohol is a more aggressive solvent, especially for additives and residual oligomers in organic polymers. Second, results show a timedependent, gradual increase in extractables for both water and ethanol. That indicates a continuous but slow leaching of extractables from the polyethylene biocontainer, the only component in contact with the f luid during storage. Figure 4 shows FTIR spectra of residues in the ethanol extract from the system f lush and the extracts after 12 months storage. The major difference between spectra is the presence of some peaks (circled) in the system-f lush sample, which are 58 BioProcess International N ovember 2010 Table 6: Elements in water and ethanol extracts Element B Na Mg Water Extract Flush Sample 12-Month ppb1 Sample ppb1 1.25 1.93 2.82 0.27 0.57 0.17 Ethanol Extract 12-Month Sample Flush Sample ppb1 ppb1,3 <LOD <LOD <LOD <LOD <LOD <LOD Al K Ca 1.15 0.32 5.6 <0.14 <0.15 3.0 <LOD <LOD 5.9 <LOD <LOD <LOD Ti Cu Zn 0.11 0.18 0.34 <LOD2 0.2 0.57 <LOD <LOD <LOD <LOD <LOD <LOD 1 Corrected with negative control or solvent blank; 2 LOD = 0.04 ppb; 3 LOD of 1­­–5 ppb due to dilution not present in the extracts stored for 12 months. This result indicates that these compounds can be easily removed by system f lushing to minimize extractables. The absence of additional peaks after storage indicates a relatively stable environment during storage with no significant extraction of additional nonvolatile compounds or release of nonvolatile breakdown products. Group 3 — GC/MS, LC/UV/MS, and ICP/MS: These methods are powerful tools for identifying a range of organic compounds and inorganic elements in extraction fluids and can quantify them down to ppm, ppb, and, in some methods, ppt (parts per trillion) levels. GC/MS Analyses: We applied the following analytical strategies for GC/ MS when investigating trace levels of extractables: • Concentrate extracts to maximize detection • Carefully interpret MS data • Use authentic standards • Match the mass spectra and retention times • Ensure accurate calibration and quantification • Perform recovery studies. Results show no detectable peaks in water samples for volatile and semivolatile compounds in both the f lush sample and after 12 months storage and extraction (Table 5). Derivatization results for organic fatty acids identified only three acids, all <0.1 ppm. Because most pharmaceutical products are water-based, GC/MS results indicated very low extractables for these types of compounds can be expected for this type of multicomponent single-use system. The ethanol extracts revealed several identifiable volatile and semivolatile compounds in the flush sample (Table 5) and some additional compounds (shown in italics) after 12 months of storage and extraction. The data demonstrate a much stronger solvent action of ethanol. However, all compounds can be traced back to the individual single-use components in the test system, as reported previously (5,6). Furthermore, all were present at a low concentration of <5 ppm. Similarly, some additional fatty acids were identified in ethanol extracts but all at concentrations <0.3 ppm, with no additional compounds present after 12 months of storage. LC/UV/MS analyses are ideal for detecting trace levels of antioxidants and their degradation products, as well as heat-sensitive organics in extraction fluids. An analytical strategy to achieve precise identification and highest possible resolution must include careful evaluation and interpretation of MS data, use of authentic standards, matching mass spectra and retention times, and precise calibration and quantification. Analysis of water samples by LC/ UV/MS showed no peaks at LOD between 0.1 ppm and 1 ppm using a mixture of antioxidants as standards. For the ethanol extracts, the compounds identified included 1,3-ditertbutylbenzene (1,3-DTBB) and 2,4-ditertbutyl phenol (2,4-DTBP), which we identified in previous studies as degradation products from polymer additive (Irgafos 168 phosphate) in specific single-use components of the test system (5, 6). ICP/MS Analyses: Inorganic elements, especially heavy metals, can influence the efficacy, safety, and stability of some drug products. Analysis with ICP/MS provides a convenient and highly sensitive method for identifying and quantifying a wide range of metallic ions. The ethanol extracts showed no elements higher than the LOD or LOQ , except for calcium at 5.9 ppb (Table 6). For water extracts, nine elements were detected in the flush sample at low ppb concentrations. The 12-month sample showed reduced levels, mostly <1 ppb or the LOD, indicating that the system flush had generally removed the majority of the extractable elements. Discussion and Conclusions In this study, we generated additional information about extractables from single-use systems that could impact the qualification and validation of biomanufacturing processes. In our previous studies, we took one type of component (e.g., a capsule filter or a biocontainer) and designed a specific extractables procedure to represent a worst-case condition for that component (e.g., continuous recirculation of extraction fluid through a filter or storage of filled biocontainers at 40 °C for 30 days). In this way, a worst-case extractables profile (qualitative and quantitative) could be established for each component. This data library facilitates selection and qualification components for single-use systems. Furthermore, during process validation, if such data from all components of single-use system are available and the test conditions represent a worst case to process conditions, then little or no further extractables testing may be required. Otherwise, a process- and productspecific extractables validation study may need to be performed on the whole single-use system for determining potential leachables and assess any toxicity or impact on quality of a final drug product. The study results for components (5, 6) and model single-use system (this article) can facilitate process- and product-specific extraction tests (potential leachables) using model solvent as well as process fluid because the potential leachable compounds (at least the majority of them) are already identified. Furthermore, the effect of preflushing the system could provide supporting data for preparing suitable standard operating procedures (SOPs) to minimize leachable compounds. From the results, we showed: • It is feasible to perform extractable studies on complete singleuse systems. • A short system flush can remove a substantial proportion of extractable material. • Water extractables were substantially lower than ethanol extractables for organic compounds. • In most cases, no significant increase in extractables was seen after storage for up to 12 months. • Identified compounds were also found in previous studies on the individual components. • Those compounds could be traced to the materials of construction of single-use components. • With advanced analytics, a wide range of compounds can be identified and quantified. Such characterization is ideal and suitable for analyzing extractables from single-use systems. We conclude that a suitable method for extractables testing of multicomponent single-use systems has been developed and qualified. The data generated can also be available and of benefit to end users in their qualification and validation of similar bioprocesses. References 1 Langer E. Advances in Large-Scale Pharmaceutical Manufacturing; 2nd Edition, BioPlan Associates Inc., Rockville USA. November 2007. 2 Caine B. BPSA Survey: The Impact of Single-Use Technologies. Bio-Process Systems Alliance, 2009; www.bpsalliance.org. 3 Colton R, et al. Extractables and Leachables Subcommittee of the Bio-Process Systems Alliance. Recommendations for Extractables and Leachables Testing. BioProcess Int. 6(3) 2008: S28–S39. 4 Martin J, et al. Recommendation for Testing and Evaluation of Extractables from Single-Use Process Equipment. Bio-Process Systems Alliance, April 2010; www.bpsalliance. org. 5 Ding W, Martin J. Implementing SingleUse Technology in Biopharmaceutical Manufacturing: An Approach to Extractables/ Leachables Studies, Part One — Connectors and Filters. BioProcess Int. 6(9) 2008: 34–42. 6 Ding W, Martin J. Implementing SingleUse Technology in Biopharmaceutical Manufacturing: An Approach to Extractables/ Leachables Studies, Part Two — Tubing and Biocontainers. BioProcess Int. 7(5) 2009: 46–51. • Weibing Ding is technical manager at Pall Life Sciences Scientific and Laboratory Services, David B. Pall Technical Center, 25 Harbor Park Drive, Port Washington, NY 11050; 1-516-801-9254, weibing_ding@pall.com. Jerold Martin is senior vice president of scientific affairs at Pall Life Sciences; 25 Harbor Park Drive, Port Washington, NY 11050; 251516-801-9086, fax 1-516-484-5228; jerold_ martin@pall.com; www.pall.com.