Fatigue Crack Growth Importance of Fatigue • Bottom line: • Example:

advertisement

Importance of Fatigue

• Bottom line: Fluctuating loads are more detriment than

monotonic loading

• Example: Comet Airliner– First jet propelled aircraft.

Fatigue Crack Growth

- Actual cabin differential pressure during flight 8.5psi (57kPa)

Ashraf -F. Bastawros

-The design pressure was 20psi (138kPa), [FOS >2].

Aerospace and Engineering Mechanics

Iowa State University

bastaw@iastate.edu, X4-3039

Howe Hall Rm. 2347

- Pressurized once to double its working pressure of 114kPa

Thought would not fail under the action of fatigue {WRONGE}

¾Crack growth due to cyclic loading caused catastrophic

failure of the aircraft

Spring 2006

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

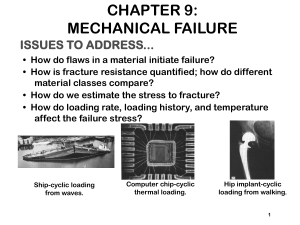

Types of Fatigue Loading

Fatigue Failure

• Mechanical Fatigue: pure fluctuation in applied load

• Fretting Fatigue: cyclic stress with oscillatory relative motion

and frictional sliding.

• Contact Fatigue: rolling and sliding contact

• Corrosion Fatigue: chemical aggressive or embitterment.

• Creep Fatigue: cyclic loading at constant elevated temperature

Aloha Airlines, 4/28/1988. The aircraft lost 1/3 of its roof

due to a stress fracture while cruising at 24,000 feet.

• Thermal Fatigue: cyclic temperature at constant or zero load

• Thermo-mechanical Fatigue: combined cyclic variation of both

From: http://www.airdisaster.com/

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

loading and temperature

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

1

Cyclic Loading definitions

Cyclic Loading Definitions

Parameters defining a cyclic loading history

- Stress Range:

∆σ = σmax −σmin

- K-Range:

∆K = Kmax − Kmin

- Stress amplitude:

•Typical stress history during cyclic loading

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

σa = 12 (σmax −σmin )

- Mean Stress:

σm = 12 (σmax +σmin )

- Loading ratio:

R=

- Nf : No. of cycle to failure

Iowa State University

Cyclic Loading Definitions

σmin Kmin

=

σmax Kmax

Fracture Mechanics, Spring 2006

Ashraf Bastawros

Cyclic vs. Static Loading

¾Frequency: f (Hz or cycle/s). Rotating machinery at 3000rpm,

f = 50Hz. The running frequency generally influences fatigue

crack growth if there are environmental effects present, such

as humidity or elevated temperature. The frequency of the

on/off cycle could be more detriment in limiting the life.

Key difference between static and cyclic loading

¾ Static: until applied K reaches K c ( 30MPa m for example )

the crack will not grow

¾ Cyclic: K applied can be few percent of K c ( 3MPa m

Over time, the crack grows.

for example )

¾Waveform: is the profile of the stress history; sine wave,

square wave or any other regular or random profile. It would

influence the fatigue crack growth if there are environmental effects.

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

The design could be safe under static loading, but any cyclic

loading must be considered.

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

2

Fatigue Crack Growth

Fatigue Crack Growth

σ

B

da

= f (loading)

dN

a

Crack length, a

σ 2 > σ1

FG da IJ

H dN K

a1 ,σ 2

FG da IJ

H dN K

a1 ,σ 1

Cycle N

σ

Paris, Gomez and Anderson (A rational analytical theory of fatigue, the Trend in

Engineering, Vol 13, 9-14, 1961)

postulated that the rate of crack growth

depends on ∆ K in the following way:

Iowa State University

∆a

da

m

→

= C ( ∆K )

dN

∆N

Fracture Mechanics, Spring 2006

Ashraf Bastawros

da

m

= C ( ∆K )

; ∆K = Y ∆σ π a

dN

Y is a geometric constant depends on the specimen type

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

Fatigue Crack Growth

Iowa State University

Fracture Mechanics, Spring 2006

Ashraf Bastawros

3