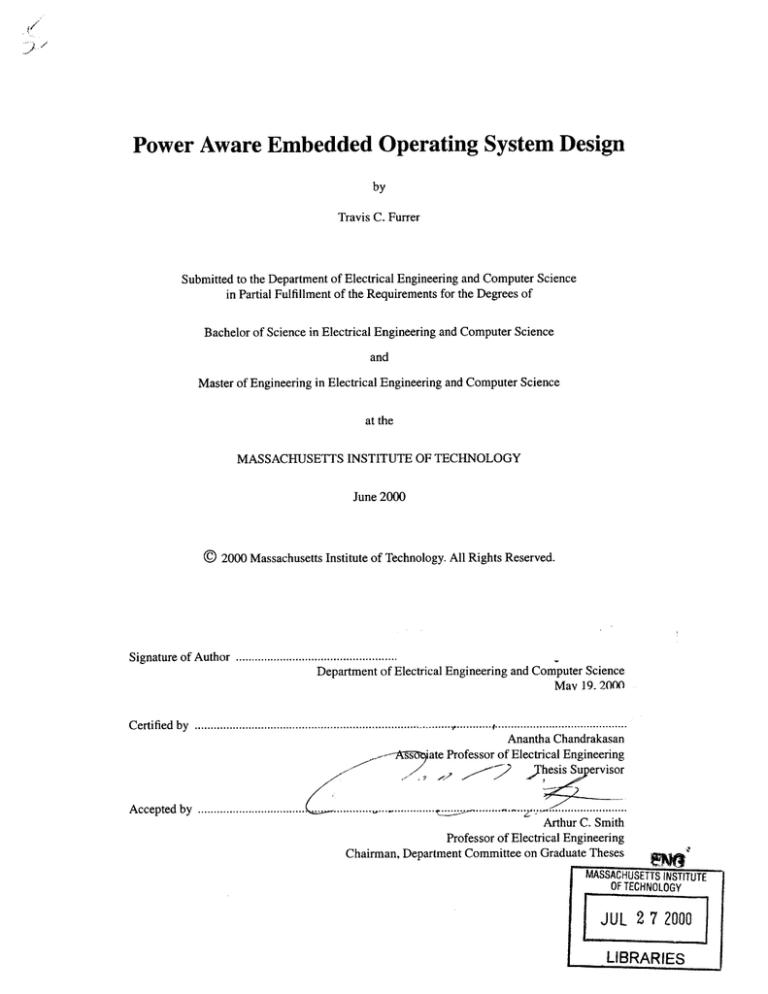

Power Aware Embedded Operating System Design

by

Travis C. Furrer

Submitted to the Department of Electrical Engineering and Computer Science

in Partial Fulfillment of the Requirements for the Degrees of

Bachelor of Science in Electrical Engineering and Computer Science

and

Master of Engineering in Electrical Engineering and Computer Science

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2000

2000 Massachusetts Institute of Technology. All Rights Reserved.

Signature of Author ..................................................

Department of Electrical Engineering and Computer Science

May 19.2000

............................

Anantha Chandrakasan

Professor of Electrical Engineering

C ertified by ...........................................................................

sA

iate

hesis Su ervisor

Accepted by ..................................

...........

.................

.

. ......................

.

Arthur C. Smith

Professor of Electrical Engineering

Chairman, Department Committee on Graduate Theses

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

JUL 2 7 2000

LIBRARIES

2

Power Aware Embedded Operating System Design

by

Travis C. Furrer

Submitted to the Department of Electrical Engineering and Computer Science on

May 19, 2000, in Partial Fulfillment of the Requirements for the Degrees of

Bachelor of Science in Electrical Engineering and Computer Science

and

Master of Engineering in Electrical Engineering and Computer Science

Abstract

The ptAMPS low-power distributed wireless sensor project seeks to design small embedded systems that

will require an operating system (OS). I chose to port the Embedded Cygnus Operating System (eCos) to the

StrongARM 1100 microprocessor (SA-1100) so that it can be used on the pAMPS system. The OS was

debugged and tested for execution from both RAM and ROM on an SA-1100 evaluation board. A

description of how the OS was ported and debugged is given. A simple form of Dynamic Voltage Scaling

(DVS) was implemented and energy-efficiency experiments were done. FIR filtering with a variable-length

filter was used as a sample application to show that DVS provides a significant energy savings. Detailed

results from these experiments are presented. Additional ideas for ways to save energy in the OS, left as

future work, are included.

Thesis Supervisor: Anantha Chandrakasan

Title: Associate Professor of Electrical Engineering

3

4

Acknowledgements

I would like to acknowledge and thank Anantha for inspiring me to work with his group, for arranging

for my research assistantship funding, for giving me the freedom to organize my own project, and for his

enthusiasm about each success along the way. I feel privileged to have worked with him and his group.

I would also like to thank the following people and organizations for their invaluable help, without

which I could not have completed this thesis:

My parents, for their loving and wise direction that led me to pursue this degree, for always trying to

give me the best, and for letting me call them to talk anytime about anything. Without their persistent

encouragement I could not have made it through MIT. I hope they're able to stick around to see me through

many more successes! I would also like to thank the rest of my family for serving as an encouragement and

a good example to me while I was in college.

Rex, Amit, Manish, SeongHwan, Jim, Eugene, Wendy, Alice, PaulPeter, and everyone else in Anantha's

group who have contributed to the optimistic, courteous, friendly, humorous, and intelligent atmosphere

here. I am impressed with each of you and your research. Special thanks to Rex who provided the DVS test

board for use with the Brutus, and helped run the experiments. Special thanks also to Manish for help

designing the variable-length filter experiment.

Red Hat Software (formerly Cygnus Solutions), for giving me early access to their StrongARM 110

version of eCos. Thanks also to various people of the ecos-discuss@sourceware . cygnus . com

mailing list, such as Andrew Lunn who provided source code to measure CPU load under eCos.

The brains behind the zephyr help instance, who are available 24 hours a day to answer any question. It

was from them that I learned many important skills that allowed me to do a project of this kind.

Charles Leiserson, Harald Prokop, and Jamey Hicks for their involvement with my UROP research last

year, which initially led me onto the topic of low power software (or "cool" software, as Charles says).

My friend Ryan, for preventing much anguish for me by advising me (from experience!) to get my thesis written early.

5

6

"The harderI work, the luckier I get."

- Alvin Furrer

7

8

Table of Contents

1

2

3

4

5

A

B

C

D

E

Introduction.............................................................................................................................................

1.1

M otivation: The uAM PS Project ..............................................................................................

1.2 Background ..................................................................................................................................

1.2.1

General Low Power Software Techniques ................................................................

1.2.2

Low Power OS Techniques .......................................................................................

1.2.3

The StrongARM 1100 M icroprocessor .........................................................................

1.2.4

Em bedded Real-Tim e Operating System s.................................................................

1.2.5

The Em bedded Cygnus Operating System .................................................................

1.3

O verview ......................................................................................................................................

Porting the OS.........................................................................................................................................

2.1

Initial W ork on the Source Code .............................................................................................

2.1.1

Copying the SA-I10 HAL as a Starting Point..........................................................

2.1.2

Porting of Self-Contained Functions and M acros .....................................................

2.1.3

O verview of the Boot Sequences .............................................................................

2.1.4

Building the V irtual M emory Page Tables.................................................................

2.1.5

Enabling the M M U ...................................................................................................

2.2

The D ebugging Process ...............................................................................................................

eCos Applications...................................................................................................................................

3.1

Early Dem o Program s..................................................................................................................

3.2

Developing a D V S Demo ............................................................................................................

Ideas for Energy Efficiency Im provem ents.........................................................................................

4.1

DV S-Related Techniques.............................................................................................................

4.1.1

Choose the Right Boot Frequency..............................................................................

4.1.2

Energy vs. Quality Scaling .........................................................................................

4.1.3

Thread-based Voltage Scheduling..............................................................................

4.2

N on-D V S Techniques..................................................................................................................

4.2.1

K now your Hardware ................................................................................................

4.2.2

Efficient/Restricted use of M em ory ...........................................................................

Conclusion..............................................................................................................................................

D V S Test Board Specifications ..............................................................................................................

A .1

A .2

A .3

eCos

Control Signals from Brutus to D V S Test Board .....................................................................

Specification for D V S Test Board Inputs ................................................................................

A C Characteristics .......................................................................................................................

Regression Test Results.................................................................................................................

The Big Picture of StrongARM Power Consum ption ............................................................................

Instructions .............................................................................................................................................

15

15

15

16

18

20

23

23

25

27

27

29

31

32

36

. 43

45

47

47

47

51

51

51

51

51

51

51

52

53

55

55

55

57

59

61

D . 1 Building eCos for the Brutus ....................................................................................................

D .2 Program m ing Flash M em ories................................................................................................

R aw D ata From Experim ents..................................................................................................................

63

63

65

67

E. 1

Data from V oltage/Frequency Scaling Experim ent.....................................................................

E.2

Data From V ariable-Length Filter D V S Experim ent...................................................................

Photos .....................................................................................................................................................

67

69

71

F

B ibliograp hy .............................................................................................................................................

9

73

10

List of Figures

Figure 1.1: Diagram of a uAMPS Node ....................................................................................................

Figure 1.2: SA-1100 Block Diagram............................................................................................

..

Figure 1.3: SA- 1100 Power and Clock Supply Sources and States During Power-Down Modes .............

Figure 1.4: Scalability of eCos [5].................................................................................................................

Figure 1.5: Modularity of eCos [5]................................................................................................................

Figure 2.1: SA-1100 vs. SA-110....................................................................................................................

Figure 2.2: eCos Configuration Tool.............................................................................................................

Figure 2.3: eCos Configuration for Brutus Platform ..................................................................................

Figure 2.4: SA- 1100 Memory Map for the entire 4Gb 32-bit Address Space...........................................

Figure 2.5: Memory Layout for STUBS Startup .......................................................................................

Figure 2.6: Memory Layouts for RAM and ROM Startup ............................................................................

Figure 2.7: Before Enabling the MMU..........................................................................................................

Figure 2.8: After Enabling the MMU ............................................................................................................

Figure 3.1: Measured Energy per Operation vs. Frequency and Supply Voltage .....................................

Figure 3.2: Energy per Operation with Voltage Scaling vs. without Voltage Scaling ...............................

Figure 3.3: Screen Shot from DVS Demo ..................................................................................................

Figure A. 1: Transients in output voltage of DVS Board ...........................................................................

Figure F. 1: Photo of Brutus Board.................................................................................................................

Figure F.2: Photo of DVS Test Board .......................................................................................................

Figure F.3: Photo of Brutus with DVS Board connected ...........................................................................

Figure F.4: Screen Shot of Graphical Demo on Brutus LCD .....................................................................

Figure F.5: StrongARM 1100 Chip Photo.....................................................................................................

11

16

21

22

24

24

29

30

31

37

41

42

43

44

49

50

50

57

71

71

71

72

72

12

List of Tables

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

2.1: Boot Sequence for RAM Startup ..................................................................................................

2.2: Boot Sequence for ROM Startup..................................................................................................

2.3: Boot Sequence for STUBS Startup............................................................................................

2.4: Virtual Memory Mapping as specified in Page Tables ...........................................................

3.1: Voltages used with DVS for each Clock Frequency ................................................................

A .1: V oltage C ontrol Signals...............................................................................................................

A.2: DVS Test Board Voltage Control Signals ................................................................................

B. 1: eCos Regression Tests Results for Brutus Port........................................................................

C. 1: Breakdown of Power Consumption of SA- 110 processor when running Dhrystone ...............

E. 1: Data from Voltage/Frequency Scaling Experiment ................................................................

E.2: Data from Variable-Length Filter DVS Experiment.................................................................

13

34

35

36

39

49

55

56

59

61

68

70

14

Chapter 1

Introduction

1.1 Motivation: The uAMPS Project

The micro-Adaptive Multi-domain Power-aware Sensors (pAMPS) project [19] is being done by students in the Integrated Circuits and Systems group of the MIT Microsystems Technologies Laboratory. The

project vision is to perform efficient distributed remote sensing using small wireless sensor nodes. Each

node is battery-powered and contains a microsensor (for collecting remote data), an embedded microprocessor (for local pre-processing of sensor data), and a radio transceiver (for wireless transmission of sensor data

to a central base station). The type of the sensor and other details will depend on the application, but the

pAMPS system is being designed as a general substrate to be used in various remote sensing applications.

Although the long-term vision is for the nodes to be fully integrated into a custom system-on-chip (SOC),

the initial prototypes will be built with commercially available components, including the Intel StrongARM 11001 low-power microprocessor [9], assembled on a circuit board (Figure 1.1).

My contribution to the pAMPS project has been to provide the operating system (OS) to control the

software running on each node. The nodes have several special needs that constrain the type of OS that can

be used. For example, because the signal from a sensor must be sampled at a precise rate even while other

computing tasks are being performed, a real-time and multi-threaded OS is needed. More importantly,

though, the OS needs to operate under strict power/energy constraints because the nodes are battery powered. The design and implementation of an OS that can meet the needs of the pAMPS project is the main

topic of this thesis.

1.2 Background

Some background will be helpful before discussing the actual project. I will first make some comments on

the concept of low power software in general, and introduce an important low power software technique that

can be implemented at the OS level specifically. After this comes a short look at the StrongARM 1100

microprocessor. Finally, I will comment on embedded real-time operating systems in general and explain

why I chose ECOS as the OS to base my project on.

1.

StrongARM and ARM are registered trademarks of Advanced RISC Machines Limited.

15

External Stimulus (application-specific)

Sensor

(acoustic,

seismic, etc.)

AiD

Converter

To/From Base Station

or Remote Node

DRAM

(16Mb EDO)

To PC

(for debugging)

Battery

Figure 1.1: Diagram of a uAMPS Node

1.2.1 General Low Power Software Techniques

Many techniques for energy efficiency [1, 30] are applicable at the level of hardware, but there are also

methods that can be applied in software. 2 In this thesis, I use the term low power software to refer to software on which some sort of optimization has been done (whether at the algorithmic level in the source code,

at lower levels by a compiler, or both) with the energy consumption of the system in mind. Traditionally,

runtime has been used as the metric for most optimizations because performance is so important. In battery powered embedded systems, however, battery lifetime is at stake and thus energy consumption is at

least as important as performance.

The difference between energy consumption and power consumption is a distinction that needs to be

highlighted. Although there are cases in which one might be interested in minimizing peak power consump-

2.

It is worthwhile to make a special note of any techniques that are unique to software (no effort

in hardware could accomplish a similar improvement). However, it is still useful to consider

techniques that attempt to use software enhancements to make up for inefficient hardware. For

example, the hardware available on a satellite is fixed, but more energy-efficient system

software could perhaps be uploaded.

16

tion, for the pAMPS nodes we are interested in minimizing overall energy consumption (while maintaining

the required functionality) since that is what matters for battery life. The term "low-power software" seems

to imply simply that we are minimizing average power, but that would not be enough since time is also a factor in overall energy consumption. For this reason, the term "energy efficient software" might have been

more accurate.

The most obvious low power software technique is to make the software "lean" by eliminating inefficient code or unnecessary functionality that increases code size, which effects energy consumption by wasting both memory and clock cycles. Other techniques include: compiler enhancements for more energy

efficient code generation, compiler enhancements for memory alignment of code and data for cache performance, algorithmic transformations for performance or for cache efficiency, algorithmic transformations for

trading off energy vs. quality, as so on [8, 13, 26, 35, 36].

Optimizing software for energy consumption is not unlike optimizing for performance. In fact, very

often these two can coexist: most transformations that decrease runtime (increase performance) will

also reduce energy consumption. This is an important point to keep in mind. The synergy between these

two types of optimizations is convenient. Also, when evaluating low power optimizations we need to be

careful to distinguish between those that would already have been done traditionally for performance's sake,

and those that are unique to low-power systems.

An example of an OS optimization that would be done for the sake of energy, but never for performance, is to coarsen the grain of scheduling at times when the performance of all threads is non-critical (i.e.

it is okay for threads to wait for a longer time while other threads run). Since context switches have a cost in

terms of energy (due to the flushing of caches, saving and restoring state, etc.), minimizing them by coarsening the scheduling would save energy. But since performance is non-critical in these situations, it would

make no sense to do coarsening for the sake of performance.

Naturally, to perform low power software optimizations you need to have a detailed understanding of

how energy is consumed by the hardware. While some components consume energy at a constant power

level that cannot be significantly effected by software (i.e. leakage), the energy consumption of other components can be effected dramatically depending on how the software operates (for example, energy expended

in SRAM due to cache misses). While there are large similarities between embedded systems that make certain low power optimizations generally useful, one should watch out for details of energy consumption in

particular hardware that could effect optimization tradeoffs that are made with appropriate use of Amdahl's

law. 3 For example, if your floating point unit is an off chip coprocessor and communicating with it is expen-

17

sive in terms of energy, it may actually be more efficient to perform certain floating point calculations using

software emulation instead. There is clearly a different tradeoff between energy and performance in this

case, as compared to one where floating point operations are energy-efficient, and thus the types of software

optimizations used should be different.

One of the frustrations in designing low-power software is that it almost always involves stripping away

functionality that is considered unnecessary, but that seems useful. We may wish to retain some of this functionality at least part of the time. A power aware system attempts to provide different levels of quality/functionality (and thus energy consumption) at different times by intelligently monitoring the available system

energy and activity, and user preferences (i.e. desired latency or quality). By providing high functionality/

performance sometimes and dynamically scaling down to more limited functionality at other times, the hope

is to have the best of both worlds: average energy consumption is reduced without sacrificing peak performance. This technique is useful as long as the overhead associated with scaling functionality does not outweigh the average energy savings it provides. 4

1.2.2 Low Power OS Techniques

Since the OS is at the heart of the system, it is likely in some cases to be an important place to apply general

low power software techniques. We need to focus on the OS in addition to applications because it performs

certain privileged system management activities that can have an important impact on energy efficiency.

Also note that any techniques that happen to be platform specific (for example, those for which cache size or

other details of the hardware are important parameters) are more naturally applied to the OS code since it is

usually very platform-specific anyway (applications, on the other hand, may be compiled to run on several

different platforms and therefore such techniques may not be as feasible).

Research has been done on how to implement OS schedulers that make good use of the idle and sleep

modes of both the processor and peripherals [14-18, 27, 31]. This is a "power aware" technique because the

OS can actively manage power consumption by varying the set of enabled functional units while still meet-

3.

Although Amdahl's law should always be kept in mind, we may sometimes need to consider

energy efficiency in almost every area simultaneously in order to meet an absolute energy

constraint.

4.

There is overhead involved in executing the algorithms that are used to manage the scaling.

There may also be a small amount of energy used by any additional hardware needed to

support the scaling. If these overheads turn out to be large, it may have been better to use a

traditional low-power design approach.

18

ing the needs of user applications. Implementing power awareness at the OS level is advantageous since it

can improve energy efficiency even for applications that are not themselves power aware.

There are several ways in which an OS can be power aware. Any of the common OS features might be

implemented to vary their functionality based on the available energy or user demands. For example, a

power aware file system/disk driver might provide synchronous disk access when necessary for robustness,

but switch to asynchronous disk access at other times so that energy could be saved by clustering disk

accesses together and minimizing the number of disk accesses (assuming that there is a constant component

to the cost in terms of energy of each separate disk access). Another example might be a power aware scheduler that modifies the scheduling policy in such a way that allows dynamic trade-offs between performance

and power consumption.

The most important example of power awareness in the OS for this thesis, however, is the use of a technique called dynamic voltage scaling (DVS) 5 [22, 24, 33]. DVS takes advantage of an important property

of static digital CMOS logic: the energy consumed to perform a given computation (i.e. to execute a

sequence of instructions) is roughly proportional to the square supply voltage, as can be seen in the following formula [28]:

Energy

= CtOtV2D +

IleakVDDM

Where Cot is the total switched capacitance of the computation, VDD is the supply voltage, Ileak is the

leakage current, N is the number of clock cycles taken by the computation, and f is the clock frequency. 6

Note that Co, is the sum of the total switched capacitances in each individual clock cycle. The total

switched capacitance will be different for different clock cycles because different instructions are being executed and different functional units are being used. Here, we ignore these details by lumping everything into

the single value CtotIt has been shown previously [3, 38] that the quadratic dependency on voltage can be exploited to provide significant energy savings by staticallyscaling down frequency and voltage together. DVS, on the other

hand, takes advantage of this concept to scale frequency and voltage in the context of dynamically changing

5.

It is interesting to note that Transmeta's LongRun TM technology [37] is essentially dynamic

voltage scaling. The TM5400 can apparently scale from 500 MHz at 1.2 V to 700 MHz at

1.6V.

6.

Recall that the maximum achievable frequency depends on voltage (this can be seen in Figure

3.1 on page 49), which constrains the combinations of values we can use to reach a desired

energy efficiency.

19

system activity and requirements (i.e. at runtime). Because the fraction of time spent at different frequencies

is highly application dependent, so are the actual energy savings that can achieved with DVS. In fact, there

are even unusual cases in which DVS can actually be worse in terms of battery life. Battery life is sometimes

shorter when drawing energy at a constant rate than when drawing the same amount of energy in periodic

pulses [21]. In many cases DVS might fall short of the best-case (in terms of battery life) pattern of power

consumption even despite its energy efficiency.

The fundamental software problem of DVS is in implementing an algorithm that decides exactly what

frequency/voltage level to use at each instant in time. Algorithms that do this are called voltage scheduling

algorithms, and they are a topic of ongoing research [23, 25, 29]. The simplest such algorithms are intervalbased. Time is divided into equal intervals and the algorithm uses data (such as processor utilization in terms

of idle cycles) gathered in previous intervals to determine the frequency/voltage for the next interval.

Although such algorithms provide enough energy savings in many cases to justify the use of DVS, they are

not optimal. Potential enhancements could involve mechanisms to dynamically vary the interval length, and

to better predict the processor usage in the next interval by independently considering the activity of each

thread (this is discussed at the end of [25]).

1.2.3 The StrongARM 1100 Microprocessor

The Intel StrongARM 1100 processor was chosen for tAMPS for several reasons. Foremost is probably that

it has a very high performance/power ratio. 7 However, it is also a good choice because it has built in capability for software controlled frequency scaling, which is needed for DVS. Supply voltage scaling, however,

requires off-chip hardware which will be built into the ptAMPS board.8

The SA- 1100 is also nice because it has several integrated peripheral units. As you can see from Figure

1.2, there are general-purpose 1/0 pins (GPIO), 5 specialized serial ports, and a built in LCD display controller.

In addition to software-controllable clock frequency, the SA-1 100 also has idle and sleep modes. The

idle mode stops the clock to the ARM core, but most of the peripherals remain active. Power consumption in

idle mode is lowered by about a factor of 5. The sleep mode shuts almost everything off, and power consumption is lowered by orders of magnitude. Figure 1.3 gives more detail about which functional units

7.

The Hitachi SH3 processor has a higher performance/power ratio, but lower raw performance

than the StrongARM.

8.

The second generation StrongARM chips, due in mid 2000, will supposedly have voltage

scaling built in also.

20

remain active is which modes. For complete details on the SA-1 100, consult the SA-1 100 developer's manual [9].

--

r --

3.686

Os

-- -

I;

Instruction

tes

(1

32768

OSCDDUao

PC

and

ARMTm*

SA-1

Core

I

Read

Buffer

I

I

Addr

(8bye)E

Minicache

IDMMU

Misc

Test

Load/Store Data

I Processing

OS Timer

GeneralPurpose I/O

Interrupt

Intel*

Strnn ARML

SA-1100

JA

.

(16 Kbytes)

IMMU

1

PL

.

Core

Write

Buffer

System Bus

System

Control

-r

Module i-(SCM) I

Management

Reset

Controller

1

~

Memnory

I

Cont...l.

Cont--

-

-DMA

90ontrollerl

Module

--

LCD

Controller

(MPCM)

I

I

P-erip e l Control

MOdule (PCM)

Peripheral Bus

SSerial

Channel 0

UjSB

+

Channel 1

SDLC

erial

Channel 2

IrDA

Serial

Channel 3

UART

(from Intel SA- 1100 Developer's Manual)

Figure 1.2: SA- 1100 Block Diagram

21

+

Serial

Channel 4

CODEC

4

I

Power Management Mode

Supply Source

Run

Idle

Sleep

Module

Pwr

CIk

Pwr

Clk

Pwr

Pwr

CIk

Disabled

Stopped

On

Running

CIk

CPU

MMUs (l&D)

Stopped

Write buffer

Read buffer

JTAG

VDD

3.6864

MHz

OS timer

LCD controller

On

Serial channel 0-4

Running

On

Memory and

PCMCIA

Running

control

Real-time clock

Interrupt

controller

Power manager

VDDX

32.768

kHz

General-purpose I/O

(from Intel SA- I100 Developer's Manual)

Pin pads

Figure 1.3: SA-

1100 Power and Clock Supply Sources and States During Power-Down Modes

Software development for the StrongARM 1100 is done on the "Brutus" evaluation board [10, 11].

Once the software works on the Brutus, porting it to the initial pAMPS board should not be difficult since it

will be similar to the Brutus. The Brutus computer was designed as a test platform to demonstrate almost all

of the capabilities of the StrongARM 1100 microprocessor. Its components include:

" SA-1100 Microprocessor

- Memory System (16Mb DRAM, 512K SRAM, 256K Flash, 256K ROM)

- Two PCMCIA Slots

* 320x240 Color LCD Screen

- Audio Accessories (microphone, speaker)

" HEX LED Display (one digit)

- Touch Screen

- Keyboard

" Two RS-232 Serial I/O Interfaces

Since most of these components will not be present on the ptAMPS board, direct OS support (i.e. drivers) for

them will not be needed. However, these peripherals (especially the LCD screen and keyboard) are helpful

for providing direct interaction with demonstration applications that are meant to be run only on the Brutus.

22

1.2.4 Embedded Real-Time Operating Systems

Some of the applications of pAMPS will be real-time. 9 Rather than writing an embedded real-time operating system (RTOS) of our own from scratch, we chose to start with an existing RTOS and make modifications as needed. The current state of RTOS's is amazingly diverse; there are well over 100 different available

RTOS's [5, 34] with many distinguishing factors.

For pAMPS, we need an open source RTOS because we intend to modify the source code to add power

aware features. StrongARM support is preferable, so that we don't have to port it ourselves. We need scalability since we want to be able to have very lean code (no unneeded features). Preferences regarding other

distinguishing features are less important.

1.2.5 The Embedded Cygnus Operating System

After reviewing a long list of RTOS's, my conclusion was that the Embedded Cygnuslo Operating System

(eCos) [6], from Cygnus Solutions, would be suitable as a starting point for use with our pAMPS prototype.

The features of eCos that make it attractive for this project are:

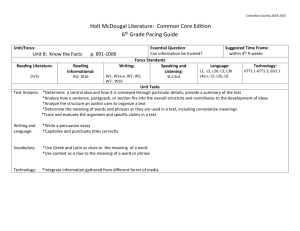

- scalability: eCos has over 200 configuration options (which can be chosen using a handy configuration tool, seen in Figure 1.4) for fine grain scalability, and code size can be as small as a few kilobytes.

- compatibility: eCos has pITRON compatibility, and will soon have EL/IX [7] compatibility which

makes it more compatible with Linux.

" multi-platform: Should we ever choose to stray from StrongARM, eCos is more likely to support

our next choice of platform.

- modularity: eCos is implemented with a hardware abstraction layer (HAL) that makes it easier to

port to new platforms. It is also implemented in such a way that makes it easy to plug in a custom

scheduler, device driver, etc. (see Figure 1.5).

" open source: eCos source code is freely downloadable at sourceware.cygnus.com

* development toolchain: eCos uses the standard GNU toolchain

" support: There is an active mailing list (ecos-discuss) for free support. Increasing volume on this

mailing list indicates that eCos is becoming more popular.

9.

For a concise introduction to the topic of real-time systems, look at [32]. For more than you

probably want to know about rate-monotonic real-time scheduling, refer to [12]. The topic of

real-time systems has been studied for decades and is rather advanced, and thus I do not

attempt to discuss it in this thesis.

10. ECOS was named prior to the acquisition of Cygnus Solutions by Red Hat Software, which

happened in January 2000.

23

Configuration and Build Tools

Application-specific

operating system

eCos Kernel Components

st

Interrupts

Schedulers

Exception

Handlin

Acd-ns

Memory

AlocatIon

Synch

Dr!vers

F

Libraries

(from Cygnus eCos Market Backgrounder)

Figure 1.4: Scalability of eCos [5]

Figure 1.5: Modularity of eCos [5]

24

Unfortunately, eCos does not currently allow the dynamic loading of code. Until eCos supports this feature it will not be easily possible for us to download additional application code onto a ptAMPS node after

deployment. Instead, the entire OS and application (which are actually compiled together into the same

binary image) must be replaced together.

Other OS's that were considered did not appear to meet our needs as well as eCos. For example,

embedded Linux has real time support, but is not nearly lean enough and is not scalable (it is not trivial to

eliminate the file system, for example). The uCLinux OS is leaner, but has not yet been ported to any ARM

platforms. ChorusOS (from Sun) is not open source. LynxOS has an interesting patented interrupt handling

mechanism, but is not open source and also doesn't support ARM. RTems is open source and actually has

advantages over eCos, but has no ARM support. Several other RTOS's were considered and all had similar

issues.

1.3 Overview

Chapter 2 gives details about what is involved in porting and debugging an embedded operating system such

as eCos. Chapter 3 describes the DVS demo application that I developed. Some ideas for energy efficiency

improvements are given in Chapter 4. After the conclusion in Chapter 5, several appendices give useful data

and more information about the OS and DVS experiments.

25

26

Chapter 2

Porting the OS

It is of course necessary to get the basic OS features working before any experimentation can be done with

special low-power OS features like DVS. This chapter describes how eCos was ported to run on the Brutus.

A lot of low-level details had to be taken care of to get eCos to boot properly.

2.1 Initial Work on the Source Code

Fortunately, eCos is designed with portability in mind. Most of the kernel is written in C++ and is entirely

portable. The platform dependent code is isolated in what is called the Hardware Abstraction Layer

(HAL) and is written in C. Porting eCos to a new platform means creating a HAL for that platform. The

HAL code contains the routines necessary to boot and initialize the system. It also contains several functions

and macros that are used by the rest of the eCos code. Although there are many features in common between

microprocessors, the method of accessing and controlling the features is different for each processor. For

example, most platforms have caches, interrupts, timers, and MMU's. The HAL presents a common interface for these features to the platform dependent part of eCos, through various functions and macros. Most

of these functions are short and self contained (it doesn't take very many instructions to mask an interrupt,

for example), and thus are simple to port.

Since there are often many different platforms based on the same architecture (for example, ARM, Intel,

and Cirrus Logic all make their own chips based on the ARM instruction set), the HAL is divided further

into sections that are architecture-specific and sections that are platform-specific. This made the job of porting eCos to the Brutus easier because the ARM architecture was already supported. The parts of the HAL

that actually needed to be ported included about 5000 lines of C and ARM Assembly code scattered across

no more than two dozen files.

There are two different ways to run eCos code: from RAM or from ROM. Running code from ROM

requires first programming the ROM, while running code in RAM requires first downloading the code into

RAM. Since downloading code into RAM is faster and easier than reprogramming a ROM, it is generally

desirable to perform debugging on code in RAM. However, since the SA- 1100 always boots from ROM,' 1

11. When the SA- 1100 is powered on, it begins executing code starting from address zero, which

happens to fall in the ROM area of memory. This makes sense because RAM will normally

contain garbage at boot time, and thus the boot code could not be run from there.

27

there is a small portion of code that must run from ROM and implement some sort of download protocol to

allow other code to be downloaded and run in RAM. For the ARM Software Development Toolkit (SDT),

this small portion of code is called Angel. For eCos, which uses the GNU tool chain, this code is called a

GDB Stub. The protocol is specific to the GNU Debugger (GDB) which is used on a PC to download the

code to the Brutus over an RS-232 connection. It is called a "stub" because it only implements a small subset

of the gdb remote debugging protocol -just

enough to allow code to be downloaded and run from RAM. 12

The first task in porting eCos was to get a working set of GDB stub ROMs. Since much of the initialization code in the HAL is necessary even for GDB stubs, most of the HAL had to be ported before GDB stubs

would work. All 5000 lines of code had to be ported before any real testing or debugging could be done. Fortunately, porting the GDB stubs is the majority of the work that needs to be done to get all of eCos working

(except for several additional bugs that needed to be fixed), since the remaining code is platform independent

and already debugged on other platforms.

Since GDB has a feature for using the ARM debugging protocol (adp), it can connect to a Brutus running Angel. Therefore it would be possible to use Angel to debug eCos in RAM instead of first debugging

the GDB stubs. However, various issues in connecting to Angel with gdb make this undesirable. For example, after stopping execution at a breakpoint there are bugs that prevent the execution from continuing further. This renders breakpoints useless and one is left with only single-stepping, which severely limits

debugging capability. Also, Angel does not support multi-threaded debugging (the ability to control execution on a thread-by-thread basis). So I chose to port the GDB stubs and use them instead. However, the

Angel source code is a valuable reference when writing the GDB stubs (much of the early boot code is the

same).

Since GDB stubs are a subset of eCos (they both use the same HAL), the process of compiling them is

very similar to compiling an eCos kernel. Section 2.1.1 talks about how the Brutus HAL code was prepared

for configuration and compilation in the eCos configuration tool. Section 2.1.2 goes on to discuss how the

various functions and macros in the HAL were ported (as we discussed earlier in this section). Then, Section

2.1.3 gives an overview of the boot sequence, which is the final and most difficult part of the HAL porting.

Section 2.1.4 and Section 2.1.5 describe how the SA- 1100's virtual memory system is initialized at boot

time.

12. It is the necessity of this separate downloading step that qualifies eCos as an embedded

operating system. Since embedded computers often have no text displays or keyboards, all

communication and debugging must be done from a remote host.

28

2.1.1 Copying the SA-1 10 HAL as a Starting Point

Since Cygnus had already created an eCos HAL for the EBSA285 (the SA- 110/21285 evaluation board), I

chose to use this as a starting point for my Brutus/SA- 1100 HAL. There is enough similarity between the

SA- 110 and SA- 1100 that this saved some work. The shaded areas in Figure 2.1 show the features of the SA1100 that are identical to the SA- 110. Unshaded areas are units that either did not exist in the SA-1 10, or

were significantly changed, or used to be part of the 21285 companion chip but were integrated onto the SA1100. Any code that accesses features in the unshaded areas of the SA- 1100 in this figure needs to be ported

or completely re-written.

1.

Read Buffer

8KB

Data Cache

I

512-byte

MiniDcache

nGeneral-Purpose

Interrupt

Controller

/

Memory/

Controller

DMA

Controller

Serial

Controllers

LCD

Controller

Interval

Timer

Real-Time

Clock

(from Intel SA-1 100 Developer's Manual)

Figure 2.1: SA-1100 vs. SA-110

29

rn eCos HAL

u...

.........

True

....T....r

....TrueCs.lbrb

C library

Math

library

True

True

-

mmon error code support

WA"subsysdemc

1~Waiclock

E6

device

Watchdog device

CygMon ROM monitor

True

T

True

True

True

Type

Value

Defauk Value

Macro

Fie

Boolean

True

True

CYGPKGKERNEL

Defined at line

URL

Vu is required by

file://C-\Program Files\ygnus Solutions\eCos\doc\ref*

Vrequires

CGFUNHALCOMMON KERNELSUPPORT

is required by

dby

is re

is required by

V is required by

. is required by

is required by

Vis required by

CGFUN.HALCOMMONERNELSUPPOR T

CYGPKGUITRON

CGPKLIBCMALLOC

CYGSEM LIBC STDIO THREADSAFESTREAMS

CYGSEMLIBC SIGNALS THREAD SAFE

CYGSEMLUBCSTARTUP MAINTHREAD

CYGSEM LIBCEXaTSTOPSSYSTEM

,CYGPKGsYGMON

This package contains the core functionality of the eCos kernel. It relies on

unctionality provided by various HAL packages and by the eCos

nrastructure. In turn the eCos kernel provides support for other packages

such as the device drivers and the uITRON compaibilty layer.

Figure 2.2: eCos Configuration Tool

user interface to the actual eCos

The eCos configuration tool, seen in Figure 2.2, provides a graphical

or disable entire sections of the code

source code. At the top level (seen in the figure), the user can enable

configurations within each package. The

called packages. At lower levels, the user can perform fine-grain

it by looking at the source code

hierarchical menu is not hard-coded into the tool; the tool actually generates

the tool copies the source code for the

repository. Once a specific set of configurations have been chosen,

and the configurations are writenabled packages into a build tree (separate from the source code repository)

C macros. The rest of the eCos source

ten into the build tree in the form of several header files containing

configured.

code includes these header files and uses the macros to behave as

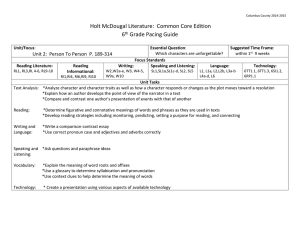

/hal/arm/ebsa285/)

After copying all the files of the EBSA285 HAL ($ECOSSRC /packages

($ECOSSRC/packages /hal /arm/

and doing string replacements to create a distinct Brutus HAL

possible to build an eCos kernel with the

brutus /) in the eCos source code repository ($ECOSSRC), it is

new Brutus HAL using the configuration tool (Figure 2.3).

30

D-

I eCos HAL

Enumeration

206400

Delault Value 206400

CYGHWR HAL ARM BRUTUS PROCESSOR CLOCK

Macro

- CAProgram Files\Cygnus Solutions\eCos\packages\hal\a

File

Detined athlne~154fie-//C-\Program Files\Cygnus Solutions\eCos\doc\ref\ec

URL

Type

QI

Platform-independent HAL options

El L Source-level debugging support

El (CARM architecture

Provide.diagnostic dump for exceptions

FProcess all exceptions with the eCos application

Support GDB thead operations via ICE/MultCE

[E 0 ARM PID evaluation board&

El C ARM AEB-1 evaluation board

Citrus Logic EDB7pXX evaluation boards

DT

E C lntel EBSA285 StrongARM evaluation boards

E 0 Intel StrongARM 1100 evaluation boards"

uN Startup type

serial port

serial port baud rate

Value

False

False

son ... as .......... guena. .

xpressed in KHz.

ram

0

38400

0

port baud rate

seNal device divers

er Systems CMA230 board

38400

206400

False

Figure 2.3: eCos Configuration for Brutus Platform

2.1.2 Porting of Self-Contained Functions and Macros

The first file to be ported is:

$ECOS_SRC/packages/hal/arm/brutus/v-2_10/include/hal-brutus .h

because it contains a large number of one-line macros describing the register locations of the SA- 1100 that

are used throughout the rest of the HAL code. The register locations in this file are copied from the SA- 1100

developer's manual, as are several special bitmask macros for some of registers. Browsing these macros is a

good way to become familiar with the SA- 1100's features. For example, here are the definitions of the macros for the real time clock (RTC). The register names correspond to the names used in the SA- 1100 manual:

/* SA-1100 Internal Registers for System Control Module

Real-Time Clock Definitions */

#define

#define

#define

#define

/* RTSR

REG32

REG32

REG32

REG32

SA1100_REGRCNR

SA1100_REGRTAR

SA1100-REGRTSR

SA1100_REGRTTR

*/

#define SA1100_ALARMDETECTED

#define

#define

#define

/* RTTR

SA1100_1HZRISINGEDGEDETECTED

SA1100_ALARMINTERRUPTENABLE

SA1100_1HZINTERRUPTENABLE

*/

#define SA1100_CLOCKDIVIDERCOUNTMASK

#define SA1100_TRIMDELETE_COUNTMASK

31

_PTR(0x90010004)

_PTR(0x90010000)

_PTR(0x90010010)

_PTR(0x90010008)

Ox1

0x2

0x4

0x8

Ox000 )FFFF

OxO3F FOOOO

Once these basic macros are defined, several larger (but still small) macros and functions can be ported.

For example, below are the macros used by the eCos code to mask or unmask interrupts. These are defined

in $ECOSSRC/packages/hal/arm/brutus/vl_2_10/src/brutusmisc.c:

Original (for SA-110):

void haljinterrupt-mask(int vector)

*SA110_IRQCONT_IRQENABLECLEAR = 1 << vector;

void haljinterrupt-unmask(int vector) {

*SA110_IRQCONT_IRQENABLESET = 1 << vector;

Ported (for SA-1 100):

void hal interruptjmask(int

*SA1100_REGICMR &= -(1

vector)

{

<< vector);

void haljinterrupt-unmask(int vector) {

*SA1100_REGICMR I= (1 << vector);

This example is representative of the type of editing that needs to be done in a large number of macros and

functions throughout the HAL in the following files (this is not necessarily an exhaustive list):

$ECOS_SRC/packages/hal/arm/brutus/v1_2_10/include/halcache.h

$ECOSSRC/packages/hal/arm/brutus/v2_10/include/halplatformints .h

$ECS_SRC/packages/hal/arm/brutus/v12_10/include/hal_diag.h

$ECOSSRC/packages/hal/arm/brutus/v12_10/include/pkgconf/halarmbrutus

$ECOSSRC/packages/hal/arm/brutus/vl_2_10/include/plf-stub.h

$ECOSSRC/packages/hal/arm/brutus/v1_2_10/src/plf_stub.c

$ECOSSRC/packages/hal/arm/brutus/v1_2_10/src/hal_diag.c

$ECOS_SRC/packages/hal/arm/brutus/v1_2_10/src/brutusmisc .c

$ECOSSRC/packages/io/serial/v1_2_10/include/pkgconf/io-serial.h

$ECOSSRC/packages/io/serial/vl_2_10/src/arm/brutusserial .c

.h

2.1.3 Overview of the Boot Sequences

The most complex part of the Brutus HAL is the initialization code. Fortunately, the main flow of the boot

sequence is the same for all ARM processors and thus did not need to be ported. The file that contains the

code that runs when the processor boots is:

$ECOSSRC/packages/hal/arm/arch/v1_2_10/src/vectors.S

and this file did not need to be edited at all. However, the very first thing this code does is call a

PLATFORMSETUP macro. This macro, which is for platform specific initialization, is defined in:

$ECOSSRC/packages/hal/arm/brutus/v1_2_10/include/hal-platformsetup.h

and this file required a complete rewrite.

Before we discuss any details of boot-time initialization, it would be good to overview the list of actions

that are performed when eCos boots. The boot sequence is different depending on whether eCos is running

32

from ROM or RAM. The boot sequence for the GDB stubs is similar to ROM startup, but there are differences.

During the boot sequence, the Brutus HEX LED display is used to display numbers which indicate visibly which part of the boot process is currently executing. If the SA- 1100 crashes or hangs during the boot

sequence, the user can use the value on the HEX display for clues to debug the problem. The LED value at

the end of each boot sequence is zero. Normally, the boot sequence occurs so quickly that you see nothing

but a zero on the display. If you see any other number, you know immediately that the corresponding step

has failed.

Table 2.1, Table 2.2, and Table 2.3 list the actions performed as part of the boot sequence for each startup type (RAM, ROM, STUBS), along with the LED values that are displayed for each. Note that some

details have been left out from these tables. The best way to discover the complete details of what happens

when eCos boots is to read the source code directly.

There are a couple of details of the boot sequences that exist for energy-efficiency, as is recommended

by the SA- 1100 manual. First, notice that the instruction cache is enabled early (even before the MMU is

enabled), in order to allow the boot code to run much more efficiently. This means that later, when the MMU

is enabled, the ICACHE needs to be temporarily disabled, flushed, and re-enabled. Second, the clock frequency is set and clock switching (a feature that allows the core clock to double in frequency relative to the

memory clock) is enabled early in the boot sequence, in order for the boot code to run at the desired frequency (which can be chosen to trade off boot time with boot energy).

33

Next Boot Action Performed

Readout

8

If already in supervisor mode, jumps to step 5 (below).

7

Sets up exception vectors for undefined instruction and software interrupt exceptions.

6

Switches to supervisor mode.

5

Sets up exception vectors for IRQ, FIQ, prefetch abort, data abort.

4

Initializes stack pointers.

Initializes CPSR, SPSR.

Clears BSS.

3

Platform specific hardware initialization in halhardware inito. For Brutus, this sets up the

interrupt environment by masking all interrupts and setting them all to do IRQ and not FIQ.

2

(Nothing)

1

Invokes static constructors (for all the C++ code of eCos).

0

Starts the eCos kernel by calling cyg-starto.

Table 2.1: Boot Sequence for RAM Startup

34

Hex LED

Readout

(blank)

Next Boot Action Performed

Enters SVC mode, sets frequency, flushes caches.

Initializes HEX LED display.

F

Enables instruction cache.

E

Initializes peripheral pins and GPIOs.

Clears OS timer count register.

D

Sets clock frequency and enables clock switching.

C

Initializes memory interfaces (DRAM waveforms, ROM type, etc.).

B

Builds virtual memory page tables.

A

Disables domain access control.

Sets page table base address register.

9

Enables MMU and caches.

8

(Nothing)

7

Sets up exception vectors for undefined instruction and software interrupt.

6

Makes sure we are in supervisor mode.

5

Sets up exception vectors for IRQ, FIQ, prefetch abort, data abort.

4

Sets up reset exception vector (for warm reset).

Relocates data from ROM to RAM.

Initializes stacks.

Initializes CPSR and SPSR.

Clears BSS.

3

Platform specific hardware initialization in halhardwareinito. For Brutus, this sets up the

interrupt environment by masking all interrupts and setting them all to do IRQ and not FIQ.

2

(Nothing)

1

Invokes static constructors (for all the C++ code of eCos).

0

Starts the eCos kernel by calling cyg-starto.

Table 2.2: Boot Sequence for ROM Startup

35

Hex LED

Readout

(blank)

Next Boot Action Performed

Enters SVC mode, sets frequency, flushes caches.

Initializes HEX LED display.

F

Enables instruction cache.

E

Initializes peripheral pins and GPIOs.

Clears OS timer count register.

D

Sets clock frequency and enables clock switching.

C

Initializes memory interfaces (DRAM waveforms, ROM type, etc.).

B

Builds virtual memory page tables.

A

Disables domain access control.

Sets page table base address register.

9

Enables MMU and caches.

8

(Nothing)

7

(Nothing)

6

Makes sure we are in supervisor mode.

5

Sets up exception vectors for software interrupt, IRQ, FIQ, prefetch abort, data abort.

4

Sets up reset exception vector (for warm reset).

Relocates data from ROM to RAM.

Initializes stacks.

Initializes CPSR and SPSR.

Clears BSS.

3

Platform specific hardware initialization in halhardware inito. For Brutus, this sets up the

interrupt environment by masking all interrupts and setting them all to do IRQ and not FIQ.

2

Initializes stubs (initializes serial port, etc.).

1

Invokes static constructors (for all the C++ code of eCos).

0

Starts the eCos kernel by calling cyg-starto.

Table 2.3: Boot Sequence for STUBS Startup

2.1.4 Building the Virtual Memory Page Tables

One step of the boot sequence implemented by the PLATFORMSETUP macro (mentioned in the previous

section) is to build the virtual memory page tables. The use of virtual memory allows for flexibility in defining the memory layout. Implementing and debugging the code that builds the page tables and enables the

MMU (next section) is one of the more difficult tasks of porting eCos to the Brutus.

36

The layout of physical memory, shown in Figure 2.4, is already determined by the SA- 1100 platform

and cannot be altered:

Reserved (384 Mbyte)

OhCOO0 0000

Zeros Bank (128 Mbyte)

DRAM Bank 3 (128 Mbyte)

Cache flush replacement data

Reads return zero

128 Mbyte

DRAM Bank 2 (128 Mbyte)

Dynamic Memory

DRAM Bank 1 (128 Mbyte)

512 Mbyte

DRAM Bank 0 (128 Mbyte)

LCD and DMA Registers (256 Mbyte)

Oh8000 0000

Memory and Expansion Registers (256 Mbyte:

Internal Registers

System Control Module Registers(256 Mbyte

1GB

Peripheral Module Registers (256 Mbyte)

Reserved (1GB)

Oh4000 0000

PCMCIA Socket 0 Space (256 Mbyte)

PCMCIA Interface

512 Mbyte

PCMCIA Socket 1 Space (256 Mbyte)

0h2000 0000

Static Bank Select 3 (128 Mbyte)

Static Bank Select 2 (128 Mbyte)

Static Bank Select 1 (128 Mbyte)

OhOO0O 0000

Static Memory

52 Flash, SRAM)

Static Bank Select 0 (128 Mbyte)

(from Intel SA- 1100 Developer's Manual)

Figure 2.4: SA- 1100 Memory Map for the entire 4Gb 32-bit Address Space

Note that a large portion of the address space is devoted to the "Internal Registers." When addresses in

this range are used, the SA- 1100 routes the data to or from special internal registers instead of to off-chip

memory. This is the mechanism by which most of the features of the chip are accessed and controlled.

Also notice that ROM is found at address

0x00000000, while DRAM begins at address

0xC 0 0 0 0 0 0 0. Although the SA- 1100 is not the only processor with a memory layout like this, it is somewhat uncommon to have ROM at address zero. The reason is because the ARM architecture (as well as many

others) requires the exception vectors to begin at address zero, and generally the exception vectors need to

be in RAM so that software can exchange exception handlers at runtime. Since the SA- 1100 has ROM at

37

address zero, if you want exception vectors to be in RAM you will have to enable the MMU and create a

non-flat 13 virtual memory mapping.

The ARM architecture defines the page tables and other details of the virtual memory system (these are

not specific to the SA-1 100). A two-level page table scheme is used. The LI page table occupies 16Kb of

memory, contains 4096 entries, and each entry governs a

4Gb). The L2 page tables each occupy

the address space (for a total of

1Mb section of the address space (for a total of

1Kb of memory, contain 256 entries, and each entry governs 4Kb of

1Mb). There is also a special "sub-page" feature that allows access control

(but not address remapping) to extend to a resolution of 1Kb. As with any multi-level page table scheme, the

use of the lower level page tables is optional. Thus, I chose to avoid the use of L2 page tables because they

waste memory and make the each page table walk (which is implemented in hardware) less efficient. By

using only an LI page table, several "holes" are left in the address space where the latter part of a range of

addresses (that is less than the

1Mb resolution, such as the 256K of boot ROM) has a mapping in the virtual

memory system but has no underlying physical memory (and thus accesses to these addresses could be

unpredictable). This is a sacrifice that I chose to make for the sake of energy efficiency. 14

13. By "non-flat," I simply mean that the predicate (virtual address == physical address) does not

hold true for all locations in memory, and thus address translation is actually necessary.

14. I make no claim here as to how much this effects energy efficiency because I did not perform

actual experiments to measure this.

38

Table 2.4 shows the memory layout that I chose to use for eCos on the Brutus:

Purpose of

Size

Physical Address Range

Virtual Address Range

Boot ROM

1 Mb

OxOOOOOOOO. .OxOOOFFFFF

0x04000000. .OxO40FFFFF

Peripheral

Control Module

(PCM) Registers

1 Mb

0x80000000. .Ox80OFFFFF

0x80000000. .Ox80OFFFFF

System Control

Module (SCM)

Registers

1 Mb

0x90000000. .Ox900FFFFF

0x90000000. .Ox900FFFFF

Memory Control

Registers

1 Mb

OxAOOOOOOO. .OxAOOFFFFF

0xAO000000. .OxA0OFFFFF

DMA/LCD

Registers

2 Mb

0xB0000000.

0xB01FFFFF

0xB0000000. .0xB01FFFFF

DRAMBank1

4Mb

OxCO00000..0xCO3FFFFF

0x00000000..OxO03FFFFF

DRAM Bank 2

4 Mb

0xC8000000. .OxC83FFFFF

0x00400000. .OxO07FFFFF

DRAM Bank 3

4 Mb

OxDOOOOOOO. .OxDO3FFFFF

0x00800000. .Ox0OBFFFFF

DRAM Bank 4

4 Mb

OxD8000000. .OxD83FFFFF

OxOOCOOOOO. .OxOOFFFFFF

OxE000000.

OxEOOO OOOO. .OxE80FFFFF

Memory Area

Zeros Bank

128 Mb

.

.OxE80FFFFF

Table 2.4: Virtual Memory Mapping as specified in Page Tables

RAM has been remapped to address zero, while ROM has been moved up to address

0x0 40 00 0 0 0.15

The rest of the address space has a flat mapping to avoid confusion. No mapping is created for SRAM or

Flash since they are not used at this time. 16 Any reads or writes to virtual addresses outside any of the ranges

in the table will produce page faults. The access permissions and cacheablility are not shown in the table, but

DRAM Bank 4 is mapped uncacheable and unbufferable, so that it can be used for things such as the LCD

frame buffer (which is required to be uncacheable and unbufferable). This memory mapping is one of the

few things that will need to be adjusted when eCos is finally ported from the Brutus to the ApAMPS prototype.

Once the memory map is decided, eCos needs to be configured so that the linker knows where to place

code and data when compiling eCos. Normally, this would require the direct use of a linker script, which is

15. This location for ROM will be okay as long as there is less than 64Mb of DRAM (otherwise

the DRAM starting at address zero will occupy space beyond 0x040 0 0 0 0 0).

16. Before running eCos, it is important that the Brutus switches be set to enable DRAM instead of

SRAM, and to enable 32-bit wide ROM accesses.

39

beyond the level of many programmers. Therefore the eCos configuration tool has a graphical feature to aid

in the automatic generation of a linker script (and a couple of other related files).

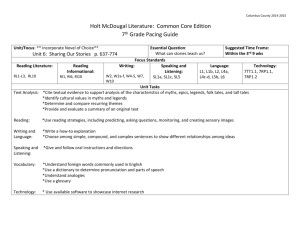

Figure 2.5 on page 41 and Figure 2.6 on page 42 show the memory layouts as they were defined in the

eCos configuration tool for STUBS, RAM, and ROM startup. You can see in Figure 2.5 that the GDB stub

code resides in ROM starting at address

0x0400 0 0 0 0 and can use the entire 256Kb range of ROM if nec-

essary, while (writable) data is limited to the lower 16Kb of RAM. The remaining part of RAM is reserved

for downloading code that is to be run from RAM. Notice that the data section appears in both the RAM and

ROM regions in the layout. This is because this section contains initialized data and is copied (relocated)

from ROM to RAM at boot time. The 800Kb reserved section at the bottom of RAM to leave room for the

exception vectors.

Looking at Figure 2.6, we see that eCos programs compiled for RAM startup only use the first three

banks of DRAM (as mentioned earlier, the fourth bank is mapped uncacheable and unbufferable and is for

special uses such as the LCD buffer). The 32Kb of reserved space in the lower part of DRAM is for the GDB

stubs and the virtual memory page tables (which reside at OxO 0004000). Programs compiled for ROM

startup use RAM very similarly, and use ROM in the same way it was used for STUBS startup (except now

it is much more likely that the entire 256Kb range would be needed).

40

1*

"2''

C

S

16

-D

0

2

CD

ii

2

LD

0D

0D

C3

O)

8

0D

CD

E

2

Figure 2.5: Memory Layout for STUBS Startup

41

1

Cu

C

2

C

0b

8~

*1

'N

'N

ii

'U

2

La'

Ll.

0

C

8

8

C

00.

8

8C)

0

8

-C

C

CD

0

CD

*3

Figure 2.6: Memory Layouts for RAM and ROM Startup

42

-C

2.1.5 Enabling the MMU

Once the page tables have been created, the next step is to enable virtual memory using them. Enabling virtual memory should be as simple as setting the page table base address register to the physical address of the

page table (OxC004000) and turning the MMU on. However, when the memory mapping is not flat (for the

region of code that actually enables the MMU) things get complicated because the address of the next

instruction "magically" changes when the MMU is enabled (which is effectively like a jump instruction). On

some pipelined architectures, it is possible to place a branch in exactly the right position so that execution

will continue seamlessly. However, this does not work on the SA- 1100, so an interesting "hack" must be performed instead.

Figure 2.7 illustrates the steps of the hack that occur prior to the activation of the MMU, and Figure 2.8

shows the steps that happen afterward:

Virtual Address Space

Step 1:

Physical Address Space

DRAM:OXCOO#####

ROM:

Ox040#####

DRAM: OXOOO0###

ROM: OX0 0 #####

Virtual

Physical

Program Counter

I x000#####

Step 2:

DRAM: OxCOO#####

ROM: OxO40 #####I

DRAM: OxOOO #####

PC

IOx00 0#

####]

Figure 2.7: Before Enabling the MMU

43

ROM: OXOOO #####

Physia

Virtual

Step 3:

DRAM: OxCOO#####

ROM: Ox040#####

PC

_______

________

DRAM:Ox0 0#####

x000#####

Physical

Virtual

Step 4:

ROM:OxOOO#####

DRAM: OxCOO#####

ROM:Ox04O#####

PC

DRAM:OxOOO#####

0x040#####

Physical

Virtual

Step 5:

ROM:OxOOO#####

DRAM:OXCOO#####

ROM : 0x040#####

0x040#####

DRAM:Ox000#####

ROM:OxOOO#####

Figure 2.8: After Enabling the MMU

In Step 1, the page tables have been built normally (DRAM mapped to OxO 0 0 00 0 00, ROM mapped to

OxO 40 0 0 00 0, etc.) and the program counter points directly to the code that is executing from ROM. If we

enabled the MMU in this condition, the next instruction would be fetched from a nonsensical location in

DRAM because the address in the program counter would suddenly be mapped there. To prevent this from

happening, Step 2 temporarily overwrites the page table entry for the corresponding page in DRAM so that

it points to the page in ROM where the code is executing. Since the memory mapping for this page is now

flat, the MMU can be safely enabled.

In Step 3, the MMU is enabled and code is still running from the same place in ROM. We now need to

update the PC, however, so that the code will be running at its new virtual address. This is done by a branch

instruction (Step 4) that sends the PC to the next instruction at its correct virtual address. Now we need to

44

restore the page table entry that was temporarily overwritten so that we can again access the first page of

DRAM. This is done in Step 5, and now things are back to normal with the MMU enabled.

There is one detail that was glossed over, however. Although the steps as described would work in general, there is a complication as we have defined the memory map for eCos because the page table itself is in

the first page of DRAM - the very area of memory that becomes temporarily unavailable in step 2. The

page table must have a mapping in the virtual address space, however, in order for us to restore the page

table entry in step 5. I accomplished this by creating an alias to the first page of DRAM in the page table.

The very last page table entry (which was otherwise unused) points to the first page in DRAM where the

page tables are stored. When the temporarily overwritten page table entry is restored in step 5, the code

writes to the page table at the address OxFFF04 000, which points to the correct place in DRAM. By creating this alias to the page in memory where the page tables are stored, we are assured to always be able to

write to them if necessary.

Some subtle points needs to be mentioned. First, the TLBs must be flushed each time the page tables are

edited, as is done in steps 2 and 5. Second, the caches are temporarily disabled during all of these steps to

prevent aliases from being created in them after the MMU is enabled. Finally, note that any registers that

contain addresses must be updated when the MMU is enabled. For example, if the link register (LR) contained a return address, it will need to be translated before returning.

If the MMU ever needed to be disabled, there would be a similar set of steps to follow. However, with

eCos on the Brutus it is never necessary to disable the MMU.

2.2 The Debugging Process

Once all of the code in the HAL was finally ported to the Brutus as described in the various parts of Section

2.1, the next step was to compile GDB stubs and begin debugging the code in ROM. The debugging of the

early parts of the boot sequence was the hardest because the only feedback available was from the HEX LED

display (serial ports are not initialized until late in the boot sequence). To debug the code that performs the

steps described in Section 2.1.5, for example, I actually had to write code to display the values in the SA1100 registers one digit at a time.

Once the GDB stubs are working, it is possible to connect to the Brutus with gdb and download code

just as would be done with Angel. The next step is to compile a full eCos kernel and test an eCos application.

Since eCos comes with over 150 test programs, the existing test suite was used to verify the functionality of

45

eCos on the Brutus. Initially, most of the tests passed. Tests that failed were mostly due to a bug in the floating point code that gcc generates to pack or unpack doubles.

46

Chapter 3

eCos Applications

3.1 Early Demo Programs

To verify that eCos was working reasonably well on the Brutus, and to get some more experience writing

eCos applications, a few simple demo programs were written.

My earliest test programs print messages to the serial port, which are then displayed in the gdb terminal

on the PC. It wasn't long, however, before we wanted to be able to interact with the Brutus directly using its

own peripherals. I ported the LCD and keyboard drivers from some of Intel's code (that was written to run

on Angel), and used these to write a series of graphical demos. One of the demos, for example, displays colored bouncing squares on the LCD screen. Each square is animated by a separate thread. A screen shot of

this program is shown in Figure F.4 on page 72.

The next step before implementing DVS was to write a test program to allow the frequency of the SA1100 to be changed at runtime. I wrote this program as an extension of the graphical colored squares demo

so that any runtime errors would be visibly obvious. The keyboard is used to control frequency as desired.

The SA- 1100 manual actually recommends that clock frequency only be set at boot time. However, the

SA- 1100 clock frequency can actually be safely changed at any time, as long as certain peripherals are not in

use (because the clock signal to some peripherals such as serial ports is unstable during the 150us that it

takes for the PLL to re-lock).

One issue that surfaced in developing this program is that some peripherals need to be re-configured

when the frequency is changed. For example, the LCD pixel clock is derived from the core clock using a

configurable divider. When the core clock frequency changes, the divisor must be updated in order to maintain the same LCD refresh rate.

3.2 Developing a DVS Demo

Now that frequency scaling worked, I was ready to begin developing a program to do actual Dynamic Voltage Scaling. The first part that needed to be developed was code to determine the processor load. The average load value over each interval is what is used (in the simplest implementation of DVS) to determine what

frequency to use in the next interval (in this case, intervals are on the order of a second or two). The method

this program uses for determining load is to create a thread of lowest priority (so that it only runs when nothing else is ready to run) with an infinite loop. A counter is incremented inside the loop, so that the counter

47

value can be used to determine roughly how much time the processor has spent running the lowest priority

thread. A load-monitoring program implemented in this manner was posted to the ecos -discuss mailing