FOREST SERVICE MANUAL PACIFIC NORTHWEST REGION (REGION 6) PORTLAND, OREGON

advertisement

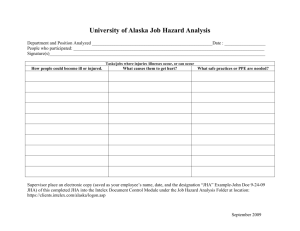

6713 Page 1 of 7 FOREST SERVICE MANUAL PACIFIC NORTHWEST REGION (REGION 6) PORTLAND, OREGON FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION R6 Supplement No.: 6700-2012-2 Effective Date: August 21, 2012 Duration: This guide is effective until superseded or removed. Approved: Nora B. Rasure For the Regional Forester Date Approved: 08/16/2012 Posting Instructions: Supplements are numbered consecutively by title and calendar year. Post by document; remove the entire document and replace it with this supplement. Retain this transmittal as the first page(s) of this document. The last supplement to this title was R6 FSM-6700-2012-1. New Document R6 FSM 6713.2 - 6713.5 Superseded Document(s) by Issuance Number and Effective Date None 7 Pages 0 Digest: 6713.2 to 6713.5 – Establishes Region 6 Risk Management Guide. These guidelines are for Region 6 Forest Service only. R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION TABLE OF CONTENTS 6713 – STANDARDS ........................................................................................... 3 6713.1 – Adoption of Standards ..................................................................................... 3 6713.2 – Principles ......................................................................................................... 3 6713.3 – Region 6 Program Requirements ..................................................................... 3 6713.4 - Tools ................................................................................................................. 4 6713.5 – Risk Assessment Implementation .................................................................... 5 6713 Page 2 of 7 R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION 6713 – STANDARDS 6713.1 – Adoption of Standards 6713.2 – Principles This guide establishes the Region 6, Risk Management Program. The intent behind making risk based decisions is to identify, mitigate, and control risk at the lowest possible levels. This guide outlines a five-step process that provides employees and managers with a systematic and consistent method for identifying and managing risks associated with any operation. There are four foundational principles associated with risk management which should be continuously employed throughout all operations. These principles are as follows: 1. Integrate risk management into decision-making, planning, preparation, and execution of agency activities during the earliest stages possible. 2. Make risk decisions at the appropriate level in the chain of command. 3. Accept no unnecessary risk. 4. Accept risk only if the benefit outweighs the potential cost. 6713.3 – Region 6 Program Requirements 1. Management of risk will be incorporated into policy decisions, project planning, and field operations. The five-step risk management process is as follows: a. Identify the hazards. Employees and supervisors will work together to break down the operation into the essential tasks and identify the hazards associated with each task. This typically can be accomplished by completing the agency Job Hazard Analysis (JHA) Worksheet. b. Assess the risks. Analyze each hazard and assess the risk using the Risk Assessment Code Matrix see in Exhibit 01. c. Develop control measures and make a risk decision. Develop mitigating measures that eliminate or reduce the hazard and associated risk. As mitigating measures are developed, reevaluate hazards until all risks are reduced to an acceptable level. The level of risk remaining after controls have been identified and selected is the residual risk. 6713 Page 3 of 7 R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION The decision to accept or reject the residual risk(s) associated with an action continues to reside with line officers. d. Implement control measures. Put mitigating measures (defenses) in place that eliminate the hazards or reduce their risks to an acceptable level. e. Supervise and evaluate. Enforce use of selected controls. Evaluate the effectiveness of controls and adjust or update as necessary. 2. When employees and managers use this five-step process collaboratively to identify potential hazards and risks associated with their work assignments, they should be able to mitigate potential risk exposure to the lowest levels possible. When risk levels cannot be reduced, employees and managers may then make informed, risk-based decisions, as to whether or not the work truly needs to be accomplished. These basic foundational risk management concepts are consistent with our agency value that reads, “The safer we are the more successful we are”. Employee and managerial responsibilities for integrating risk management are: a. Supervisors will ensure their employees are knowledgeable of this guide, how to make risk based decisions and how to complete a Job Hazard Analysis (JHA), R6-FS Form 6700-7, as well as familiarity with using the Risk Assessment Code Matrix in Exhibit 01. b. Line officers, managers, supervisors and employees will work collaboratively to employ the 5-step process to mitigate unacceptable risks. c. Managers and employees will integrate risk management principles into decisions, policies, processes, planning, and operations. 6713.4 - Tools Risk assessments should be accomplished during the planning stage of an operation using the Risk Assessment Code Matrix (in Exhibit 01) and the JHA Worksheet. Remember, JHAs are a form of risk assessments in that they are a document which identifies potential risk and associated risk mitigation measures. Risk Assessments should be completed for each facility safety deficiency and employee hazard report in order to prioritize risk mitigation efforts and agency resources. 1. Use of the JHA Worksheet. The JHA Worksheet provides a tool for identifying hazards, assessing risk, developing and implementing control measures, enforcing use of selected controls, and evaluating their effectiveness. When used effectively, JHAs should help reduce the knowledge gap between employees and supervisors when designing new 6713 Page 4 of 7 R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION work procedures or when accepting new job tasks. Instructions are on the back side of the form. 2. Use of the Risk Assessment Code (RAC) Matrix. The RAC Matrix is a tool that can be used to determine how risky an identified hazard is in terms of probability and severity. Each severity definition hazard is first assessed in relation to the probability of a hazardous event occurring below (Exhibit 02). Then the potential severity of each hazard is assessed in the probability definitions in (Exhibit 03). Severity is expressed in terms of degree of injury or illness, loss of or damage to equipment or property, or environmental damage. Finally, probability and severity are translated into a risk level that must be either accepted or rejected. 3. Levels of Risk. There are four levels of risk that leadership must consider and accept or reject. These levels are determined through the use of the Risk Assessment Matrix, and are based on the severity of a hazard should it occur, and the probability that the hazard will occur. Decisions to accept or reject risk continue to reside with line officers. The four risk levels are: a. Extremely High Risk: Death or permanent disability, system loss, major property damage. b. High Risk: Permanent partial disability, temporary total disability in excess of 3 months, major system damage, significant property damage. c. Medium Risk: Minor injury, lost workday accident, compensable injury/illness, minor system damage, minor property damage. d. Low Risk: First aid or minor medical treatment, minor system damage. 6713.5 – Risk Assessment Implementation 1. Risk assessments come in many versions but the two most common forms in the Forest Service are the JHA and the Tailgate Safety Session. 2. The JHA Worksheet, used in concert with the Risk Assessment Matrix, should be accomplished during the planning phase of any project that may expose employees to considerable risk of injury, illness or property damage. JHAs tend to lose their value when developed for every single work task imaginable. The unintended consequence for this is that JHAs for high risk projects and tasks become hidden amongst a volume of JHAs that were developed for basic, everyday tasks, such as walking across a parking lot, using a shredder, etc. 6713 Page 5 of 7 R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION a. The JHA Worksheet should be filled out completely and approved at the appropriate level. This approval does not necessarily have to be received in writing. If verbal approval from the risk decision authority is received, note this fact on the worksheet (i.e., date, time and person issuing the verbal approval). b. All personnel involved in the operation must be briefed on the JHA as it pertains to their operational area. c. A copy of each applicable JHA will be available at the work site. d. Supervisors will review JHAs with crew members prior to beginning new projects or changing work sites. Identify hazards not noted on the JHA. Discuss ways to reduce these hazards, including the use of protective equipment. Document these meetings. File documentation with other project work documents when the project is completed. e. At the conclusion of the operation, the JHA should be reviewed to determine its level of effectiveness. An informal after action review should address shortfalls and should lead to recommendations which can improve the JHA and subsequently enhance employee safety for future, similar operations. 2. Field Risk Assessments (Tailgate Safety Sessions). Tailgate sessions will be used: a. At the beginning of each shift prior to commencing field work. A written tailgate safety session summary, or reviewing the JHA, is not required when the work is pretty consistent each day. However, when new hazards become apparent, or changing environmental conditions potentially increase the risk of the work, these situations should be discussed and addressed. b. When a JHA is not necessary, such as for low risk projects and routine recurring work. 6713 Page 6 of 7 R6 SUPPLEMENT FSM-6700-2012-2 EFFECTIVE DATE: August 21, 2012 DURATION: This supplement is effective until superseded or removed. 6713 Page 7 of 7 FSM 6700 – SAFETY AND HEALTH PROGRAM CHAPTER 10 – SAFETY AND HEALTH PROGRAM ADMINISTRATION 6713.2 – Exhibit 01 Risk Assessment Code (RAC) Matrix Safety Risk Assessment Codes HAZARD PROBABILITY Frequent A SEVERITY Catastrophic Critical Likely B Occasional C Extremely High I II High (RAC 2) (RAC)1 Marginal III Negligible IV High (RAC 2) Unlikely E Medium High (RAC 2) (RAC1) Extremely High Seldom D (RAC3) Medium (RAC 3) Medium (RAC 3) Low (RAC 4) Low (RAC 4) Low (RAC 4) 6713.4 – Exhibit 02 Severity Definitions Severity Effect Catastrophic I Death or permanent disability, system loss, major property damage Critical II Permanent partial disability, temporary total disability in excess of three months, major system damage, significant property damage Marginal III Minor injury, lost workday mishap, compensable injury/illness, minor system damage, minor property damage Negligible IV First aid or minor medical treatment, minor system impairment 6713.4 – Exhibit 03 Probability Definitions Probability A. Frequent B. Likely C. Occasional D. Seldom E. Unlikely The event occurs often, frequently, or with regularity in one’s career or the life cycle of equipment items The event occurs periodically with some regularity but not frequently enough to be predictable The event occurs sporadically but not with consistent regularity or predictability in ones career of the life cycle of equipment Possible to occur but the chances of the event occurring are remote In this case, it is unlikely the event will ever occur