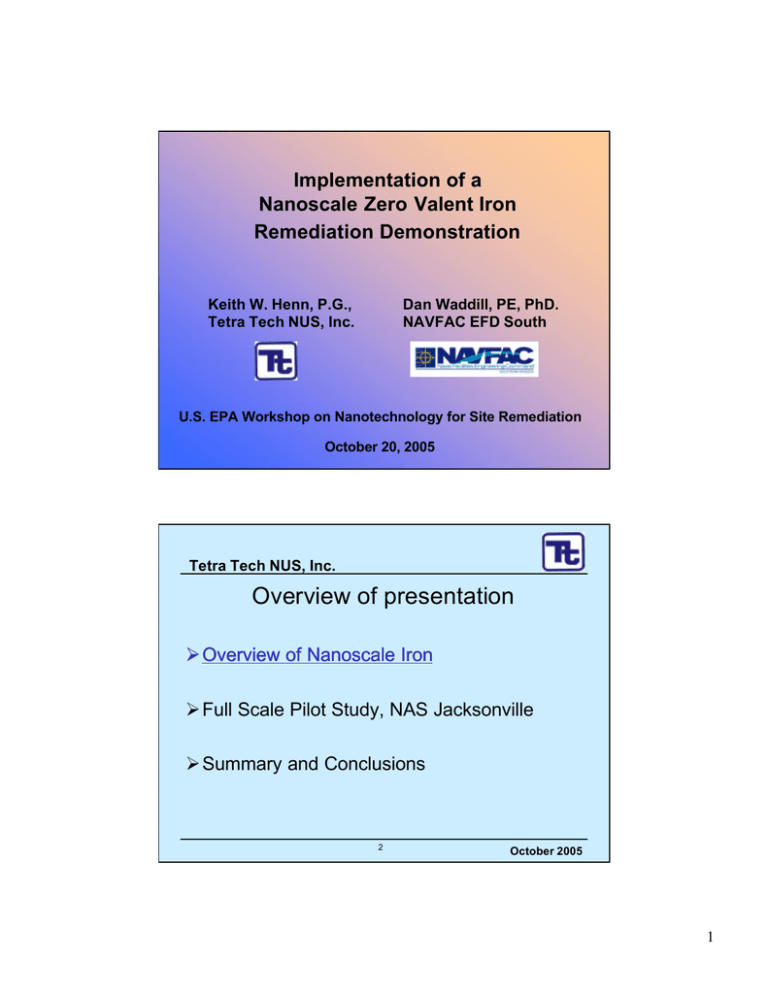

Overview of presentation Implementation of a Nanoscale Zero Valent Iron Remediation Demonstration

advertisement

Implementation of a Nanoscale Zero Valent Iron Remediation Demonstration Keith W. Henn, P.G., Tetra Tech NUS, Inc. Dan Waddill, PE, PhD. NAVFAC EFD South U.S. EPA Workshop on Nanotechnology for Site Remediation October 20, 2005 Tetra Tech NUS, Inc. Overview of presentation Ø Overview of Nanoscale Iron Ø Full Scale Pilot Study, NAS Jacksonville Ø Summary and Conclusions 2 October 2005 1 Nanoscale Zero Valent Iron Dehalogenation Schematic C2 Cl3 Other Contaminants •Chlorinated VOCs •Nitrates •Metals (e.g, Cr, As) •Chlorinated Pesticides C2 H6 + 3Cl- eFe2+ Base metal - Electron donor Noble Metals: - forms galvanic cells - catalyze hydrogenation ~10-600 nm Base Metal Noble Metal Fe 0 Pd Source: modified after Lehigh University MW-28 Site Background N MW-33 Ø Small area (1050 sq ft) MW-32 MW-30 MW-37 Ø Utility corridor MW-8 MW-29 Ø Geology MW-34 • Silty to fine sand from 0 to 24 feet bgs MW-31 MW-36 • Dense clay from 24 to 54 ft bgs MW-38 MW-01 Ø Hydrogeology • Flow toward southeast • Water table at 7 feet bgs Groundwater flow direction • Hyd. Conduct. ~2 ft/day 0 4 5 10 15 MW-39 October 2005 2 Site Contamination Summary GW Flow Hangar 1000, NAS Jacksonville Maximum Total VOC 550 mg/kg in soil 80 mg/L in groundwater Chemical oxidation conducted in 2001 Full Scale Pilot Study Design • Remedial Goal as defined in the Work Plan – Reduce contaminant mass 40 to 50% – Not expected to reach groundwater MCLs – MNA anticipated as next step • How much iron is needed? – – – – Reaction Capactity (VOCs : Nano Fe) = ~1:5-10 by wt. CVOC mass estimated: 42 to 125 lbs Need an estimated 210 to 1250 lbs Injected 300 lbs • Two injection methods: – Strategic DPT injections – Recirculation Process Source: U.S. Navy 6 October 2005 3 Tetra Tech NUS, Inc. Recirculation Setup 7 October 2005 8 October 2005 Nanoscale Iron – Polymer Supported w/Palladium Catalyst – No carbon substrate 4 Recirculation: Hydraulic Results •Keep iron in source •Good mixing Before •Good iron distribution (Dec 29th) During (Jan 21st ) After (Jan 23rd) Injections #1 and #2 October 2005 Chlorinated Ethene 150 Source Well H10MW37 Molar Concentrations Injections #1 and #2 VC CIS-1,2-DCE TCE 100 PCE 75 50 25 Chlorinated Ethane 0 4 /03 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 3/0 /04 /04 /04 /04 /04 /04 /04 /04 /04 /20 /02 1/15 1/28 2/10 2/23 3/07 3/20 4/02 4/15 4/28 5/11 5/24 6/06 6/19 7/02 7/15 7/28 8/10 8/2 9/05 9/18 0/01 0/14 0/27 1/09 1/22 2/05 2/18 12 01 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 30 Molar Concentration (uM/L) Molar Concentration (uM/L) ETHENE+ETHANE 125 3 6 Date Months 9 12 25 20 ETHENE+ETHANE 15 1,2-DCA VC 10 1,1-DCE CA 5 1,1-DCA 1,1,1-TCA 0 /03 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /20 /02 /15 /28 /10 /23 /07 /20 /02 /15 /28 /11 /24 /06 /19 /02 /15 /28 /10 /23 /05 /18 /01 /14 /27 /09 /22 /05 /18 12 01 01 01 02 02 03 03 04 04 04 05 05 06 06 07 07 07 08 08 09 09 10 10 10 11 11 12 12 0 3 6 Date Months 9 12 5 Injections #1 and #2 Chlorinated Ethene ETHENE+ETHANE Source Well H10MW34 Molar Concentrations Molar Concentration (uM/L) 100 CIS-1,2-DCE 75 TCE PCE 50 25 0 Chlorinated Ethane Injections #1 and #2 VC 4 4 4 4 4 4 /03 /04 /0 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /0 /04 /04 /0 /04 /04 /0 /0 /04 /0 /20 /02 /15 /28 /10 /23 /07 /20 /02 /15 /28 /11 /24 /06 /19 /02 /15 /28 /10 /23 /05 /18 /01 /14 /27 /09 /22 /05 /18 12 01 01 01 02 02 03 03 04 04 04 05 05 06 06 07 07 07 08 08 09 09 10 10 10 11 11 12 12 0 20 3 6 Date Months ETHENE+ETHANE 18 12 1,2-DCA 16 Molar Concentration (uM/L) 9 VC 1,1-DCE 14 12 CA 1,1-DCA 10 1,1,1-TCA 8 6 4 2 0 /03 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 /20 /02 /15 /28 /10 /23 /07 /20 /02 /15 /28 /11 /24 /06 /19 /02 /15 /28 /10 /23 /05 /18 /01 /14 /27 /09 /22 /05 /18 12 01 01 01 02 02 03 03 04 04 04 05 05 06 06 07 07 07 08 08 09 09 10 10 10 11 11 12 12 0 3 6 Date Months 9 12 Injections #1 and #2 Butane 5 Beta-Elimination Pathway 4 Concentrations (mg/L) 6.6 mg/L 3 2 Acetylene, Butane, & Isobutane 0 Injections #1 and #2 12 /2 0/0 01 3 /0 5/0 01 4 /2 1/0 02 4 /0 6/0 02 4 /22 /0 03 4 /0 9/0 03 4 /25 /0 04 4 /10 /0 04 4 /26 /0 05 4 /12 /0 05 4 /28 /0 06 4 /1 3/0 06 4 /29 /0 07 4 /1 5/0 07 4 /3 1/0 08 4 /1 6/0 09 4 /0 1/0 09 4 /17 /0 10 4 /03 /0 10 4 /19 /0 11 4 /04 /04 11 /20 /0 12 4 /06 /0 12 4 /2 2/0 4 Injections #1 and #2 1 Acetylene Time 0.2 Concentrations (mg/L) 3 2 0.1 1 0 12 /20 /0 01 3 /05 /04 01 /2 1/0 02 4 /0 6/0 02 4 /2 2/0 03 4 /09 /0 03 4 /2 5/0 04 4 /1 0/0 04 4 /2 6/0 05 4 /12 /0 05 4 /28 /0 06 4 /13 /04 06 /2 9/0 07 4 /1 5/0 07 4 /3 1/0 08 4 /16 /0 09 4 /0 1/0 09 4 /1 7/0 10 4 /0 3/0 10 4 /19 /0 11 4 /04 /0 11 4 /20 /0 12 4 /0 6/0 12 4 /2 2/0 01 4 /07 /05 0 0 3 6 Months Time 9 12 12 /20 /0 01 3 /05 /0 01 4 /21 /0 02 4 /06 /04 02 /22 /0 03 4 /09 03 /04 /25 /0 04 4 /10 /0 04 4 /26 /04 05 /12 /0 05 4 /28 /0 06 4 /13 06 /04 /29 /0 07 4 /15 /0 07 4 /31 /04 08 /16 /0 09 4 /01 /0 09 4 /17 10 /04 /03 /0 10 4 /19 /0 11 4 /04 /04 11 /20 /0 12 4 /06 12 /04 /22 /04 Concentrations (mg/L) Isobutane Isobutane 4 0 3 6 Time Months 9 12 6 Round 1 (baseline) TCE isoconcentrations 13 October 2005 14 October 2005 Round 3 (after inject) TCE isoconcentrations 7 Round 11 (after inject) TCE isoconcentrations 15 October 2005 Injections #1 and #2 Dissolved Oxygen 3 Oxygen & ORP 2.5 Concentrations (mg/L) Geochemistry Results 2 1.5 1 0.5 0 Injections #1 and #2 Oxidation-Reduction Potential 250 4 4 /03 /04 /04 /04 /04 /04 /04 /04 /04 /04 /04 3/0 /04 /04 /04 /04 /04 /04 3/0 /04 /04 /04 /04 /04 /20 1/05 1/21 2/06 2/22 3/09 3/25 4/10 4/26 5/12 5/28 6/1 6/29 7/15 7/31 8/16 9/01 9/17 0/0 0/19 1/04 1/20 2/06 2/22 12 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 0 3 6 Time Months 9 12 ORP (millivolts) 150 50 H10MW10 (upgradient well) H10MW32 (source well) -50 H10MW34 -150 H10MW37 -250 (source well) H10MW38 (down grad. well) H10MW39 (down grad. well) 12 /20 /0 01 3 /05 /0 01 4 /21 /0 02 4 /06 /0 02 4 /22 /04 03 /09 /0 03 4 /25 /0 04 4 /10 /0 04 4 /26 /0 05 4 /12 /0 05 4 /28 /0 06 4 /13 /04 06 /29 /0 07 4 /15 /0 07 4 /31 /0 08 4 /16 /04 09 /01 /0 09 4 /17 /0 10 4 /03 /0 10 4 /19 /0 11 4 /04 /0 11 4 /20 /0 12 4 /06 /0 12 4 /22 /04 -350 (source well) 0 3 6 Months 9 12 8 12 /2 0/0 01 3 /05 /0 01 4 /2 1/0 02 4 /06 /0 02 4 /2 2/0 03 4 /0 9/0 03 4 /2 5/0 04 4 /1 0/0 04 4 /26 /0 05 4 /1 2/0 05 4 /28 /0 06 4 /1 3/0 06 4 /2 9/0 07 4 /15 /0 07 4 /3 1/0 08 4 /16 /0 09 4 /0 1/0 09 4 /1 7/0 10 4 /03 /0 10 4 /1 9/0 11 4 /04 /04 11 /2 0/0 12 4 /06 /0 12 4 /22 /0 01 4 /0 7/0 5 Concentrations (ug/L) 12 /2 0/0 3 01 /0 5/0 01 4 /2 1/0 4 02 /0 6/0 02 4 /22 /04 03 /0 9/0 03 4 /25 /04 04 /1 0/0 04 4 /26 /04 05 /1 2/0 4 05 /2 8/0 06 4 /1 3/0 4 06 /2 9/0 07 4 /15 /04 07 /3 1/0 08 4 /16 /04 09 /0 1/0 09 4 /17 /04 10 /0 3/0 4 10 /1 9/0 11 4 /0 4/0 4 11 /2 0/0 12 4 /06 /04 12 /2 2/0 4 Concentrations (mg/L) 25 0 12 /2 0/0 01 3 /0 5/0 01 4 /21 /0 02 4 /06 /0 02 4 /22 /04 03 /0 9/0 03 4 /2 5/0 04 4 /10 /0 04 4 /26 /0 05 4 /12 /04 05 /2 8/0 06 4 /1 3/0 06 4 /29 /0 07 4 /15 /04 07 /3 1/0 08 4 /1 6/0 09 4 /01 /0 09 4 /17 /0 10 4 /03 /04 10 /1 9/0 11 4 /0 4/0 11 4 /20 /0 12 4 /06 /04 12 /2 2/0 4 Injections #1 and #2 0 3 Time 0 6 Months Geochemistry Results Carbon Dioxide, Methane & pH (stable from 6-7) Injections #1 and #2 2500 3 6 Months Concentrations (mg/L) 12 /20 /0 01 3 /05 /0 01 4 /21 /0 02 4 /06 /0 02 4 /22 /0 03 4 /09 /0 03 4 /25 /0 04 4 /10 /0 04 4 /26 /0 05 4 /12 /0 05 4 /28 /04 06 /13 /0 06 4 /29 /0 07 4 /15 /0 07 4 /31 /04 08 /16 /0 09 4 /01 /0 09 4 /17 /0 10 4 /03 /04 10 /19 /0 11 4 /04 /0 11 4 /20 /0 12 4 /06 /0 12 4 /22 /0 01 4 /07 /05 Geochemistry Results Dissolved Iron & Sulfate 3000 9 Concentrations (ug/L) Injections #1 and #2 12000 15 10 5 9 Injections #1 and #2 0 0 3 2000 1000 500 Dissolved Iron 14000 10000 26,000 ug/L 8000 6000 4000 Sulfate 2000 0 3 6 Months Time 6 Months 9 9 12 20 H10MW10 (upgradient well) H10MW32 (source well) H10MW34 (source well) H10MW37 (source well) H10MW38 (down grad. well) 0 H10MW39 (down grad. well) 12 250 Carbon Dioxide 200 150 100 Methane 50 12 4750 ug/L Time 1500 H10MW10 (upgradient well) H10MW32 (source well) H10MW34 H10MW37 (source well) (source well) H10MW38 (down grad. well) 0 H10MW39 (down grad. well) Time 12 9 Is there evidence for biological activity? Ø qPCR analysis for Dehalococcoides (GC/ML) conducted in 3 wells: Well Baseline (GC/ML) 12 months after injection (GC/ML) H10MW10 500 U 18 H10MW37 500 U 25 U H10MW39 174 1.65 19 October 2005 Soil Sampling Summary Percent change: Soil data before & after study Soil Boring H1K -03 H1K -31 H1K -31 H1K -34 H1K -35 H1K -36 H1K -38 Depth ( feet-bgs) 19' 8' 20' 20' 22' 20' 20' 16' - -50% -93% -100% -92% - - -99% 1,1,1-TCA H1K -39 1,1-DCA 5% - - -84% -43% - -91% 46% 1,1-DCE - -36% - - -77% - -97% - Methylene chloride - - - -100% - - - - PCE - -28% -100% - -99% - - - TCE -100% 141% -96% -100% -100% -100% -100% - - - - - - - - - cis-1,2-DCE 267% - 1026% 174% 11% - -71% 18% Total % Change 11% 8% 92% 92% 75% 94% 88% 25% Vinyl chloride RED/Yellow - indicates DECREASE in concentration BLUE/ Gray - indicated INCREASE in concentration 20 October 2005 10 Mass Reduction Summary Ø Total Mass Reduction before & after study Ø Soil mass Ø Dissolved mass Ø Sorbed mass Maximum Most Likely Minimum Pre-Injection (Baseline) Post-Injection (after Round 11) Pounds destroyed Percent Difference 125 lbs 61 lbs 42 lbs 47 lbs 47 lbs 35 lbs 78 14 7 62% 23% 16% RED/Yellow - indicates DECREASE in concentration BLUE/ Gray - indicated INCREASE in concentration 21 October 2005 How much was it? Ø Total Cost to Implement: $260K (2004) • Iron injection costs: $112K • Nanoscale iron: $37K (late 2003) * • Today this cost would have been $5 to 14K • Monitoring costs: $111K Ø Comparable to other technologies today… • • • • Nanoscale iron: $185K (2005) Chemical Oxidation: $145K Bioremediation $ 150K - $175K Excavation: $385K – $485K * Pound per pound is not a good comparison 22 October 2005 11 Summary Ø Data suggests favorable results • Significant TCE & 1,1,1-TCA reductions across the site • Generation of daughter products • cis-1,2 DCE, 1,1-DCE, 1,1-DCA • very little VC • Mass destruction evident • Good mass balance in some wells • Ethene & ethene conentrations increased up to 2 order (770%) • Acetylene and light hydrocarbons increased up to 2 order • Longevity of iron: 6 to 9 months 23 October 2005 Summary (cont.) Ø Data suggests favorable results (cont.) • • Plume extent was reduced (MW-33 & MW-36) At or below GCTLs levels in MW-39 (downgradient well) • Reduced mass flux from source Ø Concentrations in the ‘core’ returned (expected) • Elevated concentations returned in source wells (MW-08, MW-32, MW- 37) Ø Mass reduced between 16 and 63 % • • We met the 40-50% reduction goal (regulators) To be included in the ROD for site Ø Further reductions could have been achieved (not needed to meet project goals) 24 October 2005 12 Is this the Silver Bullet ? Ø It works…but not in all cases. – Quick…Not much to do (no nutrients, no pH issues) – Good for small sources…not for very large ones – Bioremediation may work better in some environments – An emerging science that is making strides – Treatment trains and ‘combinations’ 25 October 2005 Tetra Tech NUS, Inc. Thanks for attending Keith Henn, PG Phone: 412-921-8146 Email: hennk@ttnus.com 26 October 2005 13