Developments in SRC Willow R & D in Northern Ireland, UK

advertisement

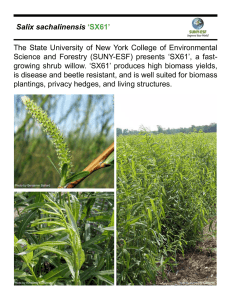

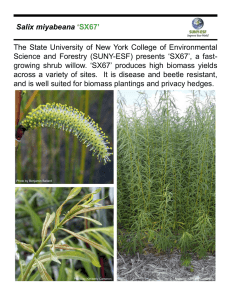

Developments in SRC Willow R & D in Northern Ireland, UK Alistair R. McCracken & Linda Walsh Northern Ireland has been involved in SRC willow R & D since the mid- 1970s NORTHERN IRELAND • • • • • Less than 6% tree cover Imports >95% of its energy Strongly agricultural Maritime climate (wet and cool) Very good growth potential A green patchwork of small, irregular fields N. Ireland ca. 1000 ha SRC willow ca. 86,000 ha forestry Why Salix (willow) ? • Native • Pioneer species • Ease of propagation: Preformed root initials (adventitious roots) • Ease of coppicing • Vigorous juvenile growth Genotype evaluation • Swedish Breeding Programme (Lantmännen Agroenergi AB) • European Breeding Programme (formerly at Long Ashton: now at Rothamsted Research) • US Breeding Programme (Prof. Larry Smart) N. Ireland Trial US genotypes: European / Swedish genotypes US Trial • Only four (out of 13) genotypes had good growth potential and did not suffer excessively from potato leaf hopper – Nimrod – Terra Nova – LA970253 – LA980451 Rust (Melampsora epitea) Plant genotype mixtures 7 ha trial (two blocks) using mixtures with 20, 15, 10 and 5 components planted at three densities Mixtures • Delay onset of rust • Slows build up of disease • Significantly reduces impact of disease • Reduces impact of beetle damage • Helps sustainability following frost • Increases yields Mixtures give increase in yield Plant genotype mixtures Use at least SIX genotypes THREE from Sweden THREE from European programme Plant in random / short runs Willow beetle Phratora vulgatissima SRC Willow harvesting • Direct chip • Whole stem harvesting • ‘Biobailer’ SRC Willow harvesting systems Direct harvest and chip Requiring forced air drying Rod harvester Requiring specialist chipping equipment Deterioration of stored wood chip Pattern of drying with forced air under-floor system 6 ha Miscanthus and novel biomass crops Research into biomass drying and storage Renewable Energy Centre with advanced biomass heating and electricity generation Solar panel water heating for dairy parlour Research into Anaerobic digestion of manures Research into Bio-remediation of farm dirty water CHP Biogas 350 Kw Biomass 150 Kw Biomass Performance of Biomass Fuels Boiler heat output and ash Energy from willow wood chip • SRC willow wood chip dry matter has approximately 19 MJ kg-1 • This is 45% of the energy of an equivalent volume of light fuel oil • One hectare produces equivalent of ~ 3,300 – 5,700 litres of heating oil per year 3000 litres of oil year-1 8.02 t CO2 year-1 Wood: 7 Kg CO2 per GJ Heating oil: 79 Kg CO2 per GJ Burning wood chip will reduce CO2 emissions by 90% South West College (Omagh Campus) South West College (Omagh Campus) Carbon Trust Report (January 2007) Utility Electricity Fuel Oil LPG Willow (biomass) Total energy Purchased Energy Cost CO2 emissions (t) kWh yr-1 % £ yr-1 % 1,150,180 34.0 72,344 52.1 494.6 1,1529,724 45.3 51,976 37.4 397.7 75,967 2.2 4,606 3.3 16.0 625,000 18.5 10.000 7.2 0 3,380,871 100 138,926 100 908.3 Carbon sequestration by SRC Willow • Non-harvested above-ground biomass (stumps) • Below-ground biomass (coarse and fine roots) • Inputs to soil organic matter Using willow as a multi-functional crop • Bioremediation of effluents and sludges Trial site Culmore WWTW Soil water Soil Water - Ec Case Study Linwoods Food Processor Produce 26,000 m3 effluent / year Tankered to WWTW 11km away 3,000 round trips yr-1 = 66,000 Km Food Processor Effluent to SRC Willow Pictures from Rural Generation Ltd Carbon savings • Transport (66,000 km) – 17 t CO2 yr-1 (400 g Km-1) • Effluent treatment – 3 t CO2 yr-1 • Production of wood chip (10 t ha-1 yr-1) – 180 t CO2 yr-1 (wood chip = 500,000kWh) • Total C savings approximately 200t yr-1 Conclusions • SRC willow is ‘coming of age’ • Contributes to Renewable Energy targets • Contributes to GHG emission targets • NI technologies are transferable Thank You