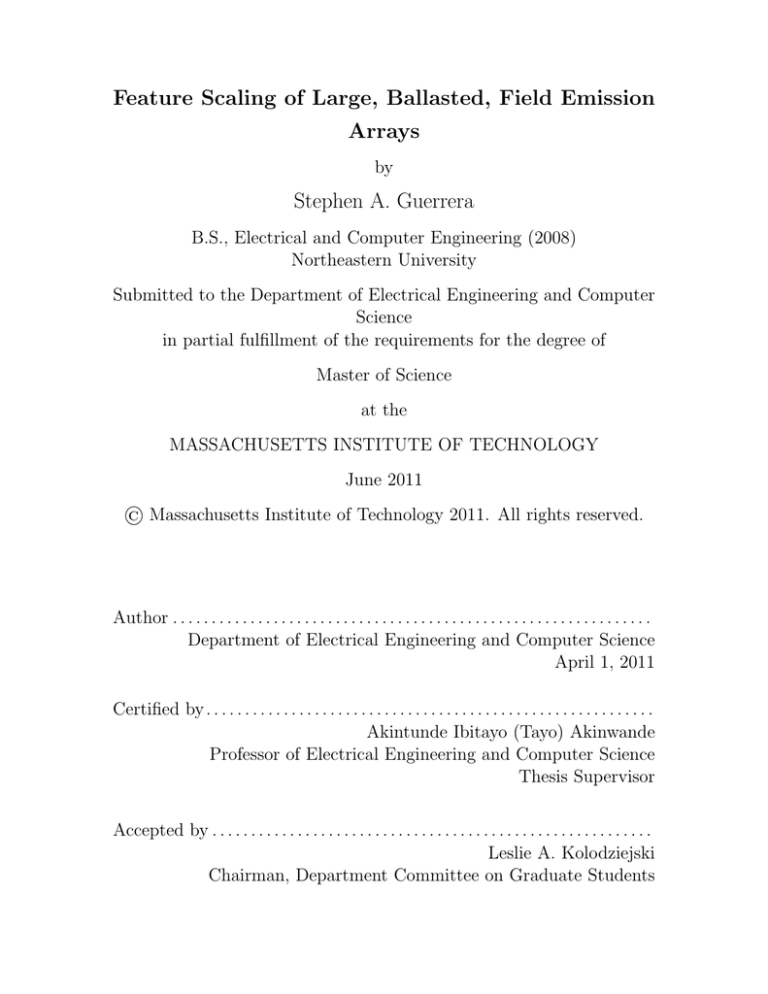

Feature Scaling of Large, Ballasted, Field Emission Arrays Stephen A. Guerrera

advertisement