2006 SUNY-ESF Green Building Conference The Economics of Green May 16-17, 2006

advertisement

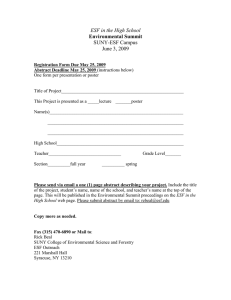

2006 SUNY-ESF Green Building Conference The Economics of Green May 16-17, 2006 Current/Upcoming GBC Conference SUNY-ESF hosted the Annual Green Building conference on Tuesday, May 16 and Wednesday, May 17, 2006 on the SUNY-ESF campus in Syracuse, NY. "The Economics of Green" Press Release Presentations Enable’s Greening Experience - Tracie Baule-Hall Wood as a Green Building Material - Jim Wilson Construction Waste Recycling - Michael Deane LEED and Sustainable Buildings: Contractors Role - Steve Beck Sponsored by: Also sponsored by: Pathfinder Engineers LLP Pella Windows & Doors ASHRAE (American Society of Heating, Refrigerating Hill & Markes and Air-Conditioning Engineers) Robson Woese Inc. C & S Companies Turner Construction Agenda Tuesday, May 16th Agenda Time Green Building Agenda 8:00 - 8:30 am Registration and Continental Breakfast, Alumni Lounge, Marshall Hall 8:30 - 9:15 am Presentation: Enable's "Greening Experience" Tracie Baule-Hall, Enable 9:15 - 10:00 am Presentation: Sustainable Buildings and LEED: The Contractor's Role Steve Beck, LeChase 10:00 10:15 am Break 10:15 11:15 am Presentation: Wood as a Green Building Material Jim Wilson, Oregon State, Oregon. Topic: Life Cycle Analysis, Consortium for Research on Renewable Industrial Materials (CORRIM) 11:15 - Presentation: Construction Recycling Michael Deane, Turner Construction 12:00 pm 12:00 - 1:15 pm 1:15 - 2:15 pm 2:15 - 2:30 pm Lunch (provided) Presentation of the USGBC NY Upstate Chapter's Web Site with the new interactive "Green Events" Calendar, presented by Charle-Pan Dawson, NYSERDA and Bill Burdick, W D Burdick Company Narrated Tours of the SUNY Campus Green projects - See them all: Fuel Cell, Green Roof, Photovoltaic installation, Biodegradable plastic, Wood Chips and Biomass Break 2:30 - 3:15 pm Round Table Discussion: Question and Answer Session with all of the presenters 3:15 - 4:00 Presentation on Campus Green Building projects President Neil Murphy Q&A from the Press 4:15 pm 5:00 pm Social Hour and Cash Bar available 5:00 - 6:30 pm Buffet Dinner with keynote address by: Wayne Trusty, Athena Institute, Ottawa, Canada. Topic: Life Cycle Assessment 6:30 - 6:45 pm Q&A with Wayne Trusty Wednesday, May 17th Agenda -Earn a total of 7 CEUs for BOTH modules! Seats available! Time LEED MODULES -Each Module earns 3.5 Continuing Education Units (CEUs) 8:00 8:30 am Registration and Continental Breakfast in the Baker Lobby Room 140 Baker LEED Module (AM) Understanding LEED Project Cost & Returns 8:30 am 12:30 pm 12:00 pm 1:30 pm Lunch served in the Alumni Lounge Marshall Hall (provided to registrants who attend the AM session AND the PM session only). View Exhibits Room 140 Baker LEED Module (PM) Incorporating LEED into Project Specifications 1:30 pm 5:30 pm Hear about strategies for building green with no added costs. Get insights on LEED project cost issues including professional fees, construction costs, and lifecycle costs based on current data from LEED-certified projects and available research. Leave with tools to calculate and evaluate cost and benefits of LEED certification on a given project. Learn how to get maximum benefit from chosen resources. Learn the basic principles of specifications as they apply to green building. Project team members will be provided with strategies to develop construction specifications appropriate to project goals and tips for achieving LEED compliance. Enable’s Greening Experience Tracie Baule-Hall, Development Director at Enable 4th Annual SUNY-ESF Green Building Conference The Economics of Green May 16, 2006 Why did Enable build ‘green’? Comparable mission + Compatible goals Why did Enable build ‘green’? = Healthy For economy people environment Who benefits from our green building? Participants9healthier for compromised immune systems 9more comfortable space 9ideal environment to achieve maximum results from therapies Who benefits from our green building? Employees– 9healthier work environment 9improved morale 9 increased productivity. Who benefits from our green building? Enable – 9energy savings 9reduced operating costs 9stronger marketability 9less absenteeism 9higher productivity. Who benefits from green building? Community – 9better air quality 9economic impact 9reduced solid waste Primary Goal ¾Construct 30,000 square foot facility with: warm water therapy pool wellness center conference & training facilities Initial Challenges ¾Researching ¾Educating ¾Convincing ¾Funding Ultimate Goal ¾ Receive LEED® certification while: Incorporating new technology Focusing on collaborative partnerships Addressing payback of incremental costs Process ¾ Initial charrette held May 2003 ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ Technical Assistance Study & Modeling February 2004 NYSERDA incentive March 2004 LEED® charrette May 2004 Registered with USGBC August 2004 Finalizing plans. drawings, etc. Construction began May 2005 Commissioning began January 2006 Certificate of Occupancy issued February 2006 Challenges ¾Integrated Design Approach ¾‘Green’ Washing ¾Justification of LEED point vs. initial cost vs. incremental cost vs. payback period ¾Funding Concepts Explored High efficiency: roofing, windows, lighting & HVAC Unique dehumidification for natatorium Building Management System Maximizing day lighting LEED-NC® Certification A three step process: Step 1: Project Registration LEED Letter Templates, site access, and on-line project listing Step 2: Technical Support Reference Package Credit Inquiries and Rulings (CIR) Step 3: Building Certification Upon documentation submittal and USGBC review “THE PROJECT” SUSTAINABLE SITES WATER EFFICIENCY ENERGY & ATMOSPHERE MATERIALS & RESOURCES INDOOR ENVIRONMENTAL QUALITY INNOVATION & DESIGN LEED® (Version 2.1) Credit Summary Category Definite Possible Sustainable Site (SS) 8 1 Water Efficiency (WE) 3 1 Energy & Atmosphere (EA) 5 1 Materials & Resources (MR) 3 0 Indoor Environmental Quality 8 3 Innovation & Design 2 Sampling of Resources ¾ High-Performance Buildings http://www.eere.energy.gov/ Detailed profiles of green-building projects to inform and inspire architects, designers, and builders ¾ Five E's Unlimited http://www.eeeee.net information on green building and urban planning ¾ BuildingGreen.com http://www.buildinggreen.com Products reviews, news, articles, and more on green building for architects, designers, and planners ¾ BetterBricks http://www.betterbricks.com Resources for architects, designers, and building managers on using energy efficiency as a design tool and a financial strategy ¾ Sustainable Sources http://www.greenbuilder.com ¾ Green Building Virtual Tours http://www.virtuallygreen.com virtual tours of LEED-certified buildings, serving architects, funders and manufacturers in the green building industry including: Cleveland Environmental Center (Cleveland, OH) TreePeople Center (Los Angeles, CA) Honda Northwest Regional Facility (Gresham, OR) Jasper Ridge Field Station (Woodside, CA) San Mateo County Forensics Lab (San Mateo, CA) ¾ SustainableABC http://www.sustainableabc.com dedicated to exploring the connection between ecology and sustainability as it relates to architecture and design ¾ U.S. Green Building Council http://usgbc.org Ultimate resource for LEED certification and accreditation ¾ GreeningUSA http://GreeningUSA.org Non-profit organization offering advocacy and education for sustainable communities defined through twelve traits Ongoing Challenge "Always design a thing by considering it in its next larger context – a chair in a room, a room in a house, a house in an environment, an environment in a city plan." -Eliel Saarinen, "Time", July 2, 1956 WOOD AS A GREEN BUILDING MATERIAL Life-Cycle Assessment of Wood in Residential and Commercial Construction Jim Wilson CORRIM CORRIM, Inc. and Oregon State University jim.wilson@oregonstate.edu 541-829-1622 Outline Green building guidelines, standards, and policy CORRIM’s effort to document wood as green based on product and building lifecycle studies Example of a whole building and wall assembly life-cycle studies comparing wood to steel and concrete Summary Benefits to using wood products for green building Green Building Guidelines, Standards, and Policy Examples of green building guidelines, certification, and assessment: – LEED (Leadership in Energy and Environmental Design) – Green Globes (Green Building Initiative) – NAHB Model Green Home Building Guidelines – BEES (Building for Environmental and Economic Sustainability) Examples of Green Building to Certification Standards Green Globes LEED Kelley Engineering Center Oregon State University Green Building Guidelines, Standards, and Policy Washington State Law Mandates Green Building April 21, 2005 Olympia, Washington Washington's Gov. Christine Gregoire signed the high performance green buildings bill into law which, according to the governor's office, makes Washington the first state to require that new public buildings meet "green building" standards of energy efficiency, water conservation and other environmental standards. Standard follows LEED for buildings greater than $5 million. Green Building Guidelines, Standards, and Policy U. S. Government Agencies go to Environmentally Preferable Purchasing (EPP)—USDOE, USDA, others…. – Bio-based products – Fuel products Green Building Guidelines, Standards, and Policy Nations (161) sign Kyoto Protocol to limit CO2 emissions U.S. government proposes to reduce “carbon intensity” Governors of seven NE States agree to reduce CO2 emissions and propose carbon credit exchange Governors of three Western States sign Global Warming Initiative NAHB─How to Get Green Green Building Guidelines say to “incorporate environmental issues into project’s decision-making process.” Green Building Guidelines say to base “the selection of building material on their environmental impact.” Guidelines—Use Life Cycle Analyses to Assess Projects ENVIRONMENTAL ISSUES Raw Material Product Manufacture Home Building Process Maintenance & Operation Home Demolition Product Reuse To Determine Whether a Material or Home is Green Is it a renewable resource? Does it use resource efficient material? Does environmental data such as energy consumption and CO2 emissions exist for material (use Life-Cycle Inventory)? Is Life-Cycle Analysis (LCA) used to analyze product or building Are there comparisons of environmental impacts to select best material, building design, wall assembly, etc.? Demonstrating Wood is a Green Building Material Easy to say but can it be proved! CORRIM Need for Unbiased, Sound Environmental Data Consortium for Research on Renewable Industrial Materials CORRIM National effort to document the environmental performance of all wood products. CORRIM, Inc. A non-profit corporation CORRIM formed by 15 research institutions to conduct lifecycle inventory (LCI) and life-cycle assessment (LCA) studies of wood products. CORRIM’S Purpose To develop a public database and models of environmental performance measures over the life cycles of all wood products To examine a range of management, product, and process alternatives to identify strategies to improve environmental performance of wood products and residential buildings CORRIM’s Research Protocol CORRIM CORRIM’s research follows Life-Cycle Inventory (LCI) and Life-Cycle Assessment (LCA) international protocol of ISO 14040s Standards CORRIM to Provide Environmental Data for Wood Products Life cycle inventory (LCI) data for wood building materials CORRIM AthenaTM EIE LCA Software to assess performance Life cycle assessment of home buildings US LCI Database Environmental database of all US materials and processes CORRIM’S Initial Effort Targeted Structural Wood Products and Home Construction Phase 1 Report July 2004 Reports, presentations, publications, and news releases available on: www.corrim.org Overview CORRIM’s Phase 1 Research “Cradle” Forest Resources & Harvesting PNW and SE Processing of Structural Materials PNW and SE “Gate-to-Gate” • Lumber • Plywood • Glulam • LVL • I-joists • OSB (SE only) Construction of Virtual Residential Buildings to Code • Minneapolis wood and steel designs • Atlanta wood and concrete designs Building “Grave” Use and Disposal Maintenance or Recycle Output of CORRIM Study LCIs of forest, harvesting, and structural wood products. LCAs of the construction, use, and maintenance of residential buildings. Carbon tracking and storage for forest, wood products, and substitution products. Biomass (wood) fuel use. Sensitivity analyses of LCI and LCA models. Benefit cost analyses. Phase 1-- Collected Forest and Production Data & Studied Residential Buildings Minneapolis House Cold Climate Atlanta House Warm Climate Phase 2—Additional Forests and Construction Sites Seattle House Wet Climate Minneapolis House Cold Climate Atlanta House Warm Climate S. Cal. House Great Climate Example of Whole House Life-Cycle Analyses to Compare Building Materials Compared wood- to steel-framed home for cold climate Compared wood-framed to concrete block wall home for warm climate Designed Homes to Local Building Code Minneapolis House Cold Climate Compared wood- to steelframed house designed to same R code. The house is 2,062 sq.ft., two story, concrete basement, sheetrock, insulation, OSB sheathing, wood trusses, vinyl windows, vinyl siding and asphalt roofing. Designed Homes to Local Building Code Atlanta House Warm Climate Compared wood framed to concrete block exterior walls designed to same R code. The house is 2,153 sq.ft., one story, slab on grade, sheetrock, insulation, wood studs, wood trusses, OSB sheathing, vinyl windows, stucco siding and asphalt roofing. CORRIM’s Life-Cycle Assessment of Wood Products & Buildings O2 CO2 Air Emissions SUN Log Management & Harvest Production Construction Water & Land Emissions Life-Cycle Assessment In Terms of Environmental Performance Indices Embodied Energy Global Warming Potential Emissions to air, water and land Resource Use Cold Climate Wood-Framed House Components by Mass Sheetrock 5% Insulation 5% Metal 3% Wood 17% Roofing 5% Siding 2% Although referred to as a wood-framed house, concrete is the dominant mass, with other materials playing lesser roles by mass. Concrete 63% Comparison of Wood- to Steel-Framed House Wood 450% 400% 350% 300% 250% 200% 150% 100% 50% 0% Steel 412% 117% 126% 114% Embodied Energy Global Warming Air Emissions 99% Water Emissions Solid Waste Comparison of Wood-Framed to Concrete Block House Wood 160% 140% 120% 100% 80% 60% 40% 20% 0% Concrete 151% 131% 123% 116% 100% Embodied Energy Global Warming Air Emissions Water Emissions Solid Waste Comparison of Structural Assemblies A menu of environmentally rated: Wall assemblies Floor assemblies Roof assemblies A shopping list of construction options for contractors, designers, and architects to select environmental designs. Fossil Fuel Consumption for Warm Climate Exterior Walls 100 90 Concrete-framed wall results in 150% more energy use. MJ per square foot 80 70 60 50 Concrete 40 Plyw ood 30 Vinyl 20 10 Lumber Stucco Fiberglass Fiberglass Gypsum Gypsum Vapor 0 Lumber wall Concrete wall Exterior w all designs for w arm climate home Lumber Fossil Fuel Consumption for Cold Climate Exterior Walls 100 90 MJ per square foot 80 70 60 Steel 50 40 30 20 Lumber EPS Fiberglass Plyw ood Fiberglass Plyw ood Vinyl Vinyl 10 Gypsum 0 Lumber wall Vapor Gypsum Vapor Steel wall Steel-framed wall results in 30% Lumber more fossil fuel Plyw ood use. w/substitutes Lumber Exterior w all designs for cold climate home CORRIM’s Expanded Effort CORRIM to complete Phase 2 research on wood products this summer, it expands upon the initial study: – Extends source location of forest resources to other regions – Assess home building in other regions – Assess low-rise, multi-family home buildings – Extend wood products to non-structural products such as hardwood flooring and MDF – Full product LCI’s and LCA’s – Component-by-component construction analyses of walls, floors, roofs and assemblies. Summary Wood is Green—Study validates the environmental friendliness of wood compared to other common structural building materials. Material Selection—Study provides ways to enhance environmental performance of buildings through material selection and design. Publicly available database—Study provides environmental data on structural wood products. Benefits to Using Wood Products Wood is a green building material in comparison to other materials – Data is available in U.S. LCI Database; however, for your use it will likely be by using building guidelines, standards and design assessment software (i.e., AthenaTM, BEES, Bio-based EPP, and eventually LEED and Green Globes) Benefits to Using Wood Products Wood is sustainable and renewable whether for forest, products, or fuel Wood is resource efficient Wood can store carbon in forest, products, and landfills removing it from the atmosphere as CO2 −reducing global warming CORRIM For more information please see: CORRIM: www.corrim.org AthenaTM: www.athenaSMI.ca US LCI database: www.nrel.gov/lci NAHB Green Build Guidelines: www.nahb.org/gbg BEES: www.bfrl.nist.gov/oae/software/bees.html Green Globes: www.thegbi.com/greenglobes/ Need for Green Building Which Earth will we have? THE HOWS AND WHYS OF CONSTRUCTION WASTE RECYCLING Prepared for SUNY – ESF Green Building Conference May 16, 2006 Michael Deane East Coast Operations Manager Sustainable Construction Turner Construction Company I would like to speak about: • • • • • • • • Brief overview of Turner Green Building Experience Brief overview of Turner Green Commitments Recycling Construction on Every Job - Making it work. How does the leading general builder in the US implement such a process on an average of 1500 projects per year across 40 Business Units throughout the country? How does capacity vary and what different responses are successful in different areas. Where can it work? Where is it still an unrealized goal? Implementation of policy and procedures, progress and pushback Turner Green Building Experience Since Turner Green Building Experience 1995 • Over 150 Projects with Green Building Elements Completed or Under Construction • Construction value: Over $10 Billion • Over 42 million sq. ft. • 20 LEED Certified Projects • 50 LEED Registered Projects • Over 110 LEED Accredited Professionals • (and counting…) Turner’s Commitment to Green • • • • • • • Recycle Construction Waste on All Projects Greening our Field Offices Emerging Green Builders Online LEED Training Double LEED Accredited Professionals Advisory Board Center of Excellence Why is this Important? (Hint: its not about chasing LEED points) • C&D Waste accounts for between 20% and 50% of all waste sent to landfills • Diverted material can be reused, reducing use of virgin materials • Potential cost savings to Owner • Potential revenue stream to Hauler • Good for business • Good for the planet Chapter One – Ignorance is Bliss • January 2005 – this will be easy • February 2005 – we can’t do that in our market • March 2005 – No more *#%! forms Early Wins • New York – Cardella Carting - Already doing it. Just get others to follow. • Boston – Charles George Trucking – Only game in town. He got it. • Nashville - Tennessee Waste – Opportunist. Created a market. • Waste Management – National Firm wanted to serve a big client. Already pretty sophisticated. Early Setbacks • Ohio – Duh? • Texas – too much “wide open space” • Many other places – Hello? Pleasant Surprises • Dallas – A number of green projects gets Management Attention. “Gray Hair” takes over. • Florida – Ditto. And Ditto. Negotiated rebates. Innovators • Ace Waste – market differentiator – committed to green (business model) • Construction Waste Management – committed to green (environmental model) Results – Year One • Turning the Queen Mary BUT • Continuous Improvement BUT • Low Hanging Fruit • All or nothing Results – Year Two (to date) • More reporting = less spectacular results BUT • Standardized reporting now a requirement • Goal One – complete and accurate reporting • Goal Two – improve performance The Future – Are We There Yet? • NO What Does the Future Hold? • Deconstruction CONSTRUCTION WASTE MANAGEMENT INITIATIVE 2006 David Hodgson, Turner Michigan Green Champion Ryan Kline, CWMI Manager Turner Construction Company May ??, 2006 CWMI 2006 - Objectives REDUCE DIVERT RECYCLE CWMI 2006 - Benefits • Develop proficiency in rapidly growing “Green Building” market – Approximately 50% of our earnings comes from LEED projects where construction waste management is a requirement • Influence local C&D debris handlers by increasing demand for diversion – Several local haulers constantly competing for Turner contracts • Earn positive Owner / Public attention – Every little bit helps in Michigan’s competitive market CWMI 2006 - Background September 2004 – Tom Leppert announces Turner’s commitment to sustainability February 2005 – Turner introduces Construction Waste Management Initiative (CWMI) March 2005 – Business Units begin reporting June 2005 – Michigan Green Team issues CWMI Workbook to Business Unit w/ Presentation to PM’s & PX’s October 2005 – Michigan Green Team partners with Michigan Purchasing to incorporate CWMI language in Subcontracts February 2006 – Turner Purchasing provides revised hauler Subcontract; Turner Sustainable Construction provides revised Monthly Project Progress Report CWMI 2006 – Turner’s Mission • Report waste management activity on ALL projects. • Within 3 years, achieve diversion on 100% of projects. • Within 3 years, achieve overall diversion rate of 50%. CWMI 2006 – Michigan’s Mission • Report on 100% of Michigan Projects • Report monthly • Projects implement project-specific CWM Plan • Develop waste hauling market by providing demand for diversion CWMI 2006 - Procedure • 1st Step - Be Proactive!!! • 2nd Step – Remain flexible!!! “Success is not the result of spontaneous combustion. You must set yourself on fire.” - Reggie Leach CWMI 2006 - Procedure • Step 3 – Prepare Project Specific Construction Waste Management Plan Site’s logistical parameters Haulers’ experience/abilities Staff experience/commitments • Step 4 – Include CWMI in Subcontracts Include CWM Plan 2nd Tier haulers must also comply CWMI 2006 - Procedure • Step 5 – Release hauler subcontract Use Form 124 - Rubbish Removal Include CWMP & Monthly Report • Step 6 – Inform workforce Tradesmen need to buy-in Use CWMI Orientation & Toolbox Talk CWMI 2006 - Procedure • Step 7 – Work the CWM Plan Inspect boxes for compliance Issue backcharges/withold payment when necessary • Step 8 – Report Monthly Hauler reports to you You report to BU CWMI Manager CWMI 2006 – Procedure • Step 9 – Follow-up Make sure you’re achieving your target diversion rate Flexibility – May need to revise CWM Plan • Step 10 – Share lessons learned!!! CWMI 2006 – Project Flowchart PRECONSTRUCTION CONSTRUCTION Site Logistics CWM Plan Purchase Hauling Services • Primary Hauler (PA’s) • Second Tier Haulers (Subcontracts) Educate Workforce Work the CWM Plan REPORT CWMI 2006 – Reporting Timeline PREPARE REPORTS Prepared by Haulers – 26th of previous month to 25th of current month REQUEST REPORTS 26TH Day of the Report Month RECEIVE REPORTS COLLATE REPORTS SUBMIT REPORTS Submit to Business Unit CWMI Manager (Ryan Kline) by 1st Tuesday of the Month CWMI – Monthly Project Progress Report • Prepared by Sustainable Construction Division • Developed with the hauler in mind (let them do it!) • Located in Michigan Green Room on TKN - Michigan Pharmacia Building Q CWMI 2006 - Resources • Form 124 – Rubbish Removal Agreement • Construction Waste Management Plan • CWMI Jobsite Orientation • CWMI Toolbox Talks • Local Hauler / Recycler Matrix • Michigan Green Team CWMI 2006 – Lessons Learned DPS Sinai Educational Campus Learning: • Inexperience resulted in lower diversion rates & more staff time invested • Late implementation compromised enforcement Lesson: Steep learning curve = Poor planning/implementation CWMI 2006 – Lessons Learned Metro Hospital Learning: • Researched options for diversion of gypsum wallboard > found vendor • Maintaining dialogue with hauler and subcontractors Lesson: Proactive Management = Successful Diversion (Currently 67%) CWMI 2006 – Lessons Learned Ford Field Parking Deck Learning: • Staff transitions resulted in gaps in communication between project staff. Lesson: Lack of communication = Lost Diversion CWMI 2006 – Future Projects 5th Royal Oak Learning: • Tight site logistics complicate CWMI implementation • Sharing knowledge assisted project team with expanded options Lesson: Proactive Project Staff + Green Team Coordination = Optimized Resources CWMI 2006 – Future Projects HFHS – West Bloomfield Learning: • Project staff included Green Team from start • Discussing challenges with Architect reduced risk in the future Lesson: Proactive Project Staff + Green Team Coordination = Improved Potential for LEED Compliance CWMI 2006 - Strategies • Contract Compliance – Include CWMP in all subcontracts – Enforce compliance through backcharges/fines • Educate the Workforce – Subcontractor PM’s may not explain requirements to Foremen / Tradesmen CWMI 2006 - Strategies • Well-Planned Logistics – Site Separation vs. Commingled • Site Separation = Greater Diversion • Commingled = Reduced Field Management • Hybrid = Optimal – Plan for Progress • Be prepared to adapt CWM Plan for changing site / construction waste CWMI 2006 - Summary • • • • Set up Site Logistics & CWM Plan Use available resources Get everyone on board Report!!! Dolan Center Dalles Middle School Natomas High School Questions?? Any questions please send me an email Mdeane@tcco.com LEED and Sustainable Buildings The Contractors Role TM LeChase Construction Services LLC LEED Green Building Rating System TM z z z z z Of the 7 pre -requisites and 69 available credits: The Contractor has decision making responsibilities for 23 credits The Contractor is responsible for calculations (cost spreadsheets) for 14 credits The Contractor is responsible for 30 submittals The Contractor is responsible for recordkeeping and tracking for 19 credits Credit Responsibilities Sustainable Sites Point Credit Value SSPR1 PR SS 1 1 SS 2 1 SS 3 1 SS 4.1 1 SS 4.2 1 SS 4.3 1 SS 4.4 1 SS 5.1 1 SS 5.2 1 SS 6.1 1 SS 6.2 1 SS 7.1 1 SS 7.2 1 SS 8 1 Subtotal 14 Decision Making Description Construction Activity Pollution Prevention Site Selection Development Density Brownfiled Redevelopment Alternate Transportation - Public Alternate Transporation - Bicycles Alternate Transporation - Efficient Vehicles Alternate Transportation - Parking Capacity Site Development - Protect/Restore Habitat Site Development - Open Spaces Stormwater Design - Volume/Treatment Stormwater Design - Flood Control Heat Island Effect - Non - Roof Heat Island Effect - Roof Light Pollution Owner Design X X X X X X X X X CM Design CM Submittal Design X X X X X X X X X X X X Calculation X X X X X X X X X X X X X X X X CM X X X X X X X X X X X X X Record Keeping Design CM Contractor “Credit” Responsibility z Decision Making Responsibility: ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ SSPR1 – Construction Activity Pollution Prevention SS5.1 – Site Development, Protect/Restore Habitat SS7.1;7.2 – Heat island Effect EAPR1 – Fundamental Commissioning EA3 – Enhanced Commissioning MR2.1; 2.2 – Construction Waste Management MR3.1; 3.2 – Resource Reuse MR4.1; 4.2 – Recycled Content MR5.1; 5.2 – Regional Materials MR6 – Renewable Materials MR7 – Certified Wood EQ3.1; 3.2 – Construction IAQ ID1.1 – 1.4; 2 – Innovation in Design Contractor “Credit” Responsibility z Calculation (cost analysis) Responsibility ¾ ¾ ¾ ¾ ¾ ¾ ¾ MR2.1; 2.2 – Construction Waste Management MR3.1; 3.2 – Resource Reuse MR4.1; 4.2 – Recycled Content MR5.1; 5.2 – Regional Materials MR6 – Renewable Materials MR7 – Certified Wood EQ4.1; 4.2; 4.3; 4.4 – Low Emitting Materials Contractor “Credit” Responsibility z Submittal Responsibility ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ SSPR1 – Construction Activity Pollution Control SS5.1 – Site Development Protect/Restore Habitat SS7.1; 7.2 – Heat Island Effect EAPR1 – Fundamental Commissioning EA3 – Enhanced Commissioning EA5 – Measurement and Verification EA6 – Green Power MR1.1; 1.2; 1.3 – Building Reuse MR2.1; 2.2 – Construction Waste Management MR3.1; 3.2 – Resource Reuse MR4.1; 4.2 – Recycled Content MR5.1; 5.2 – Regional Materials MR6 – Renewable Materials MR7 – Certified Wood EQ3.1; 3.2 – Construction IAQ EQ4.1; 4.2; 4.3; 4.4 – Low Emitting Materials ID1.1;1.2;1.3.1.4;2 – Innovation in Design Contractor “Credit” Responsibility z Record Keeping Responsibility ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ ¾ EAPR1 – Fundamental Commissioning EA3 – Enhanced Commissioning MR1.3 – Building Reuse; Interior MR2.1; 2.2 – Construction Waste Management MR3.1; 3.2 – Resource Reuse MR4.1; 4.2 – Recycled Content MR5.1; 5.2 – Regional Materials MR6 – Renewable Materials MR7 – Certified Wood EQ3.1; 3.2 – Construction IAQ EQ4.1; 4.2; 4.3; 4.4 – Low Emitting materials MR2.1; 2.2 - Construction Waste Management z z z z z z Design to Prevent Waste Plan for Waste Prevention Use Construction Methods that prevent waste Practice Jobsite Waste Prevention Methods Purchase to Prevent Waste Salvage, Reuse, Recycle Construction Waste Management z Design to Prevent Waste – – – – – Design with standard sizes Specify materials that can readily be disassembled at the end of useful life Specify durable, non – toxic interior finishes Design spaces to be flexible Consider reusing materials Construction Waste Management z Plan for Waste Prevention – – – Target specific waste producing practices Include waste prevention in waste management plan (Attachment C) Communicate the waste management plan; at every meeting, post it and promote it (and the results) Construction Waste Management z Use Construction Methods that Prevent Waste – – Wood Construction; use advanced framing techniques Consider off site assembly of components Construction Waste Management z Practice Jobsite Waste Prevention Methods – – – Set up central cutting areas Recycle concrete forms or choose reusable steel or fiberglass forms Practice material storage and handling that prevents loss or damage Construction Waste Management z Purchase to Prevent Waste – – – – Purchase salvaged, recycled or recycled content materials and equipment Deliver only the required amount of material to the site Use “JIT” ordering and delivery Replace hazardous materials with non – hazardous to reduce packaging Construction Waste Management z Purchase to Prevent Waste (cont.) – – – Choose materials with little or no packaging Have suppliers deliver materials with sturdy, returnable pallets and containers Require vendors to buy back substandard, rejected or unused materials Construction Waste Management z Salvage, Reuse and Recycle – – – – – Develop waste management plan Identify reusable or Salvageable materials Select Salvage removal alternatives Plan for recycling Establish what materials can be recycled, what salvaged materials can be sold or donated to charities (503B) See Attachment D EQ3.1; 3.2 - Construction IAQ z EQ3.1 – During Construction – – – Meet or exceed the recommended control measures of the “SMACNA IAQ Guidelines for Occupied Buildings Under Construction” Protect On Site Stored Materials from Moisture Damage If permanently installed AHU’s are used during Construction, install MERV 8 filtration media at all return air openings EQ3.1 – Construction IAQ z SMACNA Guideline – – – – – – – Seal all duct openings Temporary filtration on all return openings (MREV 8) Use only low emitting materials Isolate work areas from clean or occupied areas by temporary partitions and/or negative pressurization HOUSEKEEPING – DO IT! Schedule contaminant generating activities to have minimum impact on IAQ Use temporary ventilation units are required to maintain proper ventilation EQ 3.2 – Construction IAQ – Before Occupancy z z Flush Out – provide 14,000 cfm of outdoor air per SF of building area while maintaining at least 60 deg.F and no greater than 60% rH Air Quality Testing – conduct baseline testing that demonstrates that contaminant concentrations are below acceptable levels – – – – Particulate – 50mg (micrograms) per CM (0.00000011# per CF) Carbon Monoxide – 9 parts per million and no greater than 2 parts per million above outdoor air TVOC – 500mg per CM (0.0000011# per CF) Formaldehyde – 50 parts per billion Contractor’s Role in LEED z Questions Other Sustainable Movements z z z z z Labs21 – offshoot of LEED; will become LEED category in 2006 Green Guide for Healthcare – includes operational activities. Project activities should become a LEED Category in 2007 Green Building Initiative – focused on residential, NAHB based, should become a LEED category in 2006/2007 ASHRAE Green Guide – focused on HVAC Talloiries Declaration – University Based Commitment to Sustainable Campuses Contractor’s Role in LEED z References – – – – – – – USGBC NC 2.2 Reference Manual www.usgbc.org SMACNA; IAQ Guidelines for Occupied Buildings Under Construction www.SMACNA.org New York State Energy Research and Development Authority www.nyserda.org US EPA “Federal Green Spec’s.” www.epa.gov WBDG “Construction Waste Management Database” www.wbdg.org ASHRAE “Engineering for Sustainability” www.engineeringforsustainability.org Washington State GSA, “Construction Waste Management” www.ga.wa.gov/EAS/CWM Abstract for Presentation by Tracie Baule-Hall, Development Director at Enable Board of Directors GreeningUSA Member US Green Building Council, Upstate Chapter From A Client’s Perspective…Why Be Green? The mission of Enable is to provide the highest quality of life for children and adults with disabilities. The fundamental concept of green building is to provide the highest quality environment, with conscious decisions and an integrated design approach impacting both internal and external atmospheres. Individuals who receive services through Enable already have physical and developmental disabilities, many of which are compounded by environmental sensitivities and depressed immune systems. By constructing a facility designed with maximum accessibility and special attention to indoor environmental quality, Enable hopes to enhance the benefits of the therapeutic services provided to individuals with disabilities; increase the productivity and retention of qualified staff; reduce overall operating expenses through energy and water conservation; reduce absenteeism for staff and participants Through adherence to green building practices, and striving for LEED certification, Enable’s 30,000 square foot addition seeks to provide the ideal environment to achieve maximum results from therapeutic services. SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster William Burdick Principal / Senior Creative Director The WDBurdick Company / WDBurdick.com Since the mid 80’s, Bill has evolved The WDBurdick Company into an internationally recognized, full service advertising and communications design firm serving a wide variety of industries and clientele. Headquartered in a restored 1874 mission church in Skaneateles Falls, New York, Bill leads a team of dedicated professionals who help progressive companies implement green marketing strategies into their existing culture, through a variety of media. Most recently, the U.S Green Building Council utilized Bill’s services to create marketing materials to promote its highly successful 2005 Greenbuild International Expo held in Atlanta, edit LEED reference manuals and supply ongoing consulting and marketing tools for upcoming USGBC events. Bill is a member of the U.S. Green Building Council Upstate New York Chapter and holds a BFA degree from the University of Tampa. An avid motorcycle rider and photographer, he is currently restoring a 100-year-old camp on Skaneateles Lake utilizing green materials. The WDBurdick Company 4592 Jordan Road Post Office Box 189 Skaneateles Falls, New York 13153-0189 P: 315.685.CRE8 (2738) F: 315.685.0001 www.wdburdick.com SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster SEARCH: HOME | GATEWAYS | ACADEMICS | ADMISSION | DIRECTORIES | VISIT | LOG IN | SITE INDEX General Information ▼ HOME Adobe Contribute ▼ STUDENT ORGANIZATION WEB HOSTING Social Networking Accessing & Editing Websites ▼ PUBLIC INFORMATION SYSTEMS LOGIN Digital Signage ▼ THE STAFF ESF HOME The page you requested cannot be found. Search www.esf.edu: SEARCH: ESF homepage Site Index Directory of Faculty & Staff State University of New York College of Environmental Science and Forestry SUNY-ESF | 1 Forestry Drive | Syracuse, NY 13210 | 315-470-6500 Copyright © 2013 | Information | Webmaster