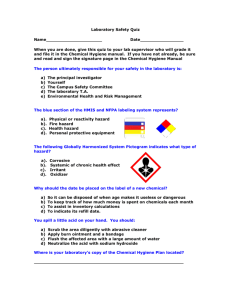

Hazard Communication Program

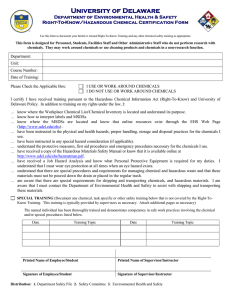

advertisement