Cadence Acoustic Separator Enabling Technology for Continuous Clarification of Batch Cell Culture

advertisement

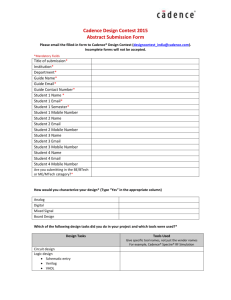

USD3133 Cadence™ Acoustic Separator Enabling Technology for Continuous Clarification of Batch Cell Culture The Cadence Acoustic Separator (CAS) enables the continuous removal of CHO cells and cell debris using a Cadence single-use acoustic chamber to achieve clarification of harvested cell culture fluid (HCCF) ready for downstream processing. The acoustophoretic removal is intrinsically scalable and is optimized for the clarification of high density Chinese Hamster Ovary (CHO) cell lines to provide a robust single-use primary clarification solution that delivers quality that is equivalent to centrifugation without the scaling, footprint and cleaning issues common with this solution. The Cadence Acoustic Separator is an easy to use technology without the volume limitations experienced by depth filtration solutions that lead to large footprint and buffer consumption or the need for process additives to enhance the performance. • • • • • • • Optimized for high CHO cell densities in the range 20 - 50 x 106 cells/mL Performance scales directly from process development to full scale processes Quality of HCCF unaffected and comparable to centrifugation Small footprint compared to equivalent centrifugation or depth filter solutions Reduced depth filtration requirement for secondary polishing Lower buffer consumption throughout the clarification process Continuous operation to link with continuous downstream purification including chromatography using the Cadence BioSMB PD system Description Features and Benefits Advances in fed batch cell culture have led to higher cell densities of up to 50 x 106 cells/ml and product titers of > 5g/L. Accompanied by a shift towards the use single-use technology in cell culture there is a drive to improve the efficiency of the cell harvest and clarification stage to generate HCCF for capture chromatography and subsequent downstream processing. This is further driven by the evolution of continuous processes where there is a preference for a continuous feed of HCCF available for direct load to the continuous multicolumn capture chromatography step using the Cadence BioSMB PD system. Existing cell culture clarification using either centrifugation or depth filtration are typically operated in batch mode and require bulk storage of feed or HCCF during the process. No adverse effects on the quality of the HCCF following clarification by the Cadence Acoustic Separator have been observed for CHO cell culture expressing a monoclonal antibody (mAb) (Table 1). The Cadence Acoustic Separator provides a novel scalable single-use technology for cell culture clarification based on an acoustophoretic separation. Acoustic wave separation (AWS) technology involves the use of low frequency acoustic forces to generate a 3 dimensional standing wave across a flow channel. Cell culture from a fed batch bioreactor enters the flow channel, and as the cells pass through the 3D standing wave they are trapped by the acoustic forces. The trapped cells migrate to the nodes of the standing wave, and begin to clump together till such time as their buoyancy decreases and they settle out of the suspension by gravity. After separation of cells and cell debris, the permeate from Cadence Acoustic Separator shows a significant reduction in turbidity and reduces the area requirements for secondary clarification using depth filtration and subsequent filtration for bioburden control. Table 1 Performance Comparison Sample mAb SEC Description(g/L) agg1 (%) Feed Permeate pool Post filtration DNA (µg/mL) HCP (mg/mL) 1.240.67 7.79 0.96 1.24 0.62 7.11 0.78 1.19 0.66 3.94 0.46 Designed for single-use operation the Cadence Acoustic Chamber comprises a flow path with 4 acoustophoretic chambers in series each providing an increasing level of clarification. The degree of clarification can be monitored at each stage of the cell separation with the in-line turbidity detectors. The efficiency of the clarification for a typical CHO cell culture (10-20 L) is illustrated in Figure 1. Figure 1 Clarification performance by stage over time as a percentage of total starting cell density (TCD) for a typical CHO cell culture (10 -20 L) % TCD Reduction 100 90 80 70 60 50 40 30 20 10 0 %TCD vs Time vs Stage 2 hrs 4 hrs 6 hrs 9 hrs 12.5 hrs Stage 1 Stage 2 Stage 3 Stage 4 Following primary clarification of CHO cell culture using the Cadence Acoustic Separator the cell culture fluid can be further polished using an in-line depth filtration stage. When used in this way, the Cadence Acoustic Separator not only reduces the solids content of the HCCF to a level suitable for sterile filtration and chromatographic purification, it has also been demonstrated to normalise any batch to batch cell culture variability within a given process, as shown in (Figure 2). nTurbidity Reduction By Stage 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% Optimization of the clarification process performed at process development scale can scale directly based upon the optimal flowrates identified for the primary separation using the Cadence Acoustic Separator and throughput of the depth filter selection for secondary polishing. An important design feature of the Cadence Acoustic Separator system is the ability to replace the Cadence Acoustic Chamber kit with a single large chamber. This chamber, for use in the Process Scale Cadence Acoustic Separator, has an identical flow path geometry and materials of construction as the chamber kit used in the development scale separator. This feature supports scale-up method development and verification during process development rather than having to conduct additional trials within the GMP environment. Advantages of using Cadence Acoustic Separation The replacement of the primary depth filtration step by a Cadence Acoustic Separator achieves economic benefits by reducing the overall operating footprint, reducing the secondary depth filter area requirements and the associated conditioning and flush buffers as well as reduced storage and disposal costs. These become key process drivers as processes enter clinical manufacture. An example of the anticipated process requirements for a 1000 L CHO cell culture is summarized in Table 2. Table 2 Anticipated Process Requirements for clarification of a 1000 L CHO cell harvest (>20 x 106 cells/ml) Primary Separation Technology Depth Cadence Filtration Acoustic Separator (6 43 8% ) .8 ( 25 58% .1 ) ( 26 68% .5 ) ( 23 65% .5 ) (8 23 2% (7 ) 2 21 %) (4 40 4% ) .2 (9 6 22 .5 %) (9 23 2% (6 ) 26 9% ) .6 (5 8% ) Total depth filter area Depth filter footprint Pre-use WFI rinse Post-process buffer flush 23 Normalized Turbidity Reduction (%) Figure 2 Scalability Cell density Stage 4 /106.mL-1 (Cell Stage 3 viability) Stage 2 35 m2 10 m2 4200 L 840 L 8 m2 2 m2 800 L 160 L Recommended Process Volumes Cadence Maximum Batch Volume Acoustic Separator Minimum Batch Volume 25 liters 3 liters Figure 3 Secondary polishing by depth filtration; filter areas per 1000 L as a function of pool turbidity 14 Filter Area (m2) 12 10 ea l Ar Tota 8 6 4 2 0 0 100 200 300 400 500 600 Pool Turbidity (NTU) 700 800 www.pall.com 3 Secondary Depth Filter Recommendations Bioburden Filtration Recommendation – Post PDD1 Selection of the optimal secondary depth filtration products will require some screening but in a typical fed batch culture of a CHO-S based cell line expressing a humanised IgG1 mAb, the following Pall depth filtration grades are recommended for evaluation: Post clarification, the HCCF may be optionally stored, filtered to control the bioburden and stored or filtered to control the bioburden and processed chromatographically. In a typical fed batch culture of a CHO-S based cell line expressing a humanised IgG1 mAb, the following Pall sterilizing grade filters are recommended: Volume Format <25 L Typical Grade Area Required Pall Supracap™ PDK7 HP depth filter or capsules PDH6 <10 L <5 L 0.1 m2 2 x Supracap 100 2 x 0.05 m2 0.04 m2 1 x Supracap 100 1 x 0.05 m2 0.002 m2 1 x Supracap 100 1 x 0.0025 m2 Part Number 2 x NP6PDK71 or 2 x NP6PDH61 1 x NP6PDK71 or 1 x NP6PDH61 1 x NP5PDK51 or 1 x NP5PDH61 Bioburden Filtration Recommendation – Post PDK7/PDH6 Post clarification, the HCCF may be optionally stored, filtered to control the bioburden and stored or filtered to control the bioburden and processed chromatographically. In a typical fed batch culture of a CHO-S based cell line expressing a humanised IgG1 mAb, the following Pall sterilising grade filters are recommended for evaluation: Supor® EKV Sterilizing-Grade Filter Capsules Volume Format Grade Filter Area Part Number <25 L <10 L <5 L Kleenpak® capsules Mini Kleenpak capsules Supor EKV membrane 0.2 µm 375 cm2KA1EKVP1G 220 cm2KA02EKVP8G Tertiary Depth Filter Recommendations for PD Scale Tertiary depth filtration may not be required at small scale but when used can prevent fouling of subsequent filters and allow for a reduction in size of the bioburden control filter. In a typical fed batch culture of a CHO-S based cell line expressing a humanised IgG1 mAb, the following Pall depth filtration grades are recommended for evaluation: VolumeFormat <25 L <10 L <5 L 4 Typical Area Grade Required Pall Supracap HP PDD1 depth filter capsules 0.05 m2 1 x Supracap 100 0.05 m2 0.02 m2 1 x Supracap 100 0.05 m2 0.01 m2 1 x Supracap 100 0.05 m2 Supor EKV Sterilizing-Grade Filter Capsules Volume Format Grade Filter Area Part Number <25 L <10 L <5 L Kleenpak capsules Mini Kleenpak capsules Supor EKV 375 cm2KA1EKVP1G membrane 0.2 µm 220 cm2KA02EKVP8G Systems and Replacement Parts Part Number Description CAS-SYS-EU CAS-SYS-US CAS-AC-K1 CAS-TS-S1 Cadence Acoustic Separator System, EU Cadence Acoustic Separator System, US Cadence Acoustic Chamber Kit Individual Replacement Turbidity Sensor Product Specifications Component SpecificationsParameter Operating Flow Rate Conditions Flow rate scale-up chamber Pressure Range Feed Fluid Temperature Operating Temperature Cadence Acoustic Max Feed Pressure Chamber Connectors Wetted Materials 0 to 2 barg (0 to 30 psig) 0 °C to 40 °C (32 °F to 104 °F) 0 °C to 40°C (32 °F to 104 °F) 30 psi Weight Shelf Life Nominal Flow Rate Nominal Pressure Drop per stage Hold Up volume per stage 60 mL/min <70 mbar (<1 psi) pressure drop @ 60 mL/min 190 mL Material data Chemical Compatibility 1 x NP6PDD11 1 x NP5PDD11 50 L/h ±10 L/h 1/8” hosebarb Barbs – Polysulfone (PS) Housing - Polyphenylsulfone (PPS) Transducer Film – Polyether etherketone (PEEK) O-rings - Platinum Cured Silicone Reflector - Borosilicate Glass USP Class VI 8 hours in 0.5M NaOH (ambient temp) <0.5 kg (<1 lb) 1 year Part Number 1 x NP6PDD11 Specification 0 – 10 L/h (3.6 L/h, typical) Component SpecificationsParameter Cadence Acoustic Cadence Acoustic Separator Separator EU Version Cadence Acoustic Separator US Version RF Power Output Maximum Power Consumption Sonic Channels Sonic Frequency Pump Flow Rate Specification 220 V / 50 Hz Component SpecificationsParameter Turbidity Sensor Materials Assembly 110V / 60 Hz Specification Polyphenylsulfone (PPS) Platinum Cured Silicone O-Rings Polycarbonate 0 - 100 W per channel 1.8 kW 5 1.9 - 2.2 MHz (L/S 16 tubing); 30 mL/min – 160 mL/min (L/S 14 tubing); 1 mL/min – 40 mL/min Footprint D 559 mm x W 546 mm x (W/o Pump head)H 327 mm (22.0” D x 21.5” W x 12.875” H) Footprint D 603 mm x W 546 mm x (W/Pump head) H 327 mm (23.75” D x 21.5” W x 12.875” H) Pumps per Controller 5 CertificationUL 61010-1, CAN/CSA C22.2# 61010-1 CENELEC EN 61010-1, CENELEC EN 61326-1, FCC 47CFR 15B clA Weight 18 kg (40 lb) Configurations 4 stages of CAC20, 1 stage of CAC50 Operating Temperature 2 – 40 °C Turbidity range Operating Temperature 0 – 4400 NTU 5 x turbidity housing with caustic stability 2 – 40 °C Regulatory InformationThe Cadence Acoustic Separator meets national and international standards including UL 61010-1, CAN/CSA C22.2# 61010-1, CENELEC EN 610101, CENELEC EN 61326-1, FCC 47CFR 15B clA Visit us on the Web at www.pall.com/allegro E-mail us at allegro@pall.com Corporate Headquarters Port Washington, NY, USA +1.800.717.7255 toll free (USA) +1.516.484.5400 phone biopharm@pall.com e-mail European Headquarters Fribourg, Switzerland +41 (0)26 350 53 00 phone LifeSciences.EU@pall.com e-mail Asia-Pacific Headquarters Singapore +65 6389 6500 phone sgcustomerservice@pall.com e-mail International Offices Pall Corporation has offices and plants throughout the world in: Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, New Zealand, Norway, Philippines, Poland, Russia, Singapore, South Africa, Spain, Sweden, Switzerland, Taiwan, Thailand, United Kingdom, and Vietnam. Distributors in all major industrial areas of the world. To locate the Pall office or distributor nearest you, visit www.pall.com/contact. The information provided in this literature was reviewed for accuracy at the time of publication. Product data may be subject to change without notice. For current information consult your local Pall distributor or contact Pall directly. © 2016, Pall Corporation. Pall, , Cadence, Kleenpak, Supor, and Supracap are trademarks of Pall Corporation. ® indicates a trademark registered in the USA. TM indicates a common law trademark. Filtration.Separation.Solution. is a service mark of Pall Corporation. Acoustic Wave Separation is an exclusive technology licensed to Pall by FloDesign Sonics (FDS). 4/16, PDF, GN16.6491 www.pall.com USD3133 5