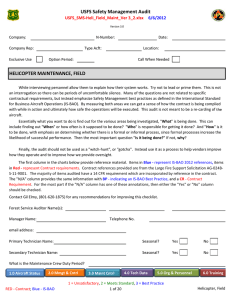

USFS Safety Management Audit USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

advertisement

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

Version 3.0

Company:

0

Company Rep:

Exclusive Use

N‐Number:

0

Type Acft:

Option Period:

0

0

Date:

January 0, 1900

Location:

0

Call When Needed 0

AIRTANKER MAINTENANCE, FIELD

While interviewing personnel allow them to explain how their system works. Try not to lead or prime them. This is not an interrogation so there can be periods of uncomfortable silence. Many of the questions are not related to specific contractual requirements, but instead emphasize Safety Management best practices as defined in the International Standard for Business Aircraft Operations (IS‐BAO). By measuring both areas we can get a sense of how the contract is being complied with while in action and ultimately how safe the operations will be executed. This audit is not meant to be a re‐carding of the aircraft. Essentially what you want to do is find out for the various areas being investigated, "What" is being done. This can include finding out "When" or how often is it supposed to be done? "Who" is responsible for getting it done? And "How" is it to be done, with emphasis on determining whether there is a formal or informal process, since formal processes increase the likelihood of successful performance. Then the most important question "Is it being done?" If not, why?

Finally, the audit should not be used as a "witch‐hunt", or "gotcha". Instead use it as a process to help vendors improve how they operate and to improve how we provide oversight.

The first column in the charts below provide reference material. Items in Blue ‐ represent IS‐BAO (2012) references, items in Red ‐ represent Contract requirements. Contract references provided are from the Large Airtanker Solicitation AG‐

024B‐S‐07‐0016. The majority of items audited have a 14 CFR requirement which are incorporated by reference in the contract. The "N/A" column provides the same information with BP ‐ indicating an IS‐BAO Best Practice, and a CR ‐ Contract Requirement. For the most part if the "N/A" column has one of these annotations, then either the "Yes" or "No" column should be checked.

Contact Gil Elmy, (801‐620‐1875) for any recommendations for improving this checklist.

Forest Service Auditor Name(s):

0

Tanker Base Manager Name:

email address:

0

0

0

Telephone No.

0

0

Primary Technician Name:

0

0

Secondary Technician Name:

Seasonal?

Yes No Seasonal?

Yes No What is the Maintenance Crew Duty Period?

1.0 Aircraft Status 2.0 Mmgt & Cntrl

RED ‐ Contract; Blue ‐ IS‐BAO

0

3.0 Maint Cntrl

4.0 Tech Data

5.0 Org & Personnel

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

1 of 18

6.0 Train

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

Requirement

Y N N/A

Rating

Ref.

Remarks

1 ‐ Unsatisfactory 2 ‐ Satisfactory 3 ‐ Best Practice

1.0 AIRCRAFT CURRENT STATUS

MNT 1.1 Weight & Balance

C‐5A11 a.

9.1.4

b.

C‐5A9 9.1.4

Is the Equipment List complete and accurate?

Has the aircraft been weighed within 12 months prior to the start of the contract, and 3 years thereafter?

Were calibrated scales used?

c. Are miscellaneous items such as unusable fuel, survival kits, PFD's, extra engine oil, 9.1.4

tools, etc., accounted for?

CR

CR

BP

MNT 1.2 Inspection and Maintenance Status

a. Is a Flight Log available, current and accurately filled out, if applicable?

Exhibit Is the current time annotated? Are 14 duplicate copies removed? Are inspections 9.1.7

and maintenance properly documented?

CR

C‐5A1 b. Are AD's and mandatory S/B's current, 6.9.1

properly annotated and signed off?

c. Are Scheduled and Unscheduled C‐5A6 maintenance actions being completed on 6.9.1

time and properly annotated and signed off?

d. Are Structural Integrity Program (SIP) C‐5B inspections and life‐limits identified in the 9.1.11

Airworthiness Limitations Section current and up to date?

MNT 1.3 Aircraft Status Sheet(s)

9.1.9

Exhibit 14 9.1.9

a. Is there a formal written procedure for tracking aircraft status?

b. Are Status Sheet(s) available and current? As a minimum does the list provide the current status of all inspections (91.409f & SIP), life‐limited components, AD's and mandatory S/B's? How often are current times/cycles sent to the home facility? How often are updated status sheets received in the field? RED ‐ Contract; Blue ‐ IS‐BAO

CR

CR

CR

BP

CR

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

2 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

9.1.9

c. Are Status Sheet(s) updated following completion of an Inspection or Scheduled/Unscheduled Maintenance, as applicable?

BP

MNT 1.4 Current Status Reporting

a. Are SAFECOMs being submitted when required?

b. Are RTCA reporting procedures being C‐5E followed? (i.e. Mx. Inspector notified, 9.1.6

Company policy, etc.)

3.2.2

CR

MNT 1.0 Aircraft Current Status {Summary of Observations}

MNT 1.0 Aircraft Current Status {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

2.0 MANAGEMENT AND CONTROL

Ref.

Requirement

Y N N/A

MNT 2.1 Operating Manuals / Specifications

8.3.1

a. Is an Operations Manual (or GMM) available?

Are technicians familiar with the contents and requirements of the manual?

C‐2B b.

8.3.1

C‐2B c.

8.3.1

d.

C‐2C 9.1.1

Is the FAA Part 137 Operating Certificate available?

Are FAA Ops Specs available, if applicable?

Is the Repair Station manual available, if applicable?

Are RS workorders available and being used, if applicable? Are technicians familiar with the RS Manual and its requirements?

RED ‐ Contract; Blue ‐ IS‐BAO

Remarks

BP

CR

CR

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

3 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 2.2 Management Oversight

3.2.3

3.2.3

9.1.4

3.2.3

3.2.3

3.2.3

BP

b. Are management audits performed on a regularly scheduled basis?

c. Does the company have procedures in place for obtaining Special Flight Permits?

BP

BP

Is someone designated who can obtain ferry permits? Are there management processes in place to ensure the safety of ferry operations?

MNT 2.3 Quality Assurance

3.2.3

a. Is there a formal written policy/procedure for conducting management audits/oversight of field operations?

a. Is there a formal written Quality Assurance Program?

b. Is there a Continuing Analysis and Surveillance Program (CASP)?

Does the program have a structured process for monitoring the performance and effectiveness of the inspection, maintenance, preventive maintenance program. It should consist of a system of surveillance and control of the processes, analysis of data collected during the surveillance process, the process for taking corrective actions, and follow‐up.

c. Is there a formal written RII / Dual Check policy or procedure?

Is the list of RII/Dual Check items well‐

defined and include how to accomplish the process? Is there a procedure to ensure only qualified personnel preform these tasks?

d. Is there a program for performing scheduled Quality Assurance audits of field operations?

Is there a method to schedule and track audits? How are discrepancies tracked and followed up? Do discrepancies noted on previous audits have corrective actions, or anticipated dates for taking corrective action?

RED ‐ Contract; Blue ‐ IS‐BAO

BP

BP

BP

BP

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

4 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

3.3.1

3.2.3

e. Do audits of field operations ensure that maintenance is performed in accordance with:

i) Federal Aviation Regulations?

ii) FAA Ops Specs?

iii) Ops/RS/GM Manual?

iv) Manufacturer's Maintenance Manuals?

f. Is there a formal written process for addressing findings that result from audits which ensures:

i) determination of root cause(s)?

ii) identification of potential hazards to operations?

iii) development of corrective actions?

iv) implementation of corrective actions?

v) evaluation of corrective actions to determine effectiveness?

MNT 2.4 Safety Management Systems

Exhibit a. Does the company have an implemented SMS Program? Does it clearly provide 11

NextGen

employees with the program's policy and objectives; a process for hazard 3.2.1

identification, assessment and mitigation (risk management); performance 3.2.2

monitoring and measurement (safety 3.2.3

assurance); and training in related duties (safety promotion)?

3.2.4

3.2.4

3.2.3

BP

b. Have employees been trained in company SMS procedures?

c. Are employees provided feedback on reported problems, incidents, mishaps, etc.?

BP

CR & BP

BP

BP

MNT 2.0 Management and Control {Summary of Observations}

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

5 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 2.0 Management and Control {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

3.0 MAINTENANCE CONTROL

Ref.

Requirement

Y N N/A

MNT 3.1 Control System

9.1.1

a. Does the Ops (GMM) Manual provide details of the Maintenance Control System?

Is it detailed and appropriate for the operation? Does it contain a description of the MEL procedures, personnel qualification and training requirements, record keeping processes, maintenance procedures to be followed, and emergency plans, etc.? Are employees familiar with the content and procedures?

Remarks

BP

b. Is the Maintenance Control System sufficient and appropriate for the number of aircraft and type of operations?

9.1.1

9.1.4

Are there procedures in place for monitoring field operations? Are procedures in place to ensure aircraft are not operated unless they are in an airworthy condition? Are discrepancies tracked and monitored? Is current aircraft status tracked?

c. If electronic recordkeeping is used, are back‐ups made and how often?

Is access controlled and password limited? Are there alternate procedures for when access to electronic recordkeeping is not available?

RED ‐ Contract; Blue ‐ IS‐BAO

BP

BP

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

6 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 3.2 Repair Station Procedures

a. Is the Repair Station Manual (RSM) available and current?

Is the manual complete, with a Table of C‐2C Contents, List of Effective Pages & Record 9.1.5

of Revisions? Are forms identified in the RSM being used? Are technicians familiar with the procedures outlined in the RSM?

b. Are general inspection procedures identified in the RSM being followed in field operations?

Are procedures for reporting malfunctions C‐2C and defects being followed? Is continuity 9.1.5

of inspection responsibility being assured? Are repairable and non‐repairable articles being properly tagged, identified and segregated?

c. Are Incoming Inspection procedures identified and followed for field operations?

C‐2C Is technical data used? How are shelf life 9.1.5

items handled? What is done with non‐

conforming items? Is traceability of items being verified? Are items being properly stored?

d. Are In‐Process Inspection procedures identified and followed for field C‐2C operations?

9.1.5

Is technical data used? Are RSM procedures followed?

e. Are Final Inspections being completed in accordance with the procedures in the RSM?

Are maintenance actions, other records C‐2C and forms being checked for completeness 9.1.5

and accuracy prior to the Final Inspection? Are inspections to ensure Tool Control and FOD Prevention being performed?

RED ‐ Contract; Blue ‐ IS‐BAO

CR

CR

CR

CR

CR

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

7 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

f. Are procedures for signing off work on RS workorders being followed?

Are only authorized personnel signing off C‐2C work? If electronic recordkeeping is being 9.1.5

used, are proper security procedures in place to prevent unauthorized access?

CR

g. Are aircraft properly Approved for Return to Service?

C‐2C Are only authorized personnel performing 9.1.5

RTS? Do maintenance releases fulfill the requirements of the RSM, 43.9 and 43.11?

MNT 3.2 Parts and Supplies

CR

a. Is there a formal written procedure to ensure only approved parts are installed, to include processes to ensure traceability 9.1.4

and minimum documentation requirements?

Is there a procedure for obtaining parts when away from Home Station?

b. Are Serviceable and Unserviceable Parts properly stored and segregated, if C‐5A1 applicable?

9.1.4

Is suitable storage and packing provided?

C‐5A1 9.1.4

BP

CR

c. Can all parts on hand be positively identified and traced, if applicable?

Are Company approved tags being used?

CR

d. Is there a formal written procedure for disposing of Life‐Limited parts?

MNT 3.3 Defect Reporting and Tracking

9.1.6

C‐5E

9.1.6

a. Is there a formal written procedure for reporting and documenting failures, defects and malfunctions that occur in‐

flight and during maintenance?

b. Are damage, failures, or fatigue cracks and separation of structural components being reported to the government?

CR

c. Is there a formal written procedure for reporting failures, defects and malfunctions to the FAA through the SDR or MDR program?

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

8 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

9.1.6

C‐5A3 9.1.6

9.1.6

d. Is there a formal written procedure for reporting and tracking chronic or repetitive unserviceable items?

Does the documentation include troubleshooting history, and instructions for implementing corrective actions? Is information about recurring defects disseminated between field and base units, and to flight and maintenance crews going and coming off shift?

BP

e. Is there a formal written procedure (MEL) for deferring discrepancies and are they being followed, if applicable?

f. Are deferred MEL discrepancies repaired in the time intervals specified, if applicable?

MNT 3.4 Tools

CR

BP

a. Is there a formal written tool control program?

b. Are there procedures to ensure tools are calibrated as required?

C‐5A1 Are tools in calibration? If employees own 9.1.4

special tools and equipment is there a procedure to ensure they are calibrated and serviceable?

c. Are tools in the pod/trailer properly/neatly stored?

9.1.4

BP

CR

MNT 3.0 Maintenance Control {Summary of Observations}

MNT 3.0 Maintenance Control {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

9 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

4.0 TECHNICAL DATA

Ref.

Requirement

Y N N/A

MNT 4.1 Technical Data

a. Is there a formal written procedure for ensuring completeness and currency of technical manuals?

b. Are technical manuals complete and C‐5A1 current?

9.1.4

Are they maintained in good condition?

c. Are technical manuals periodically audited 9.1.4

and inventoried to ensure completeness and currency?

d. Are all the inspection forms, AD's, C‐5A1 mandatory S/B's and manuals necessary to 9.1.4

perform maintenance available on site?

9.1.5

C‐5A1 e. Are maintenance, parts and wiring 9.1.4

diagrams available at the aircraft?

f. Are ICA's available for the modifications that have been performed on the aircraft, and to reflect Airtanker usage?

C‐5A1 9.1.4

Are ICA's revised as analysis of fleet usage is updated? Have ICA's been incorporated into the Inspection/Maintenance Program?

Remarks

BP

CR

BP

CR

CR

CR

g. Is electronic Technical Data properly used and updated?

Is access password protected? Can C‐5A1 technicians determine currency of data? 9.1.4

Are there alternate procedures for those times when electronic data/access is unavailable?

MNT 4.0 Technical Data {Summary of Observations}

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

10 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 4.0 Technical Data {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

5.0 ORGANIZATION AND PERSONNEL

Ref.

Requirement

Y N N/A

MNT 5.1 Organizational Structure

4.1.1

4.1.1

a. Is the organizational structure and manning adequate for the number and location of aircraft operated?

b. Is there an adequate number of trained and experienced field technicians?

BP

What is turnover like? What is the average employees time with the company? How close to contract start date are seasonal employees brought on?

BP

c. Do maintenance personnel have the requisite qualifications for the duties they perform?

C‐10I Does the primary mechanic have 12 4.4

months experience maintaining similar aircraft, or attended a manufacturer's training course on the aircraft?

MNT 5.2 Personnel Programs

4.6.1

6.13

6.13

a. Is there a Drug and Alcohol Program in place?

Does the company provide Drug and Alcohol training and counseling? b. Does the company have a formal written policy to counter fatigue?

c. Are employees required to work more than 14 hours a day for extended periods of time?

RED ‐ Contract; Blue ‐ IS‐BAO

Remarks

CR

BP

BP

BP

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

11 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 5.0 Organization and Personnel {Summary of Observations}

MNT 5.0 Organization and Personnel {Summary of Findings} Will be shown on Summary Sheet

6.0 TRAINING

Ref.

Requirement

Y N N/A

MNT 6.1 Company Specific Training

5.1.2

5.1.1

9.1.5

3.2.3

5.1.6

5.1.6

5.1.6

a. Is there a formal written training program?

BP

b. Are employees trained on the company policies, Ops, GMM and/or RSM Manual procedures?

c. Have employees been trained in Return To Service (RTS) procedures?

Are employees familiar with the FAA regulations and RS procedures for RTS?

d. Are employees trained in RII/Dual Check procedures, if applicable?

e. Are employees trained in MEL procedures, if applicable?

MNT 6.2 Aircraft Specific Training

a. Are employees provided aircraft specific training?

Is the training provided appropriate and sufficient for the operation? What type training is provided; OJT, factory, in‐house classroom, etc.? Are training requirements tracked and recorded? b. Do employees receive annual or bi‐annual recurrent training?

RED ‐ Contract; Blue ‐ IS‐BAO

Remarks

BP

BP

BP

BP

BP

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

12 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

MNT 6.3 Ancillary Training

5.2.2

5.1.6

5.1.6

5.1.6

5.3.1

a. Do employees receive Human Factors Training?

Does training include the impact human factors can have on accomplishing every day tasks? Does it include training on communication processes, decision making, teamwork, time management and effects and countermeasures against fatigue and stress?

b. Do employees receive Safety Training?

c. Do employees receive training in HAZMAT procedures?

d. Do employees receive training in computer programs and applications?

Have employees been trained in electronic tech data usage and how to determine currency of electronic manuals?

e. Do employees receive training in emergency response procedures such as fire, fuel spills, accident, etc.?

BP

BP

BP

BP

BP

MNT 6.0 Training {Summary of Observations}

MNT 6.0 Training {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

13 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

7.0 AIRCRAFT MAINTENANCE

Ref.

Requirement

Y N N/A

MNT 7.1 Aircraft maintenance procedures

10.1

C‐5A12 9.1.5

a. Is there a formal written procedure for documentation of aircraft records?

b. Are inspections and maintenance being performed in accordance with current inspection forms, AD's, mandatory S/B's and prescribed technical data?

BP

CR

Are inspections and maintenance being completed on time and in accordance with proper tech data? Are AD's documented with AD number, revision date, method of compliance and whether it is recurring?

c. Is maintenance being documented as required?

Are approvals for Return To Service being C‐5A6 completed IAW Part 43 and the RSM? Are 9.1.7

only authorized personnel performing RTS? Are RII/Dual Checks properly documented?

CR

d. Are checklists used and signed off during inspections, if applicable?

C‐5A6 Are all blocks completed? Can initialed 9.1.4

items be traced back to the technician who performed the work?

e. Are records being maintained and filed in accordance with the RSM?

Are Repair Station workorders and logs properly maintained and filed? Are other C‐2C records such as 8130‐3 or other approved 9.1.7

forms and records properly filed? Are inspection and maintenance forms being used the same as those identified in the RSM?

MNT 7.2 Out‐Source maintenance

9.2.2

a. Are there formal written procedures for out‐sourcing maintenance functions (other than major overhauls such as engines, props, etc.), if applicable?

RED ‐ Contract; Blue ‐ IS‐BAO

Remarks

CR

CR

BP

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

14 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/6/2012

b. Are there procedures for ensuring out‐

sourced maintenance is performed in accordance with:

C‐5A1 i) 14 CFR?

9.2.2

ii) Ops/RS/GM Manual?

Do out‐sourced maintenance facilities have a drug testing program?

MNT 7.0 Aircraft Maintenance {Summary of Observations}

MNT 7.0 Aircraft Maintenance {Summary of Findings} Will be shown on Summary Sheet provided to Vendor

8.0 AIRCRAFT, EQUIPMENT & AIRWORTHINESS

Ref.

Requirement

MNT 8.1 Operational & Required Information

C‐2A a. Is the aircraft Flight Manual available?

8.3.1

Exhibit 1 b. Are Cockpit checklists available?

CR

CR

6.12.1

c. Is the Ops (GMM) Manual available, if applicable?

d.

C‐5A3 Is the aircraft MEL available, if applicable?

8.3.1

Exhibit 1 e. Is the Flight Log available with the aircraft, 9.1.6

if applicable?

8.3.1

MNT 8.2 Emergency Equipment

BP

CR

Exhibit 1 a. Are first aid kit(s) available?

8.5.1

CR

Exhibit 1 b. Are fire extinguisher(s) available?

8.5.1

CR

RED ‐ Contract; Blue ‐ IS‐BAO

Remarks

Y N N/A

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

15 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

Exhibit 1 c. Is a Survival Kit available?

6.8.7

MNT 8.3 Aircraft and Equipment

CR

C‐2A a. Are seats, seat belts and shoulder 6.15.1

harnesses in serviceable condition?

b. Are there provisions for adequately 6.16

securing baggage and equipment?

c. Are all items of equipment in the cockpit or cabin secured to prevent injury to occupants?

MNT 8.4 Avionics Equipment

CR

BP

CR

b. Is the AFF installed and operational?

CR

C‐5A1 c. Is the ELT Annual Inspection and Battery 8.1

current?

d. Are the CVR and/or FDR being maintained in accordance with the manufacturers 8.14

recommendations and/or Ops (GMM) Manual?

e. Is OLMS equipment operative and reliable?

Exhibit 2 8.14

CR

BP

Have ICA's been incorporated into the Inspection/Maintenance Program? Is OLMS equipment experiencing excessive failures? Is data retrieval being consistently performed and sent to MTDC? Is there a procedure in the MEL for deferring inoperative OLMS equipment?

MNT 8.5 Aircraft Inspection

a. Are there any open deferred discrepancies?

Are there any open deferred discrepancies that are not on the MEL? Are C‐5A3 discrepancies being corrected in a 9.1.6

reasonable amount of time? Are deferred discrepancies repaired within the Repair Interval specified in the MEL? Are deferred discrepancies re‐deferred at each inspection, if applicable?

RED ‐ Contract; Blue ‐ IS‐BAO

C‐2D a. Are 91.411 and 91.413 Pitot‐Static and 8.13

Transponder Reporting Systems current?

Exhibit 1

CR

CR

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

16 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

b. Is the aircraft being maintained in accordance with 14 CFR, manufacturer's C‐5A1 recommendations, Company and/or RSM 9.1

Manuals, and industry standards?

CR

MNT 8.0 Aircraft, Equipment & Airworthiness {Summary of Observations}

MNT 8.0 Aircraft, Equipment & Airworthiness {Summary of Findings} Will be shown on Summary Sheet

9.0 OSHA, ENVIRONENMTAL & HAZMAT

Ref.

Requirement

Y N N/A

MNT 9.1 Occupational Safety and Health

13.1

13.1

13.1

12.1

12.1

a. Are there formal written procedures provided for workplace safety?

b. Are safety and personal protective equipment available?

c. Is safety information available to employees?

d. Are MSDS sheets available for materials on hand?

MNT 9.2 Environmental Management

12.1

Remarks

a. Are there formal written aircraft fueling procedures?

b. Are there formal written spill containment procedures?

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

17 of 18

Airtanker, Field

USFS Safety Management Audit

USFS_SMS‐Airtanker_Field_Maint_Ver 1_0.xlsx 6/5/2012

12.1

12.1

c. Are environmental requirements being taken into consideration when storing and disposing of hazardous and toxic substances?

d. Are there formal written procedures to ensure compliance with environmental requirements regarding the disposal of hazardous and waste materials such as fuel, oil, etc.?

MNT 9.3 HAZMAT

14.1

a. Are there formal written procedures provided for transporting HAZMAT?

MNT 9.0 OSHA, Environmental and HAZMAT {Summary of Observations}

MNT 9.0 OSHA, Environmental and HAZMAT {Summary of Findings} Will be shown on Summary Sheet

Overall Findings, Comments and Recommendations Will be shown on Summary Sheet provided to Vendor

RED ‐ Contract; Blue ‐ IS‐BAO

1 = Unsatisfactory, 2 = Meets Standard, 3 = Best Practice

18 of 18

Airtanker, Field