TMJ4E1 COURSE OF STUDY OUTLINE

advertisement

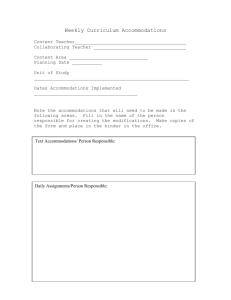

TMJ4E1 COURSE OF STUDY OUTLINE The Ontario Curriculum Grades (REVISED ) Ministry of Education Policy Document Upper Grand District School Board College Heights Secondary School Technological Studies Department Head : Carol Beatson Department Date 2010 Developed by Ed Waring Type TMJ4E1 Grade 12 Course Title Prerequisites TMJ3E1 Co-requisites Course Code TMJ4E1 none Overall Expectations: A. M ANUFACTURING TECHNOLOGY FUNDAM ENTALS Overall Expectations: A1. A2. Dem onstrate an understanding of the secondary m anufacturing industries and the processes and technologies related to them . Dem onstrate a working knowledge of how a design process is used to develop and fabricate projects in response to challenges or problem s in m anufacturing technology. A3. Dem onstrate a working knowledge of the processes required for m aking m aterial conversion conversions. A4. Apply relevant m athem atical and scientific concepts and technical literacy and com m unication skills in the study of m anufacturing technology. B. M ANUFACTURING TECHNOLOGY SKILLS Overall Expectations: B1. Use technical drawing skills and a design process to create engineering drawings that provide solutions to project developm ent challenges. B2. Select and use the proper m aterials when m anufacturing a product to m eet specifications. B3. Apply advanced m etrology skills to m easure, lay out, and inspect a product. B4. Dem onstrate the safe and proper use of tools and equipm ent when producing various projects to m eet specifications. C. TECHNOLOGY, SOCIETY, AND THE ENVIRONM ENT Overall Expectations: C1. Dem onstrate an understanding of the im portance of using sustainable and environm entally friendly m anufacturing practices. C2. Explain how the m anufacturing industry affects society locally, provincially, and/or nationally. D. PROFESSIONAL PRACTICE AND CAREER OPPORTUNITIES Overall Expectations: D1. Dem onstrate an understanding of and com pliance with health and safety legislation, standards, and practices, including m ethods to address deficiencies, as they relate to the m anufacturing industry. D2. Dem onstrate an understanding of the postsecondary pathways leading to careers in m anufacturing and the training and certification required for these careers. Course Evaluation : Exam is 30% of course mark and unit work is 70% of course mark. Exam mark is out of 100. Unit work is out of 100 . Exam mark is multiplied by .3 and unit work mark is multiplied by .7 .... Both numbers are added together to arrive at the final course mark. Units- Titles and Times Units Titles Hours 1 Technical Standards and Safety Authority Open Butt Joint-6010 root/7018 fill 30 2 CWB 20 3 5 Cubes 10 4 Technical Drawings 20 5 Forming Project 20 6 7018 Multi-pass fillet 4 7 OHSA and WHMIS 2 8 Manufacturing Industry 2 Unit 1 -Technical Standards and Safety Authority ( TSSA ) Open Butt Joint-6010 root/7018 fill Activity Name Overall Expectations Categories Focus knowledge and understanding safety oxy-acetylene knowledge and understanding angle, cut quality knowledge and understanding purpose, size,burrs assembly knowledge and understanding gap procedure to weld knowledge and understanding key hole,whipping 6011,6010,polarity root fill passes application knowledge and starts/restarts 7018,arc blow safety oxyacetylene Oxyacetylene safety test land Marks Out of 5 understanding application specimen prep knowledge and understanding sizes, grinding bend test knowledge and understanding root/face, safety welding knowledge and pass/fail criteria code understanding 10 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:All units require mastery teaching Unit Evaluation: 15 Marks. Unit 2 - Canadian Welding Bureau ( CWB ) Activity Name Overall Expectations welding test plates Categories Focus Marks Out of appplication knowledge and understanding knowledge and specimen prep understanding bend test knowledge and understanding 10 theory test knowledge and understanding 5 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:All units require mastery teaching Unit Evaluation: 15 Marks. Unit 3 Activity Name Overall Expectation Categories Focus Marks Out of cube welded application assembly, electrodes 2 with SMAW knowledge and understanding polarity cube welded application assembly, defects with GMAW knowledge and understanding wire size,gases s cube welded with GTAW application 2 assembly, mild steel killed, rimmed 2 2 knowledge and understanding cube welded with GTAW application knowledge and assembly, stainless steel types, cube welded understanding application corrosion assembly, aluminum with GTAW knowledge and understanding types, properties theory test knowledge and understanding above points 2 5 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:All units require mastery teaching Unit Evaluation: 15 Marks Unit 4 -Technical Drawing Activity Name Overall Expectations Categories Focus Marks Out 3 view drawings communication of 5 scale drawing the forming exercise radial line application communication 5 communication 5 development Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:All units require mastery teaching Unit Evaluation: 15 Marks Unit 5- Forming Project Activity Name Overall Expectations Categories Focus Marks Out of box and pan brake knowledge and understanding application safety, fingers , adjustments layout lines knowledge and understanding application scribers, bluing, ,working edge bandsaw safety knowledge and understanding application push sticks , cut line bend allowance knowledge and understanding application radius compensation forming knowledge and understanding application squares, flanges rivets knowledge and understanding application procedure to rivet, types of rivets project knowledge and understanding application theory test knowledge and understanding application 15 above topics 5 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:All units require mastery teaching Unit Evaluation: 20 Marks Unit 6- 7018 Multi-pass Fillet Activity Name Overall Expectations Categories Focus Marks Out of bead knowledge and understanding sequence what to look at thinking/inquiry when running bead sequence bead 2 top edge bead 3- 30 degrees undercut each bead purpose of multi-bead equal leg fillet weld symbol fillet weld knowledge and understanding hatachi knowledge and understanding reason for equal leg knowledge and understanding fillet weld symbol application profile of fillet weld 5 on above points 5 arrow side ,other side,reference line thinking/inquiry knowledge and understanding theory test Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:.All units require mastery teaching Unit Evaluation: 10 Marks. Unit 7 - Occupational Health and Safety Act ( OHSA ) and WHMIS Activity Name Overall Categories Focus Expectations Out of Overview of the Act d1 d2 knowledge and understanding application safety committee compliance WHMIS Symbols d1 d2 knowledge and understanding application right to know, safety MSDS Symbols in shop d1 d2 knowledge and understanding ID symbols used in welding and meaning knowledge and understanding test Marks 10 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:.All units require mastery teaching Unit Evaluation: 10 Marks Unit 8 -Manufacturing Industries Activity Name Overall Expectations Categories Focus Marks Out of Manufacturing Industries a1 c2 c1 knowledge and understanding primary,secondary manufacturing, environmental 10 Accommodations: List the common accommodations implemented in this unit. Accommodations: - All units have typed notes - Tests have extended time limit - Pre-test prior to test - Tests can be done in program support services - Compensation for auditory short term memory deficits by giving 3 steps at a time and leaving sequential steps on chalkboard for practical work Formative Assessment in the Unit:.All units require mastery teaching Unit Evaluation: 10 Marks