NOTICE INVITING TENDER (Two Bids) No. 11/4/Adm-II(A-I)/2015

advertisement

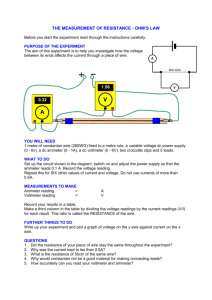

MIZORAM UNIVERSITY MIZORAM : AIZAWL Post Box No.190 Gram: MZU Phone: 0389-2330822 Email: adm3@mzu.edu.in Website : www.mzu.edu.in th No. 11/4/Adm-II(A-I)/2015 Dated Aizawl the 14 October, 2015 NOTICE INVITING TENDER (Two Bids) FOR SUPPLY & INSTALLATION OF EQUIPMENTS FOR ELECTRICAL MACHINE LABORATORY-II & POWER SYSTEM LABORATORY FOR B.TECH.PROGRAMME (ELECTRICAL ENGINEERING DEPARTMENT) AT MIZORAM UNIVERSITY, AIZAWL The Vice-Chancellor, Mizoram University invites quotation for supply & Installation of Equipment as per details at ANNEXURE-IV, in Two Bids to reach the undersigned: S.No. 01. Reference No. Items Qnty Supply & Installation of Equipment for Electrical One Machine Laboratory-II & Power System Laboratory to Package be installed at Dept. of Electrical Engineering, Mizoram University, Tanhril EMD 2% (`) in the form of DD Tender Document Fee (`) in the form of DD only. ` 1,000 1. Last date & Time for Submission :16.11.2015 2. Date/Time for Opening of Technical Bids : 23.11.2015 3. Date of notifying the Technically qualified bidders in the website : 27.11.2015 4. Evaluation of Financial bids for Technically qualified bidders : 2.12.2015 Venue of Bid Opening at MIZORAM UNIVERSITY, AIZAWL BID INSTRUCTION: 1. Quotations shall be submitted in TWO Bids: i) Technical Bids & ii) Financial Bids; which will be submitted in 2 separate envelopes, super-scribing the nomenclature of bids, with name & address of firms. And these 2 envelopes shall be placed inside a single sealed envelope, andmust be prominently super scribed: QUOTATION FOR SUPPLY & INSTALLATION OF EQUIPMENTS FOR ELECTRICAL MACHINE LABORATORY-II & POWER SYSTEM LABORATORY OF ELECTRICAL ENGINEERING DEPARTMENT AT MIZORAM UNIVERSITY, AIZAWL, REF. NO. 11/4/AdmII(A-I)/2015 DATE:14th October, 2015 2. Submission ofCompliance Certificate: Duly filled and signed Compliance Certificates (as per formats at Annexure I (A & B)are must with the Technical bid. 3. Bid not transferable: The bid documents are not transferable and the seal and signature of the authorized official of the firm’s must appear on all the papers and envelopes submitted QUALIFICATION REQUIREMENTS 1.The Bidder should be an Original Equipment Manufacturer (OEM) or a firm of reputation having sufficient expertise and experience in the subject tender with sound warranty / service support capability and authorization from Manufacturer/Distributor. 2. The Bidder has to quote for all the items and Bidders who do not Quote for all the items are subject to be disqualified. MIZORAM UNIVERSITY TERMS & CONDITIONS: 1. Rates: Rates quoted in the Price Bid should be on DOOR DELIVERY Mizoram University basis, as per details below: Sl. No. I Particulars Rate Basic Price (per unit) Total Taxes(pl. give break up) Grand Total for the item on door delivery at Mizoram University Bidders shall indicate their rates in clear / visible figures as well as in words and shall not alter/overwrite/make cutting in the quotation. In case of a mismatch, the rates written in words will prevail. 2. Validity of Quotation: Quoted rates must be valid for 90 days from the date of quotation. 3. Warranty: The quoted equipment and components must be warranted for a minimum of 1(One) year after satisfactory installation. 4. Literature a must: All the quotations must be supported by the printed technical leaflet / literature and the specifications mentioned in the quotation must be reflected/ supported by such printed technical leaflet/literature. The model and specifications quoted should invariably be highlighted in the leaflet / literature for easy reference. 5. After Sales Service: Vendors should clearly state the available nearest after sales service facilities in the region, without which their offers will be rejected. 6. Dealership Certificate: Dealers or Agents quoting on behalf of Manufacturer/Distributor must enclose valid dealership certificate. 7. Earnest Money: Refundable Earnest Money Deposit (EMD), 2% of the Quoted Value through Demand Draft drawn in favour of “The Finance Officer, Mizoram University”, payable at Aizawl, shall accompany the Technical Bid. The EMD of unsuccessful bidders shall be returned after award of supply. EMD of the successful bidder will be released on submission of the Performance Bank Guarantee. Offers received without Earnest Money or valid Certificate shall be summarily rejected. 15. Performance Bank Guarantee (PBG): In case of items with order value of Rupees Five lakhs (` 5,00,000/-) and above, the successful bidder shall furnish an unconditional PBG (as per format at Annexure II) for 5% of the Purchase Order value from a scheduled Bank of India, after receiving the purchase order. Where the PBG is obtained by a foreign bank, it shall be got confirmed by a Schedule Indian bank and shall be governed by Indian Laws and be subject to the jurisdiction of courts at Aizawl. The PBG will be kept till the Warranty Period and The PBG shall guarantee that, (a) The Vendor guarantees satisfactory operation of the Equipment & components against poor workmanship, bad quality of materials used, faulty designs and poor performance. (b) The Vendor shall, at his own cost, rectify the defects/replace the items supplied, for defects identified during the period of guarantee. (c) This guarantee shall be operative from the date of installation till 120 days after the warranty period. 16. Delivery: a) Time Limit: Maximum within 12 Weeks from the date of issue of the purchase order. b) Safe Delivery: All aspects of safe delivery shall be the exclusive responsibility of the vendor.At the destination site, the package will be opened only in the presence of Mizoram University representative and vendor's representative. The intact condition of the package and the seal / indicators for not being tempered with, shall form the basis for certifying the receipt in good condition. c) Insurance: The supplier is to establish ‘All Risk Transit Insurance’ coverage till door delivery at Mizoram University, Tanhril, Aizawl. d) Part Delivery: Acceptance ofpart delivery shall be a prerogative of the institute. e)Penalty for delay in delivery: The date of delivery should be strictly adhered to otherwise the Vice-Chancellor, Mizoram University reserves the right not to accept delivery in part or full. 17. Genuine Pricing: Vendor is to ensure that quoted price for the particular item is not more than the price quoted to any other customer in India, particularly to Mizoram University, and other Government Organization. 18. Conditional tenders not acceptable: All the terms and conditions mentioned herein must be strictly adhered to by all the vendors. Conditional tenders shall not be accepted on any ground and shall be rejected straightway. Conditions mentioned in the tender bids submitted by vendors will not be binding on Mizoram University. 19. Road Permit: Mizoram University will provide Road Permit to the Vendors of outside Mizoram on demand. 20. VAT deduction at source: In case of supply within Mizoram, VAT deduction at source, as per Order / notification of the Govt. of Mizoram will be applicable. 21. Late and delayed tender: Late and delayed tender will not be considered. In case any unscheduled holiday occurs on the prescribed closing/opening date the next working day shall be the prescribed date of closing/opening. 22. Payment: 100% payment within 30 (thirty) days from date of delivery, Satisfactory installation, acceptance and Training. 23. Payment for Imported Goods: By an irrevocable letter of Credit at CIF/CIP Kolkata value negotiable through any overseas branch of State Bank of India / any Schedule Bank of India. Note: Please note LOC will not be opened unless and until Letter of Acknowledgement in original is received at Mizoram University, Tanhril, Aizawl, directly from the principal (Even in case of firms having subsidiary office in India). 24. ADDITIONAL TERM FOR IMPORTED GOODS Following terms besides fore mentioned terms will be applicable in case of foreign purchases: Rates: Prices quoted must be for destination including freight and insurance charges inclusive of free delivery up to the door of department i.e. Mizoram University premises, as per details below: S.N. PARTICULARS RATE a I Basic Price (per unit) II Total III Custom Duty (Approximate) IV Grand Total for the item on door delivery at Mizoram University, Tanhril, Aizawl. 25. Free Maintenance & Service for 10 Years: An agreement is to be executed between the Institute & the Manufacturer / Distributor / Dealer for providing Free Maintenance & Service for 10 Years after expiry of the Warranty Period of the equipment by the Manufacturer / Distributor / Dealer (Preferably from the Manufacturer) within 30 Days from the day of Complaint. The cost of the Spare parts required for the service and maintenance will be paid by the Institute along with the To & Fro charges (The cheapest mode of Travel). 26. Enquiry during the course of evaluation not allowed: No enquiry from the bidder(s) shall be entertained during the course of evaluation of the tender till final decision is conveyed to the successful bidder(s). However, the Purchase Committee or its authorized representative may make enquiries/seek clarification from the bidders. In such a case, the bidder must extend full cooperation. The bidders may also be asked to arrange demonstration of the offered items, in a short period of notice. 27. The acceptance of the quotation will rest solely with the Vice-Chancellor, Mizoram University, who in the interest of the Institute is not bound to accept the lowest quotation and reserves the right to himself to reject or partially accept any or all the quotations received without assigning any reasons. 28. Force Majeure: If the performance of the obligation of either party is rendered commercially impossible by any of the events hereafter mentioned that party shall be under no obligation to perform the agreement under order after giving notice of 15 days from the date of such an event in writing to the other party, and the events referred to are as follows: i. Any law, statute or ordinance, order action or regulations of the Government of India, ii. Any kind of natural disaster, and iii. Strikes, acts of the Public enemy, war, insurrections, riots, lockouts, sabotage. 29. Applicable Law: (a) The contract shall be governed by the laws and procedures established by Govt. of India and subject to exclusive jurisdiction of Competent Court and Forum in Aizawl / India only. (b) Any dispute arising out of this purchase shall be referred to the Vice-Chancellor, Mizoram University, and if either of the parties hereto is dissatisfied with the decision, the dispute shall be referred to the decision of an Arbitrator, who should be acceptable to both the parties, to be appointed by the Head of the Institution. The decision of such Arbitrator shall be final and binding on both the parties. Encl.: ANNEXURE-I, ANNEXURE-II, ANNEXURE-III & ANNEXURE-IV ( DR. LALTHANCHAMI SAILO ) JOINT REGISTRAR MIZORAM UNIVERSITY AIZAWL, MIZORAM Annexure -I A. COMPLIANCE CERTIFICATE FOR MIZORAM UNIVERSITY TERMS (To be enclosed in the Technical bid) Sl. No. 01 02 03 04 05 06 07 08 09 10 11 12 MZU Terms and Conditions Rate quoted as per instruction AMC rate after warranty provided Validity of quoted rate for 90 days agreed EMD submitted (appropriate certificate enclosed) PBG term agreed Payment term agreed Delivery terms agreed Warranty period agreed Literature: Printed Literature provided Dealership / distributorship certificate (in case of dealers/agents) provided Sales Service: address of after Sales Service centre in India (for imported goods)/ in the region provided Applicable law terms agreed Yes/No Signature with Seal:..……………. Vendor: M/s……………………… B. COMPLIANCE CERTIFICATE FOR SPECIFICATIONS (One for each item must to be enclosed in the Technical bid) Item Sl. No. Specifications as per Annexure-IV Quoted Item Specs.* Complied (Yes/No) Signature with Seal:..……………. Vendor: M/s……………………… * Vendor must quote the parameter / specification of the quoted product in this column and not just copy the specification from the tender document. Failure to do so will lead to rejection of the tender. Annexure –II PERFORMANCE BANK GUARANTEE To: The Vice-Chancellor Mizoram University Tanhril-796004, Mizoram WHEREAS ................................................................... (Name of Supplier) hereinafter called "the Supplier" has undertaken, in pursuance of Contract No................. dated,......... 20... to supply...................... ................................................. (Description of Goods and Services) hereinafter called "the order". AND WHEREAS it has been stipulated by you in the said order that the Supplier shall furnish you with a Bank Guarantee by a recognized bank for the sum specified therein as security for compliance with the Supplier's performance obligations in accordance with the order. AND WHEREAS we have agreed to give the Supplier a Guarantee: THEREFORE WE hereby affirm that we are Guarantors and responsible to you, on behalf of the Supplier, up to a total of ................................... ........................................ (Amount of the Guarantee in Words and Figures) and we undertake to pay you, upon your first written demand declaring the Supplier to be in default under the order and without cavil or argument, any sum or sums within the limit of ................................ (Amount of Guarantee) as aforesaid, without your needing to prove or to show grounds or reasons for your demand or the sum specified therein. This guarantee is valid until the ........day of...................20...... Signature and Seal of Guarantors ................................ ................................ ................................ Date......................20.... Address:........................ ................................ ................................ All correspondence with reference to this guarantee shall be made at the following address: Mizoram University P.O. Box. 190 Tanhril -796004, Mizoram Annexure -III MANUFACTURERS'/ DISTRIBUTOR’S AUTHORIZATION FORM No. Dated __________ The Vice-Chancellor Mizoram University Tanhril-796004, Mizoram Dear Sir: We…………………………………………………………………. who are established and reputable Manufacturers/distributors of ……………………………………………………………………having factories/office at--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------(address of factory/office) do hereby certify that………………………………………………………………………………………………………… ……………………………………………………………………………………………………………… ………………(Name of the Authorised Dealer)is our authorized dealer to quote against your tender enquiry no ……………………………………………………………………………………………………….. ,Last Date of Submission is: Yours faithfully, (Name) (Name of Manufacturer/Distributor) ANNEXURE-IV TECHNICAL SPECIFICATIONS FOR ELECTRICAL MACHINE LABORATORY-II & POWER SYSTEM LABORATORY, ELECTRICAL ENGINERING, MIZORAM UNIVERSITY. A. No. ELECTRICAL MACHINE LABORATORY-II (EE 591) Technical Specification Name of the kits/experiment and description Qty (Nos) EXPERIMENT NO – 1 : SCOTT CONNECTION OF 1 PHASE TRANSFORMERS 1 KVA / 440 – 220 V / Air Cooled / Oil cooled Single Phase Transformer with sheet metal 2 1 enclosure. ACCESSORIES 1 Control Panel consisting TPN MCB, 5 A AC Ammeter 1 No., 500 V AC Voltmeter 4 Nos., all 1 other indicators, terminals andswitches required. 2 Three Phase / 6 A / Autotransformer ( Variac ) 1 Input : 3 Phase / 415 V / 50 Hz. / AC Output : 3 Phase / 0 – 470 V / 6 A AC EXPERIMENT NO – 2 : HEAT RUN TEST ON 3 PHASE TRANSFORMER 1 1 KVA / 415 V Delta Primary – 200 V Delta secondary / Air Cooled / Oil cooled Three Phase 1 Transformer with sheet metal enclosure. ACCESSORIES 1 Control Panel consisting TPN MCB, 5 A AC Ammeter 2 No., 500 V AC Voltmeter 1 No., 1 Temperature sensor with indicator, 1Phase plug with switch to connect variac, all other indicators, terminals and switches required. 2 Single Phase / 10 A / Autotransformer ( Variac ) 1 Input : 1 Phase / 230 V / 50 Hz. / AC Output : 1 Phase / 0 – 250 V / 10 A AC EXPERIMENT NO – 3 &13 : 1 ) NO LOAD & BLOCK ROTOR TEST ON 3 PHASE INDUCTION MOTOR. 2 ) DIRECT LOAD TEST OF 3 PHASE SQIM 3 ) PF IMPROVEMENT OF INDUCTION MOTOR USING CAPACITORS. MACHINES 1 5 HP / 415 V / 1440 RPM / TEFC / 50 Hz. / Star or Delta 1 Connected / Three Phase Sq. Cage Induction Motor with Mechanical Loading arrangement. ACCESSORIES 1 Control Panel consisting TPN MCB, DOL Starter, AC Ammeter 1No, AC Voltmeter 1 No., 3 1 Ph. / 2 E / 415 V Digital wattmeter with external auxiliary supply, Power factor meter, all other indicators, terminals and switches required. 2 Three Phase / 8 A / Autotransformer ( Variac ) 1 Input : 3 Phase / 415 V / 50 Hz. / AC Output : 3 Phase / 0 – 450 V / 8 A AC 3 3 Phase / 415 V / Capacitive bank controlled by rotary switches in 5 steps. Complete with 1 Capacitor discharging lamp mounting holders. ( Without lamps – 60 W Lamps to be arranged locally) EXPERIMENT NO – 4: SPEED CONTROL OF 3 PHASE INDUCTION MOTOR BY 1 ) CASCADE CONNECTION 2 ) ROTOR IMPEDANCE CONTROL 3 ) POLE CHANGING METHOD 4) ROTOR SLIP RECOVERY-CRAMER DRIVE MACHINES 1 1.0 HP / 415 V Stator & Rotor / 3 Phase / 4 Pole / 1420 RPM / Double shaft extended / Slipring 1 Induction Motor @ non drive end coupled with 1.0/2.0 HP – 1420/2880 RPM, 4/2 Pole, 3Phase, Sq. Cage Induction Motor with for pole changing operation @ drive end of SLIM Mechanical loading arrangement will be provided. (Cumulative cascade 4+2 = 6 pole i.e. 1000 RPM will be available with cascade connection. Differential cascade will not be possible.) ACCESSORIES 1 Control Panel consisting TPN MCB, DOL Starter, AC Ammeter 1No, AC Voltmeter 1 No., 1 Rotor resistance bank one no., all other indicators, terminals and switches required. EXPERIMENT NO - 5 : RETARDATION TEST – DYNAMIC BREAKING ON DC SHUNT MOTOR. 1 5 HP / 220 V / 1500 RPM / DC Shunt Motor with Flywheel Mounted on the shaft of Motor. ACCESSORIES 1 Control Panel consisting MCB, 3 point Starter, 2 Nos. DC Ammeter, 1 No. DC Voltmeter, 1 1 1 No. Field Rheostats ( External), DP / 2W rotary switch, 440 Ohms / 2 A resistance in 2 steps for resistive braking, all other indicators, terminals and switches required. EXPERIMENT NO - 6 : PERFORMANCE CHARACTERISTICS OF 1 PHASE SQUIRREL CAGE INDUCTION MOTOR. MACHINES 1 1 HP / 230 V / 1440 RPM / 50 Hz. Single Phase Sq. cage Induction Motor with Mechanical Loading arrangement having linear scales and Friction Belt for Torque Measurement. With all terminals brought out for various connections. With provision to observe operation of Centrifugal switch. ACCESSORIES 1 Control Panel consisting DP MCB, DOL Starter, AC Ammeter 1 No, AC Voltmeter 1 No., 1 Ph. Digital wattmeter 1 No. with external aux. supply, all other indicators, terminals and switches required. 2 Single Phase / 10 A / Autotransformer ( Variac ) Input : 1 Phase / 230 V / 50 Hz. / AC Output : 1 Phase / 0 – 250 V / 10 A AC EXPERIMENT NO – 7 : 1 ) REGULATION OF THREE PHASE ALTERNATOR BY SYNCHRONOUS IMPEDANCE METHOD. 2 ) REGULATION OF 3 PH. ALTERNATOR BY AMPERE TURN METHOD. 3 ) REGULATION OF THREE PHASE ALTERNATOR BY ZPF METHOD. MACHINES 1 5 HP / 220 V / 1500 RPM / Shunt Wound DC Motor coupled to 3 KVA / 415 V / 3 Phase / 1500 RPM / 50 Hz. / Four Pole / Rotor Wound / Stator Excited/ Separately excited / Manually Regulated Salient Pole Alternator with base and couplings. ACCESSORIES 1 Control Panel consisting MCB, 3 point Starter, 25 A DC Ammeter 1 No., 2 A DC Ammeter 2 Nos., 500 V AC Voltmeter 1 No., 5 A AC Ammeter 1 No., Field Rheostat ( External) 1 No., Separate excitation unit for Alternator, all other indicators, terminals and switches required. 2 3 Phase / 4.2 A / 50Hz continuous variable Inductor ( Inductive Load) for ZPF Test 3 3 Phase / 5 A / wire wound / resistive load bank controlled by rotary switches in 6 steps. ( if required for Direct resistive loading ) EXPERIMENT NO – 8 : REGULATION OF ALTERNATOR BY SLIP TEST MACHINES 1 5 HP / 220 V / 1500 RPM / Shunt Wound DC Motor coupled to 3 KVA / 415 V / 3 Phase / 1500 RPM / 50 Hz. / Four Pole / Rotor Wound / Stator Excited/ Separately excited / Manually Regulated Salient Pole Alternator with base and couplings. ACCESSORIES 1 Control Panel consisting MCB, 3 point Starter, 25 A DC Ammeter 1 No., 2 A DC Ammeter 2 Nos., 500 V AC Voltmeter 1 No., 5 A AC Ammeter 1 No., Field Rheostat ( External) 1 No., Separate excitation unit for Alternator, all other indicators, terminals and switches required. 2 Three Phase / 6 A / Autotransformer ( Variac ) Input : 3 Phase / 415 V / 50 Hz. / AC Output : 3 Phase / 0 – 450 V / 6 A AC EXPERIMENT NO – 9 &10 : 1 ) V & INVERSE V CURVE FOR 3 PHASE SYNCHRONOUS MOTOR. 2 ) POWER ANGLE CHARACTERISTICS OF A SYNCHRONOUS MOTOR MACHINES 1 5 HP / 415 V / 1500 RPM / 50 Hz. / Star Connected / Rotor Wound / Stator Excited / Separately Excited / Manually Regulated / Salient Pole type / Auto Synchronous Motor with damper windings for auto induction start complete with Mechanical Loading arrangement having Round dial scales and Friction Belt for Torque Measurement. ACCESSORIES 1 Control Panel consisting DOL Starter interlocked with Excitation Unit, 10 A AC Ammeter 1 No., 2 A DC Ammeter 1 No., 500 V AC Voltmeter 1 No., 415 V / 10 A AC PF Meter 1 No., all other indicators, terminals and switches required. 2 Digital Stroboscope EXPERIMENT NO – 11 : LOAD CHARACTERISTICS OF INDUCTION GENERATOR MACHINES 1 5 HP / 220 V / 1500 RPM Dc Shunt Motor coupled with 3 HP / 415 V / 50 hz. / 3 Phase / 1440 RPM Sq. cage Induction Motor with base and couplings. ( This SQIM will behave as Induction Generator when it runs beyond its synchronous speed) ACCESSORIES 1 Control Panel consisting DC MCB, AC MCB, DOL Starter, 3 Point DC Starter, Field Rheostat for Motor field control, 10 A AC Ammeter 1 No., 2 A DC Ammeter 1 No., 25 A Dc Ammeter 1 no., 500 V AC Voltmeter 1 No., 500 V AC Ammeter 1 no., 3 Phase wattmeter 1 no., all other indicators & terminals required. 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 OTHER ACCESSORIES REQUIRED PERFORMING ALL ABOVE TESTS. 1 : DC THYRISTOR CONTROLLED REGULATED POWER SUPPLY With close loop feedback and Isolation Transformer. With regulation +/- 2.5 %. Input : 3 Phase / 415 V / 50 Hz. / AC Supply, Out Put : 230 V DC – 100 A 2 : DISTRIBUTION BOX PANEL DC Feeders having 25 A DP MCB, 1 12 3 Phase ac panel having 10 A TPN MCB, 12 AC Ammeter, AC Voltmeter, 1 3 Digital contact type tachometer 60-50,000 rpm 3 B. POWER SYSTEM LABORATORY Technical Specifications : Sl. No. 1 2 Details Work Schedule Transmission Line Simulation Study Unit List of Experimetns : Study of Ferranti Effect. Study of Load Compensation Study of Line Compensation Transmission Line Efficiency and Calculation of Losses. Study of ABCD Parameters Study of Load Flow. Study of Impedance relay characteristics. Study of Overcurrent and Earth Fault ion Transmission line. Stidu of Voltage Improvement of Reactive power control using tap changing transformer. Specifications : TransmissionLinetype : Artificial single phase transmission line model. No. of π Secrtions : 5 ( 80 kms each) Power Supply : 1Ph 230V AC, 50Hz. Current Rating : 4A, Short Circuit Capacity : 10A, Generating Station End – Power Transformer Input Voltage : 1Ph 230V, 50Hz Output Voltage : 55 / 110 / 220 volts Current Rating : 4 A with tap changing switch for voltage regulation. Receiving Station End – Transformer Inpur Voltage : 1Ph 55/110/220V , 50Hz Output Voltage : 1Ph. 230V 50Hz. Impedance Relay : Single Element Over Current and Earth Fault Relay Power Analyzer : DSP Based Ammeter : 3 ½ digit , Voltmeter 3 ½ digit. Time Interval Meter : .0001 to 9999sec Operating Temperatuire : -5°C ........ + 45°C Stoprage Temperature : -20°C ...... + 60°C Standarde Includes ( Control Panel, Power Cable-3m, Patch Cords / Connecting Wires and Instruction Manual. Electromechanical Over Current Relay Testing Kit with Source List of Experimetns : Study of over current relay operation. Time characteristic IDMT Time characteristic at different TMS To study of operating time. To Study of pick up current level. To Study drop off (reset level) current level. Flag of Traget Study of % error. Specifications: Input Supply : 1ph 230V AC, 50Hz Output current : Continuous variable with range selector No. of ranges : 1A, 2A, 5A, 10A, 20A & 50A - selectable Current injection : Through Short / open switch Auxiliary Supply terminal : 230V AC and 24V DC Duty : Intermittent Time Interval Meter : .0001 - 9999sec Ammeter : 3½ digit Relay make : CT Sec : 1A or 5A Plug Setting : 50% to 200% of In in steps of 10% Time Setting : 0.1 - 1.0 Characteristics : IDMT Auxiliary Supply : Self-powered / Powered * Operating Temperature : -5°C…… +45°C Storage Temperature : -20°C…… +60°C Standarde Includes ( Source unit, Relay unit, Power Cable-2.5m, Patch Cords / Connecting Wires and Instruction Manual. Qty 01 01 Set 3 4 5 Bucholtz Relay Trainer Kit Features : Easy operation, NO contact for alarm, NC contact for trip indication, Conservator to fill oil to the relayReservoir to store the oil, Foot pump to create bubbles in the relayIt mainly consists of Bucholtz Relay and the Oil test setup.Bucholtz Relay used is a mechanical type oil and gas operatedrelay. The relay has one NO contact for Alarm and one NCcontact for Trip indication. Transformer Protection Study Unit Features : Enclosure made of CR sheet, galvanised, powder coated and screen printed. Necessary BTI connectors for external connectionTrip Indication, Transformer Protection Relay - % Differential Relay, Time interval meter. Digital Voltmeter, Digital Ammeter Fault Simulation Input. Necessary resistive loads List of Experimnts : Study of differential protection. Study of internal faults in transformer. Speficifications : Type : Open ended, star-star Power Supply : 1ph 230V AC, 50Hz % Differential Relay , Load : Resistive load Ammeter : 3½ digit , Voltmeter : 3½ digit Time Interval Meter : .0001 to 9999sec Operating Temperature : -5°C ....... +45°C Storage Temperature :-20°C ........ +60°C Sequence Components of Synchronous Machine Features : Screen-printed control panel with clear coat Motor mounted on sheetmetal base with vibro pads Motors coupled using lovejoy coupling and guarded Internal variac for Armature and Field BTI connectors for external connections Digital Meters for current, voltage, power, speed measurements Drive for speed control of Induction Motor Necessary Indicators & Necessary loads are provided. List of Experimetns : Sequence component of Synchronous Machine Sequence component by Fault Analysis L-G, L-L, L-L-G, L-L-L-G Specificatins : Motor Rating : 3HP Induction Motor Alternator Rating : 3kVA Power Supply : 3ph 415V AC, 50Hz Speed : 1500 RPM Drive : LS make variable frequency drive Power Analyzer : DSP based RPM Meter : 4 digit display Operating Temperature : -5°C ............. +45°C Storage Temperature :-20°C .............. +60°C Sequence Components of Tranformer Features : Screen-printed control panel with clear coat Built-in Three phase transformer Built-in Single phase transformer External three phase Variac BTI connectors for external connections Digital Power Analyzer for measurement of voltage, current, power, etc. Drive for speed control of Induction Motor Necessary Indicators. Experiments : Sequence component of three Single phase Transformer bank Sequence component of one Three phase Transformer Specifications : Input Power Supply : 3 phase 415VAC, 50Hz Transformer - 1ph : 240V/240V, 300VA Transformer - 3ph : 415V/415V, 900VA Variac: 3phase Variac Power Analyzer : Digital with Open ended connection Operating Temperature :-5°C ........... +45°C 01 01 01 6 7 Storage Temperature :-20°C ........... +60°C Transient Stability of Synchronous Machine Screen-printed control panel with clear coat Motor mounted on sheetmetal base with vibro pads Motors coupled using lovejoy coupling and guarded Internal variac for Armature and Field BTI connectors for external connections Digital Meters for current, voltage, power, speed measurements Drive for speed control of Induction Motor Necessary Indicators Experiments : Transient reactance of Synchronous Machine Sub-transient reactance of Synchronous Machine Specifications : Motor Rating : 3HP Induction motor Alternator Rating : 3kVA Power Supply : 3ph 415V AC, 50Hz Speed : 1500 RPM Ammeter : Analog Meter Voltmeter : Analog Meter RPM Meter : 4 digit display Operating Temperature :-5°C .............. +45°C Storage Temperature :-20°C ........... +60°C Characteristics of Static Relays. A) Static Percentage Differential Relay Teswt Kit Features : Enclosure made of from CR sheet with duly galvanized and powder coated. Necessary disgrams are screen printed. Stackable enclosure. Static Type Relay. Self powerred / powered. BTI/BS10 BS2 connectors for external connections. Illuminated power On / Off switch. Start / Stop Rest Switch. Trip status indicator . 24V DC 230V AC source for auxiliary. DUC relay output NO / NC connection facility. Potential free NO and NC point for project works. LED fittede on schematic for easy understanding. Experiments : To study the operation and chanrcteristics of differential relay. Specifications : Input Supply : 1ph 230V AC, 50Hz Output Voltage : 0-130V continuousluvartiable. Capacity : 220VA, Duty : Continuous. Auxiliary Supply : 230V AC and 24V DC Time Interval Meter : .0001 - 9999sec Ammeter : 3½ digit , Relay make CT Sec : 1A or 5A % Setting Range : 10% - 050% of In in steps of 10% IDMT : 1.3 / 3 sec. Construction : Drawout Operating Temperature : -5°C…… +45°C Storage Temperature : -20°C…… +60°C Standarde Includes ( Source unit, Relay unit, Power Cable-2.5m, Patch Cords / Connecting Wires and Instruction Manual. B) Static Over Current Relay Kit with Source Features : Enclosure made of from CR sheet with duly galvanized and powder coated. Necessary disgrams are screen printed. Stackable enclosure. Static Type Relay. BTI/BS10 BS2 connectors for external connections. Illuminated power On / Off switch. Start / Stop Rest Switch. Trip status indicator . 24V DC 230V AC source for auxiliary. DUC relay output NO / NC connection facility. Potential free NO and NC point for project works. LED fittede on schematic for easy understanding. Experiments : Study of over voltage relay operation. 01 01 set Time characteristics , IDMT. Time characteristics at different TMS. To study of operating time. To study of pick up voltage level. To study drop off (reset level) voltage. Flag or target. Study of % errot. Specifications : Input Supply : 1ph 230V AC, 50Hz Output Current :Continuousluvartiable with range selector. No. of Ranges : 1A, 2A, 5A, 10A, 20A, & 50A, selectable. Current Injection : Through shrot / Open switch. Duty :Interniittent. Time Interval Meter : .0001 - 9999sec Ammeter : 3½ digit , Relay make CT Sec : 1A or 5A Plug setting : 40% - 320% in steps of 5% Time setting : 0.1 – 1, Characteristics : 3 sec to 10 times. Auxiliary Supply : Self – powered / powered. Operating Temperature : -5°C…… +45°C Storage Temperature : -20°C…… +60°C Standarde Includes ( Source unit, Relay unit, Power Cable-2.5m, Patch Cords / Connecting Wires and Instruction Manual. C) Static Under Voltage Relay Kit with Source Features : Enclosure made from CR sheet with duly galvanizedand powder coated. Necessary diagrams are screen printed.Stackable enclosure. Static Type relay. Internationally approved relays are used. BTI / BS10 / BS2 connectors for external connection Illuminated power ON/OFF switch. Start / Stop / Reset Switch. Trip status indicator. 24V DC and 230V AC source for auxiliary DUC relay output NO / NC connection facility Potential free NO and NC point for project works LED fitted on schematic for easy understanding Experiments : Study of under Voltage relay operation. Time characteristic. Time characteristic at different TMS To study of operating time. To Study of pick up voltage level. To Study drop off (reset level) voltage. Flag or target. Study of % error. Specifications : Input Supply : 1ph 230V AC, 50Hz Output voltage : 0-230V continuously variable Capacity : 220VA, Duty : Continuous Auxiliary Supply terminal : 230V AC and 24V DC Time Interval Meter : .0001 - 9999sec Voltmeter : 3½ digit , Relay make PT Sec : 110V AC, Plug Setting : 30%-90% adjustable in 11 steps Time Setting : 0.1 to 1, Characteristics : 0-5sec at zero voltage Auxiliary Supply : Powered by 95V to 240V AC/DC Operating Temperature : -5°C……… +45°C Storage Temperature : -20°C……… +60°C Standarde Includes ( Source unit, Relay unit, Power Cable-2.5m, Patch Cords / Connecting Wires and Instruction Manual. D) Static Negative Sequince Relay Kit with Source Features : Enclosure made from CR sheet with duly galvanizedand powder coated. Necessary diagrams are screen printed. Stackable enclosure. Electromechanical Type relay. Internationally approved relays are usedBTI / BS10 / BS2 connectors for external connection Illuminated power ON/OFF switchStart / Stop / Reset Switch. Trip status indicator24V DC and 230V AC source for auxiliary DUC relay output NO / NC connection facility Potential free NO and NC point for project works LED fitted on schematic for easy understanding Experiments : Study of negative sequence relay operation. 8 9 DMT Time characteristic. To study of operating time. To Study of pick up level. To Study drop off (reset level) voltage. Flag or target. Specifications : Input Supply : 3ph 415V AC, 50Hz Output voltage : 0-415V, Duty : Continuous Auxiliary Supply terminal : 230V AC and 24V DC Rheostat : 150Ω variable Time Interval Meter : .0001 - 9999sec Ammeter : 3½ digit, Relay make CT Sec : 1A or 5A, I2S : 10%, DMT : 3sec Auxiliary Supply : Powered Operating Temperature : -5°C…. +45°C Storage Temperature : -20°C…… +60°C Standarde Includes ( Source unit, Relay unit, Power Cable-2.5m, Patch Cords / Connecting Wires and Instruction Manual. High Voltage Oil Test Kit Features : Easy operation. Faster trip time < 0.5 cycles. Rugged and reliable. Oil container as per IS:335 Tests insulating oils as per ASTM and IEC specifications. Automatic HV shutdown at breakdown Memory on kV meter. Specifications : Type :Manually operated. Output Voltage : 0-60kV Transformer : Step-up transformer encapsulated in epoxy resin Transformer Capacity : 500VA, Tripping Current : 2-5mA Voltage Accuracy : ± 2%, Power Consumption : 60VA Trip time : < 0.5 cycles Electrode type : Mushroom head made of brass/stainless steel Input Power Supply : 1ph 230V AC, 50Hz Operating Temperature : -5°C……… +45°C Storage Temperature : -20°C……… +60°C Standarde Includes : (Test kit, Oil cell, Gap adjusting gauge, Connecting Wires , Instruction Manual and Tesst / Calibration Certificate.. Essential Accessories : Earth megger Parallel Operation of Two Alternators Features : Screen-printed control panel with clear coat Ÿ Motor mounted on sheetmetal base with vibro pads Ÿ M-G set coupled using lovejoy coupling and guarded Ÿ Built-in DC power supply Ÿ Internal variac for Armature and Field Ÿ BTI connectors for external connections Ÿ Digital Meters for current, voltage, power, speed measurements Ÿ Power Analyzer with RS-485 communication port Ÿ Necessary Indicators, Ÿ Necessary loads are provided Ÿ Special Meters like Synchroscope, Dual Frequency Meter. Experiments: Parallel Operation of Two Alternators . Synchronization of Alternator with infinite bus bar / another alternator using lamp and synchroscope. Load sharing between two Alternators Specifications : Motor Rating : 2.2kW / 3.7kW / 5kW (as per choice) Alternator Rating : 2kVA / 3kVA / 5kVA Power Supply : 1ph 230V AC, 50Hz Speed : 1500 RPM Ammeter : 3½ digit , Voltmeter : 3½ digit Power Analyzer : DSP based RPM Meter : 4 digit display Synchroscope Operating Temperature : -5°C ............ +45°C Storage Temperature : -20°C ............. +60°C Standard Includes : Control Panel, Motor-Generator Assembly with love-joy coupling and guard, Multicore Cables, Patch Cords and Instruction Manual. 01 01 10 11 High Voltage Schering Bridge (10KV) Features : Digital Voltmeter, Digital Leakage Current Meter Open Ground Indication, Null meter sensitivity adjustment Mulitturn knob for precise control. Experiments : Capacitor Testing Capacitor Tan delta measurement Transformer Capacitance Testing of High Voltage Capacitance Bushings Specifications : Input Supply : 1ph 230V AC, 50Hz Output AC Voltage : 0-10kV AC Leakage Current : 0-100mA Capacitance Range : 1pf-0.1uf for standard capacitor of 100pf Resolution : Minimum resolution of 0.1pf,1pf,10pf corresponding to Cx factor of 0.01,0.1 &respectively Null Detector : Built-in with Sensitivity adjustment Power Supply :9V dry Battery for Null Meter. Standard Includes : Control panel AC source 10kV,100mA, Standard Capacitor 10kV, Schering Bridge with High Sensitive Null Detector, Input Power Cable-3m#, HT Cable with Aligator clips, Interconnection cable, Grounding wire, Instruction Manual, Test/Calibration Certificate Underground Cablve Fault Locator for Power Cables with Built in DC HV Power Supply Technical Specifications: Short Circuit Fault. Measurement in two-resistance section by null detection method. Indicates the distance of fault from the ends. Current measurement: 50 milli Amps. max. Input Impedance selection: In multiple ranges. Null Balance: By Vernier Potentiometer. Open Circuit Fault : Measurement by Capacitance Bridge technique. Built in Power Source with the Following Details : Input : 230 V, 50Hz, 1 phase AC. Output : Selectable in two ranges ie. 0-250Volts DC for low resistance fault or 2500Volts DC for High resistance fault. Capacity : 50mA with built-in short circuit protection. Output is featured with high impedance characteristic to have better control overmeasurement. The Power Source is provided with the followings: Power Mains ON – OFF operation is done by means of an ON – OFF switch along with ‘ON’ lamp indication& Fuse protection. ‘HT’ ON – OFF push along with ‘HT ON’ lamp indication. Continuously variable autotransformer of suitable capacity to increase the output test voltage up to the required voltage level. Zero start interlocking will be provided to ensure that the HV circuit cannot be energized unless the regulator is initially kept or brought back to zero position. Automatic tripping mechanism for protecting the DC HV Set against over loading. After tripping, High Voltage will be switched OFF. If the voltage is raised beyond the maximum rated value a lamp & buzzer will indicate over voltage for DC output. Output DC High Voltage is measured by means of properly designed Potential Divider and analog readout unit with proper scaling factor. The HV arm of potential divider is an integrated part of DC high voltage assembly. Analog Milliammeter along with ‘Press to read mA’ push button for measurement of leakage current. The Fault Locating Bridge and the Power Source are mounted within the same unit. The clearance between HT terminal & earth will be adequate as far as HT level is concerned. The Power Source consists of HV Transformer, Capacitor Bank, Diode Bank, and Resistance Bank. The DC HV Assembly used in the Test Set will be cast resin type and of suitable capacity, designed to withstand frequent intermittent spark over or short circuit conditions under which these are designed to operate. DC High Voltage is generally obtained by multiplication of relatively low AC high voltage with proper multiplier circuits. High Voltage diode bank along with surge suppressor are used in conjunction with high voltage capacitors as multiplier circuits. The output will have series 01 01 12 impedance forbetter control. The Bridge and the HV assembly will be housed within a sheet metal cabinet powder coated. Accessories : The set will be provided with input cable, discharge rod with grounding cable. Documents :Operation Manual. A) AC High Voltage Test Set 100kV Features : Easy operation. Rugged and reliable. Necessary meters for measurement. Necessary door and zewro interlocking. Tinter for withstand test. Sample pass / fail indication. Corona ring / caps at LT and HT terminals. Specifications : Input Supply : 1ph 230V AC, 50Hz Output Voltage : 0-10pkV Leakage Current : 0-50mA Transformer Rating : 2.5 kVA each Type : Cascaded (0-50kV each) Type of Transformer : Shell type Type of Cooling : Oil cooled. Type of Bushing : Epoxy fibre glass with peticoats. Transformer Mounting : Powder coated MS tank with proper bushing. Corona Rings / Caps :Aluminium with polished surface. Timer : 1 sec to 30 hr. Operating Temperature : -5°C……… +45°C Storage Temperature : -20°C……… +60°C Standard Includes : Control panel , Transformer , Input Power Cable 3m, Control desk to transformer 7m, Connecting wires and links, Grounding rod and Instruction Manual. B) Capacitance Divider Features : Highly stable high voltage capacitors are used Oil Cooled. Uniform external voltage distribution. Epoxy fibre glass insulated tubes Painted with antitracking paint Mobile Unit. Used as load capacitance for impulse generator. Used as filter for DC voltage. Specifications : Type : Mobile Unit Voltmeter : Digital kV meter Divider Ratio : 1000 : 1 Type of Cooling : Oil Cooled Material : Fibre glass insulated tubes Operating Temperature : -5°C……… +45°C Storage Temperature : -20°C……… +60°C Standard Includes : Delay cable, Peak voltmeter, power cord and Instruction Manual. Jig to measure String Efficiency Features : Easy operation. Brass / Copper / Stainless Steel spheres Enclosure made of perspex sheet. Gap Measuring device is provided Mounting clamps to fix the jig to the String Specifications : Jig Enclosure : Made of perspex sheet Diameter of Sphere : 20mm Material of Sphere : Brass Fixing threads : M6 Measuring device : Slip gauges Operating Temperature : -5°C……… +45°C Storage Temperature : -20°C……… +60°C 01 Set