UCCS – EXHIBITION HALL Concept Design - Electrical Narrative

advertisement

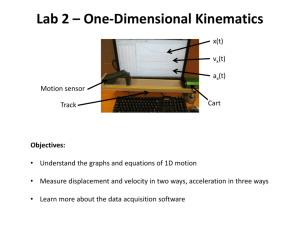

UCCS – EXHIBITION HALL Concept Design - Electrical Narrative The following narrative outlines a conceptual electrical Scope of Work for converting the “Phase 2” TRW Building to an Exhibition Hall. Demolition: The area of work shall be a complete ‘gut’; removing all electrical lights, wiring devices, and gear. Remove all branch circuit conduit and wire in its entirety. Remove electrical panelboards, unless noted otherwise. Remove cabling serving panels, disconnects and other gear back to main electrical room; capping and marking horizontal conduit in place up at structure. Maintain power in existing mechanical/electrical rooms and along south perimeter. The center restroom area is to remain; remodeled as noted under this Work. The support rooms and abandoned kitchen area along the south perimeter are not included in this phase; except as noted. The restrooms in the south area are being remodeled under this Work. A panel for a future food vendor is included as noted below. See Arch Narrative regarding salvage rights. Electrical Service: The existing gear in the lower level main electrical room will be used to serve the Exhibition Hall. The main switchboard is a 4000A, 480/277V, 3ph Square D, fuseddisconnect switchboard. A 500kVA dry-type transformer powers the 1600A, 120/208V switchboard in the main electrical room. An 800A motor control center is located in the boiler room, just outside the main electrical room. Re-fuse and/or replace existing OCDP disconnect switch units within each switchboard as required to serve the loads indicated. Reuse existing feeder conduit wherever possible. Electrical Distribution: Provide power feeders to mechanical equipment – see description below. Provide feeders to serve 125A, 120/208V 3ph Panelboards located along the perimeter walls of the Ex Hall. Provide 60A, 277/480V 3ph feeders to serve ceiling mounted j-boxes (power drops) located in a nominal 30ft by 80ft on-center pattern through-out the Ex Hall to serve 10’x10’ vendor booths. Each drop shall consist of a NEMA 1 j-box at the ceiling; with a 1 UCCS – EXHIBITION HALL Concept Design - Electrical Narrative 60A hard-service SOOW black cord with kellum grips; nominal 40-foot long, with a 60A 4-pin connector on the end. Each drop shall include a portable cord drop cradle; allowing the actual drop location to be moved within the radius served by each celing jbox. Power drops shall serve mobile ‘power carts’ to provide vendor booth power. Include a 45kVA, dry-type, aluminum winding, 150deg-rated transformer for each 208V panel noted. Mount xfmr’s directly above panelboards in the Ex Hall, near structure, using wall mounting brackets with isolation pads. Contractor has the option to power the perimeter 208V panels directly from the 208V distr switchboard MDP and eliminate the associated transformer, if cost effective. Include up to six (6) 120V, 20A cord drops along the main entrance; locations to be determined. Include 20A circuits to control panels, DDC and other misc loads. Power Carts: Provide field-assembled power carts to provide 120/208V event power in the open areas of the Ex Hall. Each power cart shall consist of the following: Metal frame cart, 4 caster wheels One 45kVA dry-type transformer One 60A, four pin, pin & sleeve recep One 125A, 120/208V 42-pole Panel (sec) One 60A, 480V fused main disc switch Each power cart shall include receptacles <Panelboard flush-mounted in two NEMA 1 <Recep Enclosures enclosures mounted either side of the <Disc Sw (opp-side) serving panelboard. Recep shall include: Two (2) 50A, 125/208V, 1ph <Dry-type Xfmr Four (4) 20A, 3ph twist-lock <Mobile Cart Four Quad 20A, 1ph (for local booths) Label each recep with assoc circuit no(s) using typed label maker. Include one power cart for each 100A power drop location. Include four (4) hard-service cords, 20-foot long, with a quad receptacle on the end for hard-wiring to power cart panelboard breakers to serve vendor booths either side of cart. Include one (1) spare power cart and four (4) spare cord/quad receptacle assemblies. Equip four (4) of the power carts required with a 200/3 disconnect. The disconnect shall be fused at 125A; and feed from the on-board transformer secondary; with instruction 2 UCCS – EXHIBITION HALL Concept Design - Electrical Narrative plaques that denote the main breaker on the panelboard must be in the OFF position before energizing the 208V disconnect. Panelboards: Perimeter wall Panels: These panels shall have one (1) 50/2 breaker serving a 50A outlet located directly under each panel; and a nominal twenty (20) 20/1 breakers to provide a dedicated 20A, 120V circuit to local quad receptacles located 10-feet on-center along associated perimeter wall(s). Provide a minimum of one panel per perimeter wall. See Plans. Power Cart Panels: Provide 200A, 120/208V 3ph, 42-circuit panelboards with the following breakers (see attached typical Power Cart Panel Schedule): Two (2) 50A, 2-pole Four (4) 20A, 3-pole Twelve (12) 20A, 1-pole Food Service Panel: Provide a 200A, 120/208V 3ph, 42-circuit panelboard for an outside food service vendor to connect their equipment. Food service is proposed to be located in the abandoned Kitchen area. Panel shall include a mix of 20/1, 20/2, 30/2 and 20/3 breakers with all 42 pole-positions occupied with breakers. Mechanical Equipment Power: Provide power to three (3) water heaters added at each of three restroom areas. The mechanical AHU connection requirements vary; based on two AHU options. Option 1: Existing AHU’s are re-used (maintain power); and supplemented with Evap Coolers. A smoke exhaust fan is added near the center core restroom area. An RTU-1 (VAV) unit is added to serve the Admin Area. Provide a 200A, 480V panelboard at center mezzanine mechanical room to serve the added 480V equipment. See scope narrative and attached panel schedule. Option 2: Existing AHU’s are abandoned; and six (6) new 50-ton RTU’s serve the Ex Hall. An RTU-1 (VAV) unit is added to serve the Admin Area. Wiring and Conduit: Conduit shall be EMT with compression or set-screw fittings; 1/2”C minimum. No floor cuts or underground conduit work is anticipated. All overhead conduit shall be installed tight to structure. 3 UCCS – EXHIBITION HALL Concept Design - Electrical Narrative Conductors shall be copper, 90 degrees C, #12 AWG min., Type THHN/THWN for dry locations, Type XHHW for wet locations. Conductor insulation shall be color coded to match existing scheme used in the building. Feeders and branch circuits shall be sized for a total voltage drop not to exceed 5 percent. Grounding: Include a green ground conductor within all branch circuit and feeder conduits. Provide a #4AWG ground from the main switchboard to the main comm headend. Provide a ground from each dry-type transformer back to the main ground bus. (Due to concrete “T” building construction.) Assume the service grounding electrode is in good condition. Wiring Devices: Wiring devices shall be grey; with galvanized metal coverplates. Provide quad 20A, 120V receptacles along outside perimeter walls of the Ex Hall; with a dedicated 20A, 120V circuit to each outlet from a local panelboard. Identification: Provide typed self-adhesive labels to label wiring devices and boxes. Label each receptacle with a typed label denoting the Panel ID and circuit no. serving it. Label each light switch using nomenclature that clearly describes lights controlled. Interior Lighting: Lighting shall be provided to meet IECC 2009 Energy Code W/SF requirements. Lighting shall be 277V, program-start ballasts, 35k lamps/80+CRI fluor lamps. Light Fixture Types are anticipated to be the following: Exhibit Hall T5HO High-Bay Fluor; Columbia LHEW or equal Two ballasts for inboard/outboard 3-level switching Corridor Recess Fluorescent Troffer Toilets Recess Fluorescent Troffer Vestibules Recess Fluorescent Troffer or Down Lights Mechanical Existing to Remain South Perimeter Existing to remain (NIC, except Restroom remodel) Storage Industrial Fluorescent or recessed 1x4 Troffers 4 UCCS – EXHIBITION HALL Concept Design - Electrical Narrative Lighting Control: “Switchology” shall be used to control Ex Hall lighting. Switches shall be located at the east main entrance by the Admin Area/Ticket Office. Ex Hall switches shall allow each of four (4) quadrants to be turned on independently; and shall include 3-level switching within each of the four quadrants. Provide mech-held lighting contactors and momentary switches where cost effective. Provide a separate switch for lights at main entry adjacent to Admin Offices. Restrooms shall be key-switched. Staff areas and offices shall be local toggle switches or occupancy switches to meet IECC requirements. Exterior Lighting: Provide a HID wall pack to replace each existing wall pack on all perimeter walls of the Ex Hall/south building; including the loading dock area on the west side; and any wall packs within the interior courtyard directly east of the loading docks. Verify photocell/time clock/contactor operation and adjust/repair/replace as required. Emergency Lighting: Provide LED exit lights with battery as required by Code; Dual-Lite LXUGWE or equal. Provide unit emergency lights, 10W-MR16, to illuminate egress pathways in Ex Hall. Provide 5W-MR16, unit emergency lights for egress lighting in support/office areas. Provide exterior emergency lamps to provide exterior egress lighting at each exit. Fire Alarm System: Provide a fire alarm detection/notification and voice alarm system per IFC 2009. The FACP will be housed in a fire control room near the main entrance near Admin. Provide a Simplex 4100U FACP with voice/alarm comm systems. Include tone/pre-recorded messaging and a mic for manual/live voice messages. Provide duct detectors per Code for AHU’s; with wall mounted indication/test switches. Provide an alpha/numeric annunciator at the main entrance. Provide dual-action manual pull stations at each exit from the building. Provide visual alarm/speaker notification devices, mounted back-to-back on columns and on perimeter walls within the Ex Hall; and wall-mounted in all support and admin area rooms per Code. Provide notification devices in the ex kitchen/eatery area; and other south perimeter rooms (noted NIC) as required by AHJ. Include NAC panel(s) as required to power devices located remote from FACP. Include battery back-up for the fire alarm system per Code. Include a telephone connection for auto-dial notification to a monitoring service. 5 UCCS – EXHIBITION HALL Concept Design - Electrical Narrative Sound System: Provide a basic public announcement system to serve the Ex Hall. Include basic horn positioned on columns/walls to provide uniform dB coverage of the Ex Hall and ceiling speakers for restrooms and other areas with a lay-in ceiling. Locate the microphone/headend panel in the Admin Office/Ticket Booth area. Option: Use FA speakers in lieu of a stand-alone speaker system; per IFC 2009. Voice/Data System: Coordinate with utilities to provide copper lines & fiber for voice/data/IP service. Provide for a telephone headend; with digital handsets as directed by the Owner. Phone system shall support IP and wireless communications. Provide a Cat 6 structured cabling system to all wall outlets within the ticket booth, admin offices and select support spaces as defined by the Owner (up to 10 locations). Provide a free-standing data rack; with required gigabit data headend equipment to provide wireless internet services throughout the Ex Hall and wired voice/data drops in admin and ticket booth areas. Provide broad-band “Wi-Max” wireless antenna with superior response located to provide service to the Ex Hall and Admin Office areas. Include all ancillary components for a turn-key complete system. Security System: Provide a central security system headend control panel with auto-dial. Provide motion detection to monitor all entry points into the facility. Provide an exterior horn to sound upon a general alarm. Include a telephone connection for auto-dial notification to a monitoring service. Include a panic button in the ticket booth/admin office area, located per Owner. Supplemental Info: Sample Panel Schedules Concept Electrical Drawings 6 1800 1800 1800 1800 VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD CONN. 1800 VENDOR BOOTH QUAD TOTAL LOAD TYPE P=PANELS L=LIGHTING R=RECEPTACLES A= APPLIANCES M=MOTORS 3M=3PH MOTORS H=HEATERS 0=SPARE LOAD SUMMARY: " 44.4 kVA 28.8 15.6 A 0.83 DEMAND pf FACTOR 0.90 1.00 0.96 1.00 0.85 50% OF > 10k 0.80 0.50 0.60 1.00 0.90 1.25 1.00 1.00 0.85 0.50 3900 3 1 1 1 3 29.1 kVA 19.4 7.8 DEMAND 50 SPECIAL VENDOR RECEP A SPARE 3900 20 20 SPARE 20 SPARE R R R R R 20 1 3 20 R 20 1800 SPARE 1 C A B C A B C 31 33 35 37 39 41 42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 1 1 1 1 1 3 3 1 1 1 CKT P 20 20 20 20 20 20 20 20 20 20 BRKR A A R R R R R R R R TYPE 4W " SPECIAL VENDOR RECEP SPARE SPARE SPARE VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD VENDOR BOOTH QUAD SPARE QUAD - POWER CART QUAD - POWER CART DESCRIPTION METAL FRAME ON CART EST. MAX. DEMAND: MIN. FEEDER AMPACITY: 3900 3900 1800 1800 1800 1800 1800 1800 1800 1800 VA MOUNTING: 3 PH [LARGEST MOTO Kw] NOTES: TYPICAL POWER CART PANELBOARD. CONNECTED PHASE LOADING PHASE A: 18.6 PHASE B: 18.6 PHASE C: 7.2 B 29 A C B A C B A C B A C B A 27 25 23 21 19 17 15 13 11 9 7 5 3 1 P CKT PH VENDOR BOOTH QUAD 20 BRKR 1 R R TYPE VOLTS: 120 / 208 MAIN LUG ONLY xx KA INTERRUPTING CAP. 20 1800 QUAD - POWER CART VA 1800 NOTES LOCATION: POWER CART QUAD - POWER CART DESCRIPTION PANEL: PC* NO. POLES: 42 BUS RATING: 125A FEATURES: PANEL SCHEDULE 29.1 kVA 86.3 A NOTES 3047 3047 " " TOTAL LOAD TYPE P=PANELS L=LIGHTING R=RECEPTACLES A= APPLIANCES M=MOTORS 3M=3PH MOTORS H=HEATERS 0=SPARE 100.6 kVA 100.6 3047 RTU-1 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 0.90 DEMAND pf FACTOR 0.90 1.00 0.96 1.00 0.85 50% OF > 10k 0.80 0.50 0.60 1.00 0.90 1.25 1.00 1.00 0.85 0.50 3047 " LOAD SUMMARY: 3047 " 3047 " EVAP COOLER 3047 3047 " 3047 3047 EVAP COOLER 3047 " " 3047 3047 EVAP COOLER 3047 CONN. 3M 3M 3047 3047 3M 3M TYPE 3047 3047 VA " NOTES 3 3 3 3 3 3 A B C 37 39 41 42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 3 3 3 3 3 CKT P 20 20 20 20 20 BRKR 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M 3M TYPE 4W " " EVAP COOLER " " EVAP COOLER " " EVAP COOLER " " EVAP COOLER " " EVAP COOLER DESCRIPTION SURFACE EST. MAX. DEMAND: MIN. FEEDER AMPACITY: 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 3047 VA MOUNTING: 3 PH [LARGEST MOTO 9.1 Kw] NOTES: FOR MECH OPTION NO. 1. SEE DWGS/NARRATIVES FOR OPTION NO. 2. CONNECTED PHASE LOADING PHASE A: 33.5 PHASE B: 33.5 PHASE C: 33.5 C B A C B A C B A C B A C B A C B A 35 33 31 29 27 25 23 21 19 17 15 13 11 9 7 5 3 1 P CKT PH VOLTS: 277 / 480 MAIN LUG ONLY xx KA INTERRUPTING CAP. 125.7 kVA 125.7 DEMAND 30 20 20 20 20 20 BRKR LOCATION: CENTER CORE " EVAP COOLER " " EVAP COOLER DESCRIPTION PANEL: MECH NO. POLES: 42 BUS RATING: 225A FEATURES: PANEL SCHEDULE 125.7 kVA 153.9 A NOTES