Document 10479718

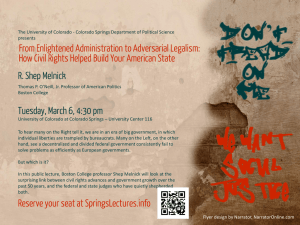

advertisement