.

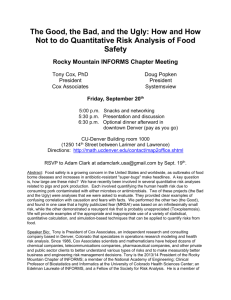

advertisement

. New England Kiln Dryers Association Peter Sformo, Loss Prevention Consultant, W.J. Cox Associates Inc. Associates, Inc Goals /Objectives Goal – Find Root Cause(s) to a incident Objectives: Obj ti 1. Explain what causal factors are. 2. Define intentional/unintentional errors. 3. Given incidents, determine what type off causall factors f are seen. 4. Given Root Cause map, apply causal f t factors to t find fi d roott causes. W. J. Cox Associates, Inc. Root Cause? W. J. Cox Associates, Inc. Root Cause? Root Cause? Lets Back Up What needs to happen for an accident to occur? Human Errors E i Equipment t Failures F il W. J. Cox Associates, Inc. Casual Factors “The human “Th h errors and d equipment i failures that directly lead to the incident i id or make k the h consequences off the incident larger” W. J. Cox Associates, Inc. Causes of Accidents Causal Factor #1 Human Error What Types of Human E Error Do D W We Have? H ? Unintentional U e o a Intentional I t ti l W. J. Cox Associates, Inc. Unintentional Human Error Committed or Omitted w/ NO prior thought typically think of these as ACCIDENTS bumping wrong switch misreading a gauge spilling coffee on control panel W. J. Cox Associates, Inc. Intentional Human Errors We DELIBERATELY Commit or Omit because we believe that for whatever reasons our actions are correct our actions will be better (safer, quicker, quicker etc) We think our way is better etc W. J. Cox Associates, Inc. Causes of Accidents Causal Factor #2 Equipment q p Failures Root Cause Definition The basic causes of events. The absence absence,, neglect, neglect, or deficiencies of managementt systems t th t caused that d th the: causal factor events to occur or allowed the causal factor conditions to exist. For the typical causal factor, there are multiple root causes. W. J. Cox Associates, Inc. 1 29 300 1-29-300 1 Serious / Fatal Injuries (0.30%) 29 300 Minor Injuries (8.8%) Near Miss Miss, Holy Smokes ! (90.99%) Causal Factors Identified Human H E Errors – Equipment E i t failures f il Lets put the Root Cause Chart to work! W. J. Cox Associates, Inc. After identifying an intermediate cause, proceed to light green to identify root causes. Start here with each causal factor Front-line Personnel Issue 3 Equipment/ Software Issue 2 Process/ Manufacturing Equipment Issue 8 Equipment Reliability Program Issue Design Issue 18 19 Design Input Issue 20 Design Scope Issue 21 Design Input Data Issue 22 Design Output Issue 23 Design Output Incorrect 24 25 26 27 Design Review/ Verification Issue No Review/Verification Review/Verification Issue 30 Critical Equipment Not Identified 32 Risk Acceptance Issue 33 Periodic Maintenance Issue 34 Scope Issue 35 Frequency Specification Issue No SPAC or Issue Not Addressed in SPAC 227 SPAC Not Strict Enough 228 SPAC Confusing or Contradictory 229 SPAC Incorrect I t 230 Company Standards, Policies and Administrative Controls (SPAC) Not Used 231 Unaware of SPAC 232 SPAC Recently Changed 233 SPAC Enforcement Issue Equipment Records and Manuals Issue 60 Documentation Content Inaccurate or Incomplete 61 62 63 64 Documents Not Available or Missing Out-of-date Documents Used Operational and Maintenance History Issue Documentation Content Inaccurate or Incomplete 80 Material/Parts Issue 95 81 Purchasing Specification Issue Readiness Review Issue 96 Review Not Performed 82 Packaging/ Transportation Issue 97 Implementation Issue 98 Change Control Issue Acceptance Criteria Issue 99 Acceptance Testing Implementation Issue 100 83 84 85 Handling and Storage Issue 86 Inventoryy Level Issue 87 Product Control and Acceptance Issue 148 Appropriate Tools/ Equipment Not Used 125 Procedure Difficult to Obtain 149 Tools/Equipment Not Functioning Properly 175 Change Identification Issue 126 Procedure Use Discouraged 150 Workplace Layout Issue 176 No Change Assessment Performed 127 Procedure Difficult to Use 151 Individual Control/ Display/Alarm Issue 177 Change Assessment Issue 128 Language Issue 152 Change Assessment Timing Issue 129 Procedure Difficult to Identify 103 Risk Acceptance Issue 130 Wrong Revision Used Proactive Risk/Safety/ Reliability/Quality/ Security Analysis Issue 131 104 Correct Procedure Used Incorrectly 132 Format Inappropriate 133 Confusing/Complex/ Difficult to Use 134 More than One Action Per Step 135 Inadequate Checklist 136 Graphics/Drawing Issue 137 Language/Wording Issue 138 Insufficient or Excessive References 159 Protective Clothing/ Equipment Issue 139 Too Much/Too Little Detail 160 101 102 Documents Not Available or Missing 88 Product Specification Issue 38 Scope Issue 66 Out-of-date Documents Used 89 Product Acceptance Criteria Issue 39 Event Specification Issue 67 Risk Assessment Records Issue 90 Inspection Issue 91 Packaging, Handling, Transportation Issue 106 Analysis Issue 92 Storage Issue 107 93 Inventory Level Issue Recommendation Identification Issue 42 Detection Method Issue Monitoring Issue 46 Data Interpretation Issue Fault-finding Maintenance and Inspection Issue 48 Scope Issue 49 Scheduling/Frequency Issue 50 Implementation Issue 51 Corrective Maintenance Issue 52 69 Scope Issue 45 47 68 Troubleshooting/ Corrective Action Issue 53 Repair Implementation Issue 54 Routine Inspection and Servicing Issue 55 Scope Issue 56 Scheduling/Frequency Issue 57 Troubleshooting/ Corrective Action Issue 70 71 72 Documentation Content Inaccurate or Incomplete Documents Not Available or Missing Out-of-date O t f d t Documents D t Used Personnel Records Issue Documentation Content Inaccurate or Incomplete 73 Documents Not Available or Missing 74 Out-of-date Documents Used 75 76 77 78 Other Documents and Records Issue Documentation C t t Inaccurate Content I t or Incomplete Documents Not Available or Missing Out-of-date Documents Used 122 105 108 109 110 111 Analysis Not Performed Recommendation Implementation Issue Risk Acceptance Issue Reactive Risk/Safety/ Reliability/Quality/ Security Analysis Issue Problem/Incident Reporting/Identification Issue 112 Investigation Issue 113 Recommendation Identification Issue 114 Recommendation Implementation Issue 115 Risk Acceptance Issue 124 140 141 142 Appropriate Procedure Incorrect/ Incomplete Wrong Action Sequence/Ordering Facts Wrong, Requirements Incorrect, or Content Not ot Updated 155 Awkward/Inconvenient/ Inaccessible Equipment Location Poor/Illegible Labeling of Control/Display/ Alarm or Equipment 197 173 Decision Not to Train 187 174 Training Need Not Identified Job Plan/Instructions to Workers Issue No Communication or Not Timely 198 188 Ineffective Walkthrough Method Unavailable or Inadequate 189 Job Scheduling Issue 199 178 179 180 181 182 157 Housekeeping Issue 184 Ambient A bi t Conditions C diti Issue Physical Workload Issue Sustained High Workload/Fatigue 162 High Transient Workload 163 Mental Workload Issue 164 Knowledge-based Behavior Issue 143 Inconsistent Procedural Requirements 165 Requirements Not Identified 144 Missing Steps/Content/ Situation Not Covered 166 Skill-based Behavior Issue 118 Implementation Issue 145 167 Unrealistic Monitoring Requirement 119 Recommendation Identification Issue Overlap or Gaps Between Procedures 168 Error Mitigation Issue Issue Tracking/ Implementation Issue 169 Errors Not Detectable 120 170 Errors Could Not Be Corrected/Mitigated Risk Acceptance Issue Preparation Issue 158 Inspection/Audit/ Measurement Issue 121 186 183 161 185 No Training Work Environment Issue 156 117 116 Training Implementation Issue Training Program Design/Development Issue Classroom Training g Issue Laboratory/Practical Training Issue 190 200 209 Personnel Hiring Issue 210 Resource/Staffing Issue Communication Not Timely/Not Performed 211 Rewards/Incentives Issue Communication Misunderstood/ Incorrect 212 Detection of Individual Performance Problem Issue Responsibility/Authority Issue 201 Standard Terminology Not Used 213 Individual Issue 192 Supervision During Work Issue 202 Language/Translation Issue 214 Sensory/Perceptual Abilities Issue* 215 Mental Capabilities Issue* 193 Improper Performance Not Corrected 203 Verification/Repeatback Not Used 194 Teamwork/ Coordination Issue 204 Long Message 216 Physical Capabilities Issue* 195 Too Much/Too Little Supervision 205 Other Misunderstood Communications 217 Personal Problem* 206 Wrong Instructions 218 Prescribed Drug Interaction Issue* 219 Horseplay* 220 Off-the-job Rest/Sleep (Fatigue) Issue* 221 Disregard for Company Procedures/Policies* 222 Drug/Alcohol Abuse* Abuse 223 Internal Sabotage or Criminal Activity* Continuing Training Issue Training Resources Issue Qualification Issue Root Cause Map™ Shape Description Causal Factor Type Problem Category Major Root Cause Category Near Root Cause Intermediate Cause Root Cause Type Root Cause See Appendix E of ABS Consulting's Root Cause Analysis Handbook for guidance on using this Map. AN ABS GROUP COMPANY www.ABSConsulting.com/RCA (865) 966-5232 207 Company Issue 191 On-the-job Training Issue Self Study and Computer-based Training Issue Personnel Selection/ Assignment/Scheduling Issue Personnel Performance Issue 208 Notes Available Now! Peter Sformo, W. J. Cox Associates, Inc. 154 Awkward/Inconvenient/ Inaccessible Location of Control/Display/ Alarm Rule-based Behavior Issue Root Cause Analysis Handbook: A Guide to Efficient and Effective Incident Investigation by ABS Consulting ISBN #978-1-931332-51-4 See http://www.rothstein.com/new/nr388.htm for book details and ordering Rothstein Associates Inc., Publisher 203.740.7444 or 1.888.ROTHSTEin (1.888.768.4763) www.rothstein.com info@rothstein.com 153 Control/Display/Alarm Integration/ Arrangement Issue Verbal and Informal Written Communication Issue 196 Supervision Issue 172 Training Requirements Not Completed Cause Cannot Be Determined 6 External Sabotage and Other Criminal Activity 17 16 Training/ Personnel Qualification Issue 171 Human Factors Issue 146 5 External Events 15 No Procedure for Task/ Operation 65 Implementation Issue Condition-based Maintenance Issue Natural Phenomena Tools/Equipment Issue Event-based Maintenance Issue Monitoring Issue Third-party Personnel Issue 14 Procedure Issue 123 Tolerable Risk 4 147 Implementation Issue 41 External Factors Correct Procedure Not Used 37 40 Contract Personnel Issue 13 Hazard/Defect Identification and Analysis Issue 94 Material/Parts and Product Issue 79 36 44 226 No or Inappropriate Maintenance Selected 59 Company Personnel Issue 12 Other Equipment Issue 11 Utility/Support Equipment Issue 10 Documentation and Records Issue 58 28 Equipment Reliability Program Design Issue 43 Company Standards, Policies and Administrative Controls (SPAC) Issue 9 29 31 Design Output Unclear or Inconsistent Enter here with each intermediate cause 224 225 Material/Product Issue Software Issue 7 1 Visit our web site for node descriptions. Copyright 2008, Rev. 11 (06/08) * These items are for descriptive purposes only. Code only to Personnel Performance - Individual Issue. Lets Look at the Accident Again g Another Accident Scenario Conclusion ALL accidents should be investigated Causal factors (human errors and/or equipment failures) should be identified Root Cause(s) should be identified pp Corrective actions applied W. J. Cox Associates, Inc. Thank YOU ! W. J. Cox Associates, Inc.