Br oad Crested Weirs

advertisement

Lecture 10

Broad Crested Weirs

I. Calibration by Energy Balance

•

•

•

The complete calibration of a broad-crested weir includes the calculation of head

losses across the structure. However, the calibration can be made assuming no

losses in the converging and throat sections, and the resulting values will usually

be very close to those obtained by the complete theoretical calibration

The procedure which is presented below is useful to illustrate the hydraulic

principles which govern the broad-crested weir characteristics, and to check the

calibration of an existing structure in the field with a programmable calculator

The simplified calibration approach does not include the calculation of the modular

limit; however, this is an important consideration in the design and operation of a

broad-crested weir because the structure is usually intended to operate under

modular flow conditions

(1) The specific energy of the flow upstream of the broad-crested weir can be set

equal to the specific energy over the crest (or sill) of the structure. The energy

balance can be expressed mathematically as follows:

hu + zu +

Vu2

V2

= hc + zu + c

2g

2g

(1)

where hu is the upstream flow depth, referenced from the sill elevation; Vu is the

average velocity in the upstream section, based on a depth of (hu + zu); zu is the

height of the sill above the upstream bed; hc is the depth over the crest where

critical flow is assumed to occur; and Vc is the average velocity in the critical flow

section over the crest.

Note that the zu term cancels from Eq. 1.

Recognizing that Q = VA, where Q is the volumetric flow rate (discharge) and A is

the area of the flow cross-section,

hc − hu +

Q2

Q2

=0

(2)

Q2 ⎛ 1

1 ⎞

hc − hu +

⎜⎜ 2 − 2 ⎟⎟ = 0

2g ⎝ A c A u ⎠

(3)

2g A c2

−

2g A u2

which can be reduced to,

BIE 5300/6300 Lectures

95

Gary P. Merkley

(2) Critical flow over the crest can be defined by the Froude number, which is equal

to unity for critical flow. Thus, the square of the discharge over the crest can be

defined as follows:

Q2 =

g A 3c

Tc

(4)

where Tc is the width of the water surface over the crest. This last equation for Q2

can be combined with the equation for energy balance to produce the following:

A 3c

hc − hu +

2 Tc

⎛ 1

1 ⎞

⎜⎜ 2 − 2 ⎟⎟ = 0

⎝ A c Au ⎠

(5)

This last equation can be solved by trial-and-error, or by any other iterative method,

knowing hu, zu, and the geometry of the upstream and throat cross-sections. The

geometry of the sections defines the relationship between hc and Ac, and between

hu and Au (important: if you look carefully at the above equations, you will see that

Au must be calculated based on a depth of hu + zu). The solution to Eq. 5 gives the

value of hc.

(3) The final step is to calculate the discharge corresponding to the value of Ac,

which is calculated directly from hc. This is done using the following form of the

Froude number equation:

Q=

g A 3c

Tc

(6)

This process is repeated for various values of the upstream flow depth, and in the

end a table of values for upstream depth and discharge will have been obtained.

From this table a staff gauge can be constructed. This simple calibration assumes

that the downstream flow level is not so high that non-modular flow exists across

the structure.

•

•

•

See the computer program listing on the following two pages

In the design of broad-crested weirs it is often necessary to consider other factors

which limit the allowable dimensions, and which restrict the flow conditions for

which the calibration is accurate

Complete details on broad-crested weir design, construction, calibration, and

application can be found in the book "Flow Measurement Flumes for Open

Channel Systems", 1984, by M.G. Bos, J.A. Replogle, y A.J. Clemmens

Gary P. Merkley

96

BIE 5300/6300 Lectures

//----------------------------------------------------------------------------// Broad crested weir calibration for free flow by energy balance equation.

// Written in Object Pascal (Delphi 6) by Gary Merkley. September 2004.

//----------------------------------------------------------------------------unit BCWmain;

interface

uses

Windows, Messages, SysUtils, Classes, Graphics, Controls, Forms, Dialogs,

StdCtrls, Buttons;

type

TWmain = class(TForm)

btnStart: TBitBtn;

procedure btnStartClick(Sender: TObject);

private

function NewtonRaphson(hu:double):double;

function EnergyFunction(hc:double):double;

function Area(h,b,m:double):double;

function TopWidth(h,b,m:double):double;

end;

var

Wmain: TWmain;

implementation

{$R *.DFM}

const

g =

bu =

mu =

zu =

bc =

mc =

L =

9.810;

2.000;

1.250;

1.600;

6.000;

1.250;

1.500;

//

//

//

//

//

//

//

weight/mass (m/s2)

base width upstream (m)

side slope upstream (H:V)

upstream sill height (m)

base width at control section (m)

side slope at control section (H:V)

sill length (m)

var

hu,Au,hc: double;

function TWmain.NewtonRaphson(hu:double):double;

//----------------------------------------------------------------------------// Newton-Raphson method to solve for critical depth. Returns flow rate.

//----------------------------------------------------------------------------var

i,iter: integer;

dhc,F,Fdhc,change,Ac,Tc: double;

begin

result:=0.0;

for i:=1 to 9 do begin

hc:=0.1*i*hu;

for iter:=1 to 50 do begin

dhc:=0.0001*hc;

F:=EnergyFunction(hc);

Fdhc:=EnergyFunction(hc+dhc);

change:=Fdhc-F;

if abs(change) < 1.0E-12 then break;

change:=dhc*F/change;

hc:=hc-change;

if (abs(change) < 0.001) and (hc >= 0.001) then begin

Ac:=Area(hc,bc,mc);

Tc:=TopWidth(hc,bc,mc);

result:=sqrt(g*Ac*Ac*Ac/Tc);

BIE 5300/6300 Lectures

97

Gary P. Merkley

Exit;

end;

end;

end;

end;

function TWmain.EnergyFunction(hc:double):double;

//----------------------------------------------------------------------------// Energy balance function (specific energy), equal to zero.

//----------------------------------------------------------------------------var

Ac,Tc: double;

begin

Ac:=Area(hc,bc,mc);

Tc:=TopWidth(hc,bc,mc);

result:=hc-hu+0.5*Ac*Ac*Ac*(1.0/(Ac*Ac)-1.0/(Au*Au))/Tc;

end;

function TWmain.Area(h,b,m:double):double;

//----------------------------------------------------------------------------// Calculates cross-section area for symmetrical trapezoidal shape.

//----------------------------------------------------------------------------begin

result:=h*(b+m*h);

end;

function TWmain.TopWidth(h,b,m:double):double;

//----------------------------------------------------------------------------// Calculates top width of flow for symmetrical trapezoidal shape.

//----------------------------------------------------------------------------begin

result:=b+2.0*m*h;

end;

procedure TWmain.btnStartClick(Sender: TObject);

//----------------------------------------------------------------------------// Entry point for calculations (user clicked the Start button).

//----------------------------------------------------------------------------var

i: integer;

F: TextFile;

strg: string;

Q,humin,humax: double;

begin

AssignFile(F,'BCWenergy.txt');

Rewrite(F);

Writeln(F,'

hc (m)

hu (m)

Q (m3/s)');

humin:=0.075*L;

humax:=0.75*L;

hu:=humin;

for i:=0 to 100 do begin

Au:=Area(hu+zu,bu,mu);

Q:=NewtonRaphson(hu);

strg:=Format('%12.3f%12.3f%12.3f',[hc,hu,Q]);

Writeln(F,strg);

hu:=hu+0.03;

if hu > humax then break;

end;

CloseFile(F);

end;

end.

Gary P. Merkley

98

BIE 5300/6300 Lectures

II. Calculation of Head Loss

Throat (Control Section)

Head loss in the throat (where the critical flow control section is assumed to be

located) can be estimated according to some elements from boundary layer theory.

The equation is (Schlichting 1960):

(hf )throat

CF L Vc 2

=

2gR

(7)

where L is the length of the sill; Vc is the average velocity in the throat section; and R is

the hydraulic radius of the throat section. The values of V and R can be taken for

critical depth in the throat section. The drag coefficient, CF, is estimated by assuming

the sill acts as a thin flat plat with both laminar and turbulent flow, as shown in the

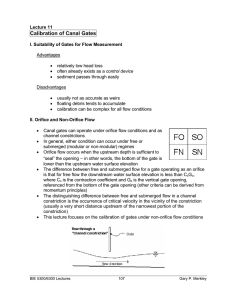

figure below (after Bos, Replogle and Clemmens 1984).

The drag coefficient is calculated by assuming all turbulent flow, subtracting the

turbulent flow portion over the length Lm, then adding the laminar flow portion for the

length Lm. Note that CF is dimensionless.

⎛m⎞

⎛m⎞

CF = CT,L − ⎜ ⎟ CT,m + ⎜ ⎟ CL,m

⎝L⎠

⎝L⎠

(8)

where CL,m is the thin-layer laminar flow coefficient over the distance m, which

begins upstream of the weir crest:

CL,m =

1.328

(9)

(Re )m

When (Re)L < (Re)m, the flow is laminar over the entire crest and CF = CL,L, where

CL,L is defined by Eq. 9.

The CT,L and CT,m coefficients are calculated by iteration from:

BIE 5300/6300 Lectures

99

Gary P. Merkley

⎡

⎛

1

k

+

0.544 CT,x = CT,x ⎢5.61 CT,x − ln ⎜

⎜ Re x CT,x 4.84x CT,x

⎢⎣

⎝

⎤

⎞

⎟ − 0.638 ⎥ (10)

⎟

⎥⎦

⎠

where x is equal to L or m, for CT,L and CT,m, respectively; Re is the Reynolds number;

and k is the absolute roughness height. All values are in m and m3/s. Below are some

sample values for the roughness, k.

Material

and Condition

Glass

Smooth Metal

Rough Metal

Wood

Smooth Concrete

Rough Concrete

Roughness, k

(mm)

0.001 to 0.01

0.02 to 0.1

0.1 to 1.0

0.2 to 1.0

0.1 to 2.0

0.5 to 5.0

The Reynolds number can be calculated as follows:

(R e ) x =

Vx

ν

(11)

where ν is the kinematic viscosity (a function of temperature); x is equal to m or L; and

V is the average velocity in the throat section for critical flow. If (Re)L is less than (Re)m,

the boundary layer over the sill is laminar only, and CF = CL,m.

The value of m can be estimated as:

m=

L⎞

ν⎛

⎜ 350,000 + ⎟

V⎝

k⎠

(12)

where the units are (m2/s)/(m/s) = m

Diverging Section

The head loss in the downstream diverging section is estimated as:

(hf )ds

ξ ( Vc − Vd )

=

2g

2

(13)

where (hf)ds is the head loss in the diverging section (m); Vc is the average velocity in

the control section, at critical depth (m/s); and Vd is the average velocity in the

downstream section (m/s), using hd referenced to the downstream channel bed

elevation (not the sill crest).

Gary P. Merkley

100

BIE 5300/6300 Lectures

The coefficient ξ is defined as:

log10 ⎡114.6 tan−1 ( zd / Ld ) ⎤ − 0.165

⎣

⎦

ξ=

1.742

(14)

where Ld is the length of the downstream ramp; and zd is the height of the downstream

ramp, also equal to the difference in elevation between the sill and the downstream

bed elevation. Note that the recommended value for the zd/Ld ratio is 1/6.

If the downstream ramp is not used, Ld equals zero. In this case, assume ξ = 1.2.

Converging Section

After having calculated the CF drag coefficient for the throat section, and assuming the

same roughness value for the channel and structure from the gauge location to the

control section, the upstream losses can be estimated. These are the losses from the

gauge location to the beginning of the sill.

For the section from the gauge to the beginning of the upstream ramp, the head loss is

estimated as:

(hf )gauge

⎛ CF Lgauge ⎞ Vu2

=⎜

⎟

R

u

⎝

⎠ 2g

(15)

where Lgauge is the distance from the gauge to the beginning of the upstream ramp; Vu

is the average velocity in the upstream section (at the gauge); and Ru is the hydraulic

radius at the gauge. All values are in metric units (m and m/s).

For the upstream ramp, the same equation can be used, but the hydraulic radius

changes along the ramp. Therefore,

(hf )us

1 ⎛ CF Lu ⎞ ⎛ Vu2 Vr2 ⎞

= ⎜

+

⎟

⎟⎜

2 ⎝ 2g ⎠ ⎜⎝ Ru Rr ⎟⎠

(16)

where the values of Vr and Rr, at the entrance to the throat section (top of the ramp),

are estimated by calculating the depth at this location:

hr = hc + 0.625 (hu − hc )

BIE 5300/6300 Lectures

101

(17)

Gary P. Merkley

III. Photographs of BCW Construction

Gary P. Merkley

102

BIE 5300/6300 Lectures

BIE 5300/6300 Lectures

103

Gary P. Merkley

Gary P. Merkley

104

BIE 5300/6300 Lectures

References & Bibliography

BIE 5300/6300 Lectures

105

Gary P. Merkley

Gary P. Merkley

106

BIE 5300/6300 Lectures