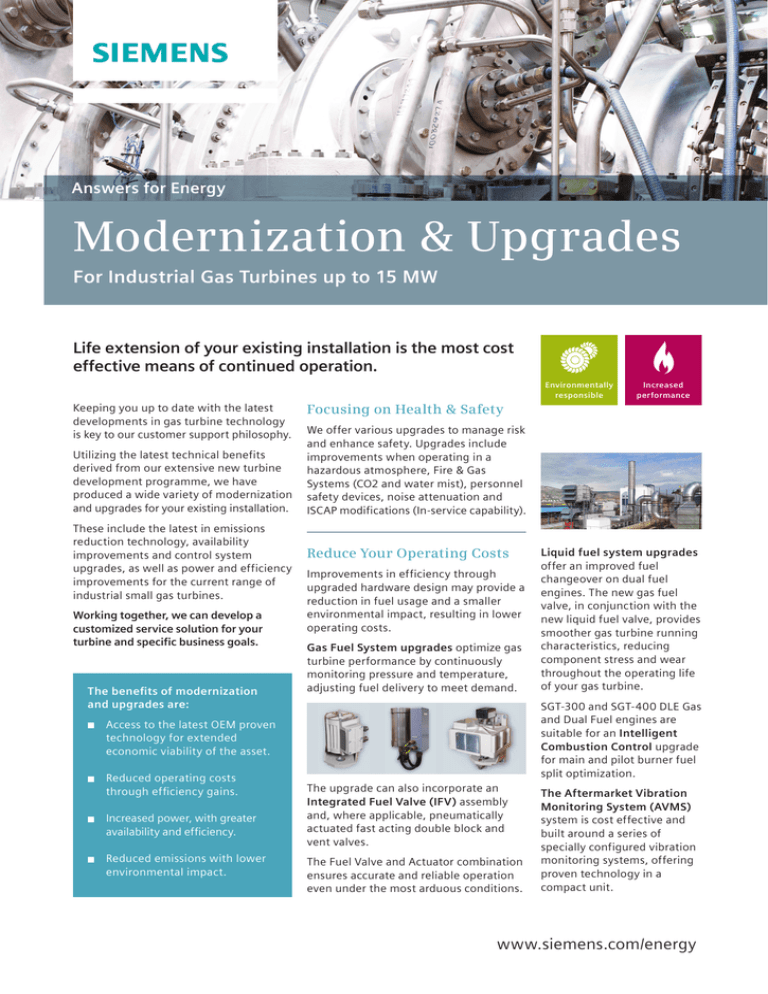

Answers for Energy

Modernization & Upgrades

For Industrial Gas Turbines up to 15 MW

Life extension of your existing installation is the most cost

effective means of continued operation.

Environmentally

responsible

Keeping you up to date with the latest

developments in gas turbine technology

is key to our customer support philosophy.

Utilizing the latest technical benefits

derived from our extensive new turbine

development programme, we have

produced a wide variety of modernization

and upgrades for your existing installation.

These include the latest in emissions

reduction technology, availability

improvements and control system

upgrades, as well as power and efficiency

improvements for the current range of

industrial small gas turbines.

Working together, we can develop a

customized service solution for your

turbine and specific business goals.

The benefits of modernization

and upgrades are:

Focusing on Health & Safety

We offer various upgrades to manage risk

and enhance safety. Upgrades include

improvements when operating in a

hazardous atmosphere, Fire & Gas

Systems (CO2 and water mist), personnel

safety devices, noise attenuation and

ISCAP modifications (In-service capability).

Reduce Your Operating Costs

Improvements in efficiency through

upgraded hardware design may provide a

reduction in fuel usage and a smaller

environmental impact, resulting in lower

operating costs.

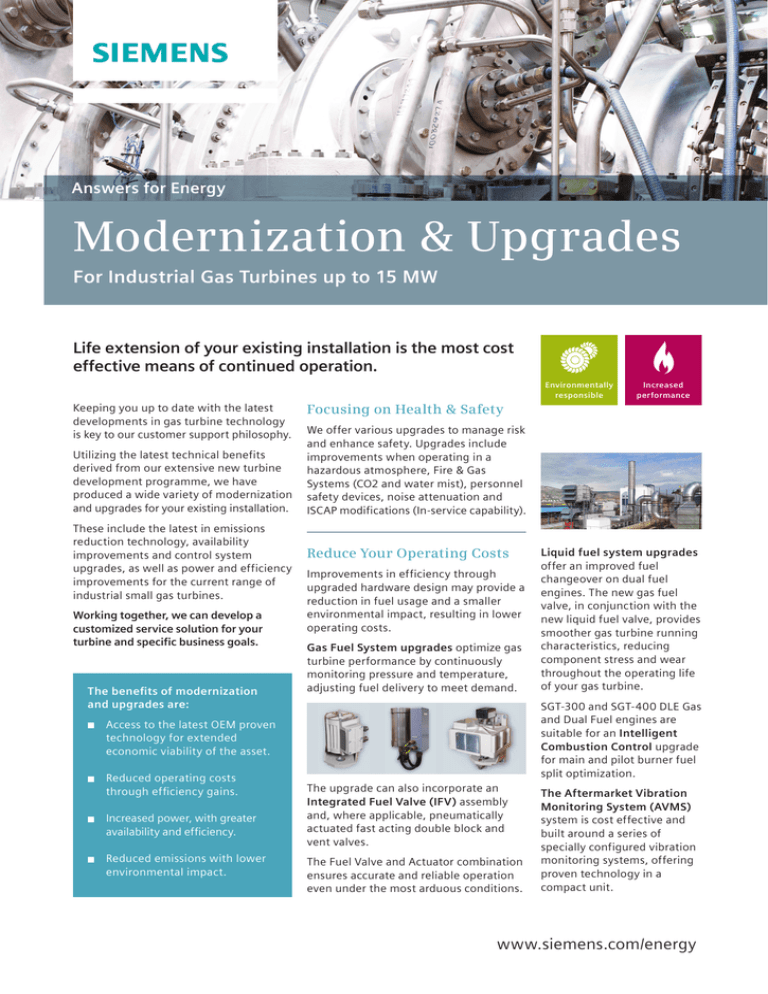

Gas Fuel System upgrades optimize gas

turbine performance by continuously

monitoring pressure and temperature,

adjusting fuel delivery to meet demand.

Increased power, with greater

availability and efficiency.

Reduced emissions with lower

environmental impact.

Liquid fuel system upgrades

offer an improved fuel

changeover on dual fuel

engines. The new gas fuel

valve, in conjunction with the

new liquid fuel valve, provides

smoother gas turbine running

characteristics, reducing

component stress and wear

throughout the operating life

of your gas turbine.

SGT-300 and SGT-400 DLE Gas

and Dual Fuel engines are

suitable for an Intelligent

Combustion Control upgrade

for main and pilot burner fuel

split optimization.

Access to the latest OEM proven

technology for extended

economic viability of the asset.

Reduced operating costs

through efficiency gains.

Increased

performance

The upgrade can also incorporate an

Integrated Fuel Valve (IFV) assembly

and, where applicable, pneumatically

actuated fast acting double block and

vent valves.

The Fuel Valve and Actuator combination

ensures accurate and reliable operation

even under the most arduous conditions.

The Aftermarket Vibration

Monitoring System (AVMS)

system is cost effective and

built around a series of

specially configured vibration

monitoring systems, offering

proven technology in a

compact unit.

www.siemens.com/energy

Prepare for the Future

Reducing waste and emissions, and

improving energy efficiency, we

work continuously to minimize

environmental impact.

Meet demands for cleaner energy

through our award winning DLE

(Dry Low Emissions) combustion

system, reducing NOx, CO, UHC and

smoke emissions.

With over 5,000,000 operating hours

of DLE experience in power generation

applications and mechanical drive

duties, you can benefit from our

extensive commercial operating

experience.

In addition, we offer more traditional

emission reduction techniques such

as steam or water injection.

HEPA air filtration system upgrade can offer various benefits:

More MW.h exhaust

heat per annum

More MW.h generated

per annum

1%

1.5%

(approx)

(approx)

A reduced fuel burn

(i.e. Life Cycle Costing)

5%

up to

Fuel is one of the most significant operation

and maintenance costs you may experience.

Extend the Life of your Gas Turbine

TM

The Siemens S7-300 control

system allows wide-spread local

support coverage through our Regional

Support Centres. HMI displays provide

you with a first line diagnostic tool to

reduce any unscheduled down time.

We also offer Micro Controllers for

both the TA and TB gas turbines. Based

on a modern compact PLC and a TFT

touch screen, they offer a standard

configuration of pre-engineered

modules, suitable for TA and TB

Generator or Pump installations and,

subject to review, compressor sets.

For more information or to arrange

an appointment, please contact

your local CSM or our Modernization

& Upgrades experts in Lincoln, UK.

Tel: +44 (0)1522 583343

SGTserviceenquiries@siemens.com

www.siemens.com/energy

Availability Enhancements

Siemens Remote Diagnostic

Services are designed to help you

maximize your unit’s performance,

and are tailored to your specific

machine type.

You can expect an emissions reduction

of 70-100% load ISO for Gas Fuel and 65-100% load ISO for Liquid Fuel engines.

Increase the Performance of your Engine

Upgrades include the High Efficiency

Particulate Air Filter (HEPA)

providing improved filtration from

airborne contaminants to lower your

life cycle costs.

All allow for improved reliability,

increased availability and lower

operational costs for your gas turbine.

Engine power uprates are available

via a modified combustion system or

core engine blade coating

enhancements. All are proven to

increase the nominal ISO power

output from your engine.

your service contract, able to offer

secure remote support and advice via

telephone with optional real time

intervention after customer release,

provided by Siemens’ 24/7 helpdesk.

The STA-RMS (Siemens Turbomachinery

Applications - Remote Monitoring

System) platform is tailor made to

improve the remote functionality of

all Siemens units, and is the only OEM

approved system commercially

available.

Based on its “common Remote Service

Platform (cRSP)” we are, dependent on

Published by and copyright © 2014:

Siemens Industrial Turbomachinery, Energy

Service Feilden House, Lincoln, LN6 3AD, UK

All rights reserved. Trademarks mentioned in this

document are the property of Siemens AG, its

affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases. The

required technical options should therefore be

specified in the contract.