Essen balancing pit –

dynamic balancing of rotors

A rotor’s balance essentially contributes

to the service life of rotating machines.

Unbalanced masses cause radial forces

that strain bearings, casings, base plates,

and not least foundations as well as building structures. Therefore, balancing of

new and refitted rotors is an inherent part

of the production and revision process.

In this context we offer balancing solutions

for a wide spectrum of rotors. Especially

the potential of performing electrical measurements on rotors of electric machines

during the balancing process considerably

shortens throughput time.

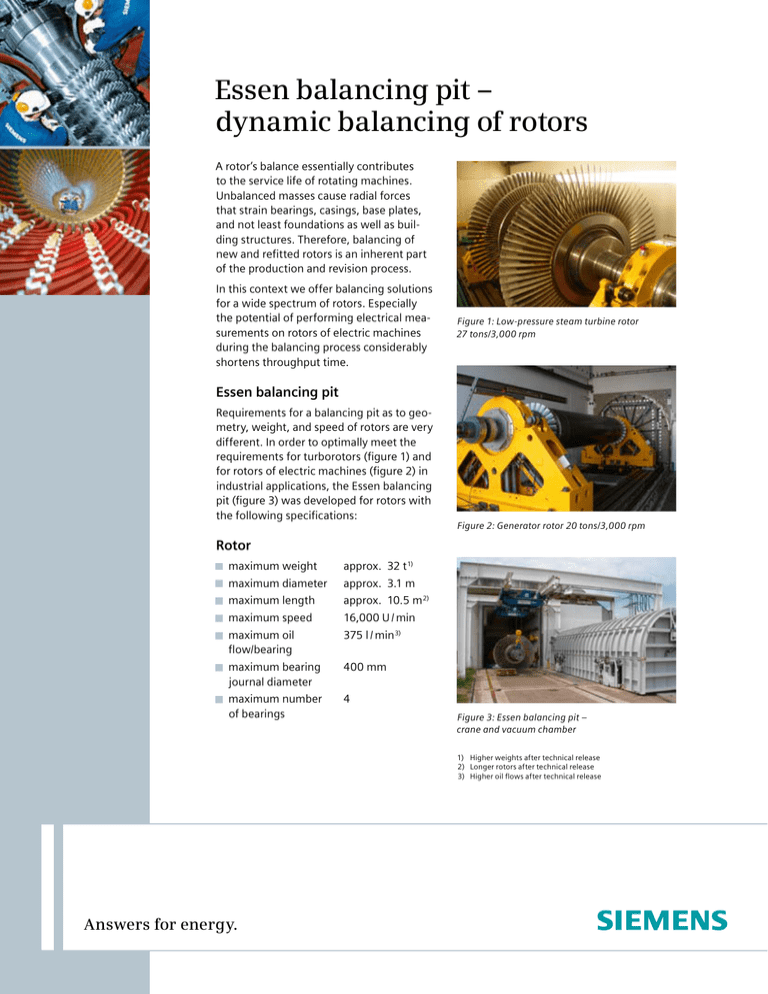

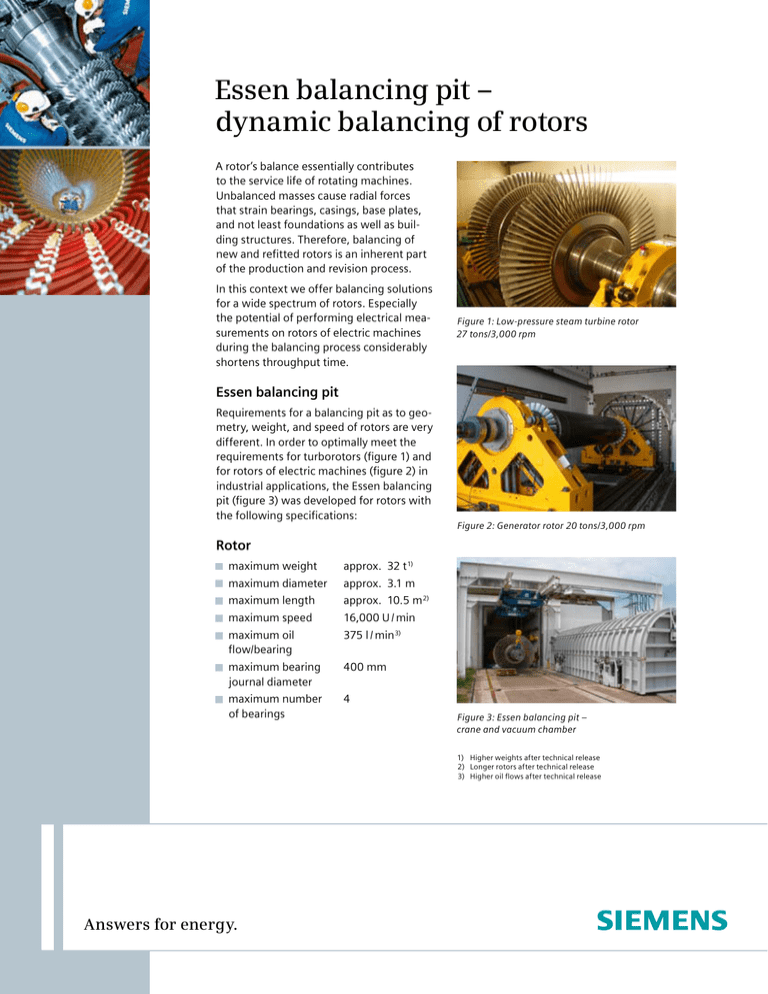

Figure 1: Low-pressure steam turbine rotor

27 tons/3,000 rpm

Essen balancing pit

Requirements for a balancing pit as to geometry, weight, and speed of rotors are very

different. In order to optimally meet the

requirements for turborotors (figure 1) and

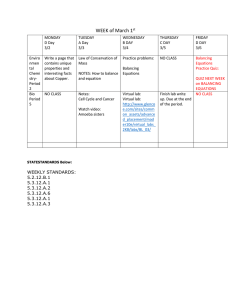

for rotors of electric machines (figure 2) in

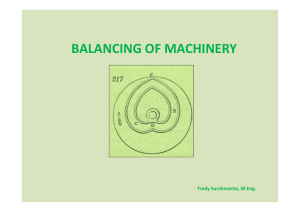

industrial applications, the Essen balancing

pit (figure 3) was developed for rotors with

the following specifications:

Figure 2: Generator rotor 20 tons/3,000 rpm

Rotor

maximum weight

approx. 32 t 1)

maximum diameter

approx. 3.1 m

maximum length

approx. 10.5 m 2)

maximum speed

16,000 U / min

maximum oil

flow/bearing

375 l / min 3)

maximum bearing journal diameter

400 mm

maximum number

of bearings

4

Figure 3: Essen balancing pit –

crane and vacuum chamber

1) Higher weights after technical release

2) Longer rotors after technical release

3) Higher oil flows after technical release

Answers for energy.

Driver unit (figure 4)

DC motor

maximum power/speed

1.35 MW / 1,300 U / min

direction of rotation left/right

gear ratios:

shift gear

transmission

1:1/1:4

turbo gear

transmission

1:3,5

shifting steps:

low-speed

high-speed Figure 4: Driver unit – direct current motor,

shift gear, turbo gear

1:1/1:3.5

0 - 4,550 U / min

1:4 /1:3.5

0 - 16,000 U / min

Main control room

The main control room of the balancing

pit (figure 5) comprises three operator

terminals:

vibration measurements and control

process control

electric measurements

For the vibration measurement the

Schenck-Systems CAB690 and Cabflex++

are used ensuring the following

standards are met:

International

ISO 1940, ISO 11342

Standard Organization

American Petroleum

Institute

Published by and copyright © 2008:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Power Generation, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, contact our

Customer Support Center.

Phone:+49 180/524 70 00

Fax: +49 180/524 24 71

(Charges depending on provider)

e-mail: support.energy@siemens.com

www.siemens.com/energy-support

Order No. A96001-G90-B188-X-4A00

Printed in Germany

1386 J DA 0208 1.

All rights reserved.

Subject to change without prior notice.

Printed on paper treated with chlorinefree bleach.

Trademarks mentioned in this document are the property of Siemens AG,

its affiliates, or their respective owners.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore be

specified in the contract.

API 617

In order to simulate realistic conditions,

balancing at operating temperature

may be carried out for rotors of electric

machines by means of electric heating.

For a final inspection, documents of

frequency analyses,

amplitude/phase diagrams,

shaft vibration measurements

are compiled in accordance with the

respective guidelines.

Figure 5: Main control room – vibration

measurements, process control, electric

measurements (f.l.t.r.)

The interaction of the plant components

(oil system, vacuum system/chamber,

and driver unit) is controlled by a modern

control circuitry system (WINCC) via pointand-click.

For rotors of electric machines, the

following electrical measurements may

be carried during the balancing process:

impedance measurement

insulation resistance/high voltage testing

ohmic resistance