Journal of Non-Crystalline Solids 299–302 (2002) 1023–1027

www.elsevier.com/locate/jnoncrysol

Silver incorporation in Ge–Se glasses used in programmable

metallization cell devices

M. Mitkova *, M.N. Kozicki

Center for Solid State Electronics Research, Arizona State University, Tempe, AZ 85287-6206, USA

Abstract

We investigate the nature of thin films formed by the photodissolution of Ag into Se-rich Ge–Se glasses for use in

programmable metallization cell devices. These devices rely on ion transport in the film so produced to create electrically programmable resistance states. The way in which Ag incorporates into the chalcogenide film during photodiffusion is examined using Rutherford backscattering spectroscopy analysis and Raman spectroscopy. The results

suggest that an Ag-rich phase separates due to the reaction of Ag with free Se from the chalcogenide glass leaving a Gerich chalcogenide matrix. Ó 2002 Elsevier Science B.V. All rights reserved.

PACS: 73.61.J; 78.30.L; 85.25.H

1. Introduction

It has been known since the mid 1960s [1] that

silver can be photodissolved in chalcogenide glasses to form materials with interesting technological

properties. In the 35 years since, this effect has

been used in diverse applications such as the fabrication of relief images in optical elements [2],

micro photolithographic schemes [3], and for direct

imaging by photoinduced silver surface deposition

[4]. The introduction of silver into chalcogenide

glasses causes substantial changes in the electrical

properties of the material, decreasing the resistivity

by many orders of magnitude [5]. However, even

with metal concentrations as high as tens of atomic

percent, these ternaries have resistivities that are

*

Corresponding author.

E-mail address: mmitkova@asu.edu (M. Mitkova).

still many orders of magnitude higher than this of

thin films of the pure metal. Alloying Ag with the

Ge–Se glass leads to formation of a solid-state

layer in which a significant portion of the silver

ions are relatively mobile at room temperature. If

electrodes are formed in contact with this photodiffused layer, an anode which has oxidizable Ag

and an inert cathode, and a voltage is applied

between them, the positively charged metal ions

will migrate toward the cathode region. At small

applied bias (much less than 1 V) in structures

which are commensurate with state-of-the-art integrated device geometries, the ions will come out

of the photodiffused layer at the cathode to rapidly

form a stable metallic electrodeposit which may be

made to extend from the cathode to the anode.

The low resistance metal electrodeposit acts to

short-out the relatively high resistance glass and

hence the overall resistance of the structure can

be reduced by many orders of magnitude via this

0022-3093/02/$ - see front matter Ó 2002 Elsevier Science B.V. All rights reserved.

PII: S 0 0 2 2 - 3 0 9 3 ( 0 1 ) 0 1 0 6 8 - 7

1024

M. Mitkova, M.N. Kozicki / Journal of Non-Crystalline Solids 299–302 (2002) 1023–1027

non-volatile electrically stimulated deposition process. A reverse bias will cause electrodissolution

of the metal link, returning the device to a high

resistance state and this write–erase cycle may be

repeated many tens of millions of times. This reversible switching effect is the basis of the programmable metallization cell (PMC) memory

technology.

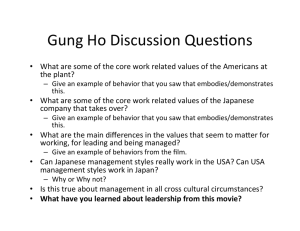

Fig. 1 depicts a schematic of a typical form of

PMC device. In this case, the Ag-photodiffused

Ge–Se glass layer is placed in a small geometry via

between two levels of metal, a configuration which

lends itself well to extreme device scaling. Typical

test devices are based on a layer of Si3 N4 deposited

by LPCVD which isolates the PMC devices (both

electrically and chemically) from the underlying

silicon substrate. The lower electrode (cathode) is

formed from an evaporated Ni film and the intermetal dielectric is also Si3 N4 . Following via formation in the nitride layer, the parent glass is

deposited in the via and then a layer of silver is

deposited on top of that. This bilayered structure

is then exposed to UV light to photodissolve the

silver and ‘saturate’ the glass but the relative layer

thicknesses are such that excess silver remains on

the surface to act as the anode. A connection is

made to this Ag layer by means of another layer of

Ni metallization. Representative dc characteristics

for a sub-micron device are shown in Fig. 2 and an

ac equivalent circuit of the electrical characteristics

is described in [6].

Fig. 2. Current–voltage characteristics of a PMC memory device. The off state is much greater than 1 MX but switches to

less than 20 kX at 0.18 V. The value of the on state depends on

writing conditions.

The key to the creation of a PMC device which

can be used in a high density memory lies with the

nature of the thin films of the Ag-photodiffused

Ge–Se glass. The aim of the work reported in this

paper is therefore to address the issues relating to

formation of such thin film ternaries by photodissolution of silver into the Ge–Se parent glass.

The effects of silver photodiffusion have been investigated by Raman spectroscopy, which yields

clues regarding the photoinduced changes in the

mesoscopic structure of the glass. The amount of

the diffused Ag in our samples has been verified

using Rutherford backscattering spectrometry

(RBS) methods. Interpretation of the experimental

results centers on the molecular structure of the

solid-state electrolytes and in particular the backbone structure of the ternary and how it relates to

the structure of the chalcogenide host.

2. Experimental

Fig. 1. Active-in-via (AIV) configuration of a PMC memory

device between two levels of metal.

In order to perform the analysis of thin films of

the ternary, a standard sample type was prepared

as follows. Amorphous layers of the parent glass

were prepared by thermal evaporation, using a

previously synthesized Ge30 Se70 glass source and

utilizing a crucible with a special membrane structure [7]. Use of the membrane crucible assured

formation of films with excellent control over ma-

M. Mitkova, M.N. Kozicki / Journal of Non-Crystalline Solids 299–302 (2002) 1023–1027

terial stoichiometry. The evaporation rate was 2

nm/s and the final deposited film thickness was in

the order of 40 nm. Following this, a silver film 25

nm thick was deposited without breaking vacuum.

The wafers were then exposed to UV light at a

power density of 115 mJ=cm2 s to form the ternary.

The amount of photodiffused silver in the glass

was determined by RBS with a 1.7 MeV Heþ ion

beam at normal incidence to the sample and with

a backscattering angle of 160°. The samples were

found to be sensitive to the measurement technique for doses between 0.5 and 1.0 lC=mm2 and

so a charge limit of around 0.25 lC=mm2 was

used.

The structure of the films was determined using

Raman spectroscopy. The Raman scattering measurements were made in a backscattering configuration with the 647 nm line (typical power of

0.5 mW) of a Kr ion laser. The excitation light

was focused on the sample in a region of 0:1 0:1 mm2 . The temperature increase caused by the

laser irradiation was less than 20 °C as calculated

from the ratio of anti-Stokes to Stokes intensities

[8].

1025

Fig. 3. RBS spectra of Ge30 Se70 film photodiffused with Ag

after 5 min of illumination and after 10 min of illumination (the

dashed line).

3. Results

The RBS analysis confirmed that the amount of

the photodiffused Ag depends upon the time of

illumination but saturation of the glass can be

achieved for the conditions of our experiment after

10 min of illumination. Beyond this time, no

change in the amount of Ag introduced into the

glassy film was found. This saturation occurs when

33 at.% silver has photodiffused into the Ge30 Se70

thin films, as shown in the RBS spectrum of Fig. 3.

Fig. 4 represents the Raman spectrum of the

initial Ge30 Se70 thin film as well as the spectra of

the Ge30 Se70 film saturated with 33 at.% Ag and

the Ag2 Se film. As shown, the Ge30 Se70 composition consists of Se–Sen chains whose vibrational

mode appears at 260 cm1 in the Raman spectrum,

edge-sharing Ge-containing structural units giving

rise to a breathing mode at 216 cm1 , and cornersharing Ge-containing units with a feature at 199

cm1 . The strength of the latter substantially pre-

Fig. 4. Raman spectra of: thin film with composition Ge30 Se70 ,

thin film – composition, resulting after saturation of the initial

Ge30 Se70 film with Ag and Ag2 Se film.

vails over the edge-shared units as the number of

Se atoms is relatively high and connection due to

sharing at the corners of the tetrahedra is preferred. The spectrum of the film resulting after Ag

diffusion shows significant reorganization of the

structure.

4. Discussion

In principle, the structure of thermally evaporated films from the Ge–Se binary does not differ

considerably from that of bulk material [9]. As

in the bulk material, they possess a fragmented

1026

M. Mitkova, M.N. Kozicki / Journal of Non-Crystalline Solids 299–302 (2002) 1023–1027

molecular structure but the size of Ge-rich and Serich clusters can be expected to be smaller than in

the bulk due to surface effects. Even though these

glasses possess a number of low co-ordinated Se

atoms, they are still quite rigid. The results of

previous work regarding the compositional variation of the glass transition temperature in the Ge–

Se system imply that the Ge30 Se70 composition can

be characterized as having medium range order in

which particular rigid moieties form [10], leading

to formation of a network with lower configurational entropy due to the occurrence of specific

chemical configurations that are energetically

preferred.

The great change of the Raman spectrum of the

photodiffused material suggests total reorganization of the films in which face-sharing units containing Ge–Ge bonds occur. These features are

characteristic of glasses with Ge concentration

>0.33 [10]. One can discern the scattering of the

180 cm1 mode of ethane-like units consisting of

one Ge–Ge and six Ge–Se bonds. So far investigations of the photoinduced changes in Ge–Se

glasses have not revealed the formation of Ge–Ge

bonds but we assume that our observation of this

effect is due to the consumption of free Se by the

photodiffused Ag and the subsequent formation of

Ag2 Se. The act of illumination of the film results in

the creation of electron–hole pairs and is accompanied by the formation of metastable states at the

chalcogen [11] that can react spontaneously with

the surrounding Ag ions. This reaction will be

preferred as the energy that it requires is about

three times less the energy for the Ge–Se bonding

(48.4 vs. 113 kcal/mol). Indeed the two compositions GeSe2 and Ag2 Se have very close heats of

formation )10.8 and 9.0 kcal/mol, respectively,

and this assures their co-existence in the system

leading to some dynamics by which Ag will slowly

dissolve from Ag2 Se into GeSe2 because of the

entropy of mixing [12] but will then react again

with the charged chalcogens. The fact that the

Ag2 Se modes do not interfere with those of the

Ge–Se backbone after Ag diffusion is one more

piece of evidence that no mixed ternary phase

arises as a result of Ag diffusion [13]. We assume

that the process reaches saturation because of the

strict number of free and under-co-ordinated Se

atoms that are available for reaction with Ag. As

the saturation of the Ge–Se films occurs with the

same amount of Ag as in bulk glasses [14], we used

these data to calculate the ratio of the thickness of

Ag film for saturation in a Ge30 Se70 film, for which

we obtained 1:3.62.

At this point we should like to mention one

more detail – we expect that there will be a slight

difference in the Ag co-ordination when it is alloyed with Se to form a glass by fast quenching

compared to when it is introduced by photodiffusion at room temperature. In fact, this difference

in the Ag co-ordination has been enumerated by

Oldale et al. [15] in their extended X-ray absorption fine structure (EXAFS) analysis. We suggest

that this is due to the fact that at quenching of the

alloyed glass because of the high rate of solidification, the solid phase that forms has a short range

order very close to the structure of the high temperature form – aAg2 Se while in the diffusion

process the phase that forms has a structure

analogous to bAg2 Se which is stable at room

temperature. However the results of Chen and Tai

[16] and our XRD experiments confirm the presence of some bcc Ag2 Se as well and this could be

due to the fact that Ag diffuses in an organized

solid-state matrix in which the formation of the

Ag2 Se structures is restricted due to space limitations. This perhaps suppresses to a great extent the

crystallization process of the Ag2 Se formed so that

the size of the crystalline particles remains in the

. This stabilizes the doped film

vicinity of several A

against Ag crystallization.

5. Conclusions

Our investigation of Ag photodoping in Se-rich

Ge–Se glass has been driven by our desire to understand the properties of thin films of solid solutions for use in PMC devices. Photodiffusion of

Ag causes significant reorganization of the structure of the initial films as revealed by Raman

spectroscopy. This effect is due to the photoinduced reaction between the Ag ions and the ‘free’

Se which forms a phase close to Ag2 Se and also

causes the formation of a backbone with Ge–Ge

bonding features. The photodissolution process

M. Mitkova, M.N. Kozicki / Journal of Non-Crystalline Solids 299–302 (2002) 1023–1027

saturates when 33 at.% Ag is introduced into the

Ge–Se matrix of Ge30 Se70 glass. The saturation

effect means that the photodiffusion process is selfcontrolled and highly repeatable.

Acknowledgements

The authors would like to acknowledge Barry

Wilkens for performing the RBS investigations

and David Wright for his technical assistance.

Work supported by Axon Technologies Corp.

References

[1] M.T. Kostyshin, E.V. Mikhailovskaya, P.F. Romanenko,

Sov. Phys. (Solid State) 8 (1966) 451.

[2] J. Hajto, P.J.S. Ewen, R.E. Belford, A.E. Owen, Thin Solid

Films 200 (1991) 229.

1027

[3] M.N. Kozicki, S.W. Hsia, A.E. Owen, P.J.S. Ewen,

J. Non-Cryst. Solids 137&138 (1991) 1341.

[4] T. Kawaguchi, S. Maruno, S.R. Elliott, J. Non-Cryst.

Solids 212 (1997) 166.

[5] A. Pradel, G. Taillades, C. Cramer, M. Ribes, Solid State

Ion. 105 (1998) 139.

[6] W.C. West, K. Sieradzki, B. Kardynal, M.N. Kozicki,

J. Electrochem. Soc. 145 (1998) 2971.

[7] T. Petkova, M. Mitkova, Thin Solid Films 205 (1991) 205.

[8] K. Murase, in: P. Boolchand (Ed.), Insulating and Semiconducting Glasses, World Scientific, Singapore, 2000,

p. 415.

[9] H. Takeuchi, O. Matsuda, K. Murase, J. Non-Cryst. Solids

238 (1998) 91.

[10] P. Boolchand, W.J. Bresser, Philos. Mag. B 80 (2000) 1757.

[11] K. Shimakawa, A. Kolobov, S.R. Elliott, Adv. Phys. 44

(1995) 475.

[12] J.C. Phillips, J. Non-Cryst. Solids 64 (1984) 81.

[13] P. Boolchand, W. Bresser, Nature 410 (2001) 1070.

[14] M. Mitkova, Yu. Wang, P. Boolchand, Phys. Rev. Lett.

83 (1999) 3848.

[15] J.M. Oldale, J. Rennie, S.R. Elliott, Thin Solid Films 164

(1988) 467.

[16] C.H. Chen, K.L. Tai, Appl. Phys. Lett. 37 (1980) 605.