Journal of Non-Crystalline Solids 353 (2007) 1844–1848

www.elsevier.com/locate/jnoncrysol

Structure of copper-doped tungsten oxide films for solid-state memory

C. Gopalan a, M.N. Kozicki a, S. Bhagat c, S.C. Puthen Thermadam a,

T.L. Alford c, M. Mitkova b,*

b

a

Center for Solid State Electronics Research, Arizona State University, Tempe, AZ 85287-6206, USA

Department of Electrical and Computer Engineering, Boise State University, Boise, ID 83725-2075, USA

c

School of Materials Arizona State University, Tempe, AZ 85287-8706, USA

Available online 9 April 2007

Abstract

Copper-doped WO3 films, which are an active media for programmable metallization cell memory devices, are studied. The highlights

of this study are the intercalation products forming on the interface between the WO3 and Cu during thermal evaporation and also after

thermal or photothermal diffusion of Cu into WO3 films. The diffusion profile is established using Auger spectroscopy. Further characterization is provided using Raman spectroscopy which gives evidence for formation of products with a lower valence state related to W

and oxidation products related to Cu. The composition of the intercalation products containing Cu is confirmed using X-ray diffraction

which shows the formation of copper oxides and tungstates.

2007 Elsevier B.V. All rights reserved.

PACS: 42.70.Ce; 78.30.j; 61.72.Dd; 82.80.Pv

Keywords: Phonons; Raman scattering; X-ray diffraction; Microcrystallinity

1. Introduction

Tungsten is a widely accepted material in the microelectronics industry, especially in its application in multilevel

interconnects. Tungsten plugs provide the required vertical

connection between the horizontally running wiring which

is now made of copper. In a typical Back End of the Line

(BEOL) process [1], the interconnects made of tungsten

plugs and copper offer excellent opportunities for the development of a memory cell, thus increasing the capacity of

the unit’s memory storage due to the introduction of Programmable Metallization Cell (PMC) memory devices [2]

fabricated on the tungsten plugs. These devices are composed of a thin film of solid electrolyte sandwiched between

a copper anode and an inert cathode. Under the influence

of an electric field, the electron current from the cathode

reduces an equivalent number of Cu-ions as injected from

*

Corresponding author. Tel.: +1 208 426 3395; fax: +1 208 426 2470.

E-mail address: mariamitkova@boisestate.edu (M. Mitkova).

0022-3093/$ - see front matter 2007 Elsevier B.V. All rights reserved.

doi:10.1016/j.jnoncrysol.2007.02.054

the anode and a metal-rich electrodeposit is thereby formed

in the electrolyte. The electrodeposit is electrically neutral

and stable; however, applying a bias with opposite polarity

can reverse the formation process. The reverse ion current

flows until the previously injected Cu oxidizes and deposits

back onto the electrode, which was the initial source of the

metal. Thus, the resistivity increases again until the high

value characteristic for the solid electrolyte is reached [3].

Since tungsten has a lower electronegativity than Cu [4],

it could be successfully used as an ‘inert’ electrode in the

construction of the PMC devices. Tungsten also offers

one more degree of compatibility and ease of processing

within the overall structure of the integrated circuit when

metal-doped WO3 is used as a solid electrolyte because

one can use the W as the starting material for the electrolyte. Doping WO3 with Cu and establishing a Cu oxidizable electrode in the PMC structure contributes towards

one more degree of technological simplicity.

WO3 is known to easily form tungsten bronzes [5]. They

are reduced phases with the general formula AxWOy where

C. Gopalan et al. / Journal of Non-Crystalline Solids 353 (2007) 1844–1848

A is typically an alkali metal but can also be some other

electropositive metal, and x is less than 1. In the case of

thin films, the structure is not as well organized as in crystals where specific tunnels exist [5] but niches and channels

are still available where metal and in particular Cu atoms

could be accommodated. Scientific and technological interest towards WO3 films stems also from the fact that they

possess electro- and photo-chromic effects [6]. It is believed

that photochromism can be explained by the doublecharge-injection model [7]. By the injection of H ions and

electrons into a WO3 lattice, a tungsten bronze structure

(HxWOWO3, 0 < x < 1) is formed and then W6+ is partially reduced to W5+ in tungsten oxide hydrate or W4+

in 12-tungstates by electrons occupying the empty W5d

orbital due to the electron localization effect. In the presence of electronegative metal in the WO3 sublattice, electron injection can be initiated by the metal and this

opens new perspectives into the diffusion mechanism. This

effect has a very important consequence for PMC technology as it suggests that there is a good opportunity to control the process of metallization of WO3 by which the

optimum conductivity of the material for the operation

of the devices can be achieved. This perspective is the driving force for the study reported in this work that is related

to research on the formation of WO3 thin films due to thermal evaporation. It complements our previous research

related to the formation of WO3 films using wet or plasma

oxidation [8] that were applied for the formation of PMC

devices. The present research is related to the creation of

specific doped products using standard thermal doping or

photo-assisted doping to form a solid electrolyte based

on WO3 and characterization of these products using Field

Emission Scanning electron microscopy (FESEM), Auger

(AES) and Raman spectroscopies, as well as X-ray diffraction (XRD).

2. Experimental

The studied films were evaporated on Si wafers covered

with a TiN film which provides a barrier to Cu diffusion

ensuring that Cu diffuses only into the WO3. Sandwiches

of 100 nm each of Cu and WO3 on top of it were evaporated using electron-beam-assisted heating for the thermal

sublimation of high-purity Cu and WO3 pieces produced

by Cerac, and the thickness was controlled using a quartz

crystal monitor. The evaporation rate was 2 Å/s while the

substrates were rotated to ensure uniform coating of the

films.

Two different means of diffusion processes were used: (i)

thermal diffusion, for which a convection oven set at

135 C was used and since the chamber of the oven did

not permit external light to interfere with the process, it

could be considered as a purely thermal diffusion. The temperature was chosen to be 135 C because this coincides

with a number of technological requirements, e.g. this is

the temperature at which the photoresist begins to denature. Hence the treatment time was restricted to 30 min;

1845

(ii) photo-thermal diffusion. To achieve photo-thermal diffusion, a setup involving a commercially available lighting

source of a 500 W tungsten halogen lamp assembly was

used. The temperature was 135 C. Photo-thermal diffusion

was also carried out for 30 min.

The films were characterized using the following methods: (i) The morphology was characterized using a Hitachi

S4700 field-emission scanning electron microscope at an

acceleration voltage of 15 kV and emission current 10 lA.

(ii) AES was carried out in a Physical Electronics SAM

590 scanning Auger microprobe surface analysis system.

Secondary electron excitation was obtained via a 5 kV electron gun with a beam spot size of 0.5 lm. Depth profiling

was accomplished by coordinating the AES analysis with

Ar+ ion gun etching in the sample surface region of interest. (iii) Raman spectra were collected using an Acton

Spectroprobe-275 with a Coherent Ar+/Kr+ ion laser for

providing 488 nm and 514 nm excitation that was detected

with a liquid nitrogen cooled CCD camera. To reveal

details about the different modes that exist, deconvolution

using Lorentzian expressions was carried out. (iv) The

XRD was accomplished with a Philips X’pert MPD diffractometer with Cu Ka radiation k = 1.54 Å). In order to

cover more lateral depth and to collect better signal from

the thin film, the experiment was run at a constant source

angle of 1, while the detector was scanned from 10 to

95. For these particular experiments, the WO3 films were

thicker than 500 nm to prevent the X-ray beam seeing the

underlying Cu film, leading to misleading results.

3. Results

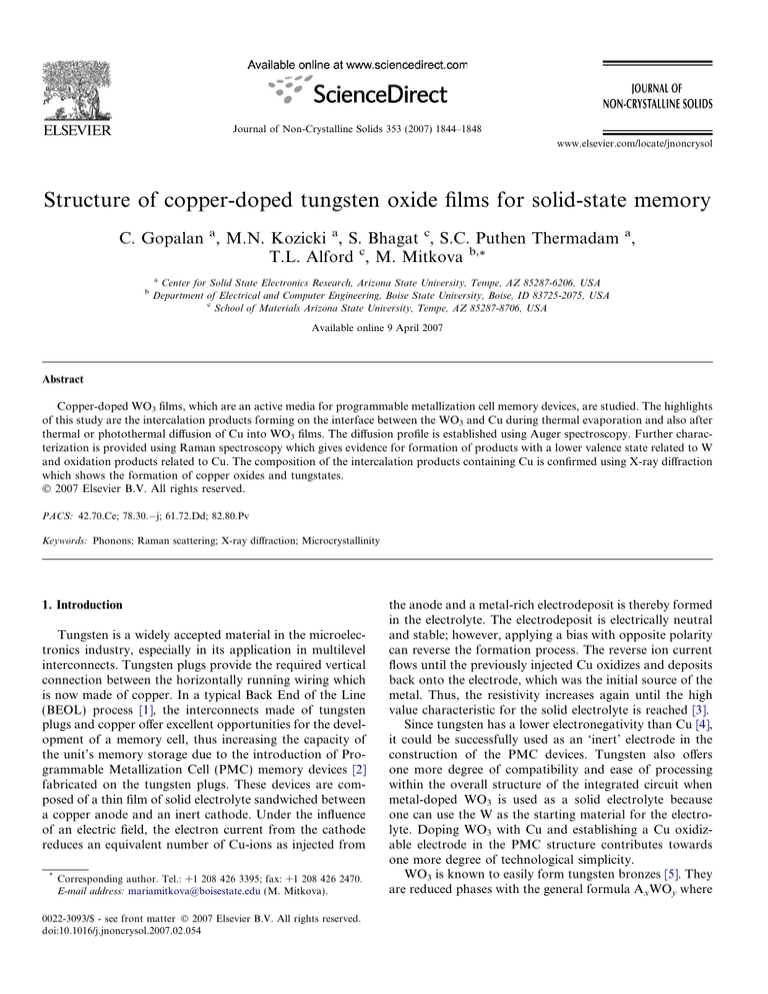

The intercalation process is very easy accessible in this

system as we have established from the AES study of the

films – Fig. 1. Note that the surface of WO3 is where the

measurement begins (from the left side) and the point at

which the Cu concentration saturates can be treated as

the boundary between the WO3 and Cu. It is obvious that

some copper diffusion occurs even during the film preparation and under these conditions some copper appears on

the surface of the WO3 film. A marked difference is noticed

in the profile when Cu is photothermally diffused, indicated

by an almost ‘step-like’ diffusion profile characteristic of

diffusion along a charge front by ionic species. In the case

of thermally diffused Cu, it follows a profile resembling an

error-function, indicating a thermally activated diffusion

from an infinite source of the impurity. Also visible on

the thermal and photo-thermal diffusion profiles is a significant pile up of Cu at the surface.

The Raman spectra of the initial WO3 films are shown in

Fig. 2. The undoped film which was maintained at room

temperature shows a pronounced peak at 926 cm1. The

main peak at 932 cm1 has a shoulder that can be deconvoluted in two peaks at 838 and 729 cm1, tracing their origin

back to the stretching modes of the O–W–O bond. Since

the considered WO3 film is amorphous, the bending mode

of the O–W–O bond is presented with a very wide peak

1846

C. Gopalan et al. / Journal of Non-Crystalline Solids 353 (2007) 1844–1848

100

90

80

C

B

A

Phothermal Diffusion

Thermal Diffusion

As deposited

70

A

60

% Cu 50

B

40

30

20

C

10

0

Depth in WO3 (arb. units)

Fig. 1. AES depth profile of Cu diffusion in WO3 achieved using thermal and photo-thermal methods.

Fig. 2. Deconvoluted Raman spectra of an undoped WO3–Cu film.

centered at 358 cm1 that is well resolved. The Raman

characteristic of the initial film is also combined with two

peaks at very low wave numbers (139 and 205 cm1) that

are not considered since their nature is questionable – they

could be either related to the lattice vibrations (but in the

given case we are dealing with quite disordered material

so that the probability for this is low), or with some interaction of the laser light with surface species.

The Raman spectrum of the photo thermally treated

sample shows similar features as seen from Fig. 3 considering the W@O mode and the stretching and bending mode

of the O–W–O bond. However in this case, modes at 423

and 642 cm1 appear, which are the breathing modes of

the Cu–O bonding, thus indicating the straightforward nature of the diffusion products as being oxidized copper.

When Cu is introduced in the WO3 matrix due to thermal diffusion, Fig. 4, the mode at 643 cm1 is well resolved

and a new wide mode at 511 cm1 appears – both of them

related to Cu–O bonding. The mode at 292 cm1 grows

substantially compared to the previous cases and at the

same time the mode at 358 cm1 becomes very weak and

Fig. 3. Deconvoluted Raman spectra of a WO3 film photothermally

doped with Cu.

Fig. 4. Deconvoluted Raman spectra of a WO3 film thermally doped with

Cu.

the mode at 729 cm1 that is seen in the previous cases does

not exist.

C. Gopalan et al. / Journal of Non-Crystalline Solids 353 (2007) 1844–1848

*

Intensity (Arb. units)

+

*

^

20

#

o

(a)

*

^

o

(b)

#

>

+-

^

>

+-

*

*

o

#

40

60

2 Theta (Deg.)

(c)

*

*

*

*

80

Fig. 5. XRD patterns of (a) the initial film; (b) the photo-thermally

diffused film; (c) the thermally diffused film. The following signs are

assigned for the different components: + for WO3; for WO2; * for Cu; ^

for CuWO4; v for Cu2WO4; for Cu3WO6; # for CuO.

The XRD data shown in Fig. 5 give some more information about the particular compositions appearing. The

WO3 compositions were predominantly amorphous. The

characteristic peaks related to these products form a rather

wide peak situated around 2h 23–280 in which the most

intense peaks of WO3 (JCPDS card 32-1395) and WO2

(card 32-1393) are situated. Among the diffusion yield we

identified Cu (card 89-2838); CuO (78-0428); Cu2WO4

(78-0928); CuWO4 (70-1732) and Cu3WO6 (83-6950).

Using the Scherrer equation, we calculated the grain size

of the diffusion products which were crystalline and form

a hetero-phase within the WOx matrix. There is a large dispersion in size distribution, ranging from 5 nm to 90 nm

with an average size of 20 nm.

4. Discussion

When we discuss the structure and the condition of the

as evaporated WO3 film it is to be noted that the vapor produced by heating WO3 does not consist of individual atoms

but is molecular in nature. The dominating species are trimeric W3O9 molecules. Their condensation organization is

complicated and highly dependent on the experimental

conditions. The undoped film which was maintained at

room temperature shows in the Raman spectrum a pronounced peak at 926 cm1 as seen in Fig. 2. This is considered to be the result of the stretching mode of a W@O

terminal bond. Daniel et al. [9] argue that this mode could

be assigned to a longitudinal optic mode of the W–O bond

in the bulk WO3 material. However, it is more convincing

that this mode is related to the W@O terminal structures

since it is the strongest bond in the system and these are

thin films with a very high surface-to-volume ratio. This

mode appears at a lower wave number than what is usually

reported in the literature – for example, the closest data for

a three-dimensional network is 945 cm1 [10]. This can be

1847

explained with the influence caused by the Cu atoms diffusing in the films during film preparation – Fig. 1 and by

means of the fact that the films were prepared via vacuum

evaporation and hence are free of water of crystallization

whereas usually, the Raman data reported consider WO3

obtained by wet methods. Decreasing water of crystallization content leads to a gradual shift towards shorter wave

numbers as shown in [11] where 960 cm1 has been

reported for WO3 Æ 2H2O, with 948 cm1 for WO3 Æ H2O,

and 945 for samples with 1/3 H2O [11].

As revealed by the XRD data, metallic Cu is registered

in this film whose presence is also confirmed by the Auger

spectroscopy. One can barely observe Cu in the Raman

data, because its occurrence results in a very weak signal,

though on the XRD pattern it gives very well resolved

sharp peaks because Cu appears in a crystallized and more

organized form than the evaporated WO3. Note that even

during the evaporation and double film formation Cu

reacts with the surrounding WO3, oxidizes and forms tungstates. These reactions are possible because of the high

kinetic energy with which the WO3 molecular fragments

condense. The cross section profile is indicative of a chemical interaction occurring at the Cu–WO3 interface.

The photo-thermally treated sample shows similar features as seen from Fig. 5 considering the W@O mode

and the stretching and bending mode of the O–W–O bond.

However these modes are shifted farther towards shorter

frequencies, which is an indication of some shortening of

the bonds. We attribute this to some distortion of the

bonds caused by the diffused species in the film. It is

known that, for amorphous films, the width of the Raman

spectra could be used as an indication of the degree of

ordering of the system. Since there are no significant

changes to the mode features, we suggest that the process

of photo-thermal treatment and diffusion of Cu into the

WO3 films does not contribute towards crystallization or

higher order of the host film. The nature of the diffused

species is fairly straightforwardly related to vibrations

coming from the CuO lattice, as they appear at frequencies

of 423 and 642 cm1. We consider the process of Cu

photodiffusion into WO3 as a two-step process by which

the Cu initially penetrates into the bulk of WO3 and takes

part in an electron-exchange reaction and oxidizes to form

CuO and a number of Cu-tungstates, as indicated also by

XRD analysis. It then mixes within the WO3 structure and

forms a hetero-structure. We suggest that this process generates charged defects that can be attributed to the photoinduced changes in the WO3 matrix under illumination.

The peaks related to pure Cu reveal formation of smaller

crystals compared to the initial film contrary to the peaks

related to the oxide and tungstates for the formation of

which part of the pure Cu is consumed during the

diffusion.

The reduction-oxidation process on Cu insertion is even

more profound when Cu is introduced in the WO3 matrix

as a result of thermal diffusion. As shown in Fig. 4, there

are two specific signs for this process: (i) on one side the

1848

C. Gopalan et al. / Journal of Non-Crystalline Solids 353 (2007) 1844–1848

mode at 643 cm1 is better resolved than in the case of

photo-thermal diffusion and a new wide mode at

511 cm1 develops; (ii) The other indication for the redox

diffusion process taking place is the growth of the mode

at 292 cm1 that is related to the appearance of a higher

amount of W5+. That the O–W–O bending mode at

358 cm1 becomes very weak and the O–W–O stretching

mode at 729 cm1 practically disappears, pointing to a

decrease of the availability of W6+ in the films. These features are may be characteristic for the mixed valency of the

Cu3+–Cu2+ dispersed in the WO3 matrix [12], evidence for

which we have found at the XRD data – Fig. 5. The WOx

peak area becomes reduced. The Cu peak follows the same

trend. That indicates that Cu is reacting with WOx. There

is obvious loss of crystallinity because of the reaction and

formation of a number of metastable tungstates. Oxidation

of Cu and formation of Cu oxides and salts always seems

to accompany its introduction in oxide systems, as for

example this effect occurs in an SiO2 matrix when Cu is

introduced in it at higher concentration at moderate temperatures [11] where Cu oxides and silicates form. XRD

data indicate some shift of the center of the peak characteristic of the WOx towards higher 2h values which are characteristic of WO2 that could be considered as a sign for the

formation of W4+ – Fig. 5 (ref. to JCPDS card 32-1393).

The relative effects from the appearance of different

phases are in good accordance when we regard the results

of all the characterization methods used. The wide variety

of products forming affects in a corresponding way the

electrical features of the systems and hence the performance of the PMC devices based on them.

5. Conclusions

The main results of our work can be summarized as

follows:

• We have shown evidence that the formation of sandwiches from Cu and WO3 using thermal evaporation

results in intercalated structures.

• The diffusion profile of Cu in WO3 is strongly dependant

upon the diffusion driving forces and related with them

charge effects; Cu piles up on the surface of the WO3

films because of kinetic effects during diffusion.

• The diffusion process is in essence oxi-reductive in nature, resulting in different structures, depending upon

the method by which the diffusion is realized. However,

the newly formed medium is heterogeneous.

• There is a big dispersion in the size of the diffusion products that we obtained but the fact that some of them are

quite small is encouraging and is a challenge for establishing a good control of the size of the diffusion

products.

• In general the results obtained give a global perspective

about the strongly promising structures based on WO3–

Cu sandwiches as medium for preparation of PMC

memory devices.

References

[1] S. Wolf, Silicon Processing for the VLSI Era, vol. 4, Lattice Press,

Sunset Beach, CA, 2002, p. 674.

[2] M.N. Kozicki, M. Mitkova, C. Gopalan, M. Balakrishnan, ‘‘Programmable structure including an oxide electrolyte and method of

forming programmable structure’’. US Patent 7,101,728 (2006).

[3] M.N. Kozicki, M. Park, M. Mitkova, IEEE Trans. Nanotechnol. 4

(2005) 331.

[4] L. Pauling, The Nature of the Chemical Bond, Cornell University

Press, 1960.

[5] A. Simon, J. Ravez, Compt. Rend. Chim. 9 (2006) 1268.

[6] C.G. Granquist, Handbook of Inorganic Electrochromic Materials,

Elsevier, New York, 1995.

[7] B.W. Faughnan, R.S. Grandall, P.M. Heyman, RCA Rev. 36 (1975)

177.

[8] M.N. Kozicki, C. Gopalan, B. Malakrishnan, M. Mitkova, IEEE

Trans. Nanotechnol. 5 (2006) 535.

[9] M.F. Daniel, B. Desbat, J.C. Lassegues, B. Gerand, M. Figlarz, J.

Solid State Chem. 67 (1987) 235.

[10] H. Rosen, E.M. Engler, T.C. Strand, V.Y. Lee, D. Bethune, Phys.

Rev. B 36 (1987) 726.

[11] F. Perez-Robles, F.J. Garcia-Rodriguez, S. Jimenez-Sandoval, J.

Gonzalez-Hernandez, J. Raman Spectrosc. 30 (1999) 1099.

[12] D.B. Hibbert, J.R. Melrose, Phys. Rev. A 38 (1988) 1036.