High-tech from Erfurt

makes the world go round

The Erfurt plant – Innovation center for generator technology

www.siemens.com/energy

Answers for energy.

Humming with energy

A tradition of expertise

Ensuring a reliable energy mix

The Erfurt generator plant has evolved remarkably since

it was founded – an evolution in which employees consistently played an important role. Over the past nearly 70

years now, they have been making the plant one of the

world’s top research and development as well as production facilities for air-cooled generators. Erfurt has also

become a competence center for manufacturing the stator

windings that are used in generators cooled with air, water,

and hydrogen and for producing stator core laminations,

brushless exciters, and slip ring shafts. Components and

generators from Erfurt are shipped to power suppliers and

companies all over the world. The Siemens Energy global

production network also relies on high-tech from the German state of Thuringia.

Thanks to their high quality and reliability, generators from

Erfurt are making a significant contribution to ensuring

that the world’s current and future energy needs are met.

Forecasts indicate that about half of the electricity consumed in 2030 will still come from fossil fuels. Only a

balanced mix of renewables – such as wind, solar, and

hydroelectric power – and clean electricity from fossil

sources will keep the supply of electricity secure even

as consumption increases. With its expertise, creativity,

and experience, the team in Erfurt contributes notice­ably to an efficient power supply through advanced

technologies.

Milestones from nearly 70 years of an eventful history

1945:

Production hall

expanded northward

1946: Contract between Thüringen-

Included as a branch of Vereinigte Energiewerke AG (VEAG) Berlin

werk AG and the Erfurt branches of AEG

Berlin and Siemens Schuckert Berlin to

provide support and assistance for the

repair department

1948:

Nationalized as the stateowned enterprise “VEB Elektro-Reparaturwerk Erfurt”

1951:

Name changed to

“VEB Reparaturwerk Clara Zetkin“

2

1961:

Founded as the repair department of Thüringenwerk AG on the premises

of the press manufacturer Henry Pels Erfurt

1978:

1984:

Construction start of the first

directly water-cooled stator winding with

an epoxy resin-mica-glass insulation and a

performance of 220 MW

1987:

Delivery of the first newly

­constructed traction current converter

1988:

Delivery of the first modernized 200 MW generator stand

The Erfurt plant –

Facts and figures

Approximately 115,000 square meters in size*

More than 800 employees*

More than 30 trainees in eight training disciplines*

Comprehensive knowledge on-site: purchasing, sales,

research and development, engineering, manufacturing, quality management, quality assurance, and

service

Production of two- and four-pole air-cooled

generators

Production of stator bars and stator core laminations

Production of brushless exciters and slip ring shafts

* As of December 31, 2011

1991:

Plant acquired by Siemens AG;

production of four-pole generators based

on the design of the Berlin dynamo plant

1993:

2004:

Development and

production of a new four-pole

generator in only 12 months;

market launch with 40 orders

Competence center for developing and manufacturing air-cooled generators; component supply to the Siemens

Power Generation global network

Delivery of the

250th generator

1996: First in-house construction of

Delivery of the

500th generator

1998: Profit center with worldwide

20th anniversary

of Siemens in the German state

of Thuringia

two-pole generators

rights of sale

2005:

2008:

2011:

3

Generating power

with a generator

A generator is an electric machine that converts mechanical

energy into electric power. It operates on the basis of the

dynamoelectric principle, that Werner von Siemens registered for a patent with the first dynamo generator in 1867.

It states that an electric generator does not need to have

electric current supplied from the outside to start generating electric power. A self-reinforcing electrical induction

can take place due to the iron’s residual magnetism. Today,

the mechanical excitation that a generator needs to generate electricity is often provided by a turbine. It drives a

shaft, which is known as the rotor. It rotates in the stator

core, in other words inside the generator. The rotor is

equipped with an electromagnet, and the moving magnetic field of the rotor causes a charge transfer in the conductor coils of the stator. The charge transfer generates

4

electric voltage between the ends of the conductors. This

is how the mechanical energy that acts on the rotor produces electric energy – power – in the stator.

Rotor and stator – a strong team

The torque needed for the generator is transferred from the

turbine to the rotor through the coupling. To reach a frequency of 50 Hz, it must rotate 3,000 times per minute –

50 rotations per second – in the stator core. The centrifugal

forces of a rotor that weighs as much as 65 metric tons and

is up to 16 meters long are enormous. Every single rotor is

tested on a gigantic test stand and adjusted with a clockmaker’s precision. It is mechanically balanced and has to

pass electrical as well as overspeed tests.

Masterpieces made in Erfurt

Siemens is one of the world’s leading generator manufacturers. High-tech production methods and meticulous

detail work adapt every generator to customer requirements.

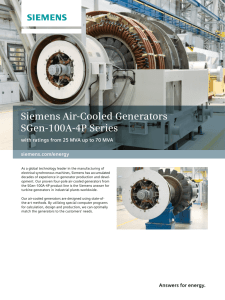

Air-cooled two- and four-pole generators are built in Erfurt

to state-of-the-art standards. The different number of poles

relates to the characteristics of the rotor and determines

the frequency of the voltage produced by a generator.

A gas or steam turbine drives the rotor. Two-pole and fourpole generators are produced in versions for the 50 Hz and

60 Hz markets. The rotor speed of a two-pole generator

must be twice as high as the rotor speed of a four-pole

generator to reach the same frequency. The four-pole

generators made in Erfurt are very compact and can

achieve ratings of up to 70 MVA. Thanks to their special

design, two-pole generators from Erfurt can achieve peak

ratings of more than 300 MVA. Both generator types have

achieved world-class efficiency of almost 99 percent and

can be used to generate power for all applications – from

power plants to industrial facilities.

More than 750 generators from Erfurt with a total capacity of almost 65,000 MVA are operating all over the world.

Those generators together can supply electricity to almost

65 million people, equivalent to the population of France.

5

Cutting-edge generator

components

Step by step to high-tech products

Erfurt is more than just a competence center for manufacturing generators. It also develops and produces the individual components of a generator: stator bars, stator core

laminations, brushless exciters, and slip ring shafts.

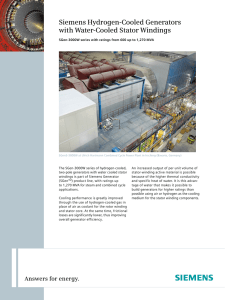

A stator winding consists of many stator bars. They are

made of high-quality electro copper. The process of manufacturing the bars requires precise knowledge of materials

6

and extensive production experience. Erfurt supplies rods

that are cooled with air, water, and hydrogen. They are installed in the generators that are produced in Erfurt, as well

as generators from other Siemens production sites, depending on the type of cooling. This includes the MICALASTIC®

GVPI (global vacuum pressure impregnation) insulation

system that was developed by Siemens. A solvent-free

epoxy resin is used in this insulation system. It ensures

outstanding electric, mechanical, and thermal properties.

The stator core laminations form the stator core, which

has the stator winding fitted to it in grooves. Each year,

gigantic punching machines and the laser cutting system

produce ten million segment laminations, which are only

0.65 millimeters thick. After the laminations are deburred

and coated, robots stack 60,000 of the laminations into

one stator core, which weighs several tons.

Brushless exciters are also developed and produced in

Erfurt. An exciter is a small auxiliary generator that produces the necessary electric power to supply DC voltage

to the rotors.

Slip ring shafts are used in larger generators – like those

produced at the Siemens Mülheim/Ruhr plant – to supply

externally generated DC to the rotor through brushes and

slip rings.

7

Erfurt electrifies the world

Crucial part of the Siemens

global production network

Generator technology from Erfurt makes an important contribution to the success of a wide variety of different projects

around the world. The Erfurt plant and its products also play

an important role in the Siemens Energy global production

network, in which selected partner companies inside and outside of Siemens work together, adhering to strict quality standards and offering maximum cost efficiency. The objective of

the production network is to take advantage of synergies and

to supply innovative, top-quality technology to customers

all over the world at fair market prices. The Erfurt generator

plant supplies components to all Siemens partner plants that

specialize in generator production: Mülheim an der Ruhr in

Germany, as well as Charlotte, North Carolina, and Fort Payne,

Alabama, both in the United States.

Quality counts all over the world

Cutting-edge technology from the Erfurt plant is used to generate

reliable energy supplies all over the world. Applications include

cogeneration plants based on fossil fuels or combined gas and

steam power plants. Siemens generators made in Thuringia are

also in great demand for projects with high sustainability, such

as solar-thermal or biomass power plants, as well as for industrial applications and in the oil and gas industry.

Siemens locations

Joint venture / strategic partner / licensee

Technology from Erfurt –

proven all over the world

Two- and four-pole generators made in Erfurt are in use

on every continent, making a vital contribution to the

efficiency of many different power plants and production facilities. The Prunéřov II steam power plant is the

largest in the Czech Republic, supplying 1,050 MW. It is

now the home of the most powerful two-pole generator

ever made in Erfurt, with a capacity of 294 MVA and

voltage of 15.75 kV. The following sites also rely on technology from Thuringia:

Andasol 2 solar-thermal power plant:

Granada, Spain

Generator type: SGen6-100A-2P

Capacity: 61 MVA

Voltage: 11 kV

8

Las Flores gas-fired power plant:

Barranquilla, Columbia

Generator type: SGen6-100A-2P

Capacity: 200 MVA

Voltage: 16.5 kV

BASF combined-cycle power plant:

Ludwigshafen, Germany

Generator type: SGen5-100A-2P

Capacity: 112 MVA

Voltage: 10.5 kV

Stora Enso paper mill:

Eilenburg, Germany

Generator type: SGen5-100A-4P

Capacity: 42 MVA

Voltage: 10.5 kV

Andasol 2 solar-thermal power plant – Granada, Spain

Las Flores gas-fired power plant – Barranquilla, Columbia

BASF combined-cycle power plant – Ludwigshafen, Germany

Stora Enso paper mill – Eilenburg, Germany

9

Always one step ahead

thanks to mutual commitment

Employees are the heart and soul

The Erfurt generator plant has had an eventful history

since it was founded in October 1945. The facility is a

technological leader today primarily because of its

employees. Their skills, talents, and dedication, as well

as their flexibility and passion for building, created a very

innovative research and development as well as production site for generators. To keep it that way, great emphasis is placed on the well-being of the employees who work

at the generator plant. Finding the right balance between

work and family plays a decisive role. This is reflected by

the generator plant’s complete “service for families”,

including a preschool and daycare center, childcare allowances, concessionary public transportation passes, and

social services.

Safety first

Occupational health and safety has always been a priority in

Erfurt. The “Sicherheit geht” safety project is setting a new

standard. The causes of accidents are jointly analyzed with

employees in manufacturing and corrected using an eightstep plan. The program includes team competitions, training

sessions, seminars, and other activities. The objective:

to make the Erfurt generator plant accident-free.

The future needs ideas

The 3i program (ideas, impulses, and initiatives) promotes

suggestions for improvement to make processes safer,

simpler, and more efficient throughout the company.

Prizes are awarded for suggestions that are successfully

implemented. The program is very popular at the Erfurt

generator plant. Many employee ideas and suggestions

have already been implemented. Plant management and

the Works Council hold special events like the annual raffle

to encourage employees toward greater achievements

through the 3i program. One example is a project that

makes it much safer and more efficient to transport stator

bars from prefabrication to the fitting of the stator winding. The transport used to be very time-consuming and

the path led through several narrow passages. It would

have been very difficult to apply the brakes to the vehicle

that carries the stator bars in an emergency. The passage

was remodeled and the room where stator bars are produced is now directly connected to the winding room. The

stator bars are now transported simply, quickly, and safely

using a crane. Plus, the remodeling reduced the time

required for the transport by half.

On-the-job fitness

Health management at the location offers employees many

opportunities for active participation in health and wellness.

These include courses on smoking cessation, mobile massages, nutritional advice, back health and relaxation courses,

and many athletic activities. Screenings to prevent cardiovascular disease and strokes are held in conjunction with

the Siemens health insurance program. Medical care provided by an on-site physician, a plant sports club, and discounts at fitness clubs all make important contributions to

employee health. Free flu vaccinations, vision screenings,

and the popular soccer and bowling tournaments round

out health-related activities at the Erfurt generator plant.

10

A broad range of training opportunities

Siemens has five locations in the German state of

Thuringia, making it one of the largest industrial

employers there, and also one of the most important

facilities for vocational training in the region. The

Erfurt plant offers many opportunities for professional and vocational training. More than 30 trainees are currently participating in programs at the

plant in the following areas:

Bachelor of engineering in electronics and

information technology

Bachelor of Arts incl. IHK industrial manager

Mechatronics technician

Electronics technician for machine and drive

technology / electronics technician for operating

technology

Cutting-machine operator

“Dual” learning ensures comprehensive

expertise

Dual training teaches theory and practice at the

same time. It is a popular training method that

offers interesting career opportunities. People

who complete a dual course of study receive

either the following degree or certification:

“Bachelor of engineering in electronics and

information technology”

Chamber of Commerce vocational certificate as

mechatronics technician, “Electronics technician

for operating technology”

This course of study was jointly developed by the

Leipzig University of Applied Sciences (HTWK) and

Siemens. Course units are held at the Siemens training

centers parallel to lectures, practical training, and

exercises at the HTWK and are tailored to activities

there.

Materials tester

Toolmaker

Warehouse logistics specialist

Industrial mechanic

11

Professionals welcome new perspectives

Sustaining the region

The Erfurt generator plant offers its employees many

opportunities for personal and professional development outside of their daily work. In-house and external education and advanced training confer new qualifications that can give careers a considerable boost.

The wide range of choices includes English courses

that are open to all, training and advanced training

for first responders and fire wardens, various educational opportunities in specific fields, and the possibility of working at another Siemens location for a time.

The Erfurt generator plant is one of the largest employers

in the city, with almost 800 employees – and that number

is rising. To strengthen the region over the long term, the

plant sources many products from the area around Erfurt,

as well as the state of Thuringia. Every generator from

Erfurt carries the Quality from Thuringia label, giving

credit where credit is due to suppliers from the region.

Another positive effect of this sourcing policy: Transport

over shorter distances is better for the environment.

“The generator plant in Erfurt is a very special location for our company.

The generators that are manufactured here are an impressive example of high-tech made in Thuringia.”

Peter Löscher, President and CEO of Siemens

12

13

Published by and copyright © 2012:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact our

Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Order No. E50001-G210-A182-X-4A00

Printed in Germany

Dispo 34802, c4bs No. 7449, 7823

fb 4462 WÜ WS 08122.0

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.