All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its

affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore

be specified in the contract.

siemens.com/energy

Published by and copyright © 2015:

Siemens AG

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399,

USA

siemens.com/energy

Field Technology Services Contact

Information: 407-736-5809

FTSinfo.Energy@siemens.com

Order No. PSPG-B10087-00-76US

Printed in USA

BU 13589T BR 0915.5

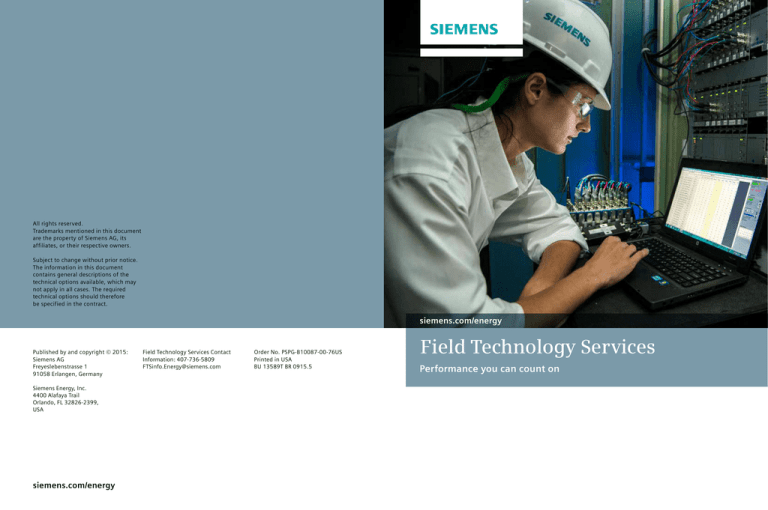

Field Technology Services

Performance you can count on

Field Technology Services (FTS) provides a variety of performance

enhancement and evaluation services for nuclear, fossil, combustion

and industrial turbine-generators.

Our People make the difference with their

extensive knowledge and 24/7 support from a

global network of engineers.

budget

Pe

o

e

y

et

f

a

S

Performance

l

ity

ua

Q

Sc

he

du

le

implementation

planning

scope

pl

Safety, it’s a mindset. You will see this in

action as we utilize industry-leading Human

Performance techniques and specially-designed

tooling.

Quality workmanship is a result of our focus

on operational excellence. We strive to provide

you peace of mind that the job will be done

right.

We understand Schedule adherence is

important to you. That is why we offer upfront

Total Maintenance Service (TMS) planning and

a rapid response network of resources, tooling

and parts.

Our Performance-minded approach provides

you scope, budget, planning and implementation support through our local District Service

Offices.

Our highly trained and experienced FTS field engineers leverage Original Equipment

Manufacturer (OEM) fleet knowledge, processes and field procedures to provide quality services

in the areas of Diagnostics, Metrology & Alignment, and Controls & Auxiliaries. Dependent upon

the scope of work, some services are performed with the unit operating and others during

maintenance outages. Benefits that may be realized from these services include:

Unit Availability Improvement

Component Life Optimization

Unit Reliability Improvement

Unit Life Optimization

Starting Reliability Improvement

Operational Flexibility Optimization

Efficiency Optimization

Power Output Optimization

Maintenance Cost Reduction

Emission Reduction

Maintenance Ease

3

Diagnostics

Vibration Surveys and Analysis

Steam Turbine Unit Condition Evaluation

Rotating Equipment Balancing

Slow Speed Balancing

In an effort to determine vibration root

cause, online surveys are conducted

under the direction of Siemens Engineering.

Vibration and sound data acquisition

locations may include rotor, frame,

structure and piping.

Performed on Nuclear and Fossil turbinegenerators, a unit walk-down is conducted at

full load operation approximately 3-6 months

prior to a scheduled outage. The objective is

to identify potential issues such that those

can be incorporated into comprehensive

outage planning. During the unit walk-down,

operating parameters are documented and

vibration and sound data acquired to provide

a snapshot of operating characteristics.

Additionally, operations and maintenance

personnel are interviewed. If advised in

advance, some unit specific issues can be

investigated during this site visit. Post outage

evaluations can also be performed to

document the results of work performed

during the outage.

Vibration levels in excess of OEM

recommended operating limits can cause

undue stress to rotating and stationary

components. These stresses can potentially

result in reduced operating life and

accelerated integrity deteriorations. Rotating

equipment vibration analysis utilizes

proprietary software, SE-MEASURE™, to

acquire transient and steady-state vibration

data to determine rotor unbalance

conditions. Extensive fleet influence

coefficients aid field balancing efficiency

which can reduce the number of balance

moves. Data collection is performed during

unit operation, whereas balance moves are

performed during a unit shutdown.

Slow speed balancing can minimize and

potentially eliminate the need for field

balancing when the unit is returned to

service. This process addresses changes in

weight distribution of the rotor which can

result from blade repair/replacement work.

Slow speed balancing is performed during an

outage when the rotor is removed from the

cylinder or on spare rotors between outages.

Balance weight consolidation is performed

during the process to maximize the number

of balance holes available for field balance

needs. Slow speed balance experience list

includes: Steam Turbine (ST) and Gas Turbine

(GT) turbine rotors, industrial rotors, Forced

Draft/Induced Draft fans (FD/ID), Boiler Feed

Pump Turbines (BFPT) and motor armatures.

Potential diagnoses may include:

Oil Instability

Steam whirl

Rotor thermal shift

Cracked shaft detection

Sequential valve operation influence

High pressure turbine inlet feature distress

Foundation degradation

Generator frame soft foot

Generator core looseness

Generator gland seal ring rub

Generator rotor thermal instability

Balance of plant (BOP) valve leakage

5

SE-MEASURE™ is available for external

software licensing. The program drives a

32 channel data acquisition system that

uses off-the-shelf hardware.

NOTE: If field balancing has been

unsuccessful in reducing elevated operating

vibration levels, slow speed balancing may

be considered to address changed rotor

weight distribution.

6

Diagnostics

Modal Analysis

Gas Turbine Fact Finding

Gas Turbine Post Outage Commissioning

Gas Turbine Tuning

Modal analysis determines the natural

frequencies and mode shapes of turbinegenerator static structures across the

relevant frequency ranges of operation.

Testing ensures that during operation the

structure is tuned away from resonant

conditions that increases structure fatigue

and chance of failure. Modal analysis can be

performed in the field or the factory.

Fact Finding is performed on V & W GT

frames during unit disassembly including

combustion chamber, minor, hot gas path

and major inspections. These inspections are

used to identify potential issues and support

root cause investigations of existing issues.

Inspection findings are documented in data

sheets from GT Engineering checklists and

photographed and associated recommendations can be used for future outage planning.

Commissioning activities are performed

following the completion of maintenance

outages or performance enhancements in an

effort to maximize the success of the unit

startup. Applicable operational and startup

service bulletins and internal procedures are

also reviewed, for proper unit startup and

optimal operational characteristics, per

specific site requirements. Toward the end of

the outage, a final inspection checklist is

performed to confirm that the unit is ready

to start.

Combustion tuning is performed on Gas

Turbines with Ultra Low NOx (ULN)/ Dry Low

NOx (DLN) premix or standard combustion

systems operating with natural gas or oil.

Unit control settings are optimized in order

to help minimize NOx and CO emissions and

combustion dynamics. During the tuning

process, the gas turbine is loaded to various load points (typically break points on

the control curves) within the unit’s normal

operating range. In special situations, tuning

is also performed at lower loads to improve

turndown or startup emissions. Combustion

tuning is typically performed when a unit

is exiting an outage, but may also be done

when an emissions or combustion dynamics issue exists. Seasonal tuning may also

be performed, typically at the onset of cold

weather and then again when warm weather

returns.

Modal analysis applications include:

Generator end windings

Generator pedestals

Generator frame

Generator lead box

Operational deflection shape (ODS)

Blade frequency testing

Turbine structural shaker test

Rotor modal analysis

Baffle plates

7

Controls and Auxiliaries

W GT Frame Compressor Hook Fit

Measurements

Hook fit measurements are recommended

during major outages on the compressor

rows 1-6 casing diaphragm grooves on some

frames. Measurements are made at select

locations in order to evaluate condition, track

each row’s performance, and assess future

operation. The “as found” measurements are

submitted to Siemens Engineering and based

upon indicated wear, specific weld and grind

repair recommendations are provided. These

repairs are performed by Siemens Turbine

Services personnel under the guidance of the

measurement engineer. Upon completion of

weld and grind repair activity, final “as left”

hook fit measurements are documented.

Checklist inspections include:

Control system settings

Inlet and Inlet Guide Vane (IGV) system

Fuel and combustion system

Exhaust system

Auxiliary skids

Upgrade verification

8

Controls and Auxiliaries

Mechanical Hydraulic Controls (Vintage

Steam Turbine)

Systems supported include:

Westinghouse 150#

Westinghouse 300#

Allis Chalmers

Westinghouse BFPT

Westinghouse extraction

Westinghouse EH (electro-hydraulic)

The mechanical hydraulic controls service

can be used to resolve control system issues

or optimize control system performance

related to component integrity, fluid contamination, debris build-up, or improper valve

sequencing. Some control system related

issues can be resolved or optimized during

operation and others may require a maintenance outage to reestablish design control

settings and system performance.

Related control system issues addressed

include:

Latching

Trip Block Analyzer

The Trip Block Analyzer is a self contained

system (independent of the turbine lube

oil and vacuum systems) that allows for

the simulation and adjustment of trip

point settings on most 300#, Analog ElectroHydraulic (AEH) and Digital Electro-Hydraulic

(DEH) control system protective trip blocks.

Performed at a maintenance outage with the

trip block removed, the low bearing oil, low

vacuum, and thrust trip set points are tested

and returned to the design settings.

Electro-Hydraulic System Analyzer (EHSA)

The EHSA is used to locate sources of EH

valve actuator internal leakage. EH actuator steam control valve assemblies can be

completely tested for leakage in place. EH

emergency trip block and servo valves can

also be tested. Performing this service at the

very beginning of a maintenance outage can

allow for lead time to replace or repair leaking components.

Generator Auxiliaries (Seal Oil, Stator

Water)

Seal oil systems

Generator performance can be adversely

affected by auxiliary system issues . Seal oil

system performance can negatively affect

hydrogen purity, hydrogen leakage, and may

induce seal rubs resulting in elevated

generator or exciter vibration levels.

Balance of plant systems

Stator water system performance can

negatively affect cooling of the generator,

corrosion buildup within cooling passages

and hydrogen leakage. Some issues related

to the seal oil and stator water systems can

be resolved or optimized during operation

and others may require a maintenance

outage to reestablish design settings and

system performance.

Flow Measurement

Excessive generator hydrogen leakage

presents a safety hazard and impacts unit

efficiency. A comprehensive procedure aids

in locating and identifying hydrogen leakage

paths on the stator frame, piping and auxiliary systems. Leakage detection walk downs

are performed on or off-line, as long as

generator hydrogen pressure is maintained.

The service can also be performed during a

generator air test by adding helium or CO2 as

a trace gas.

Non-intrusive flow measurements can be

performed in support of troubleshooting

various control system and auxiliary system

issues related to:

NOTE: Siemens Engineering can review on

a unit specific basis the utilization of CO2

(in lieu of SF6) as a trace gas for on-line leak

detection.

Lube oil systems

Generator hydrogen coolers

Generator stator cooling water systems

Hydrogen Leakage Detection

Valve operation

Protective trip functions

Lube oil system

Control devices (Gov, Aux Gov, Load Limit)

Speed / load instability

9

10

Metrology and Alignment

3D Optical Coordinate Measuring System

Laser Scanner (Long and Short Range)

Laser Tracker

Applications include:

This form of stationary component

alignment is used to help optimally align

the internal components. This service

simplifies and optimizes the internal

alignment through the use of photogrammetry principles. Unlike a tight wire or laser,

there are no wires to trip on or beams to

reset, which can result in improved outage

time savings.

Laser scanning allows the operator to scan

small and large components and structures;

then convert those scanned images (point

clouds) to working CAD models.

Laser tracker portable coordinate measurement machines (PCMM) are used to provide

the highest accuracy of any other PCMM

method (outside of a laboratory environment). Laser trackers are used to perform a

wide range of metrology functions.

Horizontal joint / surface mapping

Applications include:

GT cylinder alignment

GT stationary component alignment

ST stationary component alignment

Generator air gap baffle alignment

Applications include:

Site surveys

ST stationary component alignment

Adaptation studies

GT blade ring mapping

Generator core mapping and aligning

Pre-outage layout / lay down area surveys

Generator gland seal bracket

perpendicularity

Piping surveys

Generator air gap baffles

3-Dimensional scanning

ST catenary curve measurement

Cylinder surface mapping

Legacy parts mapping

Whole train pedestal alignment

(thermal growth analysis)

Interference checks

Turbine cylinder mapping

Inspections

Component replacement

Adaptation studies

11

12