Operating Speed Rotor Balancing

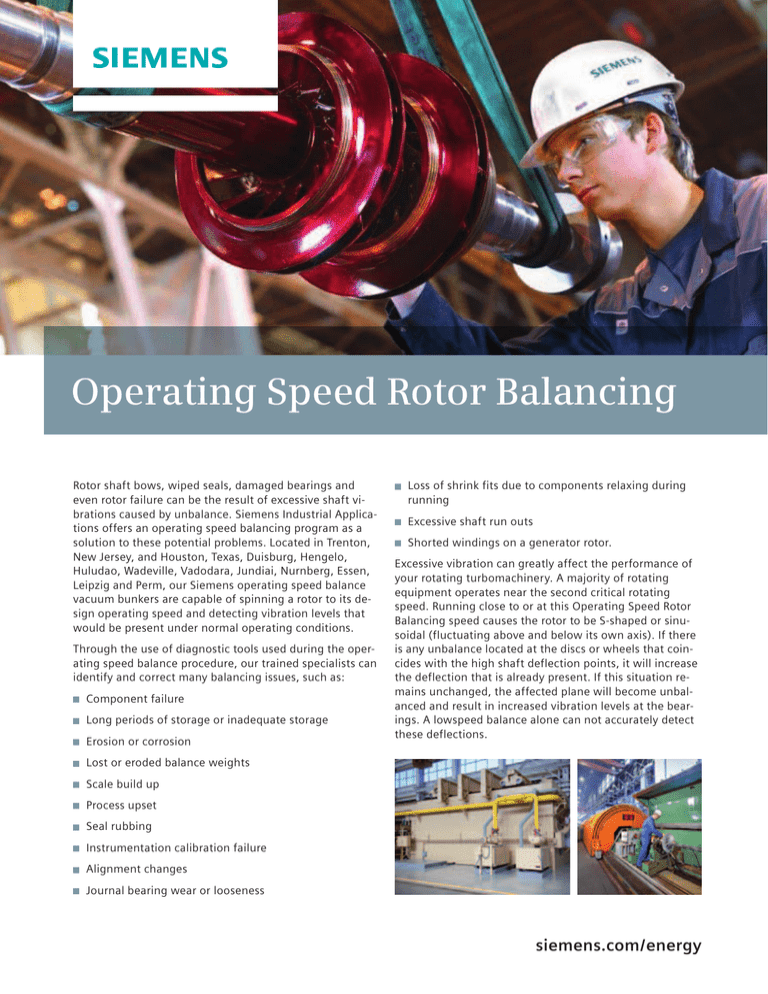

Rotor shaft bows, wiped seals, damaged bearings and

even rotor failure can be the result of excessive shaft vibrations caused by unbalance. Siemens Industrial Applications offers an operating speed balancing program as a

solution to these potential problems. Located in Trenton,

New Jersey, and Houston, Texas, Duisburg, Hengelo,

Huludao, Wadeville, Vadodara, Jundiai, Nurnberg, Essen,

Leipzig and Perm, our Siemens operating speed balance

vacuum bunkers are capable of spinning a rotor to its design operating speed and detecting vibration levels that

would be present under normal operating conditions.

Through the use of diagnostic tools used during the operating speed balance procedure, our trained specialists can

identify and correct many balancing issues, such as:

Component failure

Long periods of storage or inadequate storage

Erosion or corrosion

Loss of shrink fits due to components relaxing during

running

Excessive shaft run outs

Shorted windings on a generator rotor.

Excessive vibration can greatly affect the performance of

your rotating turbomachinery. A majority of rotating

equipment operates near the second critical rotating

speed. Running close to or at this Operating Speed Rotor

Balancing speed causes the rotor to be S-shaped or sinusoidal (fluctuating above and below its own axis). If there

is any unbalance located at the discs or wheels that coincides with the high shaft deflection points, it will increase

the deflection that is already present. If this situation remains unchanged, the affected plane will become unbalanced and result in increased vibration levels at the bearings. A lowspeed balance alone can not accurately detect

these deflections.

Lost or eroded balance weights

Scale build up

Process upset

Seal rubbing

Instrumentation calibration failure

Alignment changes

Journal bearing wear or looseness

siemens.com / energy

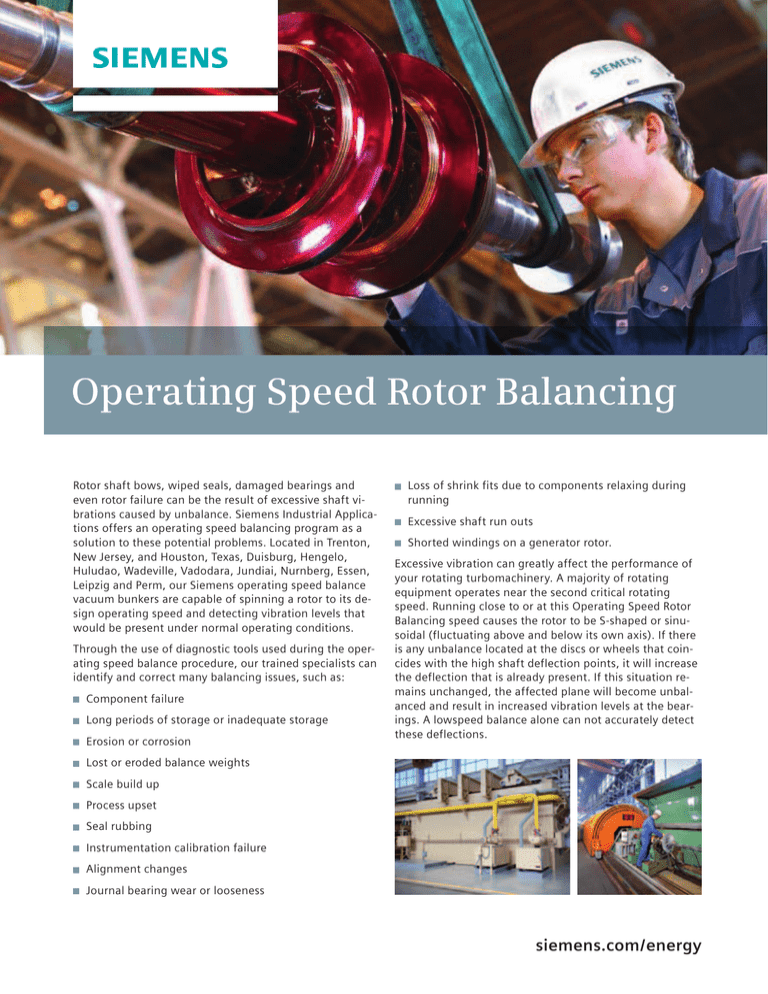

The Duisburg operating speed

balance facility specifications

are as follows:

The Hamilton, New Jersey

operating speed balance facility

specifications are as follows:

The Hengelo operating speed

balance facility specifications are

as follows:

Maximum speed:

30,000 RPM (DH6/1)

15,000 RPM (DH6/2)

Maximum speed:

15,000 RPM (DH 6 pedestals)

30,000 RPM (DH 4 pedestals)

Maximum speed:

27,000 RPM (DH4)

20,000 RPM (DH6)

Maximum rotor length:

5,950 mm (DH6/1)

5,000 mm (DH6/2)

Maximum rotor length:

305 in. (7.74 meters)

Maximum rotor length:

5,300 mm

Maximum rotor diameter:

102 in. (2.59 meters)

Maximum rotor diameter:

1,000 mm (DH4)

2,000 mm (DH6)

Maximum rotor diameter:

1,500 mm (DH6/1)

1,650 mm (DH6/2)

Maximum weight:

9,000 kg

Maximum bearing journal diameter:

225 mm

Maximum weight:

17,600 lbs. / 7983 kg (DH 6 pedestals)

2760 lbs. / 1251 kg (DH 4 pedestals)

Maximum bearing journal diameter:

9 in. (DH 6 pedestals)

5 in. (DH 4 pedestals)

However, balancing at operating speed explores the

sensitivity of each plane. This can reduce the identified

shaft deflections to minimal amplitudes where possible.

Operating speed balancing also is beneficial on large,

slower speed rotors. If the translating mode is severe at

the first critical speed, the rotor can appear C-shaped as it

runs through this speed. This can be detected during the

operating speed balancing procedure. Corrections can be

made to minimize the amplitudes, often resulting in a

smoother operating rotor. A rotor also may become

unbalanced as a result of a repair. Before reinstalling a

rotor that has been subjected to several repairs, an

operating speed balance should always be considered.

Field balancing in the equipment casing does not always

allow for access to the specific planes required for

optimum balance at operating speed. Very often,

balancing on site is more costly than in a controlled

operating speed balance chamber.

Our capabilities include an optional ADRE™ rotor dynamic

analysis for rotors that may require additional attention

due to rerates, life extension upgrades or other

modifications.

Regardless of the equipment type (steam turbine,

compressor, gas turbine, boiler feed pump or generator),

an operating speed balance can contribute to:

Maximum weight:

800 kg (DH4)

8.000kg (DH6)

Reduced maintenance costs

Increased rotor life

Improved reliability.

Operating speed balancing helps to reduce costs through

the minimization of vibrations that may cause damage to

your rotating equipment, thus helping to prevent unscheduled maintenance.

Siemens AG

Power Generation

Freyeslebenstrasse 1

91058 Erlangen, Germany

Industrial Applications

Wolfgang-Reuter-Platz

47053 Duisburg, Germany

Siemens Nederland N.V.

E S SO CP PRM

Industrieplein 1

7553 LL Hengelo, Netherlands

Siemens Demag

Delaval Turbomachinery, Inc.

840 Nottingham Way

Hamilton, NJ 08638, USA

A smoother running rotor

siemens.com/powergeneration

Increased bearing and seal life

Order No. Order No. A96001-U90-A89-V1-4A00 |

Printed in USA | bdk140038 | 4495 COLMID DA 0214

© 03.2014, Siemens AG

Longer periods between outages

For more information

please contact your local

For more

information please contact

Siemens

representative.

your local Siemens representative.

All rights reserved. Trademarks mentioned in this document are the

property of Siemens AG, its affiliates, or their respective owners.

Subject to change without prior notice. The information in this

document contains general descriptions of the technical options

available, which may not apply in all cases. The required technical

options should therefore be specified in the contract.

siemens.com / energy