E-

advertisement

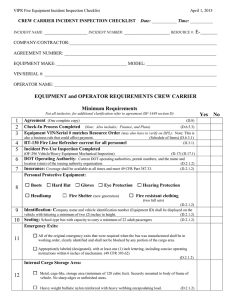

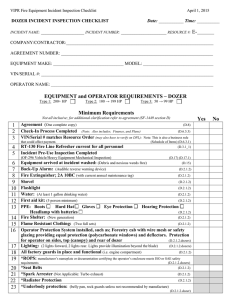

VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 ENGINE INCIDENT INSPECTION CHECKLIST INCIDENT NAME: Date: ___________ Time: __________ ___________________ INCIDENT NUMBER: ____________________ RESOURCE #: E- COMPANY/CONTRACTOR:_________________________________________________________________ AGREEMENT NUMBER: ___________________________________________________________________ EQUIPMENT MAKE: _______________________________ MODEL: _______________________________ VIN/SERIAL #: ____________________________________________________________________________ OPERATOR NAME: ______________________________________________________________________________________ EQUIPMENT and PERSONNEL REQUIREMENTS – WILDLAND FIRE ENGINE (See agreement for specific Engine Typing Standards) Type 3 Type 4 Type 5 Type 6 Minimum Requirements Not all inclusive; for additional clarification refer to agreement (SF-1449 section D) 1 2 3 4 5 6 Yes Agreement (One complete copy) (D.8) Check-In Process Completed (Note: Also includes; Finance, and Plans) (D.6.5.3) Equipment VIN/Serial # matches Resource Order (may also have to verify on DPL): Note: This is also a business rule that could affect payment. RT-130 Fire Line Refresher current for all personnel Incident Pre-Use Inspection Completed (Schedule of Items) (D.6.3.1) (D.3.1) (OF-296 Vehicle/Heavy Equipment Mechanical Inspection) (D.17) (D.17.1) Engine: arrived at incident washed (Debris and noxious free) Engine Staffing / Personnel: Minimum of 3 crew members (unless otherwise ordered and (D.15) documented on resource order). All crew members have valid and current qualification cards and government pictured I.D. (D.3.1.1) 7 Engine Boss (Name):_____________________________________________ FFT1 / FFT2 (Name):____________________________________________ 8 9 10 11 12 13 14 15 16 17 FFT1 / FFT2 (Name):____________________________________________ Additional Personnel; see remarks Company Name and Equipment I.D.: Affixed to both sides of truck cab (D.3.1.1) (D.2.2.3) Type 6 Engine, all-wheel drive (type 3,4,5 engines all-wheel drive optional) (D.2.1.2.1) *Reflective Triangles, bi-directional, set of 3 (Exhibit M) *Fire Extinguisher, 1 rated at 2A 10BC or better (D.2.1.2) 2 Wheel chocks (Exhibit M) *Seat Belts for all passengers (D.2.1.2) Back-Up Alarm: Audible reverse warning device, and 2 back up lights (D.2.1.2) Tires: All season or mud and snow tires. 4x4’s must have mud and snow tires on all wheels (Exhibit M) Spare Tire: Full size spare tire, spare is securely mounted to vehicle. Has adequate tire changing equipment (D.2.2.1.1) 1 Gallon Container for drinking water (Exhibit M) No VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 *Item may be waived if inspection successfully performed on the OF-296. Minimum Requirements – continued Yes 18 1 – First Aid Kit (5 person) Radios: Minimum of 2. 19 Programmable and one programming cable 20 One must be Handheld. Also has two battery clamshells, PPE – Per Crew Member: Boots Hard Hat Hearing Protection Headlamp with batteries (D.2.3) (Exhibit M) Gloves Eye Protection Fire Shelter: New generation (D.2.1.2) 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 Flame Resistant Clothing (Nomex): Two Full Sets, Per Crew Member (D.2.1.2) 3 – Line Gear (Day Pack) (D.2.1.2) All inventory permanently engraved with vendor/company identification and have complete inventory listing including extra items. (D.2.1.2) 1 – Live hose reel of 100’ hose non-collapsible ¾” inside diameter (D.2.1.2.1) 1 ½” Hose (see table for min. quantity) (D.2.1.2.1) 1” Hose (see table for min. quantity) (D.2.1.2.1) ¾” Hose (see table for min. quantity) (D.2.1.2.1) 2 Nozzles, combination Fog/Straight Stream, 1 ½ NH female 2 Nozzles, combination Fog/Straight Stream, 1 NPSH female 1 – Nozzle, Class A Foam, 1 ½” NH Female, minimum 20 GPM at 100 psi 2 Nozzles, adjustable ¾ inch (garden hose) 20’ Suction hose with strainer or screened foot valve 3 – Shovels, size “0” 3 – Pulaski’s 1 – Forestry, Fire Hose Clamp 4 – Spanner wrenches, combination, 2 ea 1” & 1 ½” 1 – Double Male 1 ½” NH 1– Double Female 1 ½” NH 1 – Double Male 1” NPSH 1 – Double Female 1” NPSH 2 – Gated Wyes, 1 ½” NH 2 – Gated Wyes 1” NPSH 1 – Gated Wye ¾” (garden hose) 4 – Reducers, 1 ½” NH Female to 1” NPSH Male 1 – Reducer 1” NPSH to ¾” Garden Hose 2 – Adapters 1 ½” NH Female to 1 ½” NPSH Male 2 – Adapters 1 ½” NPSH Female to 1 ½” NH Male 1 - Mop Up Wand, ¾ inch receptor, with ¾ inch nozzle tip: 5 – Inline Ball Valves ¾” 2 – Backpack pumps 10 – Fusee’s (fire starter) 3 – Mill Bastard Files Auxiliary pump (if equipped) w/spark arrester: Min. 12 Hours fuel. (Exhibit M) Pump starts and pumps min 250 psi (T3) 100 psi (T4,5,6) (Exhibit M) Pump: Discharge Pressure Gauge (D.2.1.2) Foam Proportioner System (D.2.1.2.1) No VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 Minimum Requirements – continued Yes 57 Amount of foam carried on engine in gallons: (min. 5 gal. 58 1 ea 1 ½” discharge valve full flow, rapid shut off 59 Water Tank: Firmly attached to frame, or structurally sound flatbed 60 61 62 63 64 65 66 67 68 69 70 71 72 No (Exhibit M) (Exhibit M) (D.2.1.2) Tank meets baffling requirements One longitudinal baffle and one transverse baffle every 52” or free floating baffle system with data sheet that validates baffling is sufficient to meet manufacturers recommendation. (D.2.1.2) Pump Accessories (If Pump Powered by Auxiliary Engine)(Exhibit M) Wrench, Adjustable 10” Wrench, Spark Plug (Unless adjustable wrench is suitable) 1 Pliers (Slip Joint) 2 Qts. Crankcase Oil 1 Screwdriver (Standard Blade) 1 Screwdriver (Phillips) 1 Spare Starter Rope (if required) 1 Grease Gun with Grease Spark Plugs (Sufficient to replace all plugs on auxiliary pump) 1 Chainsaw with fuel (3.0 cubic in. min w/18” bar, chaps, hearing protection gas/oil, and accessories (OSHA Approved Fuel Containers) (D.2.1.2.1) (Optional/Attributes) Compressed Air Foam System (CAFS) Actual Compressor Rating (cubic feet per minute) _______________ Equipment meets agreement specifications Equipment does not meet agreement specifications Inspector: Date: (Print and sign) Contractor: Date: (Print and sign) Contractor given the opportunity to correct noted deficiencies (See Remarks) Contactor successfully corrected noted deficiencies Inspector: Date: REMARKS:_________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 CHAINSAW and CHAINSAW KIT INSPECTION CHECKLIST (Wildland Engines Only) MANUFACTURER: ____________________________________ MODEL NUMBER: ____________________________________ SERIAL NUMBER: ____________________________________ CHAINSAW Yes No Any Visible Parts Broken All visible nuts and bolts tight Oil in chain reservoir Proper Exhaust System and spark arrester Started and checked the engine: Idles evenly, runs smoothly, satisfactory power Guide Bar: Minimum of 18 inches, not bent, or damaged Pull / Starter Rope: Functions properly Chain Brake: Functions properly CHAINSAW KIT 1 Chainsaw Kit: Bag or box to store complement 1 Wrench: Combination; bar and sparkplug wrench 1 Spark Plug: Spare spark plug that works (fits) in saw 1 pint Engine Oil (2 stroke/cycle mix) 1 pair Chaps: Wrap around leg safety chaps – OSHA approved 1 Chain: Extra chain to fit saw-bar combo 1 Chain File: Appropriate size for chain on saw 1 Felling Axe 1 Felling Wedge 1 Fuel container: OSHA approved fuel container to hold chainsaw fuel and guide bar oil. Properly secured on vehicle. 2 pair Ear Plugs Note: Contractor is required to have both the chainsaw and OSHA approved container(s) full of proper fuel mixture and oil at time of inspection. VIPR Fire Equipment Incident Inspection Checklist Wildland Fire Engine Requirements April 1, 2015