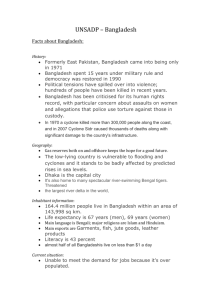

SECTOR-SPECIFIC INVESTMENT STRATEGY AND ACTION PLAN Bangladesh

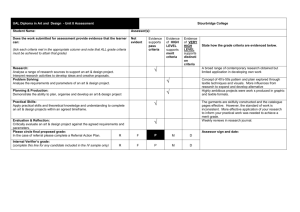

advertisement