FOREST PRODUCTS LABORATOR Y 1 of MADISON, WISCONSI N

advertisement

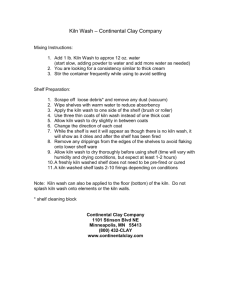

7P.c U. S. Department u'1 ti tKOOR1l - of Agriculture, Forest Service FOREST PRODUCTS LABORATOR Y In cooperation with the University of Wisconsi n MADISON, WISCONSI N 1 BRAIN WORK IN KILN OPERATIO N By C. V. SWEET Specialist in Kiln Drying Approved Copy File d 3 — 6-2Q BRAIN WORK IN K=T,N OPERATION There is no phase of kiln drying that stands out mdre clearly as essential to success or directly responsible for failure than the intelligence and attention that i s iLren to the operation of the kiln . Those who have watche d with particular interest the progress of the practice o f kiln drying lumber, especially under the stress of war conditions, have seen that the greatest difference between success and failure has been in the operation more than in th e kilns themselves, whether it has been with airplane stock , green oak vehicle stock, ship timbers, or wooden legs . Poo r kilns and good operation have often produced as good results , as good kilns and poor operation . But in the long run, th e big problems of artificially seasoning lumber will be solved only by a happy combination of the two factors . It takes a good kiln and good operation to obtain really good results . It has frequently been' brought to the attentio n of the Forest Products Laboratory of the United States For wit aervice .'at Madison, Wisconsin, that with a given typ e of drf n ; .,iandling similar kinds of stock according t o the same rtc amended schedule, one concern has dried its ma` terial with Pract i1 . .' 011 -. ther ed a loss of 40 to 50 er• Rien .1- ,' -. r, ; . L6 2 59 Al & . I I If .t' art of kiln drying lumber has come throug h its recent trials trimmed of some non-essential ideas an d b-enef ited by new conceptions, the sum total Of our informa tion concerning it has been greatly increased . On the othe r hand, if there is still a vestige of the old notion tha t "this kind of kiln will dry lumber in half the time with les s checking than that kind of kiln", a big load of inertia mus t still be moved . Emphasis on the operation of the dry kiln mean o the injection of the human, intelligent, interested elemen t into kiln drying which is too frequently absent in the methods of many concerns . The kind of kiln operation that i s possible at the hands of an ex-lumber piler whc has becom e too old to work efficiently anywhere .else, or of a ma i -wh e has grown up with the company and. in his 'later yeara deserve s an easy job ' , or of a fireman at the plant who has a few e-X - tra hours to fill in .- that kind of kiln` -ope?:atiion d:ees not .. enter into this consideration . The kiln drying of lumber, unless it, be th, ,dfyin g of air-seasoned softwoods, is an art involving speciaal ; 4ml . edge, skill and good workmanship . Without detracting• f-rya . the credit of the practical lumberman, it' iaay'be $sAcl tr t the greatest advances in kiln drying have cone in the las t few years . This advance, reflected in new methods of seas o ing, is the outgrowth of accumulated scientific knowledge o f L6 259 _2 . 1 r 1 + 4 I the physical and methmical proper't -es of Woa@ . . T Pi sizmess _fui dry kiln operatcr today has to think of, characteristic s of wood in terms which are unfamiliar and in many instance s dis astef ul to the colder -cyoe of practical lumberman . As a matter of fact this ccnception of the role of cpe •ation ' in kiln drying is opposed to a more or less genera l commercial tendency to make kiln drying an automatic proces s from which the el em'ent of personal j ud .gme+'t is remeved a s much as possible tiereby attributing to dry kiln's tai- , selves whether of, ope particular design or aniethex verve ,mye .•- ti tic, secret capacity- to dry lumber perfectly with the mi 34inum I watching by a competent operator.. Or often lumber i : . siiOse d .p to be dried successfully by some so-called "p_atefrt .dd process . ."_, L Sad experience show that it is impossible to' . i t 1! :r mbea?y % •~ : L dry kiln like a potato in an oven and take it out all done to r a queen's taste . It is not uncommon to read in advertisements i n trade journals that this or that kind of dry kiln or proces s dries lumber without checking, honeycombing, or casehardening . Such a statement is the danger signal, A simple state- ment that temperature and humidity conditions are flexibl e and under the immediate control of the operator would inspir e more confidence . The most satisfactory types of kilns yet develope d are those with featUres of automatic temperature and humidit y L6 2 59 y •' 1 LR i control which make the'operator a complete master of hi s kilns in that any conditions which he regards beneficial t o the lumber may be maintained hour after hour, or day after day, until he considers it desirable t8 change such condit 3 oils The kiln operation itself can never become automatic although the control of drying conditions may well b e that, and efforts to bring about automatic control of suc h phases are most decidedly on the right track, A brief an d general discussion of some of the features of kiln operatio n which are of utmost importance may throw additional ligh t on the importance'of the skilled operator as apart from th e kiln . RelationBetweenMethod ofPiling and Uniformity of Dryin g The first opportunity for an exhibition of skil l in kiln operation is in the adoption of the proper syste m of piling the lumber in the kiln, It may be safely said that comparatively few kilns are operated with any though t as to whether the piling suits the kiln or not . Because o f the very definite relation that exists between method o f piling and the circulation of air in the kiln, this subjec t is to be as strongly emphasized as careful temperature control and regulation of the humidity . +. 1 First and foremost, lumber is piled in the dr y kiln so as to dry uniformly and as quickly as possible . There is no more effective way of bottling up the circulation in a kiln and slowing up the drying rate than by piling in lumber across the path of the moving air . The pil- , ing should be such as to offer the least obstruction to' a free and positive circulation of air within the kiln . Methods of piling which lead to complete utilization of al l space and in greatest economy of handling the lumber throug h the kiln are important features to be sure, but entirel y secondary and subordinate to the method that conforms t o the circulation system of the kiln . The method of pilin g must be such as will throw the "stickers" parallel to th e predominant air currents and never perpendicular to an d obstructing it . End piling in a progressive type of kiln, whic h depends for its circulation on the passage of air from th e hot, dry end to the gre cool end places great obstructio n to free and uniform passage of air and is obviously wrong . Cross piling in a type of kiln in which the circulation i s vertical-lateral as in many types of ventilated and condenser kilns, is just as serious in that the normal air current s are obstructed . This point is illustrated clearly by a case o f practical experience . Some 4/4 green maple was loaded into J I' ti 'I ar-tae. N i I PLED CROSSWISE rx w /METRELATAW JIM/4/AR /NEAR Ff/RN/TVRC PLANT IN NEW VAWC STATC rr . . : 1A ' 1 1 ' 11 ' t I• : 1 1 T .1 .1 1, . r - Sketches Of representative commercial installa tions of a type of progressive kiln in which the circula1x~ili:n l tion of air is from end to end . Note that i the "stickers" oppose and obstruct the intended clroulatiO m Both end and cross piling are often used in this type of kiln, but cross piling is distinctly, superior to end piling, from the standpoint of circixlation . This il Iustrates the lack of attention to a very important item . of kiln drying . r 1 _ I I f I x 115 l1 'Q ' •~ , t- II ,°1 I1 A ~: ~ .1 ' .1 I R II 1 • _ ~1 'I• ' I II • Oa u , 111 Ih u I •■ NI . I II "I ,rl ' .5 . ~ ;. .1 0 1 IL 1 ■ I Ir 1 Sketches of representative commercial installa : tions of a type cf compartment kiln in which the circulaof air is up in the center and down and out at the sides , Cra g s Riling places greatest obstruction to this syste m of circulation, At one plant the lumber is piled crosswies_e and at the other is piled endwise . There is only on e of 'ure two methods which can be right . Another illustration of failure to give attention to circulation in th e kiln . V 1 1- k J• n II L I ' I' C . . 1• 1 r . :' I II 1 - I ~~ . • - ,1 a dry kiln having vertical-lateral circulation -. Part of th e stock was end piled and part of it cross piled . Temperatur e readings were taken daily at different parts of both piles . After the run was well started the difference between th e hottest and o-oolest portion of the end-piled stock was 1 00 ,. while the difference in the cross-piled stock was 58 0 . had a marked effect on the uniformity of drying . Thi s The end, .._ piled stock dried from 30 per cent to a maximum moisture con tent of 6 per cent in 10 days while it took 13 days for th e Pto-ck piled crosswise to dry from 30 per cent down to 12 pe r cent . T1'is shows that there is a right and wrong way lUMber to be piled in every type of l ~ .l y,• for , Zo ' Ao Pe, : inter` ed in even, rapid drying, this point is of great practica l significance . Know.le_dge . .ofMtuaiConditions in Kil n Prevents Losses in Stoc k After the lumber is properly piled in the kiln and the heat turned on, the competency of the operator agai n comes into play . It is essential that the operator knew accurately the drying conditions in every part of the 41n:. The determination of the conditions to which the lumber is , actually subjected is a eritical -phase of kiln . o}pe al orl.; Wi th t , ~kn edsA available to the olp•eTa-to:r 4wOg-t • n+e '~~ An actual record of temperature conditions during the kiln drying of heavy, green oak at an auto bod y plant in Ohio, Note the great difference in temperatur e ie eadings obtained from the recording instrument in on e part of the kiln and from a standard thermometer in anothe r p art, The operator of the kiln did not know under wha t condition the lumber was actually being dried, Result wa s loss of 70 per cent, If one part of the kiln it warmer be ruined in any dry kiln . than another, that fact should be known by the operator an d If one end of the- kiln rune a t allowances mane therefore . lower humidity than the other, that fact should be known an d reckoned with . When measurements of temperature and humid- ity are taken they are too often taken by sticking an instrument through a hole in the big door and assuming that all parts of the . kiln read the same as near the door . The temperatiare and humidity taken at any one part o_ in other parts Ito ~ .off the kiln una r ,r less the circulation ia' more perfect than in mo-Of t The kiln . operator- should know tie . b.elaswi ' lot his' ■ kiln when lumber is . being dried in it as an engineer Itnow e - the correlate-d workings of his gas. engine . actual. condition ,of the lumber in the -Mans ought to be as easily- and broadly - recogni is ate . I t ► . kiln op 1 ax, , • ' tors as, the fact that the amount of fire 34er &, oiler i s the- meaisure of the-amount of heat produced, and vat there i s a most flagrant disregard of this fundamental 1)0.0 i ; an many kiln -drying - operatooz -s . Ordinary p-rarctice invOr e,s 'in toper atioip based on the number of clays , that Use.. lxlmber ha s J inY 9 ti ~ I I ~ I I i fl_ I r 1_ 1= ~t71 Y the kiln . The variation in the original condition of th e lumber is so great, the difference in the drying conditio ire in the kiln are so pronounced that this method is un•certaifl . This practice When applied to the commercial drying of heav y green oak has resulted in exorbitant losses . The whole dry kilning operation is linked up wit h the amount of moisture in wood and obviously the operatio n of the kiln must be on that basis . It is a well established fact that there is a point in the drying process around which the entire dryingi It is the point which marks th e dividing 19een green and partially seasoned wood . Up to frd 0101, i' drying condition must be moderate and con- stant and after which the drying may take place more rapidly . Technically this point in the drying is called the fi - io.ew saturation point and practically it c9rresponds roughl y to moisture content of 25 per cent based on the bone dry weight of the wood . There is no way of knowing when the lumber in the ltirto *1rAqW[ ~ I how much.'4agpistgOto tie is left in the p-ort a and no - . ~. stgnifi } ce- in this •d . connect knowin g The one criterion of regulation is the moistur e content of the lumber and its fitness to withstand mor e severe drying conditions and never the number of days tha t the lumber has been in the kiln . It Pays to Watch Behavior of Lumbe r ]hiring Kiln Dryin g Brain work in connection with kiln operation show s up more than anywhere else in watching the effect of the drying on the condition of the stock itself . To go into a worm moist kiln, especially on a hot summer day, and look for bur face checks and other defects is not the most agreeable thin g in the world but it is worth while when a kiln load of expensive lumber is at stake, In the old-time kiln operation t o spend any time in the dry kiln was never thought of, in fact , in most kilns there is no way to get into the kiln except th e main door be opened, thereby letting out the heat and exposing the lumber . A furniture man when consulted regarding his trouble s in kiln drying green oak was urged to cut a small door in th e large kiln ' door so that the operator could get in easily t o watch the condition of the stock from day to day . His contention in opposition was that a small door was a nuisance ; tha t it was continuously getting out of repair and that it so r wea, ,erred the big door ti thre-e~years , it pieces in two o r 1 ~t him around $1000 . ' The gook in his dry-ni. He c_oult. have bui *-:fir w kiln dooms ien the old one was to o weak, for, l00,,,bt t t ..e lumber in the ktl* , , $.ccording to thi s business man's reasoning was not worth the a !batter ' =miT or . It i s . recoil that his $1000 worth of tom was a tota l loss, but -that his ition . doris still in good , What 'gre some- of the thixigs th i,etf be seen ,b y tally all of watching the stbiek? And the answer is : Pra the things that result in io'ssed off" lumber during kiln drying . Symptoms`'can _'l e seen and they can Ie -fought just as a physi cian fights the syrmpto of disease . If the temperature i n the kiln is too high and the lumber too green ,the stock arheck s and ca2ehardens■ . Maybe the class of work is such that a few n , surface checks do mot- count . the cheeks will ca•os-e Msbe •the opera r,rin:g the x aii.nd of the Ea r tha t r closes these surfae•e c-heeks•, Uau ly a compressio?i - .t .1-i1 th e surface and- a tension bra the inside w1 ch'3s c m-%t,c c1 • -ol aharden• ,'r f`; ing . And the force 'which is -powerful enough to surface ' checks is alO-o po rerfu_i eri 9 ose gh to cause a - rupturing of the fIb,erS or ho eyoothbing, wh- ., happens r' r+ ` ,IPi . J: ` : wlv ~'r' f i -pied to centiY~- . When' gieck s" 'under th e s compre gsi'®b, t ia. b ,v to detne-lro , ' : 4 71 ; Stages in the development of honey-combing from a surface check which has developed early in the dryin g and allowed to close up without proper steaming treatmen t .ri the dry kiln`. The application of steam at the proper s . me prevents honey-combing . The sketches are to be regarded as imaginar y cross-sections cut through the same check during successive stages in the drying . . at the surface - the danger sign is Dint . T%l operttor mus t be there to see the sign . W71's e Steaming is Both a Pound o f PreventionandOunce of Cur e The remedy to be applied to 1umbe T. Which showis de fects and danger signs during drying is a comparatively re cent one, not cowpl,stely understood but of broad s apt)O.icat:imn, ' It consists 'of the application of saturated , and great value . steam for a period of time and at a temperature wh4oh ,Lm . the judgment of the operator suits the _case at hand . The ap04:4gov.J. .i 7 , tion of this curativ principle =IPA, be understood before ap- plied because, like most effeOtive triatnemts, it can work (let riment as well as benifit . This principle maybe used at the beginning off' th e run to heat the . lumber through to the center befoTe . 4An g from the outside begins ; also in the case of partially se gIO& ed stock to relieve the tendencies toward casehardening which have been set up during air drying . As such it ip often *QUIP preliminary steaming . A steaniing or sweating of this .a-tu,ilo is usually for a period of about 6 hours per every Awh i n thickness and at a temperature of only about 25° higher tha n the temperature at which the run is to start . 'lL 1, . of .steami.n.A_ fur , .ik piras . ,".,. • L6 259 of 7M I .11~ The practic e days at the: i et&rt. .i:g a 1~ ' big waste of drying time ; does not accomplish more than ca n be accomplished in a few hours and actually damages the stock . To kill mold that develops on the lumber in the kil n when the drying conditions are mild, an application of saturated stream for an hour at a temperature of 165-180 degree s is most effective . The most valuable application of the remedy is t o lumber which has become casehardened to the extent that th e wood fibers tend to give way to the stresses set up or whe n the surface checks show indications of "pinching in . " It i s necessary to steam at a temperature of 16o-180 degrees for a period of one to several hours, depending on the severity o f the case as judged by the operator . This saturated steamin g at high temperature moistens the outside of the wood and reduces the stresses and the hard bony surfaces that have bee n set up in the wood fibers . With these stresses removed, th e danger+ of honeycombing is gone and the drying may continu e according to schedule until perhaps the stresses become serious again ; necessitating another application of steam . When the lumber is ready to be removed from the kiln and it is severely• Gasehar1lenedr with the teideric to: Warp after machinin g upanr : in, the milop-s and itEsawing, prap .er application of saturate d steam re r'ves the casehardening s ei- 4p a►d' greatly improves th e ual t .. ..12- Operation of Kiln Most ImportantElemen t in Kiln Dryin g Operation means knowing the exact temperature any , humidity. at ' which the lumber is actually drying all- Over . the e kiln, , it means knowing how the wood is reacting to the con - ditions as told by symptoms such as checking, casehardenin g 4. and moisture distribution . I"; ,When these things are appreciated and . knowri• .•accurately, the art of kiln drying lumber will have taken a step . forward `and more general commercial success will' be realized. I. Y