Document 10427592

advertisement

BABY INCUBATOR NOISE:

CAUSES

Carl A.

AND

SOME

REDUCTION

METHODS

Wales

Submitted in Partial Fulfillment

of the Requirements for the Degree of

Bachelor of Science

at the

Massachusetts Institute of Technology

Signature redacted

Signature of Author..

Department of Mechanical Engineering,

Aoril 15. 1975

Signature redacted

Certified by.........

.......

L

o ..

Signature redacted

..........

Accepted by......

Chairman, Departmental Comlittee on Graduate Students

Archives

(MAR

1 5 1976

4A P

BABY INCUBATOR NOISE:

CAUSES

AND

SOME

REDUCTION

METHODS

by

Carl A.

Wales

Submitted to the Department of Mechanical Engineering on

April 15, 1975 in partial fulfillment of the requirements

for the Degree of Bachelor of Science.

ABSTRACT

An investigation into the internal acoustic noise of

an Isolette Model C-86 infant (baby) incubator is discussed.

The practical lower limit of internal noise is derived.

The internal noise is discussed with regard to its

characteristics,

its sources and its paths.

Methods to

reduce internal noise are set forth and recommendations made

to reduce internal noise to the practical lower limit.

The

major question of whether the incubator noise is harmful or

helpful is not discussed by this author.

D. Graham Holmes

Title:

Asst, Prof., Dept. of Mechanical Engineering

-

2

-

Thesis Advisor:

ACKNOWLEDGEMENTS

The author would like to acknowledge the following:

.

Air Shields, Inc., including Mr. Ridley and

Mr. Weaver for providing the incubator on

which this study was performed.

.

Dr. Graham Holmes, for his supervision.

.

The personnel of the MIT Acoustics and Vibration

Laboratory for their assistance and the use of

the lab's equipment.

.

Prof. Leehey for his advice and guidance.

.

Dr. Cochrane and the personnel of the nursery of

the Boston Hospital for Women.

.

Miss Brenda Raby, R.N.,

for assistance at the

hospital and for answering many medicallyoriented questions.

Robert Gipe and George Foote for their assistance

and advice.

-

3

-

.

TABLE OF CONTENTS

Page

ABSTRACT...............................................

2

ACKNOWLEDGEMENTS.......................................

3

LIST OF FIGURES........................................

5

LIST OF TABLES.........................................

I.

INTRODUCTION.....................................

6

II.

EQUIPMENT:

DETERMINATION OF THE PRACTICAL

LOWER LIMIT ON NOISE.............................

9

III.

EXPERIMENTAL PROCEDURE...........................

12

IV.

RESULTS AND CONCLUSIONS:

DETERMINATION OF

LOWER PRACTICAL LIMIT TO THE INTERNAL NOISE....... 13

V.

EQUIPMENT:

VI.

EXPERIMENTAL PROCEDURE:

VII.

RESULTS AND CONCLUSIONS OF INTERNAL NOISE

ANALYSIS.........................................

21

NOISE ANALYSIS.......................

17

INTERNAL NOISE............ 19

VIII.

EQUIPMENT:

INTERNAL NOISE REDUCTION.............

29

IX.

EXPERIMENTAL PROCEDURE:

NOISE REDUCTION

METHODS..........................................

30

X.

RESULTS OF NOISE REDUCTION WORK..................

31

XI.

OVERALL CONCLUSIONS AND RECOMMENDATIONS............ 34

REFERENCES....................................... 37

APPENDIX 1....................................... 38

-

4

-

BIBLIOGRAPHY..................................... 41

LIST OF FIGURES

Page

1(a)

Equipment and Interconnections for

Measurements in Hospital Nursery............

10

l(b)

Laboratory Analysis of Recorded Noise.......

10

2

Equipment and Interconnections for

Generating the Sound field in the

Transmission Loss Determination.............

3

Hospital Nursery Room Levels..................

14

4

Sound Isolation.............................

15

5

Equipment and Interconnections for

Laboratory Work...............................

18

6

Incubator as Delivered........................

22

6(a)

Noise with Incubator Off....................

23

7

Internal Noise Level Contours on the

Mattress......................................

8

Accelerations of the Motor................... 27

9

0 to 1000 Hz Spectrum with Microphone

Suspended in Mid-Air in the Baby Compartment.......................................

10

35

0 to 1000 Hz Spectrum with the Microphone

36

Al

With Water in Tank............................

39

A2

Without Water in Tank.........................

40

- 5

-

Positioned at the Baby's Head position......

INTRODUCTION

The noise problem in the baby incubator was discussed

by Falk and Woods [1].

Their data (measured at a hospital)

gives the level inside an incubator which was not operating

as 61 dB and 35 dB(A).

They list the levels with the in-

cubator operating as 74.5

1.8 dB and 57.7

3.3 dB(A).

Isolette, a major manufacturer of incubators, was interested

in determining if incubators are, indeed, this noisy,

what the characteristics of the noise are, the sources of

the noise, the paths for noise transmission, and possible

solutions to reduce the internal noise.

In addressing himself to this problem, this author

divided the project into three parts:

1.

Determine the practical lower noise limit.

2.

Measure and analyze the internal noise.

3.

Decide on methods of internal noise reduction.

The determination of the practical lower noise limit gave

a reference upon which to base any efforts in practical

understanding and reducing the noise.

In this regard, the

background level was measured in the Special Care Nursery

at a Boston Hospital.

Using this level and the trans-

mission loss from outside to inside the incubator, which

- 6

-

was measured in the lab, the lowest obtainable level in-

side the incubator could be determined.

Noise reduction

efforts to reduce self noise below this level would be impractical.

With regard to the internal noise level and

characteristics, the internal amplitude levels were

measured with different configurations and conditions inside the incubator.

Narrow-band spectrum analysis was con-

ducted to determine sources of noise as well as propagation paths.

Noise reduction methods consisted of alterations to

the motor mounting and the fan, and interfering with the

propagation paths.

Theoretical methods were considered but

not tried, for the changes necessary to the incubator were

too majcr.

For this project, an Isolette Model C-86 Infant Incubator (See Pictorial 1)

hood

equipped with the intensive care

(and not equipped with iris access ports) was used.

Both the Infant Servo Control and the standard power pack

were used.

The incubator was mounted on the standard cart

- 7

-

which is supplied with the incubator.

ISOLETTE®

INFANT INCUBATOR

MODEL C-86

4

OPERATING

&

loll

MAINTENANCE INSTRUCTIONS

O ISLETTE

AR

A NARCO MEDICAL COMPANY

-

8PICTORIAL 1

II.

EQUIPMENT:

DETERMINATION OF THE PRACTICAL LOWER

LIMIT

ON

NOISE

In the Special Care Nursery of the Boston Hospital

for Women data was taken in real time using a sound level

Approximately twenty minutes of noise was tape

meter.

recorded also for further data reduction in the laboratory.

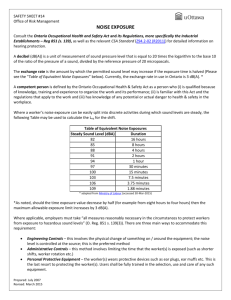

Figure l(a)

shows the specific equipments and their inter-

connections used in the work at the hospital.

Analysis in the lab of the noise which was tape recorded was done with a narrow band spectrum analyzer and

spectrum averager.

The specifics of the set-up in the lab

are shown in Figure l(b).

Transmission loss was determined

with the equipment shown in Figure 2.

A piston phone with an output of 124 decibels

(re 2 x 10-5 N/M2)

calibration.

(dB)

at 250 Hz was used in all cases for

Corrections for changes in barometric pres-

sure were ignored for being well below the accuracy

( l dB)

for this project.

The reference of 2 x 10-5 N/M

- 9

-

is used for all decibel measurements in this project.

FIGURE 1-A

EQUIPMENT ANT INTERCONNECTIONS FOR MEASUREMENTS IN HOSPITAL NURSERY

.

B&K422

1PISTONPHONE

NURSERY

tB & K 2203

UNLEEMTR

B & K 4145

B & K 2607

NECRA MODEL SJ

B&K 2619

C HER L EA E EMEASURING AMP

Kr

FEDERAL

SCIENTIFIC UA-15A

SPECTRUM ANALYZER

FEDERAL SCIENTIFIC 1015

SPECTRUM AVERAGER

03

HEWLETT-PACKARD

7015

OSCILLOSCOPE

X-Y PLOTTER

LABORATORY ANALYSIS- OF RECORDED NOISE

FIGURE 1-B

vw

w

EQUIPMENT AND INTERCONNECTIONS FOR GENERATING THE SOUND FIELD IN THE TRANSMISSION LOSS DETERMINATION

B & K 1402

RANDOM NOISE GENERATOR

bwMCINTOS' 240

-

ATLAS 60W

HORN SPAKER

POWER AMP

EQUIPMENT AND INTERCONNECTIONS FOR MEASURING THE SOUND INSIDE THE INCUBATOR

B & K 4220

PISTON PHONE

ISOLETTE

MODEL C-86

B & K 4133

MICROPHONE

B & K 2619

PREAMPLIFIER

FEDERAL SCIENTIFIC UA-15A

SPECTRUM ANALYZER

B & K 2607

MEASURING AMP

FEDERAL SCIENTIFIC 1015

SPECTRUM AVERAGER

HEWLETT-PACKARD 7015

X-Y PLOTTER

OSCILLOSCOPE

FIGURE 2

III.

EXPERIMENTAL PROCEDURE

At the Boston Hospital for Women, twenty minutes of

noise was recorded in various rooms in the Special Care

A calibration tone was recorded on the tape at the

Nursery.

beginning and the end of the noise.

Measurements were then

taken using the sound level meter which was calibrated before

the measurements were taken and checked for calibration afterwards.

Readings were taken at various locations in each of

the rooms in the nursery, in one octave bandwidths, linear

full range and A-weighted full range.

(All measurements

were taken to the nearest whole dB.)

For the determination of the transmission loss,

an

experiment was run in the lab (twice to insure valid data).

A noise field was generated in the room using a random noise

generator.

With the field present, but without the incubator,

measurements were taken to check for any significant normal

modes of the room.

The incubator was then placed in the

field and measurements were taken inside the incubator.

In

addition a plot was made of the frequency spectrum both inside and outside the incubator.

-

12

-

the incubator was not running.)

(Note:

for these tests,

IV.

RESULTS AND CONCLUSIONS: DETERMINATION OF LOWER

PRACTICAL

LIMIT

TO

THE

INTERNAL

NOISE

The results of the noise study of the hospital nurSpectrum analysis of the re-

sery are shown in Figure 3.

corded noise confirmed the data taken from the level measurements.

The noise in the hospital for purposes of further

determination efforts was 63 dB(A).

The sound field in the room for the two transmission

loss experiments was 93 dB and 102 dB.

Measured inside the

incubator at the position of the babies head the level was

measured at 76 and 87 dB.

This gives a transmission loss

(TL) of approximately 15 dB.

The spectra of inside and out-

side the incubator as shown in Figure 4 concurs with this

approximate value.

This TL differs from what be theoretical-

ly determined for the plexiglass because of the various air

leaks in the hood.

(Determining the TL using 1 octave band

levels did not differ significantly from using the broadband level as above).

With the field in the hospital of 63 dB(A) and the

TL of the incubator this places the practical lower noise

level inside the incubator at 48 dB(A).

This figure is con-

-

13

-

servative because the hood on the incubator used did not have

1OX

tO TO THE CENTIMETER

KEUWrFL & SESSER CO.

46 1512

t .~

IT;

ti

7

-

~44I'

0

.

......

0)

It

-

Ku

L

L

-- -

I- -

--

*1>1 pj

-_

-J..

-- .. .. .

.

-I-7

.7

..1

-L-

II#

-----t-- -!

-

-

-

-7-.

------7

a

--1t

--

-

-

h-f

7

-

70

0

77

-7

....

...760

I....

-.

...

tt~

.

-..

50

i

1:

II

. .

71

.

. ..

20

10

..

....

...

..

....

-.-

f-

7

- L-

31.5 63

125 250

500

1k

2k

4k

- -7

t

~1

L

-

30

.

40

r

8k

16k

.......-.

HERTZ

A-weighted

linear

FREG. RANGE

0 to 5000 HZ.

NO. OF SPECTRA AVERAGED

256

.102 DB

.

_

. .

--

7k------------

12w.

................

- ~~-

.

7

. .

center of baby compartmentV

SouND ISOLATION

7-7- : .' 7: '

-1

inside, closed 86 B9L

inside,open

MIKE LOCATION

READING

NOTES:

_ _

a5-i~

m

-1-:

7

77i

74

---

wI

-*

77

-4

-1

.FCJR

.........

+i .

!7 -7-

--

T

w

7

.

._

........

.

_

.

iris ports, the presence of which would decrease the TL

Also, the hospital nursery was in a quiet period when the

measurements were taken (based on conversation with the

nurses on duty).

In addition the Chief of Pediatrics at

that hospital uses monitoring equipment biased by personal

- 16

-

preference towards quieter models.

V.

EQUIPMENT:

A.

A Strobotac (General Radio Model 1531) was used for

NOISE ANALYSIS

determining motor rotation rate.

It was calibrated

with its internal calibration which uses the 60 Hz

power line voltage as a standard.

Laboratory noise work was conducted using the equipment

and interconnections shown in Figure 5.

The wind

screen was used only for the noise contour studies and

was not necessary for other work.

The level recorder

was used for determining long term (one-half to one day

continuous running) variation in noise level.

was done using the piston phone

-

17

-

B.

Calibration

(described earlier).

w

w

w

w

w

w

EQUIPMENT AND INTERCONNECTIONS FOR LABORATORY WORK

PISTONPHONE

B & K 4220

B& K

WINDSCREEN

B & K 2619

PREAMdPLIFIER

B & K 4145 & 4133

MICROPHONES

B & K 2607

MaSURING AMP

ISOLETTE

MODEL C-86

X-Y PLOTTER

EVLRECORDER

Ho

-

FEDERAL SCIENTIFIC UA-15A

SPECTRUM ANALYZER

FIGURE 5

FEDERAL SCIENTIFIC 1015

SPECTRUM AVERAGER

w

w

VI.

EXPERIMENTAL PROCEDURE:

INTERNAL NOISE

The first step in studying the internal noise was

to determine the rotation rate and blade passage rate of the

fan and its motor.

This was done using a strobotac

calibrated against line frequency.

rotation rate checked.

The fan was marked and

Then the fan was removed from the

motor to check the unloaded rotation rate of the motor.

The fan was equipped with twenty blades which multiplied by

the rotation rate gives the blade passage rate.

The second step was to determine the airflow pattern

inside the incubator.

This was done by releasing some

smoke into the plenum chamber underneath the base plate of

the incubator, letting the smoke flow with the circulating

air.

Having taken care of the background aspects, the

basic set-up for noise studies inside the incubator was

established.

The narrowest frequency range which still con-

tained the significant data was determined by continually

narrowing the range of the analyzer until the full spectral

window was filled with data.

Also the number of spectra

to be averaged was determined by trial and error until the

minimum number was found which did not reflect meaningless

-

19

-

fluctuations.

The standard condition for the incubator was without

water and without a baby.

Measurements were taken in a

quiet lab to remove as many external influences as possible.

Using a wind screen the noise level contour was taken inside the incubator to determine the variations which related

to position of the microphone inside the baby compartment.

Modifications were made to the incubator after running

initial tests.

a simulated baby

These modifications included running with

(a baloon of water with 35 ppt salt by

weight), running without a fan on the motor

(but with the

motor running), selection of wet or dry air for the baby

compartment, use of the different power packs, and the

location

of the make-up air tube in the inlet hole to the

fan volute, additional modifications

(and results)

are

listed in the Appendix.

Vibration spectra were taken using an accelerometer

(not calibrated because only relative measurements were

needed) mounted on the motor and on the base plate of the

baby chamber.

For all acoustic measurements the system was

-

20

-

calibrated frequently using the pistonphone.

VII.

RESULTS AND CONCLUSIONS OF INTERNAL NOISE ANALYSIS

The results of studying the spectra and levels collected are:

1.

As seen in Figure 6, the frequencies of all

significant noise are below 1000 Hz.

This low

frequency content allowed most efforts to be

devoted to study of the limited range 0 to

1000 Hz, considerably reducing the amount of

data that needed to be collected and analyzed.

2.

Figure 7 shows the significance of microphone

location.

Because of the normal mode excitation

around 185 Hz, the difference in noise level

between a mode and an antimode.

varies 7 dB(A)

3.

The location of the make-up air tube within the

supply hole to the fan volute can vary the noise

level up to 4 dB(A).

Removal and reinsertion of the power pack may

affect levels up to 4 dB(A).

This is a significant

problem not only in making laboratory data collection more time consuming by the requirement of

taking the average of multiple readings, but also

in making it difficult to predict levels in an

incubator in use and being operated by hospital

-

21

-

4.

R

,S

10 X 10 TO THE CENTIMETKrR

0 X 25 CM.

KOIJVPEL & ESSER CO.

46 1512

vInUSA

I

..... ...

w

INCUBATOR AS DELIVERED

FREQ. RANGE

1..

......

0 TO

.pp

NO. OF SPECTRA AVERAGED

~~~.

....... ....

_

MIKE LOCATION

HZ.

512

_

_

_

_

_

mid-compartment

_

7:READINGDBA

..

.....

............ ....

i~7

I

TI]

...

..

......

..

...NOTES :

.=7-K

II! ,77ll

_

_

_

_

_

_

_

i:IiT

7.7

...

..

...

71

_

T

I

:I

10 X 10 TO THE

lox

A

26 Cm.

Ktt)FKL.

T

CENTIME

ER

a X9*KR CO.

46 1512

AvgCl o...A.

1

7 E

.. . . .

21....

-T

V

;7

a.

'I'

:.. . . . .

.j I

1-

I

-K;

NOISE WITH INCUBATOR OFF

.. j

0

FREQ. RANGE

TO

-t

I

MIKE LOCATION

mid-compartment

I''

LREADING (DB(A))

NOTES:

HZ"' 200*

.... . . . . . . . . .

Incubator

ita

p

*

lIlt

It,

*'V

-I

4-

43

7-

Cl,,,A

bIti. l

L.

4-

J2

nz

...

......

~iiI,

.4~ .1

L

'I

-

II

100

NO. OF SPECTRA AVERAGED

4

4

V

KI.

TT 1.

e

L

2

V

1

p

;

'i

I

L

7

pp

I

1

PO

- .

I.

.2

C)

c:)

WEOXx

oc.TO THE

2

KgUFFEL,

5

10

15

11

CENTIMCTER

& COSER

46

A

151Z

k #).,.o.

Co,

20

25

30

35

40

45

55

s

60

{1

3

-I

T.

.

......

..

-;

'F1-

-

-

10

15

F

:

-I

; a

tj~

-

H

A

7- -.-.

20

r

.

F 'F

-

25

30

43

I

F

.

:T:

.

-.

35

55

54

53

52

51

50

49

50

INTERNAL NOISE LEVEL CONTOURS ON THE MATTRESS

NUMBERS ON GRAPH ARE DB(A)

50

51

52

53

54

NUMBERS ON THE AXIS ARE CENTIMETERS FROM THE SUPPLY

DUCT ENT) AND FROM THE REAR.

54

0

H

personnel.

5.

Even after relocating electrical components on

the circuit board in the infant servo control

(ISC) power pack to insure isolated motor

mounting, there is a difference between the

standard power pack and the ISC power pack with

the ISC being up to 5 dB(A) noisier.

6.

The presence of the simulated baby had no effect.

Consequently this author feels that all the work

done in the project is applicable to in-use

situations.

7.

The selection of wet or dry (or some combination)

This points away from air-

air had no effect.

born sound paths through the plenum chambers.

Consequently, the sources of the noise were determined

to be:

The spectra and level results are:

1.

All significant noise was below 1000 Hz as seen

in Figure 6.

The location where the microphone was positioned

had an effect up to 7 dB(A)

-

25

-

2.

as seen in Figure 7.

3.

The location of the make-up tube has up to

4 dB(A) affect.

4.

Removal and reinsertion of the power pack has up

to 4 dB(A) affect.

5.

There was a difference between the power packs

with the infant servo control power pack being

up to 5 dB(A) noisier.

6.

The presence of the simulated baby had no effect.

7.

Selection of wet or dry (or some combination)

had no affect.

The sources of the noise were determined to be:

.

Improper fan volute design which includes a

non-concentric air intake into the volute.

.

Improper fan design.

.

The vibration of the motor

(which is shown in

Figure 8).

The paths for sound propagation between source and

baby compartment are primarily structure born as various

alterations and tests could not prove the existence of

airborn path.

In conclusion, the noise level inside the incubator

-

26

-

is high and is caused by various oversights in design.

(A

K*E.

10X 10 TO THECENTIMETZR

KF0FFKL

46 1512

WSSERC CO.

.......

......

.7

'1

I!2.

7I77-

1

I

...

ij

jACCELERATIONS

1

Frequency range

132

0to 500 Hertz

SPECTRA AVERAGED

..... ...

******.*...h

.1K

til

7F-7''.J

OF THE MOTOR

T

IT-1

design established before noise was considered a

-

28

-

significant parameter).

VIII.

EQUIPMENT:

INTERNAL NOISE REDUCTION

The laboratory equipment for work in noise reduction methods was the same as used (and described) above

for noise analysis.

For practical reasons a sound level meter

(described

previously) was used at the factory to measure levels in-

-

29

-

side the incubators.

IX.

EXPERIMENTAL PROCEDURE:

NOISE REDUCTION METHODS

The procedure for determining noise reduction methods

consisted of installing a possible method and running the

same tests as were run for initial noise analysis.

Re-

sults were compared and additional modifications made and

retested.

To eliminate the differences induced by uncon-

trollable factors such as removal and insertion of the power

pack, the tests were run up to ten times with seemingly

identical set-ups.

The results were then averaged.

After the shock mount

(for the motor)

testing and

testing of the fan alterations the effectiveness of these

methods was tested at the factory using five incubators

which were chosen at random from the production line.

The

internal noise was measured using the sound level meter.

Levels were recorded before modification and after each

modification.

Power packs were rotated through each in-

cubator to show individual characteristics of each incubator

and each power pack, as well as to provide better analysis

-

30

-

of each modification.

X.

RESULTS OF NOISE REDUCTION WORK

Shock mounts for the motor and minor fan modifications

were tried with success.

Two other methods were tried

without success, and some untried theoretical methods were

examined.

The motor vibration contributed large amounts of

noise to the internal noise in the baby compartment.

Through the use of Uniroyal type 301A Shock Mounts

(the

required parameters of the Shock Mounts were determined

through the use of the Barry Mounts Catalogue

(Ref. 2),

the contribution from the motor was lowered to well below

the practical lower noise limit.

What the precise level

was depended on which power pack was used, but both power

packs had levels below 40 dB(A) when operated without the

fans.

Alterations were made to the fan itself in an effort

to reduce the noise it generated.

The motor end of the fan

had stiffening ribs which were working as radial fan blades

and causing a lower pressure stall area around the shaft.

Relief of this pressure either by removal of the ribs or by

drilling holes through the end of the fan reduced the noise

from the fan to make the overall level inside the baby

-

31

-

compartment to below the practical lower limit.

These two reduction methods were tested at the

factory on other incubators with the results listed in

Table 1.

Note, however, that up to 3 dB(A) of the figures

in the table come from measuring the levels at the factory

at the baby's head as opposed to in mid-air where most

laboratory measurements were made.

Removal of the heater proved that the heater reduced

the noise rather than contributed any.

Reducing the airflow reduced the noise significantly

which the author concluded was an added indication that the

fan is stalling in normal operation.

fan seems almost impervious.

Selection of a new

Reference 3 concludes that

backward facing fan blades are the best type for quietest

operation.

Additional theoretical methods of noise reduction

include the use of non-parallel ends to the baby compartment

which should reduce any multiple reflections of sound off

-

32

-

of the ends of the compartment.

TABLE 1

Power Pack A(ISC)

Power Pack B(Standard)

Fan

w/o

w/o

with

w

w/o

w/o

w

w

Shocks

w/o

with

w/o

w

w/o

w

w/o

w

45.33

40.57

56.8

3.37

5.0

Each X,a

based on

1.48

10 measurements

-

33

-

a,

50.64

1.03

51.17 33.25 59.8 46.82

1.34

0.84 0.40

XI.

OVERALL CONCLUSIONS AND RECOMMENDATIONS

The results of the factory trip proved two

important things:

1.

Results are variable from incubator to incubator,

and even on the same incubator from one moment

to the next.

2.

There is the possibility that the incubator in

the laboratory studies was in fact unique and

therefore the noise reduction achieved on it

will not achieve the same level of results as

on other incubators-even those made by the same

factory.

The noise contours indicate notable contributions to

the noise level measured where the microphone is located.

Spectrum analysis and the noise contour plot indicated a

normal mode associated with this problem.

and 10).

(See Figures 9

Possibly alterations to the ducting at the supply

and exhaust ports could change the noise contour pattern,

by reducing the excitation at the normal mode frequency of

approximate 185 Hz.

Further efforts should be devoted to improving the

design of the fan used, matching the fan volute to the fan,

-

34

-

and better designed ports for the circulation system.

0O X

0 TO TIM CM.

3-59.14

.F

I

I

I

F

FIUR

-ari]h ab

0

10O~zapetru

(cmprto fiue1.Fr

F

9

O t

wih mcroponesusendd i

mi

.

oprmn

I

C

.

Il#,

ox 0toyoTHr cm.

xt.uF rLL. & EIS!--LR

359-14

CO.

vii

7

77

-T--

T

:T

.41

......

...

I

....

I

......

I

i

1

I

to 1000:HZ spectrum wtthe microhone positioned at the

-baby s head position.

L

I

I

REFERENCES

1.

S.A. Falk, M.D.,

and N.F.

Woods, R.N., M.N.,

"Hospital

Noise Levels and Potential Hazards".

2.

Catalogue from Barry Mounts.

3.

J.B. Graham,

"How to Estimate Fan Noise", Sound and

-

37

-

Vibration, May 1972.

APPENDIX

1

ADDITIONAL MODIFICATIONS TESTED TO DETERMINE

THE SOURCES OF INTERNAL NOISE

A.

Levels taken with and without the heater coil in place

revealed the presence of the heater reduces the noise

by a slight amount (less than 2 dB(A).)

B.

The presence of water in the wet air chamber reduced

the noise a slight amount in upper frequencies, but did

not affect the major noise content.

(See Figures

Al and A2).

C.

Operation with the filter taken off the rear of the incubator increased the level considerably.

This was not

investigated further as normal operation will never be

conducted without a filter on the incubator.

D.

Isolation of the hood by removing the hinges did not

alter the levels inside the incubator.

Inserting baffles in the ducting in the plenum chamber

did not change the level leading to the conclusion that

the noise was not airborne.

-

38

-

E.

IN

wJ

ID

vJ4i

"x

e

FREQ. RANGE

0 TO

500

NO. OF SPECTRA AVERAGED

center

-.-..

.~

HZ.

32

a

~

-

DB(A)

-----

A4

-

- Irk--4

-

WITH WATER IN TANK

not recorded

MIKE LOCATION

READING

NOTES:

-----

i

7~~

-----_ _...

-

Tw

39 -

FIGURE Al

- t-7-

t

-.

---- -- --...... -..

_7,_

FIGUR

t

T1~

-7

q

-

t

-

f

-----------

-- -- - --

__

10080

----

--

------

Al

- -

7

..

lK

x7

n

FREQ. RANGE

6

to

500

32

center

NO. OF SPECTRA AVERAGED

MIKE LOCATION

not recorded

7

-

-

-

1:

q

71

-

HZ

- -- -

-

-----

without water

READING

7-

w

S--

NOTES:

--

-

-

4-

-

77

-

--

FIGURE

A

40-

-- *

---

w

-t

7

~

- --------.--

*

-

-7

-ce.te

-

-------------

-- -

-7

-- - -

-----------

-- --I----

BIBLIOGRAPHY

ACOUSTIC MEASUREMENT,

Bruel & Kjaer

MECHANICAL VIBRATIONS, Bruel

FUNDAMENTALS OF ACOUSTICS,

& Kjaer

Kinsler & Frey

NOISE REDUCTION, Beranek

NOISE AND VIBRATION CONTROL, Beranek

HANDBOOK OF NOISE MEASUREMENT,

- 41

-

BRUEL & KJAER CATALOGUE

General Radio