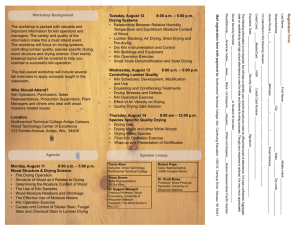

Drying Hardwood Lumber

advertisement