Dry Kiln Operator's Manual United States

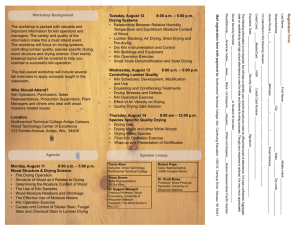

advertisement