Asset Reliability Services Smart Turnarounds and Outages ™

advertisement

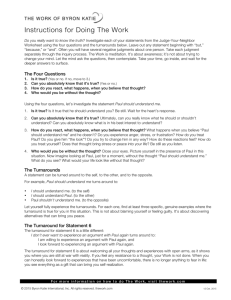

Asset Reliability Services ™ Smart Turnarounds and Outages TURNAROUNDS: A SMART APPROACH You plan for turnarounds. Now plan for a better return. enables you to determine the scope Turnarounds play a critical role in the work smarter, more targeted, plant’s life cycle. It’s a time to repair, and cost-effectively. renew, replace, and revitalize your around costs are high, it’s important When it comes to turnarounds, no one is more qualified to service your plant than Emerson. to get the job done right. Our asset reliability services experts Poor planning can result in use predictive diagnostics to assess unidentified issues with critical the condition of your electrical, assets or overlooked processes, while mechanical, process equipment, insufficient workmanship can cause instruments, and valves. With delayed startup and even worse – predictive maintenance technologies, safety and environmental mishaps. we can know in advance which assets Poorly executed turnarounds can will need work, what work should be cause extended downtime, resulting done, and in what order we should in lost production, possible fines, and do it for maximum efficiency. decreased profitability – ultimately With Emerson’s proven turnaround impacting the longevity of your plant process, you’ll be assured that the and the life of your equipment. planned maintenance is executed key assets to maximize your plant’s true potential. And, because turn- When your available time for maintenance is short, how can you be sure to get the most out of your turnaround? 2| of the turnaround and allows you to smoothly and efficiently, in the shortest amount of time. For your next turnaround, make it a Smart Turnaround with Emerson. Predictive diagnostics from key We’ll be there every step of the production assets are the drivers for way – in whatever role you need us. a successful and efficient turnaround. Together, we’ll plan for a successful Information obtained about the turnaround and build long-term life health and condition of your assets cycle efficiency for your plant. |3 A PROVEN PROCESS FOR RELIABLE RESULTS Plant turnarounds constitute the Asset Review single largest identifiable maintenance An effective turnaround strategy expense – and controlling turnaround begins with effective planning. Once the scope of work has been costs and duration represents a During this step, Emerson will clearly defined and a schedule has definite challenge. The most critical conduct a plant walk-through and been developed, we’ll create a plan objectives are: equipment assessment to identify for each element of the execution To complete the turnaround in the project objectives. We will and allocate test equipment, parts, the shortest possible time and develop a comprehensive inventory materials, and labor resources. at the lowest possible cost of your assets, including nameplate Turnaround Services Operation To achieve the best quality information, service cycles, and of workmanship age and criticality of system ■ ■ ■ To execute the turnaround components. This information provides the foundation for Resource Planning & Allocation When it’s time to execute your turnaround, we’ll be there with the right people, processes, and PREDICT & OPTIMIZE PARTNERSHIP CONFIDENCE NTEGRATE with the highest possible safety record asset planning. technology to ensure that your turnaround is done right, on schedule, Asset Planning within budget, and to your satisfaction. has developed a proven process that Emerson will conduct pre-outage Turnaround Review ensures your turnaround is done online diagnostic testing to assess right, on schedule, and within budget. the condition of your assets, The steps of our turnaround process determining which assets will include: need work and what work is To meet these objectives, Emerson required. We’ll establish the details of the project, prioritize needs, and examine the impact on the overall process. After your turnaround is completed and your process is successfully online, we’ll review the turnaround process with you and provide a final comprehensive report detailing the tasks performed, equipment serviced, and personnel involved. The report includes testing results and a summary of recommendations for future maintenance. PREDICT & OPTIMIZE 4| |5 Infrared inspection findings are carefully documented in a comprehensive report that includes high-resolution color digitized photographs and thermograms, and recommendations for correction or repair prior to the next scheduled maintenance shutdown. PREDICT & OPTIMIZE THE POWER OF PREDIC TIVE DIAGNOSTICS PARTNERSHIP CONFIDENCE NTEGRATE Production assets today are more sophisticated than ever before. AMS® Suite, a family of best-in-class With AMS Suite, you can: predictive maintenance applications, ■ helps you detect equipment problems diagnostics from field devices It is impossible to fully optimize before they occur. Before, during, to improve plant availability your assets without an advanced or after a turnaround, AMS Suite and reduce maintenance costs predictive maintenance program that can help you save time and money enables an efficient maintenance by delivering valuable diagnostic strategy and continuous information already contained in performance improvement. your smart devices. At any time Emerson’s Smart Turnaround program in your plant life cycle, online utilizes advanced technologies to diagnostics can be utilized for diagnose, monitor, and protect control valves and field instruments. PREDICT & OPTIMIZE your most critical assets. 6| ■ Fully implement predictive Identify, troubleshoot, and resolve device issues remotely and efficiently ■ Streamline calibration procedures and permanently store the calibration records FlowScanner diagnostic reports detail valve assets that need repair or replacement. This results in a 20% - 40% reduction in valve pulls, depending on the condition of the valves. Emerson’s FlowScannerTM 6000 information on all assets included for the areas that require the is a valve diagnostic system that in the work scope. Once the most attention. conducts inline testing of valves, turnaround begins, QC3 enables With predictive diagnostics, you will eliminating the need to remove project status updates, including know in advance which assets need and reinstall, to save you time percent of completion, man-hours attention so you can optimize your and money. Valves are tested to worked, and asset discrepancies. maintenance plan for maximum manufacturing specifications, Emerson’s advanced partial efficiency during your turnaround. ensuring maximum performance discharge testing technology plays and efficiency. a critical role in determining the Efficient data collection is health of your electrical assets and made possible with Emerson’s ensuring maximum uptime. It also QC3 Outage Tracking Tool. provides asset managers with Before your turnaround, Emerson critical information needed to technicians electronically capture target maintenance resources |7 EMERSON’S SERVICE E XPERTS PROVIDE THE SUPPORT YOU NEED When it’s turnaround time, take advantage of Emerson’s range of industry-leading services and expertise. your site. Equipped with lathes, assets to ensure their efficient, mills, welders, workbenches, and reliable and safe operation. Our parts, we’re prepared to diagnose, expert technicians will clean, inspect, calibrate, remove, repair, and replace and test your entire electrical Predictive Diagnostics your instruments and valves onsite – distribution system and identify areas Assess the condition of your aging saving time and money. Our for improvement. Our life-extension assets prior to your next turnaround “workbench on wheels” provides services provide repair, retrofit, and/or with Emerson’s predictive diagnostic 24/7 availability throughout the replacement for obsolete and defective services and technologies. Emerson’s duration of your turnaround. equipment in order to maximize the advanced diagnostics for valves Encore® Program for Valves value of your existing equipment while improving overall system performance. include valve leak testing and leak Repair or replace obsolete and hard to PREDICT & OPTIMIZE PARTNERSHIP CONFIDENCE NTEGRATE detection using AMS Suite and FlowScanner. find valves in a matter of hours with Emerson’s Encore program. Encore For your electrical assets, we’ll conduct partial discharge testing, oil analysis, infrared inspections, and ultrasonic testing. Conducting diagnostic testing in advance of your next turnaround will assist in prioritizing those assets that need products are units remanufactured Asset Planning and Management to original factory specifications Services provide daily technical and and assembled by expert valve around-the-clock emergency support technicians. Our strict quality for your electrical, valve, and instrument control process ensures that every applications and maintenance. Our Encore part meets industry and asset managers deliver best-practice factory standards – guaranteed. solutions during your turnarounds immediate repair – making the best use of your maintenance work. Onsite Repair Center Our mobile service trailers provide a portable maintenance facility at PREDICT & OPTIMIZE 8| Asset Planning and Management Services Electrical Testing and Maintenance Conduct electrical testing and maintenance on all your electrical and throughout your plant’s life cycle. When it’s turnaround time, turn to Emerson for proven technologies and services to help your plant succeed today, tomorrow, and beyond. TECHNOLOGY ALONE DOESN’T GET THE JOB DONE – PEOPLE DO From the moment they arrive onsite safety, including training in more from one of our conveniently-located than 60 Environment, Safety, and service centers in North America, Health (ESH) procedures. our technicians and engineers ■ Our technicians are trained and offer you the highest standards certified by the PHMSA (US of professionalism and safety. Department of Transportation ■ Emerson’s Asset Reliability Pipeline and Hazardous Materials Services team is comprised of Safety Administration) to work more than 700 of the industry’s on pipelines. premier engineers, PEs, technicians, Emerson has a history of working safely. Our Experience Modifier the InterNational Electrical Testing Rate (EMR) is one of the lowest Association (NETA), Instrument in the industry. Society of America (ISA) CCST Certification, and Emerson’s Rosemount®, Fisher®, and Micro Motion® Certification programs, our technicians have the expertise and experience to accomplish the most complex projects safely and reliably. ■ ■ and support professionals. Through Finally, when the job is complete, our technicians leave something valuable behind – expertise. Through our training programs, your in-house personnel learn about operation, troubleshooting, diagnosis, and resolution. As a result, your plant staff can benefit from Every technician is trained to Emerson’s expertise long after Occupational Safety and Health the turnaround is over. Administration (OSHA) standards for personal and environmental |9 PREDICT & OPTIMIZE TURNAROUNDS ARE JUST THE BEGINNING PARTNERSHIP CONFIDENCE NTEGRATE Leverage Emerson’s services Our AMS Suite predictive to create and run a more maintenance software is a core backed by people who are committed profitable plant. component of the PlantWeb to meeting your needs and exceeding Emerson project managers are digital plant architecture, improving your expectations. Maybe that’s why available to deliver valuable insight availability and performance of Emerson’s technologies and services during turnarounds and startups. mechanical equipment, electrical are routinely recognized as superior Between turnarounds, keep your systems, process equipment, by both customers and industry peers. processes running at peak efficiency instruments, and valves. Through So, the next time you schedule a through scheduled maintenance asset optimization, customers have turnaround, call Emerson’s Asset of your electrical systems, valves, increased production from 2%-5% Reliability Services team. We can and instrumentation. and decreased their energy costs be there before, during, and after by 15%-20%. your next turnaround to help you PREDICT & OPTIMIZE Emerson’s asset optimization 10 | Every Emerson product and service is ® technology can help raise the maximize the potential of every productivity of aging plants. asset in your plant. www.assetweb.com ©2009, Emerson Process Management. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or specifications of our products at any time without notice. All rights reserved. AMS, Smart Turnarounds, Fisher, Micro Motion, Rosemount, FlowScanner and Encore are marks of one of the Emerson Process Management group of companies. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their respective owners. D351034X012/MT-01-0209/printed in USA /7-2009 Emerson Process Management – Asset Optimization – Asset Reliability Services Instrument & Valve Services Electrical Reliability Services Machinery Health Management 205 South Center Street 8760 Orion Place, Suite 110 835 Innovation Drive Marshalltown, IA 50158 Columbus, OH 43240 Knoxville, TN 37932 www.assetweb.com