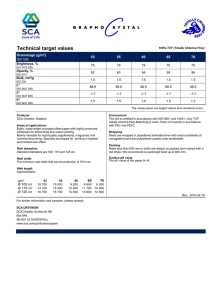

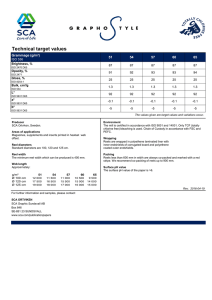

SCA Graphic Paper UK Publication Papers 2014/2015

advertisement