Document 10414698

advertisement

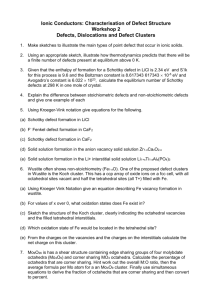

918

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

SLIDER: Simulation of Layout-Injected Defects

for Electrical Responses

Wing Chiu Tam, Student Member, IEEE, and R. D. (Shawn) Blanton, Fellow, IEEE

Abstract—Logic-level simulation has been the de facto method

for simulating defect/faulty behavior for various testing tasks

since it offers a good tradeoff between accuracy and speed.

Unfortunately, by abstracting defect behavior to the logic level

(i.e., a fault model), it also discards important information

that inevitably results in inaccuracies. This paper describes a

fast and accurate defect simulation framework called SLIDER

(simulation of layout-injected defects for electrical responses).

SLIDER uses well-developed mixed-signal simulation technology

that is conventionally used for design verification. There are

three innovative aspects that distinguish SLIDER from prior

work in this area: 1) accuracy resulting from defect injection

taking place at the layout level; 2) speedup resulting from careful

and automatic partitioning of the circuit into maximal digital

and minimal analog domains for mixed-signal simulation; and

3) complete automation that includes defect generation, defect

injection, design partitioning, netlist extraction, mixed-signal

simulation, and test-data extraction. The virtual failure data

created by SLIDER is useful in a variety of settings that include

diagnosis resolution improvement, defect localization, fault model

evaluation, and evaluation of yield/test learning techniques that

are based on failure data analysis.

Index Terms—Defect modeling, layout analysis, mixed-signal

simulation, volume diagnosis, yield learning.

I. Introduction

GGRESSIVE CMOS scaling has brought about many

benefits that include faster transistors, reduced chip size,

lower power consumption, increased functionality integration,

and others. However, it also creates formidable problems from

the manufacturing perspective. Notable examples include subwavelength lithography-induced defects [2], chemical mechanical polishing (CMP)-induced defects [3], and others. Unlike

the random defects that are caused by particulate contamination, these defects are caused by design–process interactions

and are systematic1 in nature, i.e., they can occur repeatedly

A

Manuscript received July 22, 2011; revised October 27, 2011; accepted

December 11, 2011. Date of current version May 18, 2012. This work was

supported by the National Science Foundation, under Award CCF-0541297.

This work was an extension of [1]. The major extensions include automatic

defect generation and several additional experiments performed to illustrate

applications of SLIDER. This paper was recommended by Associate Editor

C.-W. Wu.

The authors are with the Center for Silicon System Implementation,

Department of Electrical and Computer Engineering, Carnegie Mellon

University, Pittsburgh, PA 15213 USA (e-mail: wtam@andrew.cmu.edu;

blanton@ece.cmu.edu).

Color versions of one or more of the figures in this paper are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TCAD.2012.2184108

1 A systematic defect can be due to the fabrication process only or due to

interactions between the design and the process. “Systematic” in this paper

refers to the latter.

in areas with similar layout features. Systematic defects have

substantially increased over the years and have become a

substantial component of yield loss [4]. In addition, scaling

continues to increase process complexity, which inevitably

introduces new failure mechanisms [3]. Traditional test structures, while still very useful to monitor the process, have

diminished in applicability since they are limited in volume

and therefore cannot adequately capture the complex design–

process interactions that are found in the product integrated

circuits (ICs) alone [5], [6]. Diagnosis of failed product ICs has

become an increasingly important channel to gather feedback

about the fabrication process [6]–[19]. This is evident in

several recently published papers that demonstrate innovative

use of volume diagnosis. Ongoing diagnoses are used as yieldlearning techniques to identify systematic defects [6]–[10],

[18], [19] and derive important information that includes, e.g.,

design-feature failure rates [11], [12]. In [13] and [14], the

effectiveness of a given set of DFM rules is evaluated using

volume diagnosis results. Diagnosis is also used as a part

of a yield-monitoring vehicle so that defect density and size

distributions (DDSDs) can be estimated [15]. In [16], [17], and

[20], diagnosis is being used to monitor and control IC quality.

With increasing reliance upon volume diagnosis, the accuracy of diagnosis and the follow-on techniques become increasingly important as well, and therefore should be examined

carefully. Measuring accuracy is conceptually simple, but can

be very difficult to achieve in practice since it requires the

availability of the “correct answer” (i.e., the defect) for a

sufficiently large amount of failure data in order to draw a

statistically sound conclusion. Physical failure analysis (PFA)

is often performed on suspect defect locations isolated by

diagnosis in order to expose and examine the defect to identify

the culprit process step. Therefore, PFA data can provide the

“correct answer.” However, due to its time-consuming nature

[9], PFA is often selectively performed, and thus the data

collected can be insufficient and biased. To make the matter

worse, PFA data are often foundry-confidential and may be

unavailable even to the foundry customers. A better alternative

is to use simulation to generate large amounts of virtual failure

data. This paper is a step in this direction.

A. Motivation

To create virtual failure data, the ability to simulate a defect

(i.e., evaluate the output response of a circuit for the given

input stimulus in the presence of a given defect) is essential.

Moreover, since diagnosis itself is not perfect, a typical

c 2012 IEEE

0278-0070/$31.00 © 2012 IEEE. Personal use of this material is permitted. Permission from IEEE must be obtained for all other uses, in any current or future media,

including reprinting/republishing this material for advertising or promotional purposes, creating new collective works, for resale or redistribution

to servers or lists, or reuse of any copyrighted component of this work in other works.

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

diagnosis outcome consists of one or more candidates. It is

therefore important to have ranking criteria to distinguish these

candidates to reduce ambiguities in the subsequent analyses.

One of the most commonly used criteria is how closely

the simulated response of the candidate matches the actual

failure response. For this ranking criterion to be effective,

the defect must be accurately modeled and simulated. Since

logic-level simulation offers a good tradeoff between speed

and accuracy, most testing or diagnosis tasks operate at the

logic level. The erroneous behavior of a defect must also be

abstracted to the logic level as well, and is typically known as

a fault model. Unfortunately, logic-level abstraction inevitably

discards important information of the defect (e.g., voltage,

resistance, and others), and can therefore result in inaccuracies.

For example, it is well known that an open defect can exhibit

location-dependent behavior in the same wire segment [21],

[22]. Another example would be a Byzantine bridge [23]

that confounds logic-level diagnosis. These defect behaviors

actually provide important clues about the location of the

defects, but unfortunately cannot be naturally captured or

simulated by a conventional logic-level simulator.

To mitigate this problem, the concept of mixed-signal

simulation is introduced in [1]. This concept is not new

and has been used extensively in the design community for

years to achieve a reasonable speed-accuracy tradeoff for both

circuit design and design methodology validation [24]. In IC

design, it is often the case that certain parts of the circuit

(such as an analog block) require extensive simulation and

detailed analysis, while other parts of the circuit (such as

a digital block) can be simulated at a much higher level of

abstraction without significant loss of accuracy, with respect

to the parameters of interest. Mixed-signal design tools can

simulate at varying levels of abstraction for different blocks

of the design simultaneously within a single framework using

appropriate signal conversion at the block interfaces.

The same concept can be applied to defect simulation. To

accurately capture defect behavior, only the defect site and a

few of its preceding and subsequent logic stages need to be

simulated accurately. This is possible since any intermediate

voltage level that results due to the defect often becomes

logically well defined (either logic 1 or logic 0) in subsequent

logic stages, and therefore does not require circuit-level simulation accuracy from that point onward. Thus, simulation of the

remaining portions of the circuit can be carried out completely

in the digital domain. Fig. 1 illustrates this concept. Due to the

presence of a bridge defect (represented as a resistor inside the

shaded circle), the pull-up network in the OR gate and the pulldown network of NAND gate are in contention for the driver

input values applied, resulting in the unknown logic value X

for both wire networks affected by the bridge. However, all

signals have well-defined, valid logic values after two stages

of logic. In other words, only the region inside the dotted rectangle requires circuit-level (i.e., detailed analog) simulation.

Not only can the concept of mixed-signal simulation be

applied to defect simulation but the existing mixed-signal

simulation tools can also be directly used. In fact, it is more

efficient and robust to use the existing tools, rather than to

develop a new tool from scratch. This is because mixed-

919

Fig. 1. Circuit region that contains indeterminate logic value (X) due to

the presence of a bridge defect. In this example, all intermediate values are

assumed to become well-defined logic values after two stages of logic.

signal simulation is a mature technology with associated

modeling languages (e.g., Verilog-AMS [18]) and commercial

simulators (e.g., Cadence AMS Designer [19]). Using these

tools, however, requires careful partitioning of the design into

digital and analog blocks. Specifically, all regions that require

good simulation accuracy are consolidated into a single analog

block. Changes can then be made to the analog block to

represent the presence of one or more defects. The rest of the

design remains as a digital block. Once the design is properly

partitioned, the mixed-signal simulator can be directly used.

B. Prior Work

The need for more accurate defect modeling has motivated

several prior works in this area. CODEF [25]–[27] is a process

simulator that was applied to gates/cells or small pieces of

the layout in order to predict the impact of a particulate

contamination on the layout geometry. The impact can then be

mapped to a circuit-level representation that can be simulated

for improving diagnosis [25] and understanding defect behavior [26], [27]. The inductive fault analysis tool CARAFE [28]

identifies likely faults in a circuit and creates corresponding

circuit-level netlists, taking into account the layout, the defect

characteristics, and the fabrication technology. In [29], a 4-bit

arithmetic logic unit (ALU) was used as a base design for

investigating a diverse set of realistic defects (modeled as

changes in the circuit-level netlist) that are crafted specifically

to benchmark diagnosis techniques. The work in [30] simulated transistor-level defects using SPICE and abstracted the

resulting behavior to logic level by using a new algebra. The

work in [31] and [32] used mixed-level fault simulation to

simulate a defect more accurately while maintaining a tolerable simulation speed. Unfortunately, the work in [25]–[27]

and [29] depended on simulating the entire circuit at the

transistor level and therefore was not scalable. The work

in [30]–[32], while scalable, did not consider layout and

therefore sacrificed accuracy. In addition, the variety of defects

considered in [30]–[32] was quite limited.

C. Our Contribution

By making use of a commercial mixed-signal simulator and

performing defect injection at the layout level, the framework

described here solves the scalability problem with no loss of

accuracy and thus enables new applications as the result of

the efficiency improvement. This framework, which we call

SLIDER (simulation of layout-injected defects for electrical

responses), also supports multiple defect injection. This is im-

920

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

portant since defect multiplicity increases [33] with escalating

process complexity.

While it is true that many defect behaviors can be mapped

to the logic level [34] to gain scalability, the mapping process

often requires precharacterization of the defect behaviors [30].

In addition, logic-level abstraction will not be able to capture

or simulate defect behavior that is both a function of the tests

applied and its physical location of occurrence. In contrast,

SLIDER (automatically) injects defects at the layout level and

extracts a netlist of the affected area.

Despite the similarity of SLIDER to the framework in [29],

SLIDER, besides having an enhanced scalability, further distinguishes itself from the work in [29] in two other important

aspects. First, the framework in [29] models defects as circuitlevel netlist changes. Compared to logic-level simulation, this

has tremendously improved accuracy but it still does not adequately reflect the physical changes in the layout caused by the

defect. For example, if an open occurs in a long interconnect

connecting node A to node B, the physical location of the open

along the interconnect cannot be captured by simply adding

a large resistance between the two nodes. SLIDER performs

defect injection at the layout level, followed by automatic circuit netlist extraction at the defect injection site, and therefore

is more accurate. Second, the work in [29] lacks flexibility in

that there is no defect generation capability. Moreover, each

available defect is tailored to the specific 4-bit ALU circuit

considered. This means the available defects cannot be ported

to another design without significant effort. In contrast, both

defect generation and injection are completely automated in

SLIDER and thus can be readily applied to different designs.

D. Framework Usage

The SLIDER framework enables fast and accurate creation

of virtual failure data that are useful in a variety of settings.

One obvious use of virtual failure data is to benchmark different diagnosis techniques. This is possible since the type and

location of the defect is known and can be precisely controlled.

Checking the diagnosis outcome against the “correct answer”

allows us to quantify the accuracy of the diagnosis techniques

under evaluation. In fact, SLIDER can be used to evaluate any

test or yield-learning techniques that are based on failure data

analysis. For example, consider the evaluation of a systematic

defect identification methodology [6]–[10], [18], [19]. Using

SLIDER, random and systematic defects can be generated

in different proportions to evaluate how much “noise” the

methodology can tolerate and still provide the right answer.

Besides benchmarking, virtual failure data can actually aid

debugging of the test or yield-learning techniques since it can

provide examples where the technique fails. Such examples

expose incorrect assumptions and software bugs in the techniques. In fact, in the last experiment in Section IV, SLIDER

has exposed software bugs of the systematic defect identification methodology described in [7], and enabled further

refinement of the technique. This type of result can be very

difficult to achieve with real failure data that is limited in

quantity.

The virtual failure data can also be used to evaluate the

effectiveness of a fault model or test metric. Models and

metrics are used to direct automatic test pattern generation.

The resulting tests directly affect product quality (e.g., tests

that better catch defects lead to lower defect escape). Tests

generated using a given fault model can be simulated with

SLIDER to evaluate its effectiveness in defect detection. Tests

generated using a given test metric (e.g., physically aware Ndetect [35]) can be subject to the same analysis to evaluate

the effectiveness of the test metric.

A less obvious usage of virtual failure data is to improve diagnosis itself by further analyzing diagnosis candidates to infer

more information. For example, as mentioned above, diagnosis

typically reports several equally ranked candidates. SLIDER

can be used to generate virtual failure data that corresponds to

different defect-injection scenarios at the candidate locations

to resolve this ambiguity. Even when there is no ambiguity in

the diagnosis (i.e., only one candidate is reported with a “100%

match”), it is possible to use SLIDER to better characterize

the defect (e.g., identify the range of resistance of an open

or a bridge, and the actual physical location) that can help to

further characterize the defect, yielding additional information

for any follow-on analyses.

Last, virtual failure data can play another active role in

improving test or yield-learning techniques. Machine learning

[36] techniques can be applied to extract valuable information

from the virtual data. The lessons learned from the virtual

failure data can then be applied to actual failure data. It is

advantageous to use virtual failure data as the “training data,”

because its characteristics are known and can be precisely

controlled. For example, a classifier can be trained to separate

defects based on their types. There is absolute certainty in the

training-data labels (i.e., defect type) if virtual failure data are

used. Indeed, this concept was explored in a recent work in

[37]. In [37], a decision forest [38] was trained to separate

bridge and nonbridge defects using a mixture of virtual and

real failure data. The trained classifier was then applied to real

failure data whose defect types were known. The result of the

experiment was encouraging. Using the decision forest, the

work in [37] correctly classified all six failed ICs that were

deemed to be bridges by logic-level diagnosis software but

turned out to be nonbridges after PFA was performed.

The remainder of this paper is organized as follows.

Section II describes the details of the SLIDER framework.

Section III describes the various defect-generation modes

supported in SLIDER. Section IV follows with several experiments to demonstrate its accuracy, its scalability, and how

it can be used for diagnosis improvement and evaluation of

diagnosis and yield-learning methodologies. Finally, this paper

is summarized in Section V.

II. Simulation Framework

In this section, we describe the structure and flow of the

SLIDER framework.

A. Framework Structure

Fig. 2 shows the key components of SLIDER. It is composed of a defect generator (DG), an analog block generator

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

921

Fig. 3. Block diagram that illustrates the top-level testbench created by

SLIDER for mixed-signal simulation.

Fig. 2.

Block diagram of the SLIDER framework.

(ABG), a digital block generator (DBG), a mixed-signal simulator (MSS), and a result parser (RP). The shaded blocks

are implemented in SLIDER. The MSS used in SLIDER is

Cadence AMS designer [11]; however, any other mixed-signal

simulator can be easily used instead.

B. Framework Flow

The inputs to the framework are the design database, a

description of the defects to be injected into the layout or a set

of options to direct the defect-generation process, and the test

patterns. The design database must contain both the layout

and the logic-level netlist. The defect description specifies

the geometry of one or more defects (i.e., coordinates, size,

polygon, layer, and others). If the defect description is not

specified, then options must be specified to direct the defectgeneration process. The different options for defect generation

will be described in detail in Section III. The supported defect

types include open, resistive via, signal bridge, supply bridge,

and various kinds of cell defects that include the “nasty

polysilicon defect” [39], transistor stuck-open, and transistor

stuck-closed. The test patterns mimic the tester stimulus that

would be applied to the circuit during production testing.

Using these inputs, SLIDER creates a testbench that can

be understood directly by the MSS to perform mixed-signal

simulation for the defects of interest, as illustrated in Fig. 3.

The flow starts by automatically partitioning the design into

its respective analog and digital blocks, which are created by

the ABG and DBG in Fig. 2, respectively. The analog block

contains all instances and nets that are required to produce accurate circuit-level simulation results for the defect sites, while

the digital block contains everything that remains. Defects are

then injected into the analog block at the layout level. The

analog block, the digital block, and their connections form

the design under test (DUT). To capture the DUT’s response,

a Verilog module, namely, the RP, is defined to sample the

output waveform at the frequency defined by the test clock.

Once the testbench is created, the MSS performs a transient

analysis for a time duration that is sufficient for applying all

test patterns. For example, if the test pattern count is 288 and

the test clock period is 10 ns, then the duration for transient

analysis is 2880 ns. During simulation, the MSS automatically

takes care of the cross-domain signals through the use of

connection modules: an analog-to-digital (digital-to-analog)

convertor for a signal that crosses from the analog (digital)

domain to the digital (analog) domain. A connection module

is easily specified in the Verilog-AMS language [40], and can

be configured on a per simulation basis to ensure accuracy in

the signal conversion.

This process is repeated automatically for each simulation

run, where a run consists of the injection of one or more

defects. It should be noted that because the design database can

be very large, copying the database is intentionally avoided.

Instead, the design database is modified in place to output the

testbench for MSS. Changes to the original design database

are immediately discarded afterward. The design is purged and

reopened for the next iteration.

C. Analog Block Generation

Fig. 4 illustrates the flow for analog block generation. In the

first step, for each defect, its layout location of injection is used

to determine the affected nets. A net is considered affected

when its corresponding layout polygons have a nonzero-area

overlap with the defect polygon. (If the defect affects a

standard cell, then all the nets connected to the cell are deemed

to be affected.) For each affected net, an influence cone is

identified that consists of all the nets that can influence or

control the voltage of the affected net, or whose voltage can be

rendered indeterminate by the affected net. Thus, the influence

cone typically consists of signals in the transitive fan-in and

fan-out of the affected net. Table I summarizes the types of

nets in the influence cone. Column 1 gives the net type while

column 2 provides a description. Fig. 5 illustrates the various

nets in an influence cone. In this example, an open (shown

as a shaded circle) is injected into net N1 . The transitive fanin of N1 for one logic stage is {N4 }. (Refer to column 3 of

Table I for other net-type examples.) The influence cone is

the union of all the nets and is therefore {N1 , N2 , N4 –N7 }

for d = 260 nm, i = 1, and j = 2. Parameters d, i, and j

are all specified by the user for each defect to be injected.

Influence-cone determination is repeated for each defect to be

injected in the circuit. The influence cones for all the defects

are consolidated into a single cone using a set union operation.

It should be emphasized that the influence cone is intentionally

defined to have a well-defined, conservative logical boundary

(i.e., a signal net or a standard cell is never split) to simplify

the design partitioning process.

It is clear that the parameters i, j, and d should be small

to achieve faster runtimes. However, if i and j are too small,

logical indeterminate values (X) can be propagated outside of

the analog block. In addition, if d is too small, some nets

in the neighborhood could be missed, which could lead to

inaccuracy. The rule of thumb is that i and j should be as small

as possible without causing one or more unknown values to

922

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

TABLE I

Various Nets That Can Be in the Influence Cone of a Net x

Net Type

Transitive fan-in (x, i)

Transitive fan-out (x, j)

Neighbors (x, d)

Side inputs (x)

Description

Fan-in logic cone of x for i logic stages

Fan-out logic cone of x for j logic stages

Nets within a physical distance d from the net x in the layout

Nets driving the side inputs of the cells driven by x

Example (See Fig. 5)

Fan-in (N1 , 1) = {N4 }

Fan-out (N1 , 1) = {N6 } Fan-out (N1 , 2) = {N6 , N7 }

Neighbor (N1 , 260 nm) = {N5 }

Side input (N1 ) = {N2 , N5 }

TABLE II

Layout-Level Modifications Supported and the Associated

Circuit-Level Modifications

Fig. 4.

Flow diagram that illustrates analog block creation.

Fig. 5. Illustration of the influence cone (dashed rectangle) for an open

defect.

propagate to the circuit primary outputs, while d should be

chosen to include all wires in adjacent routing tracks.

In the second step of Fig. 4, a new, layout-level subdesign is

created using all the layout polygons that belong to the nets in

the influence cone. The driving cells (e.g., G1 , G2 , G4 –G7 in

Fig. 5) and the receiver cells (e.g., G1 , G3 , G6 , G7 , and G14 in

Fig. 5) of these nets are also included in the subdesign. The resulting polygons in the subdesign define a bounding area (e.g.,

dashed rectangle in Fig. 5) that is used to clip the polygons that

belong to global nets, such as VDD and GND. The clipped

polygons are included in the subdesign. Input and output pins

are then added to form the I/O of the subdesign. Using the

same example in Fig. 5, the input pins are I1 –I5 , the output

pins are O1 and O2 , and the global signals are VDD and GND.

Note that the subdesign creation is an inexpensive operation

because the subdesign layout is very small or very sparse.

The third step of Fig. 4 modifies the subdesign layout to

inject the defect. Table II summarizes the layout modifications

made to the subdesign for various defect types. Column 1 of

Table II shows the defect type, while columns 2 and 3 show

the layout before and after the modification for each defect

type, respectively. Generating cell defects is not described in

Table II since they are generated using the same methods at

the standard-cell level.

In the fourth step of Fig. 4, a circuit-level netlist is extracted

from the “defective” (modified) subdesign layout using the

Cadence extraction engine [41]. Since the layout geometry has

been modified, the extraction engine would reflect all changes

in the form of modified connectivity and parasitic components

(e.g., coupling to adjacent lines, additional load, and others)

within the netlist.

The final step (step 5 of Fig. 4) patches the extracted circuitlevel netlist. This step adds flexibility for the user to modify the

netlist to more accurately represent the defect. For example,

in open defect injection, it might be desirable to change the

resistance of the open node to better model a partial open

instead of a complete open. The patching process for each

defect type is described in column 4 of Table II. The default

impedance is 1 G for an open or a resistive via, and 10 for

a signal or supply bridge. These values can be overridden to

better mimic the defect characteristics observed in the process.

In addition, the patching process is not limited to resistance

modification. Inductance and capacitance can also be easily

included as well. The patched circuit is directly used in the

mixed-signal simulation.

D. Digital Block Generation

During the formation of the analog block, the digital block is

formed in the background. In fact, it is the design database that

remains after the polygons for the analog block are removed.

Since nets and cells are removed from the original design to

form the analog block, there is a connectivity change in the

database. Therefore, new input and output ports are used to

reflect this change. Using the same example in Fig. 5, the

output ports are I1 –I5 , and the input ports are O1 and O2 .

After the digital and analog blocks are created, the DUT

includes instantiations of these two blocks and connects them

together accordingly using analog-to-digital and digital-toanalog converters as shown in Fig. 3.

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

Fig. 6.

Plot of the probability density function for defect size distribution.

III. Defect Generation

As mentioned in Section II, there are two ways to inject

defects using SLIDER: a user-defined defect description and

automatic defect generation by the DG. In the first method,

users specify a complete XML description [42] for each defect

to be injected. The XML format is used because it is a

well-defined standard with open-source libraries that support

parsing and generation. The advantage of this method is that

users have precise control of layout-level defect injection.

The disadvantage is that users need to specify very low-level

details (e.g., the polygon vertices that describe the defect)

for every defect to be injected. This low-level description

requires knowledge of the design layout and can therefore be

tedious or inconvenient to create. The second option, namely,

automatic defect generation, allows users to specify a highlevel description of the desired characteristics of the resulting

defect population. Based on this input, the DG automatically

generates a defect population of size n (specified by the user)

that satisfies the user-defined characteristics. The DG currently

supports three modes of defect population creation, random,

systematic, and diagnostic, which are described next.

A. Random

In this mode, a defect population that follows a given

DDSD is generated. DDSD and critical area [43] are the

essential components of many widely used yield models (e.g.,

Poisson yield model [44], negative binomial yield model

[44], and others) for predicting IC yield loss due to random

contaminations. In these models, a random contaminant of

missing or extra material is often assumed to be circular in

nature (but sometimes rectangular) with radius r. A DDSD is

typically modeled using the inverse power law as follows:

⎧

2(pi − 1)r

⎪

⎪

,

0 ≤ r < X0i

⎨ D0i

2

(pi + 1)X0i

Di (r) = D0i ×fi (r) =

p −1

2(pi − 1)X0ii

⎪

⎪

⎩ D0i

, X0i ≤ r.

(pi + 1)r pi

In these equations, D0i is the defect density and fi (r) is the

probability density function for the defect size. The parameter

r is the defect radius. The subscript i denotes the layer of

interest. Both X0i and pi are models parameters (specified by

the user), where X0i divides r into two regions to better fit

any empirical data, and pi is the power index of r.

Fig. 6 shows an example plot of the probability density function fi (r). Clearly, this is not a commonly used distribution,

such as the normal distribution. Thus, no standard statistical

923

package provides a random-number generator that follows the

DDSD. Therefore, the method described in [45] is used to

sample from the DDSD and is briefly described here. Let Fi

(r) denotes the cumulative distribution function (CDF) of the

DDSD. Let u be a random number that is sampled uniformly

in the range [0, 1]. It can be shown that r = Fi−1 (u) follows the

distribution that has the CDF Fi (r), where Fi−1 is the inverse

of Fi . (A short proof is given in the Appendix.) Since fi (r) is

known, Fi and Fi−1 can be analytically calculated as follows:

⎧

(pi − 1)r 2

⎪

⎪

r

,

0 ≤ r < X0i

⎨

2

(pi + 1)X0i

fi (r)dr =

Fi (r) =

p −1

⎪

2X0ii

−∞

⎪

⎩1 −

, X0i ≤ r

(pi + 1)r pi −1

⎧

2

⎪

(p + 1)X0i

u

⎪

⎨ i

,

0 ≤ u < Fi (X0i )

(pi − 1)

−1

Fi (u) =

p −1

2X0ii

⎪

⎪

(pi − 1) , Fi (X0i ) ≤ u ≤ 1.

⎩exp ln (pi + 1)(1

− u)

More often than not, defects with radii smaller than Rmin are

not going to cause any failures, regardless of their locations.

Therefore, it is desirable to generate defects that have a size

greater than or equal to Rmin . The brute-force approach is to

discard any defect whose size is smaller than Rmin . However,

a better approach is to sample u in the interval [Fi (Rmin ), 1]

instead of [0, 1]. This ensures that no defect size less than

Rmin will be generated. Rmin is another parameter that can be

specified by the user.

Besides defect size, the defect location must also be generated. Let (xmin,i , ymin,i ) and (xmax,i , ymax,i ) denote the coordinates of the lower left corner and the upper right corner,

respectively, of the bounding box of all polygons in the layer

i. The x and y coordinates of the center of a contaminant are

sampled uniformly from the bounding box defined by (xmin,i ,

xmax,i ) and (ymin,i , ymax,i ).

Despite the requirement that the defect size has to be greater

than Rmin , the generated defect at location (xi , yi ) may not

cause a failure because the defect may not reside within the

critical area of the circuit [43]. It would be inefficient to

perform a simulation when the defect is not going to cause

failures. Thus, a “sanity check” is performed before simulation. This check is defect-type dependent and uses the design

layout to determine if a given defect will possibly cause circuit

failure. Specifically, if the defect is an open, the check ensures

that the defect will split the polygon(s) it contacts into two or

more pieces. If the defect is a bridge, the check ensures that

the defect connects at least two polygons from different nets.

For resistive vias, the check ensures that the defect contacts

at least one via. Simulation is performed only for the defects

that have passed these checks. Despite these checks, it is still

possible that the injected defect creates a defective circuit that

is, however, not detectable by the simulated test patterns.

B. Systematic

In this mode, a defect population that contains some percentage of systematic defects is generated. Systematic defects

arise due to design–process interactions, i.e., certain layout

features are more sensitive than expected to the manufacturing

924

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

users can specify the minimum number of geometries that

must be involved in the pattern, the minimum or maximum

number of times a pattern must occur in the layout, and so

on. Similar to the random-defect mode, SLIDER performs

the same “sanity checks” to ensure the systematic defects

generated have an increased likelihood to lead to failure.

C. Diagnostic

Fig. 7. Systematic defects that cause (a) a bridge and (b) an open. Courtesy

of [46].

Fig. 8.

Illustration of systematic defect injection.

process and are therefore more susceptible to failures. This

situation can lead to an increase in the likelihood of failure

in all locations with similar, sensitive layout features. Fig. 7

shows two examples of a systematic defect [46] that cause a

bridge and an open, respectively.

Systematic defects are often caused by pattern distortion

resulting from the use of subwavelength lithography [47],

but can also be due to other issues that include, e.g., metal

delamination that is induced by CMP [3]. Systematic defects

are injected at locations that have similar layout patterns.

Specifically, SLIDER uses the commercial tool Calibre pattern

matching [48] to identify similar patterns in the layout. Similarity here is defined by a set of constraints on the geometries

of the user-provided pattern. An example of a constraint

would be the via-to-via distance for the pattern in Fig. 8

must be between 0.3 μm and 0.5 μm. (The interested reader is

referred to [48] for more details on how to use constraints to

define pattern similarity.) Defects are automatically injected at

predefined locations of the matching geometry, thus creating a

population of systematic defects since all the generated defects

share a similar layout pattern. The process used by SLIDER to

create a systematic defect is illustrated in Fig. 8. The pattern

to be matched (shown on the right in Fig. 8) is searched for

within the layout. The areas identified by a square are the

matched locations. The shaded marker indicates the defectinjection location (in this case an open). In this example, a

population consisting of three open defects is generated.

Users can either provide the pattern directly or let SLIDER

randomly generate a pattern from the design layout. If the

latter is used, users must also provide the dimension and layer

of the pattern to be generated. SLIDER also provides options

for users to control the complexity of the pattern. For example,

As mentioned in Section I-A, SLIDER can be used to

explore different defect-injection scenarios for a particular net

in order to improve diagnosis resolution or defect localization.

In this mode, the user specifies a net name and the defect

type. The DG will automatically retrieve the layout geometries

associated with this net and create a defect of the specified

type in each of these geometries. For example, suppose net

N1 is routed using ten polygons from metal-1 to metal-3, and

the defect type specified is an open, then an open defect will

be injected at the center of each polygon associated with N1

in each layer. Similarly, when the defect type is a resistive

via, SLIDER will retrieve all the vias associated with the net.

Resistive vias are then injected at these via locations one at

a time to create a population. If the defect type is a bridge,

each layout geometry associated with this net is expanded by

a user-defined distance to find neighboring geometries that are

not associated with this net. For each geometry associated with

the net, bridge defects are injected one at a time between

geometry of the net currently under consideration and each

neighboring geometry. Last, if the defect type is a cell defect

(such as transistor stuck closed), the cells connected to the

given net are retrieved. For each cell retrieved, each transistor

in the cell is assumed to be faulty one at a time to create a

cell defect population.

IV. Experiments

In this section, experiment results are presented that demonstrate how SLIDER can be used in various scenarios. Specifically, four sets of experiments are presented: 1) realistic

failure behavior; 2) scalability; 3) diagnosis improvement; and

4) diagnosis and yield-learning evaluation.

A. Realistic Failure Behavior

To demonstrate the realistic failure behavior that can be

obtained using SLIDER, 12 benchmark circuits [49], [50],

varying in size and complexity, are placed and routed using

Cadence First Encounter [51]. The technology used is the

TSMC 180-nm CMOS process from the publicly accessible

MOSIS webpage [52]. In this experiment, we are interested in

creating failing tester responses that mimic slow-speed scan

test. Thus, no simulation is performed to create delay-test

responses. Test sets are created for each benchmark using

Atalanta [53], each achieving 100% stuck-at fault coverage.

The critical-path delay of all benchmarks does not exceed

3.6 ns. To balance simulation time and accurately resemble a

stuck-at, scan-test environment, the applied test clock period

is chosen to be 10 ns. The test patterns are applied to each

benchmark one-by-one in a single simulation, i.e., all tests for

a single defective circuit are simulated in a single run.

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

925

TABLE III

Statistics of Simulated Tester Responses That Exhibit Location Dependency for Opens, Resistive Vias, and Signal Bridges

Benchmark

Name

C432

C499

C880

C1355

S208

S382

S386

S444

S510

S641

S713

S953

N diff

45

83

92

181

11

26

70

34

73

65

49

173

Opens

N modified

Dfailed

336

1274

441

1586

646

2262

960

3361

140

509

263

931

311

1112

319

1085

399

1436

464

1781

500

1756

727

2636

Dinjected

1277

1602

2262

3372

514

932

1115

1093

1439

1783

1829

2643

N diff

13

49

58

81

5

14

29

15

35

33

29

101

Resistive Vias

N modified

Dfailed

83

646

273

906

301

1096

455

1660

58

213

132

443

165

564

133

481

179

669

212

766

234

774

365

1280

For every net in each benchmark, defects of the same type

are injected at various locations along the same segment of the

same net. Fig. 9 illustrates this process. As shown in Fig. 9, net

f has five different segments (labeled B1 –B5 ). In this example,

two defects, denoted by circular dots, are injected one at a time

at two different locations along B3 in two different simulations.

Defects are injected into the remaining segments B1 , B2 ,

B4 , and B5 in a similar manner. This process is repeated

for all the nets for each benchmark. If SLIDER accurately

captures the physical location of the defect in the extracted

netlist, the simulated tester responses of the circuit should be

different for some nets (e.g., a long net). This experiment is

repeated for three defect types that include an interconnect

open, a resistive via, and a signal bridge. Results of these

simulations are summarized in Table III. (Supply bridges and

standard-cell defects are not used in this experiment because

they do not exhibit location dependency at the interconnect

level.) The number of net segments exhibiting a locationdependent response (N diff ) is recorded along with the number

of net segments modified (N modified ). Similarly, the number of

defective circuits that fails at least one test (Dfailed ) is recorded

along with the number of defects injected (Dinjected ). This latter

data is included to show that simulation resources are rarely

wasted on undetected defects.

From these results, it is clear that even for a simple circuit

like S208, which consists of only 96 gates, the framework

is able to produce location-dependent tester responses for

all three defect categories. The ability to capture locationdependent behavior is very important especially for opens

since it is well known that the exact location of an open can

have a measurable impact on the tester response [21], [22]. For

each defect category in Table III, the ratio of the number of

nets with a different tester response (N diff ) to the total number

of nets modified (N net ) is less than the ideal value of one

because the tester response is binary in nature and does not

necessarily reflect the differences in the analog output signals

caused by location changes of the injected defect. In addition,

Table III shows that the responses generated for bridges at

different locations are very likely to be different (82% on average), when compared to the other two defect types. This result

is expected since a bridge injected at different locations along

Dinjected

648

913

1097

1664

215

444

566

484

672

767

808

1284

N diff

109

79

166

190

21

25

67

47

114

68

87

237

Bridges

N modified

Dfailed

116

435

84

407

388

1084

238

1053

28

150

36

226

72

329

63

328

121

494

76

358

101

456

251

958

Dinjected

450

428

1163

1161

158

251

340

350

512

387

512

1006

a given segment is likely to bridge to different neighboring

nets, which generally results in different tester responses.

B. Scalability

To demonstrate the scalability of SLIDER, another 11

benchmark circuits of much larger sizes than those used in

the previous experiment (including two ITC99 benchmarks

B14 and B18 [54]) are placed and routed using Cadence

Encounter using the same CMOS process. For each circuit,

100 random defects taken from Table II are injected and simulated. The results are averaged and summarized in Table IV.

Column 1 shows the circuit name, while columns 2–4 provide

the transitive fan-in and fan-out levels, and physical distance

parameter d, respectively. The total number of gates for each

circuit is given in column 5, while column 6 gives the number

of gates in the influence cone that is an approximate size

measure of the analog block. The number of test patterns, the

corresponding fault coverage, and the test-clock period (in ns)

are provided in columns 7–9, respectively. These test patterns

are generated using a commercial ATPG tool. The simulation

time and the total runtime are summarized in columns 10 and

11, respectively. Comparing columns 10 and 11, it is clear that

the additional computation time for circuit partitioning incurs

negligible overhead to the total runtime, which is dominated by

the simulation time. It should be emphasized that, more often

than not, only a subset of test patterns has to be simulated.

For example, since it is likely that interest lies on how

the injected defect behaves for failing test patterns, one can

identify those patterns that sensitize the defective net (using

inexpensive logic simulation) and then employ SLIDER for

only those patterns. The number of test patterns that sensitize

the affected net is typically a very small percentage of the

total number of test patterns. Therefore, the simulation time

and the total runtime are normalized by the pattern count

and are shown in columns 12 and 13, respectively. Note

that the simulation time is not further normalized by the

test-clock period since the circuit has to be fully simulated

for the entire test-clock period to obtain meaningful results.

Column 13 clearly shows that runtime increases slightly even

though the circuit size has increased substantially. The runtime

increase is due to the digital block getting larger as the

926

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

TABLE IV

Summary of the Runtime Experiment Results to Demonstrate the Scalability of the SLIDER Framework

Circuit

Name

C432

C1355

C3540

C7552

S13207

S15850

S35932

S38417

S38584

B14

B18

No. of

Fan-In

Levels

1

1

1

1

1

1

1

1

1

1

1

No. of

Fan-Out

Levels

2

2

2

2

2

2

2

2

2

1

1

Neighbor

Distance

(μm)

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.4

0.4

No. of

Gates

172

582

1743

3813

8483

9940

16353

22609

20193

10033

116840

No. of

Gates

in Cone

33.62

24.13

37.15

27.92

22.69

24.60

42.16

34.42

48.09

55.87

63.94

No. of

Patterns

49

101

139

102

270

135

23

108

151

746

1212

circuit scales. The neighborhood distance and fan-out level

is reduced for B14 and B18 to ensure a small analog block

size (i.e., small number of gates in the influence logic cone).

Despite these changes, there is no loss of accuracy because

the outputs have been verified to contain no unknown values

(i.e., Xs) and all the nets in the adjacent routing tracks are still

included.

Fault

Coverage

(%)

98.93

100.00

100.00

99.97

99.98

100.00

100.00

100.00

99.97

99.98

99.90

Test

Period

(ns)

10.00

10.00

10.00

10.00

10.00

10.00

10.00

10.00

10.00

10.00

18.00

Simulation

Time (s)

48.21

45.15

90.43

65.48

100.97

118.96

113.62

123.58

162.69

362.74

1750.39

Total

Time

(s)

53.55

50.65

96.29

72.11

109.07

129.74

128.09

135.93

175.15

372.16

1803.42

Simulation

Time Per

Pattern (s)

0.98

0.45

0.65

0.64

0.37

0.88

4.94

1.14

1.08

0.49

1.44

Total

Time Per

Pattern (s)

1.09

0.50

0.69

0.71

0.40

0.96

5.57

1.26

1.16

0.50

1.49

TABLE V

Characteristics of Diagnosis Candidates for Example One

Candidate

Name

N7671

FIXED− FAN-IN− N7671− 0

Fault

Matching Score

100%

100%

Fault

Type

sa01

sa01

Response

Match?

No

Yes

C. Diagnosis

To demonstrate the utility of SLIDER in the diagnosis flow,

an experiment is performed to show how diagnostic resolution

and localization can be improved. In this experiment, virtual

failures from the scalability experiment are diagnosed using

a commercial diagnostic tool. For diagnostic outcomes that

are ambiguous (nonideal resolution, long candidate nets, etc.),

SLIDER is then used to reduce the level of ambiguity. Specifically, using the diagnostic defect generation mode of SLIDER,

defects are injected at various sites along the candidate net(s)

and are simulated to identify a defect type and location that

produces a simulation response that best matches the observed

tester response. It should be emphasized that this is a blind

experiment in that the identified defect is checked against the

injected defect at the end of the experiment. Two examples are

given to illustrate improvement in: 1) diagnostic resolution,

and 2) defect localization.

The first example uses a diagnosis result for the benchmark

circuit C7552. The commercial tool reports two fault candidates whose characteristics are summarized in Table V. Both

candidates have the type “sa01” (i.e., the candidate exhibits

stuck-at-0 behavior for some failing test patterns and stuckat-1 behavior for other failing test patterns). Both candidates

match all the failing patterns and therefore they have a 100%

matching score, which is calculated using the formula [55],

[56] as follows:

tfsf

Fault matching score =

tfsf + tfsp + tpsf

where tfsf (tester-fail, simulation-fail) is the number of times

when both the tester and the simulation produce matching

failing responses, and tfsp (tpsf ) is the number of test patterns

where the tester failed (passed) but the simulator passed

(failed).

Fig. 9.

net f .

Illustration of defect injection along the same segment (B3 ) in the

Since a sa01 tester response is a strong indication of an

open, an open defect is injected at various locations along the

nets that correspond to the two diagnosis candidates. However,

only defects injected into the second candidate produce a

mixed-signal simulation response that exactly matches all the

passing and failing test patterns. Therefore, the candidate

N7671 is eliminated, leaving only the second candidate, which,

upon verification, is the actual site used to create the original

(virtual) test response. This small experiment demonstrates

that diagnostic resolution can be improved using SLIDER.

The second example uses a diagnosis result for the benchmark circuit C3540. In this example, we demonstrate defect

localization improvement. For this run, the commercial diagnosis tool returns a single candidate (N317) of type sa01 with

a 100% matching score. This net has four fan-outs, G1 –G4 , as

shown in Fig. 10. (Fig. 10 is drawn based on the topology of

the actual layout but is not drawn to scale.) Again, because of

the sa01 tester response, open defects are injected at various locations (numbered circles) along the layout-level net that corresponds to the candidate. A simulation response match occurs

only when the defect is injected at location 1 shown in Fig. 10.

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

927

TABLE VI

Quantification of Diagnosis Accuracy

Benchmark

Name

C432

C499

C880

C1355

S208

S382

Fig. 10. Injection of an open defect (circle) in various locations along the

diagnosis candidate (N317) for better defect localization.

In other words, the defect has been localized to the region

defined by the dashed bounding box (a wire-length localization

improvement of 53%) that has been verified to be correct by

examining the analog block used to create the test response.

D. Methodology Evaluation

In this experiment, virtual failure data is created using

SLIDER for investigating: 1) the accuracy of a new diagnosis

approach, and 2) the effectiveness of a systematic defect

identification methodology.

In the first experiment, the physically aware diagnosis

methodology described in [57] and [58] is applied to the

population of failures described in Section IV-A. In [57] and

[58], both passing and failing tester patterns are analyzed at the

layout level to identify potential defect site(s) and conditions

for defect or failure activation. At the layout level, nets that

are physically close to the defect site (i.e., neighbors) that

are found to influence defect activation are identified. The

neighbors and the logic values required for defect activation

are mapped to a set of one or more fault-tuple products [34],

which are then disjunctively combined into a macrofault that

is an expression that represents the logical conditions that

must be satisfied for a site to become faulty. For example,

the macrofault (n1 , 0, i)c (n2 , 0, i)c (sx , 1, i)e + (n1 , 1, i)c (n2 ,

1, i)c (sx , 1, i)e indicates that site sx becomes stuck-at-1 when

n1 = n2 = 0 or n1 = n2 = 1. (More details of fault-tuple

macrofaults can be found in [34].) The resulting macrofault

is then fault simulated using all test patterns applied to the

failing chip. Only those macrofaults that produce a simulation

response that exactly matches the tester response are reported

as an outcome of diagnosis.

Table VI reports the accuracy of physically aware diagnosis.

A diagnosis outcome is considered correct if it has at least

one macrofault that contains the injected defect location. From

Table VI, we can see that the diagnosis methodology described

in [57] and [58] is of high accuracy and achieves 85% accuracy

on average. More interestingly, the failure data generated

using SLIDER has concrete examples where physically aware

diagnosis fails. Such examples facilitate debugging and enable

further improvement of the methodology.

In the second experiment, the systematic defect identification methodology LASIC (layout analysis for system defect

identification using clustering) [7] is evaluated. The input to

LASIC includes the volume-diagnosis results from a large

population of IC failures. Images of the layout regions that

Diagnosis

Accuracy

78.4%

89.8%

86.3%

79.3%

85.2%

77.6%

Benchmark

Name

S386

S444

S510

S641

S713

S953

Diagnosis

Accuracy

85.4%

94.9%

90.0%

76.0%

80.5%

96.7%

correspond to the failure locations isolated by diagnosis are

then extracted from the design layout. Clustering [59] of the

layout regions is performed to group similar images together.

The clusters formed are sorted according to their sizes in

decreasing order. The resulting order is called the rank of

the cluster. For example, the largest cluster has rank one,

the second largest cluster has rank two, and so on. The

dominant clusters (low-number ranks) are of particular interest

because they represent substantial commonalities in layout

features among the observed failures, and are likely to contain

systematic defects (if any). LASIC further suggests confirming

the existence of the systematic defects by simulation (e.g.,

lithography simulator [60]) or through PFA.

To investigate the effectiveness of LASIC, two failure

populations (one random and one systematic), each of size

100, are generated, using the random and systematic defectgeneration modes of SLIDER, respectively. Failures are then

randomly sampled from both populations to form a single

population that consists of both random and systematic defects.

This process is repeated to generate failure populations with

a different proportion of random and systematic defects. For

example, in the first iteration, the population has 100 systematic defects and 0 random defects, in the second iteration, the

population has 90 systematic defects and ten random defects,

in the third iteration, the population has 80 systematic defects

and 20 random defects, and so on. The goal is to evaluate

how much random “noise” can be tolerated by LASIC. The

experiment is performed using eight benchmark circuits. Four

types of defects are injected in these benchmarks: metal-2

bridge, metal-2 open, metal-3 bridge, and metal-3 open. The

results are averaged over the eight benchmarks. In addition,

to isolate the “noise” that can happen due to inaccuracies or

ambiguities in diagnosis, this experiment is performed under

two scenarios: ideal diagnosis and “real” diagnosis. Ideal

diagnosis here means that the outcome of diagnosis correctly

pinpoints the site of the injected defect with no ambiguity,

while real diagnosis can be inaccurate (i.e., diagnosis outcome

does not contain the injected-defect site) and/or low resolution

(i.e., additional sites are reported along with the actual site

of the injected defect). Since virtual failure data is used,

ideal diagnosis data can be easily obtained by just finding

the net(s) whose geometry overlaps with that of the defect.

Real diagnosis is obtained by applying a commercial diagnosis

tool to the virtual failure data, which results in inaccuracies

or ambiguities due to the inherent limitation of logic-level

diagnosis. This can be viewed as another source of “noise” in

the data. Comparing the two scenarios allows us to understand

928

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 6, JUNE 2012

through our website [the Advanced Chip Testing Laboratory

(ACTL), www.ece.cmu.edu/∼actl] enabling other researchers

to have access to large populations of virtual failures.

Appendix

Fig. 11.

LASIC evaluation for (a) ideal and (b) real diagnoses.

how the technique performs under the ideal and real scenarios.

The cluster that contains the underlying pattern of the injected

systematic defect is the correct cluster. For each scenario,

the averaged rank of the correct cluster is plotted against

the percentage of systematic defects injected. The data is

summarized in Fig. 11 for ideal and real diagnoses.

It is clear from Fig. 11 that the average rank of the

correct cluster decreases (which of course is desirable since

a lower rank means the layout geometry associated with the

injected defect resides in a larger cluster) as the percentage of

systematic defects increases for both ideal and real diagnoses.

It is also evident that the technique is effective for both ideal

and real diagnoses because the correct cluster is present in

the top 40 ranked clusters (top 3%) even when the population

only consists of 20% systematic defects. The performance of

LASIC is expectedly worse in the real-diagnosis scenario due

to diagnosis ambiguities and inaccuracies.

As a side note, the initial result was different from what is

shown in Fig. 11 when LASIC was first evaluated. Bugs were

discovered and LASIC was subsequently improved. Identifying the bug in LASIC would have been difficult without the

use of the virtual failure data generated by SLIDER.

V. Conclusion

This paper described SLIDER, a comprehensive framework for performing accurate and scalable defect simulation.

SLIDER made use of mature, commercial mixed-signal technology, making it capable of handling large designs and poised

to benefit from any future improvements in mixed-signal

simulation environments. SLIDER performed automatic defect

injection at the layout level, thus ensuring that the defect is represented as accurately as possible. SLIDER enabled automatic

fast and accurate virtual failure data creation that is useful in

a variety of settings that include diagnosis resolution improvement, defect localization, test metric or fault model evaluation,

diagnosis, and yield-learning methodology evaluation. Various

experiments have demonstrated the utility of SLIDER to

improve diagnosis. Specifically, diagnosis resolution improvement and defect localization were achieved through more

accurate defect simulation with SLIDER. Other experiments

have also demonstrated the utility of SLIDER to quantify

diagnosis accuracy, and to understand the performance and

limitation of a recently introduced systematic defect identification methodology [7]. We plan to “release” SLIDER data

To generate defect sizes that follow the distribution fi (r),

we have used this theorem. Let F be a CDF and let U ∼

Uniform(0, 1), then R = F −1 (U) follows the distribution that

has the CDF F .

Proof: We first note that all CDFs have a range of [0, 1]

and that, when U ∼ Uniform(0, 1), Pr (U ≤ u) = u, for u in

[0, 1]. Now, by definition, the CDF for R is Pr (R ≤ r) = Pr

(F −1 (U) ≤ r) = Pr(U ≤ F (r)) = F (r).

References

[1] W. C. Tam and R. D. Blanton, “SLIDER: A fast and accurate defect

simulation framework,” in Proc. VLSI Test Symp., 2011, pp. 172–177.

[2] D. Z. Pan, S. Renwick, V. Singh, and J. Huckabay, “Nanolithography

and CAD challenges for 32 nm/22 nm and beyond,” in Proc. Int. Conf.

Comput.-Aided Des., Nov. 2008, p. 7.

[3] P. Leduc, M. Savoye, S. Maitrejean, D. Scevola, V. Jousseaume, and

G. Passemard, “Understanding CMP-induced delamination in ultra lowk/Cu integration,” in Proc. Interconnect Technol. Conf., 2005, pp. 209–

211.

[4] J. H. Yeh and A. Park, “Novel technique to identify systematic and

random defects during 65 nm and 45 nm process development for faster

yield learning,” in Proc. Adv. Semicond. Manuf. Conf. Workshop, 2007,

pp. 54–57.

[5] B. Kruseman, A. Majhi, C. Hora, S. Eichenberger, and J. Meirlevede,

“Systematic defects in deep sub-micron technologies,” in Proc. Int. Test

Conf., 2004, pp. 290–299.

[6] R. Turakhia, M. Ward, S. K. Goel, and B. Benware, “Bridging DFM

analysis and volume diagnostics for yield learning: A case study,” in

Proc. VLSI Test Symp., May 2009, pp. 167–172.

[7] W. C. Tam, O. Poku, and R. D. Blanton, “Systematic defect identification

through layout snippet clustering,” in Proc. Int. Test Conf., 2010, p. 13.2.

[8] L. M. Huisman, M. Kassab, and L. Pastel, “Data mining integrated

circuit fails with fail commonalities,” in Proc. Int. Test Conf., 2004, pp.

661–668.

[9] M. Sharma, C. Schuermyer, and B. Benware, “Determination of

dominant-yield-loss mechanism with volume diagnosis,” IEEE Des. Test

Comput., vol. 27, no. 3, pp. 54–61, May–Jun. 2010.

[10] R. Desineni, L. Pastel, M. Kassab, M. F. Fayaz, and J. Lee, “Identifying

design systematics using learning based diagnostic analysis,” in Proc.

Adv. Semicond. Manuf. Conf., 2010, pp. 317–321.

[11] H. Tang, M. Sharma, J. Rajski, M. Keim, and B. Benware, “Analyzing

volume diagnosis results with statistical learning for yield improvement,”

in Proc. Eur. Test Symp., 2007, pp. 145–150.

[12] M. Keim, N. Tamarapalli, H. Tang, M. Sharma, J. Rajski, C. Schuermyer,

and B. Benware, “A rapid yield learning flow based on production

integrated layout-aware diagnosis,” in Proc. Int. Test Conf., 2006, pp.

1–10.

[13] W. C. Tam and R. D. Blanton, “To DFM or not to DFM?” in Proc. Des.

Automat. Conf., Jun. 2011, pp. 65–70.

[14] R. Kapur, M. Kapur, and M. Kapur, “Systemic diagnostics for increasing

wafer yield,” U.S. Patent 20110040528, 2011.

[15] J. E. Nelson, W. Maly, and R. D. Blanton, “Diagnosis-enhanced extraction of defect density and size distributions from digital logic ICs,” in

Proc. SRC TECHCON, 2007.

[16] X. Yu and R. D. Blanton, “Estimating defect-type distributions through

volume diagnosis and defect behavior attribution,” in Proc. Int. Test

Conf., 2010, pp. 1–10.

[17] X. Yu, Y.-T. Lin, W.-C. Tam, O. Poku, and R. D. Blanton, “Controlling

DPPM through volume diagnosis,” in Proc. VLSI Test Symp., May 2009,

pp. 134–139.

[18] J. Jahangiri and D. Abercrombie, “Value-added defect testing techniques,” IEEE Des. Test Comput., vol. 22, no. 3, pp. 224–231, May–Jun.

2005.

TAM AND BLANTON: SLIDER: SIMULATION OF LAYOUT-INJECTED DEFECTS FOR ELECTRICAL RESPONSES

[19] M. Sharma, B. Benware, L. Ling, D. Abercrombie, L. Lee, M. Keim,

H. Tang, W.-T. Cheng, T.-P. Tai, Y.-J. Chang, R. Lin, and A. Man,

“Efficiently performing yield enhancements by identifying dominant

physical root cause from test fail data,” in Proc. Int. Test Conf., Oct.

2008, pp. 1–9.

[20] S. Eichenberger, J. Geuzebroek, C. Hora, B. Kruseman, and A. Majhi,

“Towards a world without test escapes: The use of volume diagnosis to

improve test quality,” in Proc. Int. Test Conf., Oct. 2008, pp. 1–10.

[21] R. Rodriguez-Montanes, D. Arumi, J. Figueras, S. Einchenberger, C.

Hora, B. Kruseman, M. Lousberg, and A. K. Majhi, “Diagnosis of full

open defects in interconnecting lines,” in Proc. VLSI Test Symp., May

2007, pp. 158–166.

[22] Y. Sato, L. Yamazaki, H. Yamanaka, T. Ikeda, and M. Takakura, “A

persistent diagnostic technique for unstable defects,” in Proc. Int. Test

Conf., 2002, pp. 242–249.

[23] D. B. Lavo, T. Larrabee, and B. Chess, “Beyond the byzantine generals:

Unexpected behavior and bridging fault diagnosis,” in Proc. Int. Test

Conf., 1996, pp. 611–619.

[24] P. Ke, H. Yu, P. Mallick, W.-T. Cheng, and M. Tehranipoor, “Full-circuit

SPICE simulation based validation of dynamic delay estimation,” in

Proc. Eur. Test Symp., May 2010, pp. 101–106.

[25] J. Khare and W. Maly, “Rapid failure analysis using contaminationdefect-fault (CDF) simulation,” IEEE Trans. Semicond. Manuf., vol. 9,

no. 4, pp. 518–526, Nov. 1996.

[26] J. Khare and W. Maly, “Inductive contamination analysis (ICA) with

SRAM application,” in Proc. Int. Test Conf., 1995, pp. 552–560.

[27] J. Khare, W. Maly, and N. Tiday, “Fault characterization of standard cell

libraries using inductive contamination analysis (ICA),” in Proc. VLSI

Test Symp., 1996, pp. 405–413.

[28] A. Jee and F. J. Ferguson, “Carafe: An inductive fault analysis tool for

CMOS VLSI circuits,” in Proc. VLSI Test Symp., 1993, pp. 92–98.

[29] T. Vogels, T. Zanon, R. Desineni, R. D. Blanton, W. Maly, J. G. Brown,

J. E. Nelson, Y. Fei, X. Huang, P. Gopalakrishnan, M. Mishra, V. Rovner,

and S. Tiwary, “Benchmarking diagnosis algorithms with a diverse set

of IC deformations,” in Proc. Int. Test Conf., 2004, pp. 508–517.

[30] P. Banerjee and J. A. Abraham, “A multivalued algebra for modeling

physical failures in MOS VLSI circuits,” IEEE Trans. Comput.-Aided

Des. Integr. Circuits Syst., vol. 4, no. 3, pp. 312–321, Jul. 1985.

[31] W. Meyer and R. Camposano, “Fast hierarchical multi-level fault simulation of sequential circuits with switch-level accuracy,” in Proc. Des.

Automat. Conf., 1993, pp. 515–519.

[32] M. B. Santos and J. P. Teixeira, “Defect-oriented mixed-level fault

simulation of digital systems-on-a-chip using HDL,” in Proc. Des.,

Automat. Test Eur., 1999, pp. 549–553.

[33] X. Yu and R. D. Blanton, “Multiple defect diagnosis using no assumptions on failing pattern characteristics,” in Proc. Des. Automat. Conf.,

2008, pp. 361–366.

[34] R. D. Blanton, K. N. Dwarakanath, and R. Desineni, “Defect modeling

using fault tuples,” IEEE Trans. Comput.-Aided Des. Integr. Circuits

Syst., vol. 25, no. 11, pp. 2450–2464, Nov. 2006.

[35] Y.-T. Lin, O. Poku, N. K. Bhatti, and R. D. Blanton, “Physically-aware

N-detect test pattern selection,” in Proc. Des., Automat. Test Eur., Mar.

2008, pp. 634–639.

[36] C. M. Bishop, Pattern Recognition and Machine Learning, 1 ed. New

York: Springer-Verlag, 2006.

[37] J. E. Nelson, W. C. Tam, and R. D. Blanton, “Automatic classification

of bridge defects,” in Proc. Int. Test Conf., 2010, p. 10.3.

[38] L. Rokach and O. Z. Maimon, Data Mining with Decision Trees: Theroy

and Applications. Singapore: World Scientific, 2008.

[39] R. D. Blanton, J.T. Chen, R. Desineni, K. N. Dwarakanath, W. Maly,

and T. J. Vogels, “Fault tuples in diagnosis of deep-submicron circuits,”

in Proc. Int. Test Conf., 2002, pp. 233–241.

[40] K. Kundert and O. Zinke, The Designer’s Guide to Verilog-AMS, 1 ed.

New York: Springer, 2004.

[41] The Diva Reference Manual, Cadence Design Systems, Inc., San Jose,

CA, 2009.

[42] W3C. Extensible Markup Language (XML) 1.0 (Fifth Edition). (Nov.

2008) [Online]. Available: http://www.w3.org/TR/2008/REC-xml20081126

[43] W. Maly and J. Deszczka, “Yield estimation model for VLSI artwork

evaluation,” Electron. Lett., vol. 19, no. 6, pp. 226–227, 1983.

929

[44] C. H. Stapper, F. M. Armstrong, and K. Saji, “Integrated circuit yield

statistics,” Proc. IEEE, vol. 71, no. 4, pp. 453–470, Apr. 1983.

[45] L. Wasserman, All of Statistics: A Concise Course in Statistical Inference, 1 ed. New York: Springer, 2004.

[46] D. Abercrombie. (Aug. 2009). DFM for Non-PhD’s-Part 3: Real Life Examples [Online]. Available: http://blogs.mentor.com/david− abercrombie/

blog/2009/08/20/dfm-for-non-phds-part-3-real-life-examples

[47] A. B. Kahng and Y. C. Pati, “Subwavelength lithography and its potential

impact on design and EDA,” in Proc. Des. Automat. Conf., 1999, pp.

799–804.

[48] The Calibre Pattern Matching User Manual, 1.0 ed. Mentor Graphics

Corporation, Wilsonville, OR, 2010.

[49] F. Brglez and H. Fujiwara, “A neutral netlist of 10 combinational

benchmark circuits and a target translator in fortran,” in Proc. Int. Symp.

Circuits Syst., 1985, pp. 1929–1934.

[50] F. Brglez, D. Bryan, and K. Kozminski, “Combinational profiles of

sequential benchmark circuits,” in Proc. Int. Symp. Circuits Syst., 1989,

pp. 1929–1934.

[51] The Cadence Encounter Reference Manual, Cadence Design Systems,

Inc., San Jose, CA, 2009.

[52] MOSIS. The MOSIS Service [Online]. Available: www.mosis.com

[53] H. K. Lee and D. S. Ha, “Atalanta: An efficient ATPG for combinational

circuits,” Dept. Electric. Eng., Virginia Polytechnic Inst. State Univ.,

Blacksburg, VA, Tech. Rep. 93-12, 1993.

[54] F. Corno, M. S. Reorda, and G. Squillero, “RT-level ITC’99 benchmarks

and first ATPG results,” IEEE Des. Test Comput., vol. 17, no. 3, pp. 44–

53, Jul.–Sep. 2000.

[55] The Tetramax User Guide, Synopsys, Inc., Mountain View, CA, 2009.

[56] The Cadence Encounter Test User Guide, Cadence Design Systems, Inc.,

San Jose, CA, 2009.

[57] R. Desineni, O. Poku, and R. D. Blanton, “A logic diagnosis methodology for improved localization and extraction of accurate defect behavior,” in Proc. Int. Test Conf., 2006, pp. 1–10.

[58] R. Desineni and R. D. Blanton, “Diagnosis of arbitrary defects using

neighborhood function extraction,” in Proc. VLSI Test Symp., 2005, pp.

366–373.

[59] A. K. Jain, M. N. Murty, and P. J. Flynn, “Data clustering: A review,”

ACM Comput. Surveys, vol. 31, no. 3, pp. 264–323, 1999.

[60] The Optissimo User Manual, 6.0 ed., PDF Solutions, Inc., San Jose,

CA, 2001.