Document 10414697

advertisement

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

1405

Diagnosis-Assisted Adaptive Test

Xiaochun Yu, Member, IEEE, and Ronald DeShawn Blanton, Fellow, IEEE

Abstract—This paper describes a method for improving the test

quality of digital circuits on a per-design basis by: 1) monitoring

the defect behaviors that occur through volume diagnosis; and

2) changing the test patterns to match the identified behaviors.

To characterize the behavior of a defect (i.e., the conditions when

a defect is activated), physically-aware diagnosis is employed

to extract the set of signal lines relevant to defect activation.

Then, based on the set of signal lines derived, the defect is

attributed to one of several behavior categories. Our defect level

model uses the behavior-attribution results of the current failing

population to guide test-set customization to minimize defect

level for a given constraint on test costs, or alternatively, ensure

that defect level does not exceed some predetermined threshold.

Circuit-level simulation involving various types of defects shows

that defect level can be reduced by 30% using this method.

Simulation experiment on actual chips also demonstrates quality

improvement.

Index Terms—Adaptive test, defect behavior, diagnosis, test

quality.

I. Introduction

T

HE DIAGNOSIS of test data for improving yield is a

topic of great interest [1]–[5]. For example, the work

in [2] uses diagnosis results to track failure rates for various

design features. These empirically observed failure rates are

compared with expected failure rates to identify anomalies in

the design and/or manufacturing process. The thinking is that

the identified anomalies can be remedied in order to improve

yields.

Diagnosis methods such as the ones described in [6] and [7]

derive defect behaviors (i.e., defect activation conditions) in

addition to the potential defect locations. The defect characteristics derived from a statistically significant population suggest

the susceptibilities of a design to a specific manufacturing

process. Customizing a test set to those failure characteristics

is likely to increase test quality, which is commonly measured

using defect level (DL). DL is the ratio of defective chips to

all the chips that fully pass all the tests, and it is typically

expressed in units of defective parts per million shipped

(DPPM). Since the failure characteristics may change over

time, the custom test set should also change accordingly.

Custom test is a type of adaptive test. Different from a

Manuscript received September 10, 2011; revised January 8, 2012; accepted

February 17, 2012. Date of current version August 22, 2012. This work was

supported by the National Science Foundation, under Award CCF-0427382.

This paper was recommended by Associate Editor C.-W. Wu.

X. Yu is with Intel Corporation, Hillsboro, OR 97124 USA (e-mail:

xiaochun.yu@intel.com).

R. D. Blanton is with the Department of Electrical and Computer Engineering, Carnegie Mellon University, Pittsburgh, PA 15213 USA (e-mail:

blanton@ece.cmu.edu).

Color versions of one or more of the figures in this paper are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TCAD.2012.2193580

static test method (e.g., a test set that is generated using a

fault model) that does not depend on changing parameters,

an adaptive test method can alter test conditions, test flow,

test content, and test limits based on statistical analysis of

various forms of manufacturing data [8]. Adaptive test has

been successfully employed in various ways. For example,

test cost can be reduced by reordering test patterns based on

fail count [9]–[12]. Adaptive limit setting for quiescent supply

current (IDDQ) and minVDD outlier screening has also been

shown to improve test quality [9], [11]–[15].

This paper describes diagnosis-assisted adaptive test (DAT),

an approach that improves test quality or test cost for static

defects by identifying and applying tests that optimally detect

the defect characteristics of integrated circuits (ICs) being

currently manufactured. In its current incarnation, DAT targets

static defects which are different from a sequence-dependent

defect (e.g., a transistor stuck-open defect) whose activation

can require multiple clock cycles. The activation and error

propagation of a static defect, on the other hand, occurs

within a single clock cycle. Moreover, for a static defect at

a site f , defect activation is assumed to be controlled by the

neighborhood of f , which is the set of signals that are in close

physical or logical proximity to f [6].

DAT uses diagnosis-extracted models of chip failures along

with a model for estimating DPPM. Both are incorporated in

a quality-monitoring methodology that ensures a desired level

of quality by changing some proportion of the production test

patterns to match the current defect characteristics derived

from diagnosis. DAT is dynamic in nature and thus differs

from the typical approach that assumes sufficient quality levels

are maintained using the tests developed during the time of

design or “first silicon.” DAT presupposes that failure characteristics can change over time but with a time constant that is

sufficiently slow, thereby allowing the test set to be altered so

as to maximize coverage of the failure characteristics actually

occurring. If the failure characteristics are unchanging, it

will then be possible to tune the test set once to match the

fixed failure characteristics. We therefore believe it is possible

to minimize DPPM for a given constraint on test costs, or

alternatively, ensure that DPPM does not exceed some predetermined threshold. Fig. 1 illustrates a possible scenario

where DPPM changes over time. At t1 , DPPM prediction

begins based on a sufficient amount of diagnosis data obtained

during the period between t0 and t1 . When the predicted DPPM

approaches a specific DPPM limit at t2 , the tests are altered

to lower DPPM at t3 . When DPPM is sufficiently low (e.g.,

t5 ), test quality can be traded off to reduce test application

time, which leads to the slight increase in DPPM shown at

t6 . Notice, however, at t4 , an excursion is assumed to have

c 2012 IEEE

0278-0070/$31.00 © 2012 IEEE. Personal use of this material is permitted. Permission from IEEE must be obtained for all other uses, in any current or future media,

including reprinting/republishing this material for advertising or promotional purposes, creating new collective works, for resale or redistribution

to servers or lists, or reuse of any copyrighted component of this work in other works.

1406

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

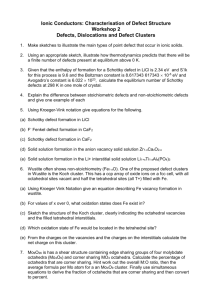

TABLE I

Behavior-Attribution Rules

Id

1

Relevant Neighborhood

Fail in deriving RNf

Defect Behavior

Unknown

2

RNf = ∅

RNf = ∅ and

∃c, (RNf ∪ {f })\Pc = ∅

Stuck-at

3

Fig. 1. Illustration of how DPPM can change over time for a given design

in a given manufacturing process.

4

5

6

7

8

Fig. 2.

Overview of DAT.

occurred. Again, DAT does not presumably need to cope with

excursions since effective techniques already exist to deal with

them [16].

An overview of DAT is shown in Fig. 2. Multiple defect

diagnosis using X-evaluation (MD2 X) [17], a multiple defect

diagnosis method that makes no assumption of defect behavior,

is first applied to each failing chip to derive defect sites. Then,

for each defect site found via MD2 X, the defect behavior

(i.e., its activation condition) is derived using the failing

behavior identification (FBI) method described in [7]. In FBI,

activation of a static defect is assumed to be controlled by

its relevant neighbors (i.e., signal lines in close physical and

logical proximity to the defect site), which are identified

using an entropy analysis. Based on the relevant neighbors

identified, each chip failure is placed into one of several

behavior categories, each of which corresponds to one or more

defect types [7] (Section II). Using the behavior-attribution

results derived from a large sample of failing ICs, the defect

level of chips passing a specific test set can be estimated

using a novel, data-based defect-level model (Section III). The

defect-level model guides test-set customization for improving

test quality without additional test cost (Section IV).

II. Defect Behavior Attribution

2

MD X and FBI derive, for each failing chip, the defect

sites and each site’s relevant neighbors. Based on the relevant

∀c, (RNf ∪ {f })\Pc = ∅ and

RNf ∩ (Vtotal \Vf ) = ∅

∀c, (RNf ∪ {f })\Pc = ∅ and

RNf ∩ (Vtotal \Vf ) = ∅ and

RNf ∩ (DPNf +

DVf )\(PNf + SIf ) = ∅

|RNf | = |RNf ∩ PNf | = 1

and ∀c, (RNf ∪ {f })\Pc = ∅

and RNf ∩ (Vtotal \Vf ) = ∅

|RNf | = |RNf ∩ PNf | > 1

and ∀c, (RNf ∪ {f })\Pc = ∅

and RNf ∩ (Vtotal \Vf ) = ∅

|(RNf ∩ SIf )\(PNf +

DPNf + DVf )| > 0 and

∀c, (RNf ∪ {f })\Pc = ∅ and

RNf ∩ (Vtotal \Vf ) = ∅

Cell misbehavior

f ’s value depends

on other defective

sites

f ’s value depends

on drive strength

f ’s value depends

on one physical

neighbor

f ’s value depends

on > 1 physical

neighbors

f ’s value depends

on its receiver-gate

side inputs

Defect

Type

Unknown

All types

possible

All types

possible

Bridge

Bridge

Bridge

or open

Bridge

or open

Open

neighbors identified, each defect can be placed into one

of several mutually exclusive behavior categories. Since the

behaviors of some defect types overlap, there is no one-onone mapping from defect behavior to defect type in many

cases. Thus, the objective of defect behavior attribution is not

to derive the defect type directly from the relevant neighbors

identified. But instead, behavior-attribution results in a behavior distribution, that is, the relative occurrence rates of various

behavior categories. The behavior distribution of a failing

population of chips captures the failure characteristics of that

population. The details of behavior attribution are explained

in the following subsections. Specifically, in Section II-A, the

behavior-attribution rules are described and the relationship

between each behavior category and defect type is analyzed.

In Section II-B, various experiments are conducted to validate

the relationships described in Section II-A.

A. Categorizing Defect Behavior

Table I lists the behavior-attribution rules that are based

on different sets of relevant neighbors. (The notation used in

Table I is described in Table II.) Specifically, Table I lists eight

different behavior categories and their association to the four

defect types considered, namely, open, bridge, cell defect, and

“unknown.” Though eight behavior categories and four defect

types are considered in this paper, behavior attribution can be

extended to other, and more refined defect types and behaviors.

Category 1: FBI identifies the relevant neighbors using the

characteristics of the common defect types under consideration. If the relevant neighborhood cannot be identified, then

the behavior of the defect is deemed “unknown” to signify the

observed behavior does not completely align with the common

defect types under consideration.

YU AND BLANTON: DIAGNOSIS-ASSISTED ADAPTIVE TEST

TABLE II

Definition of Notation

Term

RNf

PNf

DVf

DPNf

SIf

Vtotal

Vf

Pc

Description

Deduced relevant neighborhood of f

Physical neighbors of f

Inputs of the cell driving f

Inputs of the cells that drive lines in PNf

Side inputs of the cells driven by f

All defective sites identified by diagnosis

Defective sites that have the same effect as f on the

failing circuit under the given test set

Inputs and output of a cell c

Category 2: If a defective site f does not have any relevant

neighbors, then f manifests faulty behavior regardless of its

neighborhood. In other words, f behaves as a signal line being

permanently stuck-at a fixed logic value (i.e., a stuck-at fault),

under the applied test set. Any type of defect can behave as a

stuck-at fault, especially when the applied tests do not expose

all the possible behaviors of a defect.

Category 3: If: 1) the union of a defective site f and

its relevant neighborhood is a subset of the union of the

inputs and the output of a cell; and 2) there is at least one

relevant neighbor, then the behavior of the defect mimics a

misbehaving cell (i.e., the truth table of the cell’s function has

changed). This is likely due to a cell defect, but there are other

possibilities. For example, a cell input affected by an open can

manifest as a change in cell functionality. Also, for a given test

set, a bridge whose activation depends on the driving strength

of a cell can also mimic cell misbehavior.

Category 4: If: 1) the relevant neighborhood of a defective

site f includes another defective site g; 2) f and g have

different effects on the failing circuit; and 3) the behavior does

not agree with Categories 1, 2, or 3, then the value of f is

dependent on g. A bridge defect affecting two signal lines

can produce this behavior. Although an open on a stem line

can also cause several (or all) of its downstream branches

to be defective, error manifestation on the defective branches

does not depend on each other. Neither can a cell defect cause

the aforementioned behavior. Thus, a defect that causes this

observed behavior can be classified as a bridge.

Category 5: If: 1) the relevant neighborhood of a defective

site f includes inputs to the cell driving f or inputs to the

cells driving the physical neighbors of f ; 2) at least one of the

inputs included in the relevant neighborhood is not a physical

neighbor of f or a side input to any of the cells driven by f ;

and 3) the behavior does not agree with any of the Categories

1–4, then the logical value resulting in a defective site f is

a function of the drive strength of its driving cell and/or its

physical neighbors. A bridge defect can cause such behavior,

but an open or a cell defect cannot. Thus, a defect that causes

this behavior can be classified as a bridge.

Categories 6 and 7: If the relevant neighborhood of a

defective site f includes only the physical neighbors of f ,

and the relevant neighborhood does not conform to any of

the Categories 1–5, then the value of f depends only on its

physical neighbors. For this situation, f can be affected by

an open or bridge, but not a cell defect. If f is affected by

1407

an open and the activation of the defect is only dependent on

its physical neighbors, then the coupling between f and its

relevant neighbors should be large enough to determine the

value of f . Thus, when f is affected by an open, it is more

likely that the combined effect of multiple physical neighbors

will determine the value of f rather than a single neighbor

[18]. Also for an open, it is less likely that the value of

f is always controlled by a specific physical neighbor. On

the other hand, if f is affected by a bridge, the physical

neighbors that control f are likely the lines bridged with

f . A bridge involving two lines is much more likely than

a bridge involving three or more lines. Therefore, an open

defect in this behavior category is more likely to have more

than one relevant neighbor. On the other hand, a bridge in

this behavior category is more likely to have a single relevant

neighbor. The behavior is further partitioned by examining:

1) the value of the defective site as a function of a single

physical neighbor (Category 6); and 2) the value of the

defective site as a function of two or more physical neighbors

(Category 7). This is reasonable since the likelihood of a defect

of Category 6 being an open over a bridge is likely different

from that of Category 7 even though the two categories

correspond to the same defect types.

Category 8: If: 1) the value of a defective site f is dependent

on the side inputs to the cells driven by f ; 2) at least one side

input included in the relevant neighborhood is: a) not an input

to any of the cells driving the physical neighbors of f ; b) not

an input to the cell driving f ; and c) not a physical neighbor

of f ; and 3) the behavior does not agree with any categories

from 1 to 7, then the value of f depends on the side inputs

of the cells driven by f . An open affecting f can cause this

type of behavior, but a bridge or a cell defect cannot. Thus, a

defect exhibiting this behavior is classified as an open.

B. Validation Experiment

To validate the effectiveness of the behavior-attribution rules

of Table I, a simulation experiment is performed using several

benchmark circuits [19], [20]. To better mimic reality, a pool

of defective circuits is generated by randomly injecting cell

defects, gross interconnect opens, and two-line bridge defects,

one at a time, into a layout implementation of each benchmark

[21]. The cell defects injected include internal line opens,

bridges between internal lines, bridges between inputs of a

cell, feedback bridges between the inputs and output of a

cell, transistor stuck-opens, transistor stuck-close defects, and

“nasty polysilicon” defects1 [22]. For each layout with an

injected defect, the corresponding circuit-level [23] netlist is

extracted and circuit-level simulation is performed using a test

set that achieves 100% stuck-at fault efficiency (i.e., a 1-detect

test set), and the circuit responses are digitized and collected.

A clock cycle that is much slower than the rated clock is

used so as to mimic scan test. Table III shows the number of

defective circuits created for each defect type and benchmark.

1 A nasty polysilicon defect (NPSD) refers to a spot deformation of extra

polysilicon that causes an unwanted connection between the gate and the

source (drain) of a transistor that also prevents the metal terminal connection

of the source (drain) of a transistor. Since an NPSD causes a short and an

open at the same time, it is inherently “nasty.”

1408

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

TABLE III

Number of Defective Circuits for Various Defect

Types and Benchmarks Used for Validation

Benchmark

c432

c880

s713

s953

c1355

Cell Defect

363

1061

610

847

1250

Bridge

260

486

321

554

493

Open

1277

2262

1829

2643

3372

According to our analysis in Section II-A, all cell defects

should be placed in either the stuck-at or the cell-misbehavior

category. The behavior of a bridge can be placed in any of the

categories except 1 or 8. For an open, its behavior can be in any

category except 1, 4, and 5. To evaluate our analysis of the relationship between different categories of defect behaviors and

defect types, each defective circuit is diagnosed using MD2 X

and the relevant neighbors of each defective site are identified

using FBI. Then, each defect is categorized using Table I. The

percentages of defects exhibiting stuck-at behavior are 59%,

14%, and 97% for cell, bridge, and open defects, respectively.

The behavior distributions of defects that do not behave as

stuck-at faults are shown in Fig. 3. It shows that among defects

that do not behave as stuck-at faults, 84% of the cell defects,

99% of the bridges, and 99% of the opens have behaviors

that agree with our analysis. In other words, the behaviors

of a vast majority of defects of each type are attributed to the

behavior categories corresponding to that defect type (Table I).

There is however a small percentage of disagreement, which is

due to misidentification of the relevant neighborhood [7]. The

behavior attribution error for cell defects is much higher than

bridge and open defects, since the complexity exhibited by cell

misbehavior can be mimicked by some other defect behaviors.

Fig. 4 shows the behavior-attribution results for 2533 failing arithmetic logic unit (ALU) test chips manufactured in

0.11 μm technology by LSI Corporation, Milpitas, CA. The

ALU design consists of 2509 gates. Fig. 4(a) shows that

a majority of the chip failures have misbehaviors that fall

into Categories 2 and 7. Furthermore, these failing chips can

be partitioned into four sets according to the time they were

manufactured and tested. Fig. 4(b) shows that the occurrence

rates of different behavior categories have changed slightly

over time. The most significant change occurred for defects

with cell misbehavior from March 2004 to July 2005. It should

be noted, however, that the sample size here is too small to

draw any conclusions about the significance of these changes.

In other words, based on the number of chips involved in

deriving Fig. 4(b), changes in behavior distribution cannot be

determined with high confidence.

Defect behaviors are likely to vary across different processes

and different designs, which means Fig. 4 varies for different

technologies. Thus, for a design manufactured using a different

process, behavior attribution needs to be applied to derive the

behavior distribution for that design-process combination.

III. DPPM

In this section, a model for estimating DPPM using the

behavior-attribution results is described. The derivation of the

Fig. 3. Behavior distributions of non-stuck-at-behaving defects. The percentages of cell, bridge, and open defects, exhibiting stuck-at behavior (Category

2) are 59%, 14%, and 97%, respectively.

Fig. 4. Occurrence rates for different behavior categories for (a) 2533 actual

chip failures from LSI Corporation and (b) same chip failures partitioned over

the time of manufacture.

model for estimating DPPM is given in Section III-A, and

experiment results that validate the model are described in

Section III-B.

A. DL Model

Many models for predicting DL have been proposed. For

example, a model that predicts DL using multimodel fault

coverage is presented in [24]. Their DL model is based on the

assumption that defects of different types are equally likely to

occur, which of course may not be true in reality. In [25], a

YU AND BLANTON: DIAGNOSIS-ASSISTED ADAPTIVE TEST

DL model that is based on the number of times each site is

observed is described. The particular activation conditions of

a given defect type are, however, not taken into account. It is

quite likely that the values on the relevant neighbors of a defect

that affects a site i are the same for many patterns where i is

observed. In such cases, using a test set with a repeated number

of observations does not necessarily lead to lower defect level

especially for the static defects considered here. In addition,

the model of [25] assumes that a defective chip passes the

testing process and therefore is shipped if the erroneous effect

of at least one defective site is not observed. However, in the

context of multiple defects, a defective chip passes test only if

no error from any of the defective sites is observed. So, the assumption in [25] can lead to an overestimation of defect level.

To address the shortcomings just outlined, a DL model

using an estimate of the defect-type distribution has been

proposed in [26]. As shown in [7], the defect-type distribution

for a design fabricated in a given manufacturing process

can be estimated using the behavior distribution of each

defect type (e.g., Fig. 3), which is derived from the behaviorattribution results of a sufficient number of PFAed2 defects

that affect the design. The method of [7] can effectively

estimate the defect-type distribution if the behavior distribution

of each defect type: 1) remains static or changes slowly; and

2) varies from other defect types. PFA is an expensive and

time-consuming process however. Moreover, there may be no

or not enough PFA results to generate an accurate behavior

distribution per defect type at the beginning of a product’s life

time. Thus, it is desirable if DL can be estimated without PFA

results. In the work of [26]–[29], a defective chip examined

using diagnosis is classified into one of several defect types

directly from the defect behavior extracted without the use

of PFA. However, due to the ambiguity in mapping defect

behavior to defect type, which is well illustrated by Table I

and Fig. 3, such classification methods result in defect-type

distributions that are very different from the actual as demonstrated in [7]. The DL model presented here does not depend

on an accurate estimation of defect-type distribution. Instead,

it uses the occurrence rate of each behavior category, which is

derived through diagnosis and the behavior attribution method

described in Section II-A. In the following, we define the DL

model in terms of several probabilities.

For each site i, the following probabilities are defined.

Pi (defective) = Probability that site i is affected by a defect.

Pi (detected) = Probability of detecting the defect that affects

site i.

Pi (behavior j) = Probability of a defect with behavior j

affecting i, where behavior j is one of the categories in Table I.

Pi (j detected) = Probability of detecting a defect of behavior

j that affects site i.

Pi (j activated|state k) = Probability of activating a defect of

behavior j that affects a site i when the corresponding relevant

neighborhood has state k.

To make the problem more tractable, independence is assumed to exist among the defect activation and corresponding

2 Physical failure analysis (PFA) is the very time-consuming process of

physically inspecting an IC for uncovering the root cause of failure.

1409

error-propagation conditions for defects affecting different

locations. In other words, it is assumed that the detection of a

defect at one site does not influence the detection of a defect

at another site when there are multiple defects in the circuit.

A chip C is shipped if: 1) C is defect-free; or 2) none of

the defects affecting C is detected by the testing process. In

other words, a chip C is shipped if for every site i, there is

no defect that affects i, or if there is one, it is not detected.

Thus, the probability of C being shipped, Pship , is computed as

follows:

Pship =

(1 − Pi (defective) × Pi (detected))

i∈{allsites}

=

⎛

⎝1−

⎞

Pi (behaviorj)×Pi (j detected)⎠

j∈BEHVC

i∈{allsites}

(1)

where BEHVC is the set of all behavior categories. Derivations for both Pi (defective) and Pi (behavior j) are described

next.

A defect of behavior j affecting a site i is detected if there is

a test pattern t that activates the defect and sensitizes i (despite

the possible existence of other defects) to some observable

point. Therefore

Pi (j detected)

= 1−P(j is not activated for any test sensitizing i)

=1−

(1 − Pi (j activated|state k))

(2)

k∈RNSij

where RNSij consists of all the states for the relevant neighborhood for a defect of behavior j at site i for the test patterns

where site i is sensitized. RNSij can easily be obtained by

analyzing the applied test set.

Assume the probability of a defect of behavior j affecting

a site i is the same for all sites. Thus, the fraction of a failure

population affected by a defect of behavior j, which can be

derived using the behavior attribution method (Section II-A),

j)

equals Pi (behavior

. Moreover, the theoretical yield,

P (behavior j)

j∈BEHVC

i

which is the percentage of the manufactured chips that are

defect-free, can be expressed as

(1 −

Pi (behavior j)).

(3)

Yield =

i∈{allsites}

Thus

j∈BEHVC

Pi (behavior j) = 1 −

√

i 1

Yield.

(4)

j∈BEHVC

Therefore, Pi (behavior j) can be computed for all behavior

categories at every site i for a certain value of yield.

Using the equations for Pi (j detected) and Pi (behavior j),

Pship can be derived for a given test set using (1). Since defect

level is defined to be the ratio of the defective chips in the chips

that pass all the tests, defect level can therefore be expressed

as

Pship − Yield

.

(5)

DL =

Pship

1410

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

TABLE IV

Number of Failing LSI Test Chips and

Their Associated Test Sets

Tester Data Set

1

2

3

No. of Tests

234

239

238

No. of Failing Chips

849

911

773

B. Validation

An evaluation experiment is conducted using the LSI test

chips whose behavior-attribution results are shown in Fig. 4.

The test chip design consists of 384 ALUs. Although each

ALU is identical in logic and layout, the ALUs were partitioned into several groups, each with its own test set. The

test-set size and number of failing ALUs detected for each

group are given in Table IV. The first 197 test patterns are the

same across all three test sets. The 197 test patterns are used

in this experiment.

Given a yield value, Pship and DL can be computed according to (1) and (5) using the behavior-attribution results

shown in Fig. 4 (Section II-B). For simplicity, it is assumed

for a defect of behavior j affecting a site i that for any state

k ∈ RNSij , Pi (j activated|state k) = 1/2. In other words, each

state of the relevant neighborhood for a defect of behavior

j at a site i is assumed to be equally likely to activate the

defect at 50%. However, this probability can be made more

precise by using a defect density distribution and the layout

information. The 197 tests that are common to each ALU are

simulated to derive RNSij ∀i, j, which is the set of relevant

neighborhood states for each behavior category, site pair

(i, j). Next, Pi (j detected) is computed for every site i and

every behavior category j using (2). The probability of a

defect of a specific behavior category affecting a site is derived

according to (4) using the yield value and the behaviorattribution results from Fig. 4 (Section II-B). Then, Pship is

computed using Pi (j detected) and Pi (behavior j), and DL is

derived using (5).

Since the actual escape is unknown, the DL model cannot

be directly validated. However, the number of chips failed for

each test pattern is known from the fail data. On the other

hand, the expected number of chips failed by a set of test

patterns, Estfails , equals (1 − Pship ) × Total, where Total is the

total number of chips tested. Thus, it is possible to validate

the model for Pship . Since the model for Pship is a function of

Yield, Estfails is a function of Yield and Total, both of which

are not given by the fail data. Thus, to validate the model for

Pship , a four-fold cross validation [30] is performed. In other

words, the set of the chips failed by these 197 test patterns, G,

is randomly partitioned into four groups of equal size. For each

group of failing chips, Gi , the maximum likelihood estimate

[30] for Yield and Total, Yieldi and Totali are derived from the

chips in G − Gi . Then, Estfails (Yieldi , Totali ) is compared with

the observed number of chips failed in Gi . Fig. 5 shows for

each group in the four-fold cross validation, the estimated and

the observed cumulative number of failing chips versus test

pattern index, as well as the 95% confidence intervals of the

estimations. Specifically, Fig. 5(a) compares the estimated and

the observed cumulative number of failing chips in group 1.

Similarly, Fig. 5(b)–(d) makes similar comparisons for groups

2, 3, and 4, respectively. As shown in Fig. 5, the estimated

cumulative fallout count tracks the observed very well for

each group, and the estimated values are well contained

in the corresponding 95% confidence intervals. The average

differences between the estimated and the observed values for

the four groups are 1.73, 2.98, 1.54, and 1.89, respectively.

This result means that the estimation of the Pship model tracks

the observed number of failing chips very well.

IV. Custom Test for Quality

This section explores customizing the actual test patterns

(but not increasing the number of tests) of the applied test set

to match the failure characteristics for reducing DPPM. The

use of a test-selection method [31], [32] for reducing DPPM is

described in Section IV-A, the improvement in DL is predicted

in Section IV-B, and the resulting test-quality improvement is

validated in Section IV-C.

A. Test Selection for Reducing DPPM

According to the defect level model described in Section III-A, DL can be reduced if for every site i, the defect

possibly affecting i is activated using additional relevant neighborhood states for test patterns that sensitize i. In other words,

DL can be reduced by applying a new test that sensitizes the

site i and activates some defect affecting i using an uncovered

relevant neighborhood state (i.e., a relevant neighborhood state

which has not been applied by any test where i has been

sensitized). This observation agrees with the result of an

experiment for a physically aware N-detect (PAN-detect) test

set [33], in which each stuck-at fault is detected using at

least N unique neighborhood states. In that experiment, the

PAN-detect test set, as well as stuck-at, IDDQ, logic builtin self-test, and transition-fault tests, are applied to 99 718

IBM ASICs manufactured in 0.13 μm technology. The testingexperiment result shows that the PAN-detect test set uniquely

fails three chips that passed the other test sets. This result

implies that detecting a fault using more unique neighborhood

states increases the defect detection probability.

However, since the probability of a defect of a particular

behavior category affecting a given site is different, which is

demonstrated in Section II-B, a test that activates a certain

number of uncovered relevant neighborhood states for one

behavior category can be more preferable in reducing DPPM

than a test that activates the same number of uncovered

relevant neighborhood states for another behavior category.

The implications of this observation are explored next.

According to (5), defect level decreases as Pship decreases

for a given yield. Recall that Pship can be computed using

(1). Taking the log of both sides of the equation yields the

expression

log(Pship ) =

log(1 −

Pi (behavior j)

i∈{allsites}

j∈BEHVC

×Pi (j detected)).

(6)

YU AND BLANTON: DIAGNOSIS-ASSISTED ADAPTIVE TEST

1411

Fig. 5. Failing chips are randomly partitioned into four groups of equal size. Based on the parameters derived from one group (i.e., groups one, two, three,

and four), the estimated cumulative numbers of failing chips detected for the chips in the remaining three groups are shown in (a), (b), (c), and (d), respectively.

Therefore, the reduction in log(Pship ) that results from

activating a defect of behavior j at a sensitized site i for test tk

using an uncovered relevant neighborhood state sijk , δijk , can

be computed using the following equation:

1 − j∈BEHVC Pi (behavior j) × Pi (j detected)

δijk =abs log

1 − j∈BEHVC Pi (behavior j) × Pi (j detected)

(7)

where

Pi (j detected) = 1 −

(1 − Pi (j activated|state k))

(8)

k∈RNSij

and

Pi (j detected)

= 1 −

(1 − Pi (j activated|state k)).

Procedure 1 Test selection for reducing defect level

1:

2:

3:

4:

5:

6:

7:

8:

9:

10:

11:

12:

13:

14:

15:

16:

Initialize the selected test set, Tsel , to be empty

Generate an N-detect test set, TN -det

Tpool = TN -det ∪ original test set

while the size of Tsel is less than the original test-set size do

for each test tk ∈ Tpool do

Weight(tk ) = 0

if tk ∈

/ Tsel then

for each defect behavior j and each sensitized site i in tk do

if an uncovered relevant neighborhood state sijk is established

then

Weight(tk ) = Weight(tk )+decrease of log(Pship ) due to sijk

end if

end for

end if

end for

Add the test tk with the largest Weight(tk ) to Tsel

end while

k∈RNSij +{sijk }

(9)

Again, RNSij is the set of all relevant neighborhood states

for a behavior category j in the already-selected test patterns

when i is sensitized.

The total decrease in log(Pship ) due to applying a new test

tk is the summation of the decrease in log(Pship ) due to the

activation of every uncovered relevant neighborhood state (if

any) of each defect behavior at every sensitized site i in tk .

The test that leads to the largest decrease in log(Pship ) is the

most preferable. Thus, tests are selected, one at a time, from a

large test set in a way that greedily decreases log(Pship ). The

pseudocode for test selection is given in Procedure 1.

B. Improved Test Quality

In this experiment, Procedure 1 is used to select a test set

for the ALU that is of the same size as the original test set

corresponding to the first test set shown in Table IV. The

union of a 20-detect test set generated by the Cadence Tool

Encounter Test [34] and the original test set is used as the

test pool Tpool for selection. The decrease in log(Pship ) due

1412

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

TABLE V

Comparison of Test Escapes Corresponding to the Original

1-Detect Test Set, the New Selected Test Set Tsel , and Tpool , for

Various Defect Types for the ISCAS89 Benchmark Circuit s713

Test

Set

1-det

Tsel

Tpool

Fig. 6. DPPM comparison between the original, selected, and N-detect test

sets for an assumed yield = 85% for the LSI test chips considered in Section

III-B.

to activating a defect of behavior category j at a sensitized

site i using an uncovered relevant neighborhood state sijk is

derived using (7). To compare the quality of the new selected

test set with traditional N-detect test sets, several N-detect

test sets are also generated using Encounter Test [34]. Fig. 6

shows the DPPM comparison between the selected test set,

the original test set, and the traditional N-detect test sets

assuming a yield value of 85%. Due to the randomness in

the generation of the N-detect test sets [i.e., each N-detect

test set is generated independently which means that the tests

in the (m − 1)-detect set are not necessarily a subset of the

subsequent m-detect test set], the DPPM for the conventional

N-detect test set does not necessarily decrease monotonically

with an increase in N. The selected test set achieves a lower

DPPM with a smaller test-set size than traditional N-detect

test sets that are not neighborhood aware [32], nor focused

on the characteristics of the failure population. Fig. 6 also

demonstrates that the selected test set improves test quality

(i.e., reduces DPPM) without increasing the number of tests.

Although the data shown in Fig. 6 is based on a yield value

of 85%, the DPPM comparison results hold for other values

as well.

C. Simulation Validation

The experiment in Section IV-B has shown that the test

set selected using Procedure 1 is expected to achieve a lower

DPPM value. To show that the number of test escapes can

be reduced by applying Procedure 1, a simulation experiment

using the full-scan version of the ISCAS89 benchmark s713

[20] is performed. A pool of defective circuits is generated

and the corresponding circuit responses are determined using

the method described in Section II-B for a 100% stuck-at

fault detection test set (i.e., a 1-detect test set). The resulting

defect population consists of 419 front-end cell defects, 1829

gross interconnect opens, 806 missing vias, and 512 twoline bridges. During simulation, these defects are detected and

those that escape detection are determined.

To mimic application in a production environment, the

following steps are performed. For each defect type, 25%

Test Set

Set

Size

48

48

155

Cell

27

24

24

No. of Test Escapes

Missing

via

Net Open

Bridge

39

66

37

20

37

37

20

37

36

Total

169

118

117

of the defective circuits affected by that type are randomly

selected. The selected defective circuits, referred to as Dcurrent ,

constitute the current failing population. The remaining 75%,

which are referred to as Dfuture , are assumed to be the defective

chips that are fabricated in the future. The test set applied to

Dcurrent is a 1-detect test set. The test pool (Tpool ) used for

test selection is the union of a 50-detect test set generated by

Encounter Test [34] and the original 1-detect test set. MD2 X,

FBI, and behavior attribution are performed on circuits in

Dcurrent that fail the 1-detect test set to derive the occurrence

rate of each behavior category. Then, a test set Tsel of the

same size as the original 1-detect test set is selected using

Procedure 1 and the derived occurrence rate of each behavior

category. Finally, for the defective circuits in Dfuture , circuitlevel simulation is used again to identify the test escapes, that

is, the defective circuits in Dfuture that are not detected by Tsel .

The test-set sizes and the number of defective circuits in Dfuture

that escape each test set are given in Table V.

The simulation results reveal that the resulting selected test

set Tsel reduces the number of test escapes in Dfuture by 30%

without increasing the number of tests. Moreover, the DPPM

of the selected test set is only 0.09% higher than Tpool , even

though the size of Tpool is more than three times the size

of Tsel .

V. Application Scenarios

In this section, challenges related to the application of a

DAT-based test set in an actual production environment are

discussed. The impact of process variations on the application

of DAT is discussed in Section V-A. In Section V-B, the

number of tested ICs required to determine that a DAT test set

improves test quality with high confidence is derived. Finally,

various scenarios of DAT are described in Section V-C.

A. Impact of Process Variations

The discussion thus far in this paper has been on defects that

are composed of extra or missing material within the manufactured ICs. Common defects include missing vias, interconnect opens, unintended connections between signal lines, and

others. However, due to uncertainty in the manufacturing

process, all manufactured ICs are also affected by process

variations, which are deviations from the intended structural or

electrical parameters of concern [35]. For example, transistor

gate length and width can vary significantly for small feature

sizes due to the variations in the exposure system [36]. Due

YU AND BLANTON: DIAGNOSIS-ASSISTED ADAPTIVE TEST

to reasons such as nonuniform gate oxidation temperature

and channel dopant fluctuations, manufactured transistors have

different threshold voltages. Moreover, due to copper loss in

chemical mechanical polishing, metal thickness can vary up to

30%–40% of its nominal value in a 90 nm fabrication process

[35].

Process variations can influence the behavior distribution

resulting from behavior attribution (Section II) in the following

two ways. First, for different process parameters, the behavior

of a defect at the same location may change. For example, the

logic value interpreted by a gate driven by a net affected by

an open defect is determined by: 1) the coupling capacitance

between the floating net and nets that are driven to the supply

voltage; 2) the coupling capacitance between the floating net

and nets that are driven to the ground voltage; 3) the trapped

charge on the floating net; and 4) the threshold voltage of

the gate(s) driven by the floating net. For different values of

coupling capacitance, threshold voltage, and trapped charge

resulting from different process parameters, the logic value

of the floating net may be interpreted differently. Therefore,

the behavior of the floating net may change. For example,

for a certain threshold voltage, the voltage of the floating net

may be interpreted as logic 0 for all test patterns, in which

case the defective line has stuck-at-0 behavior (Category 2 in

Table I). However, for a lower value of threshold voltage, the

value of the floating net may be interpreted as logic 0 for

some test patterns and logic 1 for the remaining test patterns

depending on the values of its physical neighbors, which

corresponds either to Category 6 or 7 in Table I. Similarly,

among all behaviors a bridge defect can exhibit, which are

given in Table I, the behavior of a line affected by a bridge

defect may change from one category to another for different

process parameters. For example, the drive current of a gate

increases with decreasing effective channel length, which may

cause the behavior of a two-line bridge defect to change from

Category 5 (i.e., the value of the defect site depending on the

driving strength) to Category 6 (i.e., the value of the defect

site depending on one of its physical neighbors). Second,

unacceptable process variations may behave as a classic spotbased “defect.” For example, when the threshold voltage of a

transistor is so high that the transistor is never turned on, the

behavior of the transistor is the same as when it is affected by

a transistor stuck-open defect, which can manifest as stuck-at

or cell misbehavior that corresponds to Category 2 or 3 in

Table I.

Since behavior distribution depends on process parameters,

the probability of a failing IC having behavior j, P(j), can be

computed using

P(j) =

P(j, p) dp =

P(j|p) × P(p) dp

(10)

PR

PR

where p is a set of values for the process parameters that can

influence the defect behaviors, PR is a region containing all

possible values for the relevant process parameters, P(j, p) is

the probability that a failing IC has process parameter values p

and exhibits behavior j, P(j|p) is the probability of a failing IC

exhibiting behavior j given that the IC has process parameter

values p, and P(p) is the probability that a failing IC has

1413

process parameter values p. Therefore, a good estimation for

P(j) requires the behavior-attribution results from a sufficient

amount of failing ICs that can approximate both the actual

distribution of relevant process parameters and the behavior

distribution for a given set of process parameter values.

In the diagnosis-assisted test, the assumption is that the

behavior distribution of failing ICs is monitored over time. A

new DAT test set is generated if the following two criteria are

satisfied. First, the current behavior distribution derived with

high confidence is different from the one used to generate the

currently employed DAT test set. Second, for any behavior

category considered, the nonoverlapping interval between the

confidence intervals for the current and the original behavior

distribution is more than the error resulting from MD2 X and

FBI, which can be deduced using simulation experiments. In

general, it is expected that a small number of failing ICs will

lead to large confidence intervals which means, of course, that

a larger change in behavior distribution has to be observed to

trigger the generation of a new DAT test set.

B. Sample Size for Validating Quality Improvement

To confirm that a DAT test set improves product quality for

actual manufactured ICs, the current and the DAT test sets

should be applied to a large population of manufactured ICs.

In the following, the number of ICs required to draw a highconfidence conclusion concerning DAT effectiveness based on

defect level (DL) is derived.

Suppose test evaluation is conducted on a population of m

ICs, some of which are defective while others are defect-free.

ˆ Crnt be the defect level resulting from the application

Let DL

of the current test set on the m ICs. In other words

ˆ Crnt = P̂shipCrnt − Yield

DL

(11)

P̂shipCrnt

where P̂shipCrnt is the percentage of ICs in the population of m

ICs that pass all the tests in the current test set and Yield is

the percentage of good ICs in the population of m ICs tested.

Thus

Yield

P̂shipCrnt =

.

(12)

ˆ Crnt

1 − DL

Similarly, P̂shipDAT , the percentage of ICs in the set of m ICs

under test that pass the DAT test set, can be calculated using

the following equation:

Yield

P̂shipDAT =

(13)

ˆ DAT

1 − DL

ˆ DAT is the defect level resulting from the application

where DL

of the DAT test set to the same m ICs. Let q be the relative

reduction in defect level resulting from the DAT test set over

the current test set for the m ICs. In other words

ˆ DAT = (1 − q) × DL

ˆ Crnt .

DL

(14)

Thus

P̂shipCrnt −P̂shipDAT =

Yield

Yield

−

ˆ Crnt

ˆ Crnt

1 − DL

1 − (1 − q) × DL

ˆ

Yield × q × DLCrnt

=

.

ˆ Crnt ) × (1 − DL

ˆ Crnt )

(1 − (1 − q) × DL

(15)

1414

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

Fig. 7. Number of ICs required to conclude that a DAT test set is of higher quality for (a) confidence level of 95% and Yield = 85%, (b) confidence level

of 90% and Yield = 85%, (c) confidence level of 99% and Yield = 85%, and (d) confidence level of 95% and Yield = 95%.

The random variable Xi is defined, where Xi equals 1 if an

IC i passes the current test set but is failed by the DAT test

set, Xi equals −1 if an IC i is failed by the current test set

but passes the DAT test set, and Xi equals 0 otherwise. Thus

1 Xi = P̂shipCrnt − P̂shipDAT .

m i=1

m

(16)

According to Hoeffding’s inequality [37], ∀ > 0

− m

1 (1−(−1)2 )

i=1

P(

(17)

Xi − (PshipCrnt − PshipDAT ) ≥ ) ≤ e

m i=1

m

22 m2

where PshipCrnt (PshipDAT ) is the probability of an IC passing

all

the tests in the current (DAT) test set. Setting to m1 m

i=1 Xi

leads to the following inequality:

m 2

m 1

P(PshipCrnt − PshipDAT ≤ 0) ≤ e− 2 ( m i=1 Xi ) .

(18)

By analyzing (15), (16), and (18), the minimum m required to

conclude PshipCrnt > PshipDAT (i.e., the DAT test set results in

a reduction in defect level) with a confidence level of (1 − α)

is derived to be

ˆ Crnt )×(1−DL

ˆ Crnt ) 2

(1−(1−q) ×DL

m=− 2×

× ln α. (19)

ˆ Crnt

Yield × q × DL

Fig. 7 shows the sample size m (i.e., the number of ICs)

required to conclude that a DAT-based test set achieves a

reduced DL (as compared to the current set of tests) for

various values of observed DL reduction resulting from a

ˆ Crnt ).

DAT test set (q) and DL of the current test set (DL

ˆ

Assuming Yield = 85%, for DLCrnt = 10 000 DPPM and q =

20%, the required sample sizes m are 1.5 million, 2 million,

and 3.1 million, for a confidence level of 90%, 95%, and 99%,

respectively. For a confidence level of 95% and Yield = 85%,

ˆ Crnt = 30 000 DPPM

the sample size reduces to 31 000 for DL

and q = 50%. This sample size changes to 25 150 if Yield

is 95%. Thus, as shown in Fig. 7, as well as in (19), the

ˆ Crnt , or

sample size m reduces with an increase in Yield, q, DL

a reduction in confidence level. The result shows that a DAT

test set can be applied with high confidence when a slight

quality improvement is observed for a large number of tested

ICs. For low volume products, however, a significant quality

improvement has to be observed to conclude that a DAT test

set improves produce quality.

C. Application Scenarios

There are two application scenarios of DAT based on

behavior distribution changes. If failure characteristics change

slowly over time, DAT can be applied over time to improve test

YU AND BLANTON: DIAGNOSIS-ASSISTED ADAPTIVE TEST

quality. Since the tester response of the failing chips and their

lot numbers are normally stored and diagnosed, the failure

characteristics can be tracked over time by analyzing the diagnosis results of failing chips using behavior attribution (Section II). To determine whether the change is slow enough, (19)

and Fig. 7 can be used. In other words, if: 1) the sample size

is large enough so that the change in fallout characteristics can

be determined with high confidence; and 2) the time needed

to customize the test set is smaller than the time for manufacturing/collecting the failing chips, then distribution change is

considered sufficiently slow. Alternatively, if the failure characteristics remain static, then the test set can be one-time tuned

to match the unchanging failure characteristics using DAT.

Under either scenario, DAT can be used to minimize DPPM

for a given constraint on test costs, or alternatively, ensure that

DPPM does not exceed some pre-determined threshold.

VI. Conclusion

A DAT methodology that ensures a desired level of quality

for chip-logic circuits on a per-design basis by changing test

content to match diagnosed-derived failure characteristics was

described. DAT began by partitioning the failure population of

a manufactured design into several behavior categories using

diagnosis results. Then, based on the occurrence rate of each

behavior category, DPPM was estimated using a new and

novel data-driven defect-level model. Also, using the resulting

behavior distribution, the test set was changed using a testselection methodology to reduce DPPM.

The efficacy of DAT was demonstrated using detailed

circuit-level simulations. Specifically, defects of various types

were injected into the layout of a benchmark circuit, extracted

to create a circuit-level netlist that accurately reflects the

presence of the defect, and then simulated to produce virtual

test responses. Applying DAT to 25% of the virtual fail

population showed that escapes from the remaining 75% could

be reduced by 30%. Although not verifiable, application to

actual chips also demonstrated quality improvement.

In addition, a formulation was derived for computing the

number of tested ICs required to confidently conclude that

a DAT-based test set would reduce DPPM. Analysis of this

formulation revealed that a DAT-based test set can be applied

with high confidence when a slight quality improvement is

observed for a large number of tested ICs. On the other hand, a

DAT-based test set can also be applied to low volume products

if a significant reduction in defect level is achievable.

Finally, though data used in this paper is based on 0.09 μm,

0.11 μm, and 0.13 μm technologies, DAT can be applied to

chips manufactured in more advanced technologies, and to

other types of defects such as delay defects.

References

[1] L. M. Huisman, “Diagnosing arbitrary defects in logic designs using

single location at a time (SLAT),” IEEE Trans. Comput.-Aided Des.

Integr. Circuits Syst., vol. 23, no. 1, pp. 91–101, Jan. 2004.

[2] M. Keim, N. Tamarapalli, H. Tang, M. Sharma, J. Rajski, C. Schuermyer,

and B. Benware, “A rapid yield learning flow based on production

integrated layout-aware diagnosis,” in Proc. IEEE Int. Test Conf., Oct.

2006, pp. 1–10.

1415

[3] H. Tang, S. Manish, J. Rajski, M. Keim, and B. Benware, “Analyzing

volume diagnosis results with statistical learning for yield improvement,”

in Proc. IEEE Eur. Test Symp., May 2007, pp. 145–150.

[4] B. Seshadri, I. Pomeranz, S. Venkataraman, M. E. Amyeen, and S. M.

Reddy, “Dominance based analysis for large volume production fail

diagnosis,” in Proc. IEEE VLSI Test Symp., Apr.–May 2006, pp. 394–

399.

[5] J. Rajski, “Logic diagnosis and yield learning,” in Proc. IEEE Des.

Diagnostics Electron. Circuits Syst., Apr. 2007, p. 19.

[6] R. Desineni, O. Poku, and R. D. Blanton, “A logic diagnosis methodology for improved localization and extraction of accurate defect behavior,” in Proc. IEEE Int. Test Conf., Oct. 2006, pp. 1–10.

[7] X. Yu and R. D. Blanton, “Estimating defect-type distributions through

volume diagnosis and defect behavior attribution,” in Proc. IEEE Int.

Test Conf., Nov. 2010, pp. 1–10.

[8] International Technology Roadmap for Semiconductors, 2009th ed.,

Semiconductor Industry Association, Austin, TX, 2009.

[9] R. Madge, B. Benware, R. Turakhia, R. Daasch, C. Schuermyer, and

J. Ruffler, “In search of the optimum test set: Adaptive test methods for

maximum defect coverage and lowest test cost,” in Proc. IEEE Int. Test

Conf., Oct. 2004, pp. 203–212.

[10] K. M. Butler and J. Saxena, “An empirical study on the effects of test

type ordering on overall test efficiency,” in Proc. IEEE Int. Test Conf.,

Oct. 2000, pp. 408–416.

[11] OptimalTest [Online]. Available: http://www.optimaltest.com

[12] Pintail [Online]. Available: http://www.pintail.com

[13] R. Daasch, K. Cota, J. McNames, and R. Madge, “Neighbor selection

for variance reduction in IDDQ and other parametric data,” in Proc.

IEEE Int. Test Conf., Oct. 2002, pp. 1240–1248.

[14] M. Rehani, R. Madge, K. Cota, and R. Daasch, “Statistical postprocessing at wafersort: An alternative to burn-in and a manufacturable

solution to test limit setting for sub-micron technologies,” in Proc. IEEE

VLSI Test Symp., May 2002, pp. 69–74.

[15] R. Madge, B. H. Goh, V. Rajagopalan, C. Macchietto, R. Daasch,

C. Schuermyer, C. Taylor, and D. Turner, “Screening minVDD outliers

using feed-forward voltage testing,” in Proc. IEEE Int. Test Conf., Oct.

2002, pp. 673–682.

[16] W. Shindo, E. H. Wang, R. Akella, A. J. Strojwas, W. Tomlinson, and

R. Bartholomew, “Effective excursion detection by defect type grouping

in in-line inspection and classification,” IEEE Trans. Semicond. Manuf.,

vol. 12, no. 1, pp. 3–10, Feb. 1999.

[17] X. Yu and R. D. Blanton, “Diagnosis of integrated circuits with multiple

defects of arbitrary characteristics,” IEEE Trans. Comput.-Aided Des.

Integr. Circuits Syst., vol. 29, no. 6, pp. 977–987, Jun. 2010.

[18] Y. Sato, L. Yamazaki, H. Yamanaka, T. Ikeda, and M. Takakura, “A

persistent diagnostic technique for unstable defects,” in Proc. IEEE Int.

Test Conf., Oct. 2002, pp. 242–249.

[19] F. Brglez and H. Fujiwara, “A neutral netlist of 10 combinational

benchmark circuits and a target translator in fortran,” in Proc. IEEE

Int. Symp. Circuits Syst., Jun. 1985, pp. 695–698.

[20] F. Brglez, D. Bryan, and K. Dozminski, “Combinational profiles of

sequential benchmark circuits,” in Proc. IEEE Int. Symp. Circuits Syst.,

1989, pp. 1929–1934.

[21] W. Tam, O. Poku, and R. D. Blanton, “Automated failure population

creation for validating integrated circuit diagnosis methods,” in Proc.

ACM/IEEE Des. Autom. Conf., 2009, pp. 708–713.

[22] R. D. Blanton, J. T. Chen, R. Desineni, K. N. Dwarakanath, W. Maly,

and T. J. Vogels, “Fault tuples in diagnosis of deep-submicron circuits,”

in Proc. IEEE Int. Test Conf., 2002, pp. 233–241.

[23] T. L. Quarles. (1989). “Analysis of performance and convergence

issues for circuit simulation,” Ph.D. dissertation, Electr. Eng. Comput. Sci. Dept., Univ. California, Berkeley, CA [Online]. Available:

http://www.eecs.berkeley.edu/Pubs/TechRpts/1989/1216.html

[24] S. K. Lu, T. Y. Lee, and C. W. Wu, “Defect level prediction using multimodel fault coverage,” in Proc. IEEE Asian Test Symp., Nov. 1999, pp.

301–306.

[25] M. R. Grimaila, S. Lee, J. Dworak, K. M. Butler, B. Stewart, H. Balachandran, B. Houchins, V. Mathur, J. Park, L. C. Wang, and M. R.

Mercer, “REDO-random excitation and deterministic observation-first

commercial experiment,” in Proc. IEEE VLSI Test Symp., Apr. 1999,

pp. 268–274.

[26] X. Yu, Y.-T. Lin, W.-C. Tam, O. Poku, and R. D. Blanton, “Controlling

DPPM through volume diagnosis,” in Proc. IEEE VLSI Test Symp., May

2009, pp. 134–139.

[27] D. B. Lavo, I. Hartanto, and T. Larrabee, “Multiplets, model, and the

search for meaning: Improving per-test fault diagnosis,” in Proc. IEEE

Int. Test Conf., Oct. 2002, pp. 250–259.

1416

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 31, NO. 9, SEPTEMBER 2012

[28] M. Sharma, W.-T. Cheng, T.-P. Tai, Y. Cheng, W. Hsu, C. Liu, S. M.

Reddy, and A. Mann, “Faster defect localization in nanometer technology based on defective cell diagnosis,” in Proc. IEEE Int. Test Conf.,

Oct. 2007, pp. 1–10.

[29] W. Tam, O. Poku, and R. D. Blanton, “Precise failure localization using

automated layout analysis of diagnosis candidates,” in Proc. ACM/IEEE

Des. Autom. Conf., Jun. 2008, pp. 367–372.

[30] C. M. Bishop, Pattern Recognition and Machine Learning. Berlin,

Germany: Springer, 2006.

[31] S. Seshu and D. N. Freeman, “The diagnosis of asynchronous sequential

switching systems,” IRE Trans. Electron. Comput., vol. 11, no. 4, pp.

459–465, Mar.–Apr. 1962.

[32] Y.-T. Lin, O. Poku, N. K. Bhatti, and R. D. Blanton, “Physically-aware

N-detect test pattern selection,” in Proc. IEEE Des. Autom. Test Eur.,

Mar. 2008, pp. 634–639.

[33] Y.-T. Lin, O. Poku, R. D. Blanton, P. Nigh, P. Lloyd, and V. Iyengar,

“Evaluating the effectiveness of physically-aware N-detect test using real

silicon,” in Proc. IEEE Int. Test Conf., Oct. 2008, pp. 1–9.

[34] Cadence [Online]. Available: http://www.cadence.com

[35] X. Li, J. Le, and L. T. Pileggi, Statistical Performance Modeling and

Optimization. Boston, MA/Delft, The Netherlands: NOW Publishers,

2007.

[36] B. Stine, D. Boning, and J. Chung, “Inter and intra-die polysilicon

critical dimension variation,” Proc. SPIE, vol. 2874, pp. 27–36, Oct.

1996.

[37] L. Wasserman, All of Statistics: A Concise Course in Statistical Inference. Berlin, Germany: Springer, 2004.

Xiaochun Yu (S’08–M’12) received the B.S. degree

in microelectronics from Fudan University, Shanghai, China, in 2005, and the M.S. and Ph.D. degrees in electrical and computer engineering from

Carnegie Mellon University, Pittsburgh, PA, in 2008

and 2011, respectively.

Since June 2011, she has been with Intel Corporation, Hillsboro, OR, where she is engaged in

diagnosis and debug solutions. Her current research

interests include multiple defect diagnosis, layoutaware diagnosis, defect-type distribution estimation,

and adaptive testing.

Ronald DeShawn Blanton (S’93–M’95–SM’03–

F’09) received the B.S. degree in engineering from

Calvin College, Grand Rapids, MI, in 1987, the M.S.

degree in electrical engineering from the University

of Arizona, Tucson, in 1989, and the Ph.D. degree

in computer science and engineering from the University of Michigan, Ann Arbor, in 1995.

He is currently a Professor with the Department

of Electrical and Computer Engineering, Carnegie

Mellon University, Pittsburgh, PA, where he serves

as the Director of the Center for Silicon System

Implementation, an organization consisting of 22 faculty members and over

80 graduate students focusing on the design and manufacture of siliconbased systems. His current research interests include the test and diagnosis

of integrated, heterogeneous systems, and design-, manufacture-, and test

information extraction from tester measurement data.