GRADIENT HEAT FLUX SENSORS FOR POWER ENGINEERING Andrey V.Mityakov

advertisement

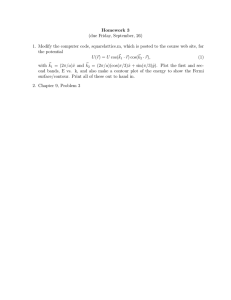

Open your mind. LUT. GRADIENT HEAT FLUX SENSORS FOR POWER ENGINEERING Andrey V.Mityakov Professor, D.Sc.(Tech.), MBA Saint-Petersburg State Polytechnical University Department of Thermodynamics and Heat Transfer 29 Polytechnicheskaya str., Saint-Petersburg, 195251, Russia mitiakov@mail.ru +7 921 590 74 21 Lappeenranta University of Technology LUT Energy, P.O. Box 20, FI-53851, Lappeenranta, Finland andrey.mityakov@lut.fi +358 40 129 9360 2 Gradient heat flux sensors Measurements of Instantaneous Heat Flux Gradient Heat Flux Measurements Gradient Heat Flux Measurements in Power Engineering HFS onto the surface 3 longitudinal transverse q E q HFS based on hyperthermocouple .Gerashenko,1970.) singlecrystalline Hot seam; T 12 2 heterogeneous HFS made of composite Bi+Bi2Te3 (S.M.Brooks, USA, 2006.) k e e2 base HFS based on bismuth (N.P.Divin, 1970) 3 cold seam; q E ke E T1 e2 HFS based on artificial anisotropic materials (Mityakov and others, 2007.) k e e1 e1 k e2 e2 e1 q k e1 E S0 F q 4 Sensitivity, Response Time and Operating Temperature HGHFS T, °C 7 2 5 4 GHFS 10 1 6 3 8 1 1 2 3 4 5 6 7 8 7 – laboratory of physical electronics (Switzerland); 8 – «Newport» (USA); 9 – «TNO» (Netherlands) (no data by min); 10 – ALTP «FORTECH HTS GmbH» (Germany) (no data by operating temperature). 1 – GHFS based on bismuth and HGHFS; 2 – Academy of Science, Ukrain; 3 – «Vatell» ((USA USA); ); 4 – «Wuntronic» (Germany); 5 – «Captec» (France); 6 – «Hukseflux» ((Netherlands Netherlands); ); 10 1 Scale in inches 3 9 4 5 9 5 Seebeck Effect in Anisotropy Thermo Element (ATE) z Law of conservation of energy q for ATE: where T Tz C1 j, B – tensor of Peltie, t j – electrical current. O s r h Fourier’s Law q Q*z T. Vector Tensor of thermal conductivity anisotropy bismuth single-crystal 11 0 0 0 0 33 i T x j T y k T . z Qz and 3 axes : Q1 z 11 Tz cos , Q3 z 33 Tz sin ; 1 OA Tz cos , OB Tz sin . and 3 axes : along x and z axes : Qx T 1 n Projection of vector of heat flux along 0 . 22 0 Tz along x u m The temperature gradient C3 A Qz Q3 z cos Q3 z sin Q1 z sin Q1 z cos ( ( 11 33 sin 2 33 ) sin cos 11 cos 2 ) Tz , Tz . Angle between vectors Qz* and Qz A temperature gradient along z axis T, Tz T k . z tg Qx Qz ( 11 33 sin 33 ) sin 2 11 cos cos 2 . 6 Transverse Seebeck effect in ATE E Electric field: 11 Seebeck Tensor 0 0 Projection of vector E along 1 and 3 axes : T. 0 0 22 0 . 0 33 E3 z 33 Tz sin , E1z 11 Tz cos . E3 z cos E3 z sin E1z sin E1z cos ( ( ) cos sin Tz , 2 ) Tz . 33 sin 11 cos 33 ez Ez h ( 33 sin 2 11 cos 2 ) z . Transverse thermopower in ATE Projection of vector E on axes x and z: Ex Ez Longitudinal thermopower in ATE 11 2 ex Ex l ( 33 11 ) sin cos z l. Heat flux in the sensor Qz Angle between vectors Ex and Ez tg Ex Ez ( 33 2 33 sin 11 ) sin cos . 2 cos 11 z lb Tz 33 sin 2 11 Transverse thermopower of the sensor ex 33 33 11 2 sin sin cos q z F . 2 b 11 cos cos 2 lb Tz . 7 Transverse Seebeck Effect in Tilted Layered Materials , 2 1 , 2 1 1 , 1 2 , 2 – thermal conductivities; – electrical conductivities; – thermopowers; – thickness of layers; z x0 1 z0 K 2 2 ;K 1 2 ;K 1 2 ;K 1 2 1 1 2 1 . 2 2 1 x Values of kinetic coefficients in directions of general axes x0 and z0: 1 2 x0 1 1 2 1 K 1 K K , 1 1 2 2 1 2K 1 2 1 2 x0 1 2 1 1 2 z0 1 1 1 2 1 1 1 2 2 2 1 2 1 1 2 1 2 2 2 K 1 K 1 2 1 T 1 2 1 1 2 1 K 1 1 K K , K 2 2 1 K K 1 K , 1 1 1 2 2 2 1 1 z0 1 1 2 2 1 K K 2 2 1 2 1 K K K 1 K K . 8 Single-crystal GHFS C1 z C3 90° F=l·b 0 h b C2 y Heterogeneous GHFS (HGHFS) x z z0 x0 1 K 2 1 2 1 2 x l Anisotropy thermo element (ATE) Volt-Watt sensitivity of ATE ex ex Ex 33 11 sin cos S0 S 0 2 q z F Qz b 33 sin 2 qz F 11 cos Artificial ATE Ex Qz z0 b z0 sin x0 2 sin cos 2 x 0 cos K K 1 K K K K sin cos K 1 K K 1 K 1 K 1 K K sin 2 cos 2 K 1 K 1 K 1 S0b 1 0 1 Optimal angle opt arctg 11 33 opt 1 K arctg 1 K K 1 K K 9 Optimisation of HGHFS opt , 0 40 K =1,5; K =0,43; K =6,067 0,03 40° K =1,23; K =1,1; K =6,067 30° 0,02 K =1,23; K =0,43; K =5 K =1,23; K =0,2; K =6,067 20 0,01 K =1,23; K =0,43; K =7 10 K =1,1; K =0,43; K =6,067 K =1,23; K =0,43; K =10 0,00 0 2 20° K =1,23; K =0,43; K =6,067 4 6 8 Volt-watt sensitivity of ATE; – composition nickel + stainless steel 500 K 10° 500 K K Optimal angle 10 Single--crystal GHFS based on Bismuth Single Bar and single-crystal of bismuth (http://wikipedia.org) electrical isolation GHFS N.P.Divin’s (1970) b 5 seams ATE 1 from 3 bismuth 4 Technologically reachable to 2009 year. 2 padding wires , opt=53 24’ 11 Heterogeneous GHFS (HGHFS HGHFS)) Characteristics of compositions parameter Average sensitivity, mV/w Working temperature, titan + molybdenum 0,02 1660 nickel+steel 12 18 0,8 1400 nichrome 20 80 + steel 12 18 0,5 1100 copper + constantan 0,2 1000 chromel + alumel 0,1 1450 silicon + aluminium 1,0 700 p-silicon+ n-silicon 1,5 800 Composition Porous HGHFS nickel + stainless steel 1 mm HGHFS from composition chromel+alumel (Mityakov and others, 2007) 1 mm 12 High Temperature HGHFS: fabrication Diffusion welding Cutting Blank Diffusion Zone 100 mkm Welding of outputs Sensor Microstructure of sensor Calibration Facility Single-crystal GHFS High temperature HGHFS 13 mV 0…2 heater extra heater holder To the vacuum pump thermocouple GHFS – «zero-indicator» basic heater HGHFS tube case cover with the socket tested GHFS mV base V A 0…2 Error S0 S0 S0 S0 0,64% 6,8% 2 q, kW/m mV/W Stainless steel + nickel 800 The sensor made from 600 bismuth 400 experiment S0= 12 mV/W = const calculation Chromel + Alumel 200 calculation 0 50 100 150 200 E, mV Uncertainty Estimation* 14 n Total standard uncertainty (Type B evaluation)* of value y(x1,x2,…,xi,…): y i 1 f xi – dispersion of value xi, that have an affect on value y. xi where Single-crystal GHFS f xi xi 2 , High temperature HGHFS The combined uncertainty of volt-watt sensitivity S0 E E S0 2 2 S0 Q . Q S0 S0 E E S0 2 S0 Q Q 0,1053 0,07 10 6,04 10 5 3 2 S0 E E 2 S0 q q 2 2 S0 F F 2 2 2 1 qF 1,108 10 3 0,054 2 E q2 F E 1 18270 45,5 10 V , W q 2 6 5,5 10 18270 45,5 10 6 100 10 6 182702 45,5 10 6 2 6 261 2 100 10- 6 6,8 10 2 E F qF 2 6 2 1,38 10 7 V , W Final error of volt-watt sensitivity S0 S0 100% 6,04 10 5 9,5 10 3 100% 0,64%. S0 S0 100% 6,8 10 6 100 10 6 100% 6,8%. *According to «GUIDELINES FOR EVALUATING AND EXPRESSING THE UNCERTAINTY OF NIST MEASUREMENT RESULTS» NIST 1297. Requirements to hardware 15 Multiplexer with amplifier (PCLD 789D) GHFS ADC (PCL 818HG) PC Up to 16 channels Up to 16 channels Total number of channels – up to 256 on one ADC Emax – signal; – ADC gain; k – ADC resolution; E* – thermal noise level; n – assurance factor. Signal ratio «signal-noise» 6 dB to every capacity bit; ADC Measuring signal E0 E0 10 0,3k E * Emax K y 2k Required ADC resolution k 3,321 n Commutators lg Fmin K y S 0 q GHFS E max Minimum area Fmin E 10 n E0 S0 q S0 q Hardware for turbo generator 160 MW («Electrosila», SaintPetersburg) Multifunction of GHFS T, C Temperature measurement q, kW/m 800 50 T(E) 600 40 2 Shear stress measurement ~ 1 ~ 1,6 Couett’s flow calibration RT 20 GH FS 1,2 400 0,8 200 0,4 4 Tf Q w q(E) 30 3 0,2…0,3 16 3 2 Tw 1 R + - Calibration in a small wind tunnel, SPbSTU R 0 0,5 1,0 E, mV Measurement and indication of fluid consumption 1 2 3 0,0 0,5 1,0 1,5 1/3 , Measurement in electricity 4 l Tw GHFS electricity network ~ meter V 8,062 exp 0,531 f, N 1/3 Response time of the sensors 17 mirror beam oscilloscope lens laser Laser data: double pulse Nb-YAG-laser; pulse energy 50…120 mJ; frequency 1…10 Hz; wave length 635 nm. GHFS photodiode base laser beam receiver Experimental installation diagram GHFS based on bismuth Oscilloscope data Tektronix TDS3034B: pass band – 300 MHz; number of channels – 4; sampling rate – 2,5 GHz; horizontal scanning – 2 ns/sample…10 s/sample. HGHFS p-silicon+n-silicon Response time of the sensors 18 Laser OGM-20 Laser Nb-YAG Laser 2* standard GHFS 10 20 GHFS based on bismuth (single-impulse mode) GHFS based on bismuth Shock tube* q, GHFS 2 80 50 ALTP 60 200 40 20 0 GHFS based ob bismuth (free generation mode) 0 1 2 HGHFS p-silicon+n-silicon *Experiments made by S.S.Kutateladze institute RAS 3 , Response time of the sensors (theory) 19 q T Laplace equation: 2 a T x2 Models Boundary condition T x, 0 q T0 ; T 0, q x T , 0; x T , T0 . Isotherms in A E (L.I.Anatychuck, 1979) B 0; T(x,0)=T0 Semi-infinite body q T x, 0 T0 ; T 0, q 0; x T h1 , T0 . T1 x,0 T 0, x T2 h2 , 0 T(x,0)=T0 Plate q C Isotherms in ATE, calculation by final element method (Mityakov and others., 2000) 0 T2 x,0 q T0 . T0 ; 0; T(x,0)=T0 Plate with bottom layer Response time of the sensors (theory) 20 T T0 q0 x 1 B T T0 q0 x x2 4a1 a 2 21 exp x An sin x h1 1 1 erfc n 1 1 n 2 n exp x ; 2 a1 0,04 x h1 ; 0,02 a1 2 h1 0 0,1 C T T0 q0 h1 2 a1 exp 2 h1 x h1 erfc h1 2 a1 1 h1 2 a1 erfc 1 x h1 x c1 1h1 exp 1 h1 c2 2 h2 T Ki Fo T0 1 x h1 2 h1 x 1 h1 4a1 1 x h1 2 2 exp h1 x 1 h1 4a1 2c2 2 h2 c h1 0,06 0,04 2 a1 2 h1 erfc h1 2 a1 1 x h1 c1 1h1 a1 c2 2 h2 h1 – dimensionless temperature; T0 q0 x – dimensionless depth; 1 T0 a1 – Fourier’s number (dimensionless time). x2 0,2 0,3 0,4 0,5 Ki 0,015 Fo 2 2c2 2 h2 c1 1h1 c1 1h1 c2 2 h2 Fo=0,02 Fo=0,015 Fo=0,01 Fo=0,005 0,06 . Ki=0,1 Ki=0,2 Ki=0,3 Ki=0,4 Ki=0,5 0,02 0 0,005 0,010 Temperature distribution in GHFS Response time of the sensors (theory) 21 Heat balance h0 T h0 dx a 0 0 2 T dx, x2 Thickness of warm layer h0 if q=const h0 using Leibniz’s formula ( ) d d ( ) f f ( x, ) dx ( ) dx f d d ( ), ( ) f ( ), d . d If min=10-8 s for GHFS Receive: h0 T 0 h0 a 0 x d d h0 dh T ( x, ) dx T (h0 , ) 0 d 0 T dx x T (h0 , ) x a T ( x,0) h0 a d d T ( x,0) h0 , T (0, ) . x T (h0 , ) x T ( x, ) T ( h0 , ) qh0 2 q h02 2 h0 qx 2h0 x HGHFS chromel+ alumel T (0, ) . x HGHFS silicon+ aluminium qx 2 2 h0 x2 T (h0 , ) Sensor type Battery GHFS based on single-crystal bismuth HGHFS nickel+steel 12 18 Finaly: T ( h0 , ) HGHFS: Parameter d d dx 6a q h0 2 h0 2 x . a, h0, m2/s m 6,0·10-6 6,0·10-7 8,16·10-6 7,0·10-7 4,7·10-6 5,3·10-7 1,92·10-6 3,4·10-7 For all the GHFS h0>2000 angstrom (minimum thickness that needs for thermopower generation) Sensors comparison 22 longitudinal E q E S0 F S0 F 2qh 2qh transverse Fo 1 E q ierfc 1 2 Fo E S0 F q erfc 1 2 Fo f Fo 1 2 Fo f Fo erfc Parameter (mV·m2)/W E/q, R, (m2 )/W 2,023·10-5 2·10-3 min , s 0,8 Sensor 0,6 .11.2.1.11. 00.1.16.00.0 GHFS based on bismuth 3,7 0,4 2,89·10-3 3,5·10-5 4,35·10-5 1 2 Fo f Fo erfc 0,2 0,0 0,01 0,1 1 10 100 1000 Fo Heat Flux Measurements in Shock Tubes (ST) 23 diaphragm high pressure chamber low pressure chamber shock wave front high-speed camera model vacuum chamber to the receiver pressure sensors vacuum pump Measurements carried out in SPbSPU, S.S.Kutateladze institute RAS and FTI of A.F.Ioffe RAS gas Plasma in ST GHFS onto surface ST at SPbSPU (Mach number 6) Heat fluxes in ST 24 Influence of electromagnetic field over the heat flux in the 2 noozle q, kW/m Pressure and heat flux in ST q, MW/m p, q, kW/m2 MPa 0,8 200 0,6 2 1,6 1,2 p q 0,8 0,4 0 0,5 1,0 1,5 , Working gas – xenon GHFS 0,4 1 2 800 100 , ms 5 10 15 Working gas – air; GHFS installed in 98 mm (curve 1) and 40 mm (curve 2) from the end of ST 0 0,0 0,5 1,0 1,5 2,0 , GHFS w =4…5 electrodes Heat flux with MHD influence ( =4) 2 q, MW/sm Without MHD Within MHD influence influence 6 400 mks 700 mks 4 2 electrodes Model without 400 0,2 0 with field 1200 Shadowgraphs 0 0 cathode anode without MHD 200 400 600 800 , mks Free convection on a vertical plate 25 ~ Nux, Nux ~ 3 10 heater 2 plate 2 1 heat isolation 5 Nu x Nu x 10 GHFS 3 1 10 5 10 4 thermoanemometric probe 6 probe drive , T 7 9 10 Local heat transfer coefficient 0,3 qw x T f q x ~ Nu x – Nusselt’s number, defined from GHFS’s signal; f Grx g Tx 2 – Nusselt’s number, defined from average temperature gradient (qw=at boundary layer; 3 – Grasgoph’s number. T) 0,0 5 10 Grx T T q 0,2 0,1 10 T f2 q T Nu x 11 10 q q2 q~w 7 10 10 9 Temperature and heat flux pulsation Grx Heat flux measurement on circular cylinder in cross flow 26 d 600 GHFS 1 w Re 4 25·10 4 15·10 4 9·10 4 5·10 4 3·10 Nu cylinder 2 400 steam 200 0 3 turntable 30 60 90 120 150 o Heat transfer coefficient 4 steam inlet condensate 5 outlet 6 manometer ,% 20 15 Re Re 4 15·10 4 9·10 4 5·10 d Nu E 10 60 90 120 150 Heat flux pulsation o 4 3 d S0 F T q 30 D·10 q d T q2 5 0 wd n D 2 i 1 n 1 Re 4 15·10 4 9·10 4 5·10 2 1 100% qi -5 q 2 0 30 60 90 120 150 Dispersion of the heat flux pulsation o Heat transfer intensification on cylinder (L.Prandtl’s experiment analogue with the ring on a ball) 27 turbolator Nu 0,5 Re 2,0 cylinder GHFS steam with turbolator smooth 1,5 =55 o 1,0 0,5 turbolator table with azimuth disk 0 30 60 90 120 150 , o Heat transfer coefficient (Re=9·104) condensate outlet Smooth ball steam inlet manometer Ball with a ring -5 D·10 4 3 o =55 2 1 0 30 60 90 120 150 o , Dispersion of heat flux pulsation (Re=9·104) Prandtl’s experiment (Van-Dyke, 1986) Heat flux measurement in a spherical dimples 28 w GHFS steam Surfaces covered with dimples in industrial heat exchangers condensate Model for heat flux measurement in single dimple h/d=0,2 Re = 3,0 103 Re = 7,0 104 Re = 10 104 s pl -1, 50 w -1, 25 w -1,00 -0,75 ) w The flow in the dimple (Re = 2500): Visualization in the hydrotube w Heat flux fields in the dimple Uncertainty Estimation* 29 q heat transfer coefficient Tw T f 2 2 E E F F Tw Tw 2 1 S0 F Tw T f E S0 F Tw T f 2 E S 0 F Tw T f S0 2 2 E Tw 2 S 0 F Tw T f 2 Tf 2 2 10 10 3 1 28 10 6 F 2 2 S0 F Tw T f Tf Tf 2 E E 2 2 2 S0 S0 E . S0 F Tw T f 100 20 6 10 2 10 6 10 10 3 2 3 28 10 6 0, 0604 10 80 2 2 10 10 10 0,99 W 2 3 2 3 28 10 6 2 1,35 10 7 3 2 10 2 80 10 10 3 3 28 10 6 80 2 0,5 . Final error for heat transfer coefficient 100% 0,99 100% 0,99% 100 *According to «GUIDELINES FOR EVALUATING AND EXPRESSING THE UNCERTAINTY OF NIST MEASUREMENT RESULTS» NIST 1297. Measuring device for radiation 30 q 2, GHFS of bismuth 1e, 2 1 1, hemisphere cover q=0 c1 2 1 1i q=0 q=0 R2 R1 sensitive element Requirements: Weight not more than 40 g; The output signal is not less than 2 V. T, c2 model E, V 1600 screen 1200 =0,98, =0,98, 10 3 hemisphere 5 10 15 20 Calculated temperature 25 ,s =0,1, =0,1, =0,1, =0,1, 10 2 800 400 273 0 4 10 =0,98 1i =0,98 1i =0,1 1i 1 0 0 5 10 15 20 Calculated signal 25 ,s 31 Heat flux measurement in diesel combustion chamber GHFS GHFS installation Diesel “Indenor” 2 q, kW/m with fuel supply, 1320 rpm without fuel supply, 870 rpm 120 100 80 60 40 20 0 -360 Calibration of GHFS 0 360 Local heat flux 720 , o Heat flux measurement in industrial boilers thermocouple 65 8,5 measuring area of the pipe tube for the wires 28 3 wires Thermocouple on the pipe Preparing the pipes for sensors mounting HGHFS 65 8,5 32 28 3 HGHFS on the pipe Pipes before welding Pipes with sensors 33 Tests of HGHFS in home water boiler hot water cover 1 T1 burner 2 3 T2 4 R400 R230 R315 cold water Sensors and thermocouples on the cover of the boiler A general view and scheme of the boiler 2 q, kW/m 1 3 2 4 100 150 4 3 2 1 0 Sensors, prepared for installation Sensors, mounted on the boiler cover 50 200 The experimental curves ,s Model experiments 34 electric heater HGHFS HGHFS screen pipe Experimental setup ) burner Calibration of HGHFS 2 q, kW/m Ti, 2400 2300 2200 2100 2000 0,99 0,98 12 8 0,97 4 Tf=350 0,96 50 calculation for pipe calculation for fin experiment (pipe) experiment (fin) 100 150 Fin efficiency 2 q, kW/m 0 0 500 1000 1500 2000 , Experimental results HGHFS on the fin 35 q max fin body HGHFS plug cover pipe wires Construction of the measuring device with HGHFS q/qmax 0,85 0,80 Radiation effective angle 0,75 0,70 1,33 0,60 1 Dependence q 1 q 0,65 q max 2 q max 3 for pipes with fins S/d 1 2 1 S d 36 Industrial experiment in the boiler BKZ 210-140f HGHFS installed in the boiler # 9 (town Kirov, Russia) Mounting zone – back wall of furnace, a mark 10,4 m, 3 m from the right lateral wall Pipes with HGHFS The results of industrial experiments 37 2 q, kW/m 03.11.2008 Heat flux : 300 1 – calculated by the temperature of the first thermocouple; 2 – calculated by the temperature of the second thermocouple; 3 – calculated by average temperature of two thermocouples; 4 – measured by frontal HGHFS; 5 – measured by lateral HGHFS; 6 – averaged over two HGHFS. 1 2 3 4 5 6 200 100 18 19 20 21 22 23 Work on gas (D=32 kg/s) 2 2 5.11.2008 q, kW/m 1 2 3 4 5 6 300 200 10.11.2008 q, kW/m 300 200 100 4 5 6 coarse grinding kindling ,h slag 0 100 0 16 Kinding 18 20 22 Work on gas (D=32 kg/s) , 0 5 Work on gas (D=48 kg/s) 10 15 20 , Work on coal (D=56 kg/s) Uncertainty Estimation* 38 q q E E 2 E . S0 F q Heat flux density q S0 S0 2 2 q F 2 1 SF F 2 E S 2F E 2 E F 2 SF S0 2 1 6 10 100 10 6 100 10 6 2 0,5 10 6 100 10 6 2 3 100 10 6 6,8 10 6 2 0,5 10 100 10 34011 W / m 2 6 3 100 10 6 2 1,35 10 7 34 kW / m 2 Final error of the gradient heat flux measurement in the furnace of boiler unit q 100% q 34 103 100% 17% 200 103 *According to «GUIDELINES FOR EVALUATING AND EXPRESSING THE UNCERTAINTY OF NIST MEASUREMENT RESULTS» NIST 1297.